- DL manuals

- Fervi

- Saw

- 275

- Original Instruction

Fervi 275 Original Instruction

Summary of 275

Page 1

Operation and maintenance manual mitre saw with table stand art. 0275 original instructions fervi.Com.

Page 2: Preface

Machines and accessories page 2 of 44 preface please ensure you have read this manual before operation translation of the original instructions reading this instruction manual is required before operating any of the machinery. The guarantee that the machine will function and perform properly is stri...

Page 3: Contents

Machines and accessories page 3 of 44 contents 1 introduction ........................................................................................ 5 1.1 preface..........................................................................................................................6 2 safety war...

Page 4: Fervi.Com

Machines and accessories page 4 of 44 10.2.4 inclined and angled cuts ........................................................................................... 31 10.3 use in bench saw mode ...........................................................................................32 11 maintenance...

Page 5: 1 Introduction

Machines and accessories page 5 of 44 1 introduction the purpose of this manual is to provide the knowledge necessary for the use and maintenance of the mitre saw with table stand art. 0275 and create a sense of responsibility and knowledge of the capabilities and limitations of the device entrusted...

Page 6: Attention

Machines and accessories page 6 of 44 graphic representation of safety, operational and risk warnings the following boxes are designed to attract the attention of the reader / user for the proper and safe use of the machine: attention this highlights behavioural rules to prevent damage to the machin...

Page 7: 2 Safety Warnings

Machines and accessories page 7 of 44 2 safety warnings 2.1 general safety regulations accident there is always a risk of injury during cutting operations due to accidental contact of body parts with the moving tool, flying debris from the workpiece, tool breakage or ejection of a badly blocked wo...

Page 8: Fervi.Com

Machines and accessories page 8 of 44 1. Always check the efficiency and integrity of the machine. 2. Before connecting the machine to the mains, make sure that the blade is not damaged or badly worn. Make sure that the switch is in the neutral position. 3. Do not start the machine in an enclosed or...

Page 9: 2.3 Technical Support

Machines and accessories page 9 of 44 replacing the disc; it is being moved or transported; during cleaning operations. 24.Do not use the machine in areas with a risk of fire and/or explosion. 25.It is recommended that users of this publication, for maintenance and repair, have a basic knowled...

Page 10: 2.4 Other Provisions

Machines and accessories page 10 of 44 2.4 other provisions it is forbidden to tamper with safety devices the first thing to do when starting work is to check the presence and integrity of the protections and the operation of the safety devices. If any defect is encountered do not use the mitre saw ...

Page 11: 3 Technical Specifications

Machines and accessories page 11 of 44 3 technical specifications model art. 0275 rated voltage (v) 230 power (w) 1800 frequency (80 - 16000 hz) 50 disc dimensions (mm) 315 x 30 x 3.0 z40 motor speed (r/min) 4000 peripheral speed of the disc (m/s) 56 cutting capacity 0° ÷ 90° (mm) hxl 100 x 170 cu...

Page 12: Machine

Machines and accessories page 12 of 44 4 intended use and description of the machine the mitre saw with table stand (art. 0275) is only used for dry cutting of wooden planks and/or boards, within the limits recommended by the manufacturer and the safety and health norms. Other types of use, or the e...

Page 13: 4.1 Main Machine Parts

Machines and accessories page 13 of 44 4.1 main machine parts figure 1 – main parts of the mitre saw art. 0275. 1 work table 8 head rotation lever / knob 2 closure unhooking lever 9 supports 3 buttons for bench saw 10 workpiece clamping adjustment device 4 mitre saw operating lever 11 head inclinati...

Page 14: 4.2 Plates And Pictograms

Machines and accessories page 14 of 44 4.2 plates and pictograms the identification plate shown below is attached to the machine. Figure 2 – identification plate. The machine has the following warning and attention pictograms: fervi.Com.

Page 15: Attenzione

Machines and accessories page 15 of 44 plate in italian plate in english non rimuovere i dispositivi di sicurezza do not remove safety devices attenzione È vietato eseguire lavori su apparecchiature elettriche sotto tensione eventuali deroghe devono essere autorizzate dal capo responsabile in co...

Page 16: 5 Description Of Controls

Machines and accessories page 16 of 44 5 description of controls 5.1 control buttons for bench saw at the front of the machine, when it is closed in "bench saw" mode, the active commands are two electromagnetic buttons - start (green) and stop (red) located near the handle. 15 start button 16 stop b...

Page 17: Cutting Hazard

Machines and accessories page 17 of 44 cutting hazard after releasing the start button (18), the blade continues to rotate by inertia. do not put body parts like hands and/or fingers near the moving blade! 5.3 locking the head the machine is supplied closed, i.E. With the head attached and in "b...

Page 18: Fervi.Com

Machines and accessories page 18 of 44 figure 6 – releasing the head from the open position to use the machine in "bench saw" mode it is necessary to lock the head in the closed position. To do this it is necessary to install the fixed protection device under the blade which also has the function of...

Page 19: 5.4 Adjustment Knobs

Machines and accessories page 19 of 44 5.4 adjustment knobs at the front part of the machine there is a knob (8 in figure 1 ) for locking the head in an angled position relative to the base. The angle can be discovered by referring to the graduated scale (21) positioned below the base and which is r...

Page 20: Fervi.Com

Machines and accessories page 20 of 44 figure 10 – adjusting the table height. On the right and the left part of the support guide square (mitre saw mode) there is a slot for the workpiece clamp. This clamp has a screw (26) for locking onto the guide and a screw (27) to tighten the pieces in positio...

Page 21: 6 Machine Safety Devices

Machines and accessories page 21 of 44 6 machine safety devices 6.1 electrical safety devices in the event of malfunction or breakdown, the mitre saw with table stand is equipped with power cable and plug without grounding conductor, as it is equipped with double isolation. The plug must be plugged ...

Page 22: Fervi.Com

Machines and accessories page 22 of 44 in this configuration, the upper part of the blade is not used, and is protected by the upper casing that is locked in the closed position by a screw (28) and is integral to the table. Figure 13 – fixed casing above the table. When the machine is used in "bench...

Page 23: Use Of Ppe

Machines and accessories page 23 of 44 the machine is equipped with two lateral stabilizers (ref. 7 in figure 1 ) to be inserted into the specially drilled holes on the base of the machine. Figure 16 – workpiece pusher accessory. 6.3 personal protective equipment (ppe) use of ppe always use appropri...

Page 24: 8 Transport And Lifting

Machines and accessories page 24 of 44 7 improper use and hazards the following actions described, which obviously can not cover the entire range of potential possibilities of "misuse" of the saw, are to be considered strictly prohibited. The following is strictly prohibited! holding the piece to ...

Page 25: 9.1 Unpacking Instructions

Machines and accessories page 25 of 44 9 assembly and commissioning 9.1 unpacking instructions the mitre saw with table stand (a rt . 0275) is supplied ready for use, with a steel disc 315 x 30 x 3.0 mm and packed in a cardboard box. Inside the package, in addition to the machine, there is a hex k...

Page 26: Fervi.Com

Machines and accessories page 26 of 44 fix the machine on a work bench (or another support surface) which is flat, solid and strong, using special bolts, so as to prevent accidental movement or overturning during operation, and excessive vibration transmitted to the operator. Figure 18 – fastening h...

Page 27: Fervi.Com

Machines and accessories page 27 of 44 9.5 connecting the power plug 1. Insert the power supply plug into a double pole socket without grounding (10/16 a, 250 v). 2. Start the machine by pressing the start button and make sure that the direction of rotation of the blade is as indicated by the arrow ...

Page 28: 10 Operation

Machines and accessories page 28 of 44 10 operation 10.1instructions for use machine operation the mitre saw with table stand (art. 0275) should only be used for cutting wood. do not cut metal parts, make sure there are no nails or other metal parts in the wood being machined. do not cut beams...

Page 29: Cutting Hazard

Machines and accessories page 29 of 44 10.2.1 making straight cuts 1. Unlock the cutting disc so that it is possible to lift the mitre saw, moving the hook backwards. Figure 21 – open hook. Pay attention to the upward displacement of the work table when the hook leaves its housing. 2. Position the p...

Page 30: Cutting Capacity

Machines and accessories page 30 of 44 10.2.2 making angled cuts cutting capacity the maximum cutting thickness is 100 x 170 mm. 1. Loosen the knob at the front of the work area. 2. Grasp the handle with one hand and the knob with the other, then rotate the base to the left or right at the desired a...

Page 31: Cutting Capacity

Machines and accessories page 31 of 44 figure 24 – adjusting the inclination to fixed positions. 4. Repeat the steps from 1 to 6, as described in paragraph 10.2.1. 10.2.4 inclined and angled cuts cutting capacity the maximum cutting thickness is 62 x 118 mm. The machine can be used with the dual inc...

Page 32: Changing The Cutting Mode

Machines and accessories page 32 of 44 10.3use in bench saw mode changing the cutting mode carefully follow the instructions on how to switch from one cutting mode to another. make sure that the saw is perfectly vertical before closing it. make sure the machine is not connected to the power su...

Page 33: Cutting Capacity

Machines and accessories page 33 of 44 cutting capacity the maximum cutting thickness, in bench saw mode is 57 mm. To reduce the cutting thickness it is possible to raise the table as described on page 17 and in figure 10. When the machine is closed to start the rotation of the saw it is necessary t...

Page 34: Cutting Hazard

Machines and accessories page 34 of 44 the cut. At the end of the cut, the protective guard will automatically cover the blade. 4. At the end of the work, turn off the saw, pressing the red button on the right side of the machine. Figure 31 - stopping the saw. Cutting hazard after releasing the sw...

Page 35: 11 Maintenance

Machines and accessories page 35 of 44 11 maintenance any maintenance, except for that specifically listed in this manual should be performed by qualified staff authorized by the manufacturer. This manual does not elaborate information on disassembly and maintenance, as these operations should alway...

Page 36: 11.3Replacing The Blade

Machines and accessories page 36 of 44 11.3replacing the blade wear ppe always wear suitable protective gloves (to reduce the risk of cut) when replacing the blade. 1. Remove the upper blade guards: both the fixed and the moveable guards, sliding it off the dividing cutter. Figure 32 – fixed and mov...

Page 37: Replacing The Blade

Machines and accessories page 37 of 44 figure 34 – locked blade movement. 5. Hold down the locking lever and unscrew the bolt clockwise using the hex key provided. The left-nut is loosened by turning it clockwise. 6. Hold the washer and then the flange and remove them from the shaft. Figure 35 – rem...

Page 38: 12 Warehouse Storage

Machines and accessories page 38 of 44 12 warehouse storage in the event that the machine should be stored and unused for some time, it must be kept in a closed environment free of moisture to avoid damage and/or deterioration. 13 disposal of parts and materials if the machine is to be scrapped, its...

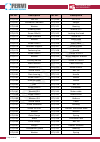

Page 39: 15 Wiring Plan

Machines and accessories page 39 of 44 15 wiring plan 16 exploded view and spare parts always clearly indicate: the symbol and the serial number of the machine; the code number of the parts; number of parts; exact address of your company. Fervi.Com.

Page 40: Fervi.Com

Machines and accessories page 40 of 44 fervi.Com.

Page 41: Fervi.Com

Machines and accessories page 41 of 44 part no. Description part no. Description 0275/001 m8x30 hex head screw 0275/034 gear 0275/002 base 0275/035 washer 0275/003 label 0275/036 screw m5x30 0275/004 m6 hex nut 0275/037 fixed guard on the blade 0275/005 rubber feet 0275/038 label 0275/006 m6x20 hex ...

Page 42: Fervi.Com

Machines and accessories page 42 of 44 part no. Description part no. Description 0275/033 nut m8 0275/066 nut m12 0275/067 inclination indicator 0275/100 seeger 0275/068 washer 0275/101 bearing 0275/069 rotating base 0275/102 washer Ø 5 0275/070 screw m6x16 0275/103 locking the head 0275/071 angle i...

Page 43: Fervi.Com

Machines and accessories page 43 of 44 part no. Description part no. Description 0275/133 auto locking device 0275/166 screw st4.8x20 0275/134 screw m6 0275/167 upper housing 0275/135 spring 0275/168 lower housing 0275/136 screw m4 0275/169 label 0275/137 head 0275/170 rotor 0275/138 cable bushing 0...

Page 44: Fervi.Com

Machines and accessories page 44 of 44 part no. Description part no. Description 0275/199 front cover 0275/204 piece press plate 0275/200 piece guide 0275/205 screw m5 0275/201 closing cover 0275/206 adjustment bar 0275/202 clamp knob 0275/207 screw m6x16 0275/203 clamp bracket fervi.Com.