- DL manuals

- Fiamma

- Boiler

- BP-L series

- Use and maintenance manual

Fiamma BP-L series Use and maintenance manual

USE AND MAINTENANCE MANUAL

ELECTRIC COMBI WALL BOILER

FOR HEATING AND SANITARY HOT WATER PRODUCTION

INSTANTANEOUS WITH ACCUMULATION TANK

Combi.

Ele

k

tra

.. BP-L

HE

series

EQUIPMENT COMPLIANT CE DIRECTIVE 2006/42 - IEC 60335-2-21:2012 with IEC 60335-1:2010 with EN

60335-2-21:2003+A1:2005+A2:2008 - EN 60335-1:2012 - EN 62233:2008.

®

Summary of BP-L series

Page 1

Use and maintenance manual electric combi wall boiler for heating and sanitary hot water production instantaneous with accumulation tank combi. Ele k tra .. Bp-l he series equipment compliant ce directive 2006/42 - iec 60335-2-21:2012 with iec 60335-1:2010 with en 60335-2-21:2003+a1:2005+a2:2008 - e...

Page 2: Electric Wall Boiler

2 electric wall boiler series ele k tra . … bp-l he presentation thank you for choosing an electric wall boiler fiamma, built with the most modern technologies, safe and tough materials, so as to ensure maximum efficiency of use, total quality of the device and extreme safety for the user. The serie...

Page 3

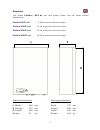

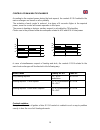

3 p h l dimensions the series elektra... Bp-l he has four power levels, but the same overall dimensions: ele k tra. 6 bp-l he 6 kw maximum electrical output ele k tra .12 bp-l he 12 kw maximum electrical output ele k tra .18 bp-l he 18 kw maximum electrical output ele k tra .24 bp-l he 24 kw maximum...

Page 4

4 af vsr ac m rc vss r electrical supply 200 65 220 165 300 95 80 120 hydraulic connections – dimensional of connection arrangement. Hydraulic connections m heating delivery : ¾” m r heating return : ¾” m af cold sanitary water inlet : ½” m ac hot sanitary water output: ½” m vsr heating safety valve...

Page 5

5 main technical features elektra 6.. - elektra 12.. Ele k tra .6 bp- l he 6 kw maximum electrical output single-phase electrical supply 230 v - 50 hz. Weight : 60 kg. Capacity of tank 37 lt. Glass-lined steel with inspection flange and magnesium anode. Electrical / heat power available at heating: ...

Page 6

6 main technical features of elektra 18.. – elektra 24.. Ele k tra .18 bp- l he 18 kw maximum electrical output single-phase electrical supply 230 v - 50 hz. Weight : 62 kg. Capacity of tank 37 lt. Glass-lined steel with inspection flange and magnesium anode. Electrical / heat power available at hea...

Page 7: Display

7 display idrometro general switch hydrometer idrometro switching-on the boiler control panel the control panel is composed of : display, function selection keys, general switch and the hydrometer it is placed in the lower left corner in front of the unit (see image above). Using analogical hydromet...

Page 8

8 j7 j6 j5 j4 j3 j2 keyboard panel (control panel) meaning of the keys in user mode key function j5 display / tank setpoint decrease (only if jp8 = 0) j6 display / tank setpoint increase (only if jp8 = 0) j7 on - off switching display temperature output / display setpoint output unlock error of safe...

Page 9

9 choice of the operation mode (winter/summer) pressing the key mode (j4), it will be chosen the mode of operation, wintry or summery. Pressing repeatedly each time for at least 5 seconds, you switch from winter to summer or from summer to winter then. When the device will be in winter mode, on the ...

Page 10

10 pressure alarm, the recovery will be automatic after that the hydric pressure will be restored at the minimum operating level (0,8 bar) by means of the opening and the closure of the charging tap placed under the boiler (black handle). The display has several symbols, signaling in addition to ope...

Page 11

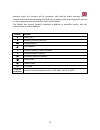

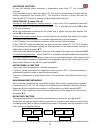

11 installation technical note for installer and technical maintenance hydraulic scheme (elektra 12 bp-l 01 5 he version) legend - ts safety thermostat. - r s filling tap. - vss safety valve for sanitary circuit 1/2”x6 ,5 bar. - pa water pressure switch. - sp brazed heat exchangers. - cc boiler body...

Page 13

13 single phase f neutral n selected phase from contactor ft electric pump pi control of contact ts on contactor of power (c-no) cts sanitary microswitch (control comfort function) ms control gate triac n°1 (4kw power) g1 control gate triac n°2 (2kw power) g2 control gate triac n°3 (4kw power) g3 co...

Page 14

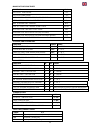

14 triac – connection scheme.

Page 15

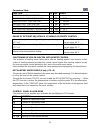

15 manufacture constants function value delta off tank probe 0°c delta on tank probe -1°c intervention temperature anti legionella 65°c intervention interval anti legionella 7 days max temperature primary 80°c time of pump functioning in anti-lock 10 sec intervention time anti-lock pump 24h temperat...

Page 16

16 control of main heat exchanger according to the required power during the heat request, the controls g1-g4 related to the main exchanger are turned on all or partially. The actuation of each control is reduced to a lapse of 4 seconds. Higher is the required power, more the control will remain ope...

Page 17

17 control of exernal probe installation and functioning at sliding temperature for the connection of the external probe, it shall be used the original kit fiamma code f.532 provided in the accessories of the electric boilers elektra. The electrical connection shall be done in the external terminal ...

Page 18

18 antifreeze function in case the delivery probe measures a temperature lower than 7°c, the circulator is activated. If the temperature goes down the value of 4°c the m ain heat exchanger is ignited until the delivery temperature has reached 20°c. The antifree ze function is active also with the bo...

Page 19

Instruction grundfos pump heating request as the contact of room thermostat closes, if the mainboard is in winter mode, the system pump is only activated if the temperature of the primary heat exchanger is higher than the temperature set by parameter n°6. If the value of temperature measured by the ...

Page 20

20 “heating elements status” the dashes located in the upper part indicate the heating elements status. Each dash corresponds to a 2 kw element. The first 6 dashes refer to heating modules of primary heat exchanger. The dash on the right upper corner refers to the heating module dedicated to the tan...

Page 21

21 “temperature display” on the small digit will appear the writing t : followed by the description of the selected temperature, while the big digit will show the temperature value. Function n° delivery temperature t: “ch” tank temperature t: “dh” external temperature t: “ep” external probe offset s...

Page 22

22 functioning with remote control encrono ot1 , ot2 or ot11 look of the remote control encrono ot1 , ot2 and kronos ot11 elektra … bp-l, can be connected by means of its card and an additional module to install on a prearranged part, to a compatible remote control device opentherm®, like encrono ot...

Page 23

Functioning of boiler elektra with remote control the actuation of heating mode takes place after an heating request from remote control (value of heating setpoint calculated by remote control higher than heating setpoint set by the user on remote control divided by two) and in the winter mode statu...

Page 24

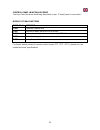

24 control panel in installer mode the keys have the same functioning described on par. “control panel in user mode”. Display of malfunctions code “err” meaning f 009 hardware eeprom fault f 001 insufficient water pressure in the system f 004 tank probe error / instant sanitary - only if jp8 = 0 f 0...

Page 25

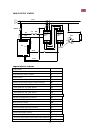

25 spare parts 4 particular particular : boiler body / resistances 3 4 5 6 8 9 10 11 12 23 24 25 27 28 29 30 26 7 21 1 2 15 14 16 17 18 19 20 22 31 32 33 13 37 38 25 46 20 16 35 34.

Page 26

26 upper particular / resistance front unit particular : flange/probe/resistance/anode group sanitary tank. 41 42 43 44 7 39 40 25 26 13 45 9 10 7 8 7 12 46 46 49 48 46 the flange/tank group, included in one vitrified piece, sheath probe, resistance probe, and inspection and support flange. The subs...

Page 27

27 spare parts - legend 1 upper closing fairing of elektra .. B/bp-l. ………………...………. Cod.P.2025 2 tetrapolar terminal block for elektra 6/12/18 … . …………..………...Cod.P.2054 tetrapolar terminal block for elektra 24 … . ………………..………... 3 terminal of the electric supply line 230v (ph). …………..…............ ...

Page 28

38 drain tap ¼” for elektra .. Boiler/tank. ………………………....…….. Cod.P.2190 39 contact safety thermostat 100°c. Elektra .. . …………….……….. Cod.P.1195 40 automatic bleed valve (jolly). ……………...…………...................... Cod.P.174 41 front panel elektra .. B/bp-l . …………..……………...................... Cod.P.2...