Gabarron MATTIRA MAC15 Installation Instructions And User Manual - page 11

11

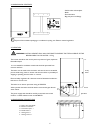

4.9 (c) DHW CONNECTIONS, DESIGN & REQUIREMENTS

CAUTION: This boiler incorporates a 50 litre unvented hot water cylinder. Installation of this appliance must be

carried out by a Competent Person and in accordance with the relevant regulations.

In every installation it is mandatory for the Group combination valve to be installed on the mains cold water supply to the

boiler. This will protect the boiler and prevent constant opening of the 7 bar relief valve (The Group combination valve is

comprised of a pressure reducing valve, a pressure relief valve, a check valve, a filter and a balanced cold water outlet all

included in a single valve. These inlet control groups are designed to control the pressure on the mains supply to the integral

unvented hot water cylinder).

The installation of a thermostatic blending valve (not supplied) is recommended, as per the diagram shown in 4.7 to ensure a

safe and economic supply of hot water.

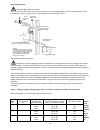

Maximum inlet pressure to Pressure reducing valve 12 Bar

Operating pressure (PRV setting)

3 Bar

Expansion vessel charge pressure

3 Bar

Expansion relief valve setting

4.75 Bar

Opening pressure of P & T Relief Valve

7 Bar

Opening temperature of P & T Relief Valve

92ºC – 95ºC

Energy cut-out thermostat setting

80ºC

Immersion heater rating

2-15kW depending upon setting

All cylinders are manufactured in accordance with the requirements of BS EN 12897.

The tundish must be positioned so that it is visible to the occupant and is away from electrical devices.

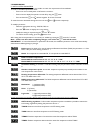

Components supplied with Gabarrón Mattira electric combi boiler (incorporating a 50 litre unvented

cylinder):

• Cold water inlet PRV combination valve/expansion relief (supplied loose)

• Pressure and temperature relief valve

• Control thermostat

• Energy cut-out thermostat

• Tundish (supplied loose)

• Immersion heaters including control and cut out thermostats

• Expansion vessel

• Technical/user product literature

In any situation where the volume of heated pipework (eg. secondary circulation pipes or manifold pipework

for multiple units) exceeds 10 litres, then an additional expansion vessel must be fitted to accommodate the

extra expansion volume.

CAUTION: Modifications should not be made to this product. Replacement parts, including immersion heaters,

should be purchased from Elnur UK Limited, or agents approved by them.

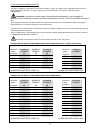

Unvented hot water storage vessels need regular routine checks, and these are detailed below. It is for this reason that this

manual must always be left with the Gabarrón Mattira combi boiler.

It is essential that these checks be carried out at the time of boiler maintenance by a qualified installer:

1. Manually open the relief valves in turn, and check that water is discharged from the valves and runs freely through the

tundish and out at the discharge point. Ensure that the valves re-seat satisfactorily. (Note – the water may be very hot).

2. It is important to check that the discharge pipework is carrying the water away adequately. Check for blockages etc. if it is

not.

3. Turn the mains water off and remove and clean the strainer element in the Pressure Reducing Valve.

4. Check the charge pressure in the expansion vessel and repressurise if required.

5. Re-fill the system and ensure that all relief valves have re-seated.

6. The Service Record should be updated at each service.