© 2014-2015 food equipment technologies company may 2015 p129 rev 002 . ® user’s guide, operator instructions and access table of contents contact information........................................................ 2 description & features .................................................. 2 factory...

2 contact information description & features cbs-2150xts series coffee brewers feature universal spray over technology from the cascading spray dome™. The following variables are programmed for each batch size: brew volume prewet percent (percentage of the brew volume) brew time prewet delay (the ti...

3 accessing equipment and control screens layout of the brewer touch-screen for brewer operation brew basket sensor (internal) sd card interface port (load & save) hot water faucet airpot or dispenser locator (two for dual side) main power switch slide out back panel for service access accessing bat...

4 Æ quick brewer setup notes install plumbing and electrical utilities -see installation section in this guide turn rear power switch “on” -located on back, lower right side brewer hot water tank will fill in 4-8 minutes -ready screen will display ” ▪ filling” heater(s) activate when tank is full -r...

5 brewing-shown by touchscreen brewer screens displayed for brewing notes cbs-2151xts single side cbs-2152xts twin side “ready screen” tap screen to display menus note: there are three “brew at temperature definitons”. The “brew at temperature ”—“on” default routine is used for the illustration belo...

6 programming- operator access programming -the fetco cbs-2150xts brewers have four brew batch menus per side. Menus are preprogrammed by the factory with basic settings that will operate the equipment as purchased. There are two batches each marked “regular” and two marked “decaf” -most operators p...

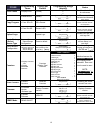

7 menu features: batch parameters program programming items factory set default programming range notes batch 1 left* • batch summary display summary • batch name regular 1(-16) choose from list: regular1 (regular 1-16) -or- write: any name cbs-2151& 2152xts 1 ½ gallon • batch volume 1.50 gal [ 0.50...

8 eco mode-energy saving mode definitons if selected: turns heaters off after 1 hour of inactivity. The hot water tank temperature will slowly decline to no lower than 60°c/170°f a screen (example to the right) will display showing “eco mode” is activated. Æ to return from eco-mode tap the screen, e...

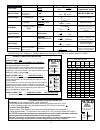

9 inputs programming items factory set default programming range (display) notes display inputs • input summery r. Brew basket sens. [ single/dual] l. Brew basket sens. H. Liquid level probe h. Tank temperature probe l. Tank temperature probe sd card recognized tank temp. 200 cal. Touch scr calibrat...

10 outputs programming items factory set default programming range (display) notes show summary • output summary left brew fr left bypass fr right brew fr right bypass fr screen contrast screen brightness touch to return 3400 2400 3400 2400 8 8 fr=flow rate ml/min left valve test or calibrate • left...

11 for factory or qualified service professional use only how to calibrate the flow rate set the flow rates of components to adjust for taste profile and for over or under potting. Built-in algorithms in brewer controller software corrects brew parameter to customer preferences or to trim variations...

13 safety notes 1. Professional installation is required. This appliance is manufactured only for commercial use. 2. Operation requirements and maintenance for commercial cooking appliances differ from household appliances. 3. Operators must be trained for this equipment and must understand the use,...

14 operator training review the operating procedures with whoever will be using the brewer. Pay particular attention to the following areas: 1. Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and letting them stand for at least 5 minutes. 2. D...

15 service guide to a successful installation (for qualified service technicians only) if not installed correctly by qualified personnel, the brewer will not operate properly and damage may result. Damages resulting from improper installation are not covered by the warranty, and will void the warran...

16 installation directions for professional installation only brewer setup 1. Review the dimensions for the unit and verify that it will fit properly in the space intended for it. Verify that the counter or table will support the total weight of the brewer and dispensers when filled (specifics-page ...

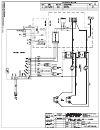

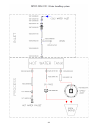

17 electrical-general 1. All fetco brewers require ground. Installation without ground may cause a hazard. 2. The electrical diagram with universal wiring instructions is located on the inside of the lower cover. 3. The installation must comply with applicable federal, state, and local codes having ...

18 technical data—cbs-2150xts 1½ gallon single and dual brewers capacities & measurements for single and dual brewers cbs-2150xts dimensions & utility connections cbs-2150xts rough-in drawings brewer height width depth empty weight filled weight total weight- brewer & full dispenser hot water tank c...

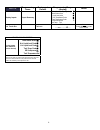

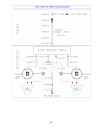

19 cbs_2151xts—single 1½ gallon version electrical configurations usa and canada cbs_2151xts—single 1½ gallon version electrical configurations configuration code plastic brewbasket stainless steel brewbasket heater configuration voltage phase wires electrical connection kw amp draw gallon/hour (1½ ...

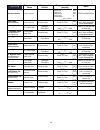

20 cbs_2152xts—twin 1½ gallon version electrical configurations usa and canada cbs_2152xts—twin 1½ gallon version electrical configurations configuration codes plastic brewbasket stainless steel brewbasket heater configuration voltage phase wires electrical connection kw maximum amp draw brew-volume...

21 rough-in cbs-2152-2 gallon xts —dual station version notice: this model uses 2 gallon dispensers cbs-2150xts utility requirements water requirements: inlet water temperature: cold supply 20-75 psig (138-517kpa) 1½gpm/(5.7lpm) coffee filter size:Æcbs-2150xts: 15” x 5 ½ ” cold water supply only; ha...

22 final setup for startup fetco home screen #1 “filling” home screen #2 “heating” final setup 1. Turn on incoming water supply line and carefully inspect both inside and outside of the brewer for leaks in all fittings and tubes 2. Turn on power. 3. Press the brewer’s main power switch (located on t...

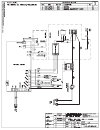

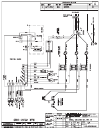

24 parts and wiring diagrams 1102.00223.00 [large] spray assembly parts cbs-21 50xts ref qty part no description 1 1 1102.00116.00 largespray housing assembly 2 1 1102.00222.00 valve, brew, assembly, 24 vdc 3 4 1082.00056.00 screw, #8-11 x 1" thrd form, p/h phil 4 1 1102.00043.00 cascade spray dome ...

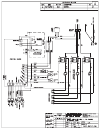

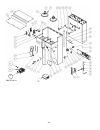

34 cbs-2152xts 52.

35 bill of materials cbs-2152xts ref # part number name 1 1 1111.00046.00 weldment body complete, cbs-2152 xts 1 1 1111.00052.00 weldment body complete, cbs-2152 xts, 2 gal 2 1 1071.00010.00 faucet hpsc-br-8 regular handle 3 1 1031.00003.00 fitting, barb 3/8'id x 1/4" fpt 4 1 1023.00147.00 plug, tan...

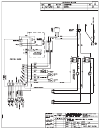

36 drawing 1101.00214.00 cbs-2151xts.

37 drawing 1101.00214.00 cbs-2151xts ce version ref # part number name 1 1 1111.00047.00 weldment body complete, cbs-2151 xts 2 1 1102.00223.00 spray housing, large, complete assembly, 24 vdc 3 8 1083.00010.00 washer, #10 screw w/neoprene-bonded seal 4 12 1084.00006.00 nut, 8-32 18-8 hex machine scr...

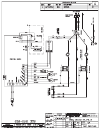

38 tank assy cbs-2152 xts ref # part number name 1 1 1114.00091.00 weldment, tank cbs-2152 2 5 1024.00050.00 grommet, silicone, 11.4mm id 3 2 1024.00062.00 grommet, short, silicone, level and temp probe 4 2 1024.00053.00 level and temp probe grommet 5 1 1023.00166.00 fitting, cold water inlet, gromm...

3 9 . Tank assy cbs-2151 xts drawing #1104.00061.00 ref # part number name 1 1 1114.00087.00 weldment, tank, cbs-2151 2 4 1024.00050.00 grommet, silicone, 11.4mm id 3 1 1023.00166.00 fitting, cold water inlet, grommet design 4 1 1023.00168.00 fitting, hot water, grommet design 5 1 1023.00183.00 fitt...

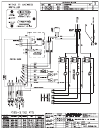

40 back panel assembly, cbs-2151xts drawing 1102.00231.00 ref # part number name 1 1 1112.00281.00 weldment, back panel, cbs-2151 2 1 1052.00002.00 terminal block, 3 pole, w/ marking strip 3 1 1003.00170.00 bracket, guard 4 1 1083.00011.00 washer, #8 screw size, internal tooth lock 5 2 1083.00016.00...

41 back panel assembly, ce cbs-2151xts drawing 1102.00216.00 ref # part number name 1 1 1112.00261.00 weldment, back panel, cbs-2151, ce 2 1 1003.00170.00 bracket, guard 3 8 1081.00006.00 spacer, 6mm od x 3.2mm id x 5mm lg, z/p 4 1 1052.00001.00 power supply, 90-264vac/24vdc, 1.8a 5 4 1029.00012.00 ...

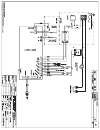

42 back panel assembly, cbs-2152xts drawing 1102.00229.00 ref # part number name 1 1 1112.00280.00 weldment back panel, cbs-2152 2 1 1052.00005.00 terminal block track 3 3 1083.00011.00 washer, #8 screw size, internal tooth lock 4 1 1086.00008.00 connector, cable clamp, 3/4" 5 1 1058.00020.00 switch...

43 back panel assembly, cbs-2152xts drawing 1102.00229.00 1 1 1112.00267.00 weldment, back cover, cbs-2152, eu 2 1 1003.00170.00 bracket, guard 3 8 1081.00006.00 spacer, 6mm od x 3.2mm id x 5mm lg, z/p 4 1 1052.00001.00 power supply, 90-264vac/24vdc, 1.8a 5 4 1029.00012.00 spacer, .25" hex x 1" lg, ...

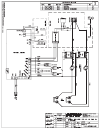

44.

45.