- DL manuals

- Gaggia

- Coffee Maker

- Brera

- Service Manual

Gaggia Brera Service Manual

SERVICE

MANUAL

Revision 00

All parts of this document are the property of Saeco International Group.

All rights reserved. This document and all the information herein is provided without liability deriving

from any errors or omissions. Furthermore, no part may be reproduced, used or collected, except where

express authorisation has been provided in writing or through a contractual agreement.

Rev. 00 / OCTOBER 2009

Summary of Brera

Page 1

Service manual revision 00 all parts of this document are the property of saeco international group. All rights reserved. This document and all the information herein is provided without liability deriving from any errors or omissions. Furthermore, no part may be reproduced, used or collected, excep...

Page 2: Table of Contents

Page 1. Introduction 1.1 documentation required 1 1.2 tools and equipment required 1 1.3 material 1 1.4 safety warnings 1 1.5 brera range 2 1.6.1 external machine parts 3 1.6.2 internal machine parts 4 2. Technical specifications 2.1 technical specifications 1 2.2 machine parameters and performance ...

Page 3: Table of Contents

Table of contents page 5. Service mode 5.1. Test mode 1 6. Servicing & maintenance 6.1 repair schedule 1 6.2 service schedule 1 6.3 final test 2 7. Disassembly 7.1 outer elements disassembly 1 7.2 dispensing spout disassembly 1 7.3 keypad card and valve card disassembly 2 7.4 power/cpu card disassem...

Page 4

Rev. 00 october 2009 page / 04 gaggia 01 introduction 1.1 documentation required the following documentation is needed for repair procedures: • instruction booklet for specific model • technical documentation for specific model (diagrams, exploded drawings) 1.2 tools and equipment required as well a...

Page 5

Rev. 00 october 2009 page / 04 gaggia 01 introduction 1.5. Brera range led interface x painted details x water/steam valve x alarm led x automatic rinse x automatic dosage x pannarello (frother) x dispensed coffee memory capacity x automatic shutdown (after 60' inactivity) x 02.

Page 6

Rev. 00 october 2009 page / 04 gaggia 01 introduction 1.6.1 external machine parts 03 power cord led display selector switch hot water/steam selector switch stand-by button brew group service door grinder adjustment knob compartment cup stacking surface dispensing spout cup holder grill on-off power...

Page 7

Rev. 00 october 2009 page / 04 gaggia 01 introduction 1.6.2 internal machine parts 04 card - pwr/cpu boiler pump temperature sensor side door microswitch coffee grinder turbine coffee grinder motor.

Page 8: Chapter 2

Rev. 00 october 2009 chapter 2 technical specifications.

Page 9

Rev. 00 october 2009 page / 04 gaggia 02 technical specifications 2.1. Technical specifications 2.2. Machine parameters and performance power supply and output: 240 v~ 50 hz 1400 w - 230 v~ 50/60 hz 1400 w - 120 v~ 60 hz 1500 w - 100 v~ 50/60 hz 1300 w temperature monitoring: variable heating elemen...

Page 10

Rev. 00 october 2009 page / 04 gaggia 02 technical specifications rinse initial rinse final rinse when performed when the machine is switched on and the boiler temperature is ≤ 50°c when the machine is switched off electronically, manually or automatically after 60’, after having dispensed at least ...

Page 11: Chapter 3

Rev. 00 october 2009 chapter 3 brief instructions.

Page 12

Rev. 00 october 2009 page / 03 gaggia 03 brief instructions 3.1. Customer and programming menu 01 indications causes solutions machine at correct temperature - for coffee bean dispensing - for hot water dispensing proceed with the dispensing process machine at correct temperature - for ground coffee...

Page 13

Rev. 00 october 2009 page / 03 gaggia 03 brief instructions 02 indications causes solutions machine in rinsing phase - wait for the machine to complete the procedure wait until end of procedure the appliance requires a descaling cycle perform the descaling cycle to enter the descaling cycle press th...

Page 14

Rev. 00 october 2009 page / 03 gaggia 03 brief instructions 03 3.2. Operation, cleaning and maintenance operating the machine 1 fill water tank 2 fill the coffee bean hop- per 3 switch on the appliance 4 fill the circuit place a container under the steam wand and turn the selector to the ” “ symbol ...

Page 15: Chapter 4

Rev. 00 october 2009 chapter 4 operating logic.

Page 16

Rev. 00 october 2009 page / 06 gaggia 04 operating logic 4.1. Water circuit 01 • traditional water system • turbine - amount of coffee dispensed into the cup • reciprocating piston type pump (13 - 15 bar) • compensation valve (opening pressure 16 - 18 bar) • boiler - 1400 w • presblok valve - select...

Page 17

Rev. 00 october 2009 page / 06 gaggia 04 operating logic 4.2. Control ringnut and valve no. Description 1 mushroom valve cap 2 spring for mushroom valve 3 mushroom valve support 4 mushroom valve 5 sealing or 1 2 3 4 5 when dispensing coffee the mushroom valve opens at 4 bar +/- 0.5 manual opening wh...

Page 18

Rev. 00 october 2009 page / 06 gaggia 04 operating logic notes: * only with prebrewing 4.3. Coffee cycle operating diagram ms status off single microswitch gearmotor on switching on when the machine is switched on, the gearmotor repositions itself as follows: - it acts on microswitch 1 (see followin...

Page 19

Rev. 00 october 2009 page / 06 gaggia 04 operating logic temperature sensor an ntc is used as a temperature sensor; in the event of overheating this reduces boiler ele- ment power consumption. The electronic system detects the current boiler temperature from the drop in voltage of the sensor and adj...

Page 20

Rev. 00 october 2009 page / 06 gaggia 04 operating logic 4.6. Coffee grinder operation 2 3 4 5 6 1 4.7. Low bean level detection, dose quantity adjustment, coffee grinder blocked t1 v t2 t3 t4 t without beans n=100% with beans n=100% without beans n=50% with beans n=50% ceramic coffee grinder the co...

Page 21

Rev. 00 october 2009 page / 06 gaggia 04 operating logic 4.8 dose self-learning with an algorithm based on three pieces of information (listed below) detected by the machine computer, the average dose is adjusted automatically (self-learning). 1. Number of coffee grinder pulses taking place during t...

Page 22: Chapter 5

Rev. 00 october 2009 chapter 5 service mode.

Page 23

Rev. 00 october 2009 page / 02 gaggia 05 service mode 5.1. Test mode to enter test mode 1. Place the control knob in the water position 2. Keep the espresso coffee key pressed 3. Switch the appliance on from the 0/i button located at the rear of it; the icons scroll through in sequence 4. Release th...

Page 24

Rev. 00 october 2009 page / 02 gaggia 05 service mode brew group operational check press notes settings illumination of icon when absorption is greater than 300 ma with the group inserted and 200 ma with the group not inserted. When the group limit microswitches are not activated in both standby and...

Page 25: Chapter 6

Rev. 00 october 2009 chapter 6 servicing and maintenance.

Page 26

Rev. 00 october 2009 page / 02 gaggia 06 servicing and maintenance action 1 visual inspection (transport damage) 2 machine data check (rating plate) 3 operational check / problem analysis 4 opening machine 5 visual inspection 6 operational tests 7 repairing the faults encountered 8 checking any modi...

Page 27

Rev. 00 october 2009 page / 02 gaggia 06 servicing and maintenance test procedure support/ tool standard tolerance espresso 2-3 espressos for adjustment purposes measuring scoop same amount 15% coffee 2-3 coffees for adjustment purposes measuring scoop same amount 15% noise standard amount of cream ...

Page 28: Chapter 7

Rev. 00 october 2009 chapter 7 disassembly.

Page 29

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 7.1. Outer elements disassembly 01 7.2. Dispensing spout disassembly 1 1 2 2 3 3 4 4 6 6 1) remove the dreg drawer, water tank, coffee bean hopper cover, drip tray, brew group, steam wand cap and pannarello (frother) 2) unscrew the screws shown an...

Page 30

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 02 7.3. Keypad card and valve card disassembly 1) unscrew the screws shown 2) release the stop device and the flat cable slide out the front panel 3) disconnect the connector shown and unscrew the cpu card support screws shown 4 /5) unscrew the sc...

Page 31

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 7.4. Power/cpu card disassembly 03 7.5. Gearmotor disassembly 2 a b d e f c 2 a b d e f c 4 h l 4 h l 3 b p 3 b p 1 1 2 2 1 1 1) unscrew the screw shown and re- move the card protection 2) slide out the card, removing all con- nections 1) unscrew ...

Page 32

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 1) remove the coffee grinder sound insulating cover 2) remove the boiler insulation 3) unscrew the screws shown. 4) unscrew the screw and remove the plastic support. Disconnect the hoses and the connections 7.6. Boiler disassembly 1 2 3 7.7. Valve...

Page 33

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 6) unscrew the screws shown to remove the insert on the base of the casing 7) unscrew the screws shown and disconnect the valve from the water connections. 7) unscrew the screws shown and disconnect the valve from the mesh hoses 7.8. Pump and turb...

Page 34

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 1) boiler connection 2) other connections replacing the hoses 1) use a suitable pair of pliers to remove the clamp (as illustrated) 2) tighten the clamp as illustrated 7.9. Disassembling and fitting oetiker clamps 1 1 2 2 06.

Page 35

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 1) to remove the coffee grinder, simply slide it out and remove its connections 2) when replacing it, make sure the spring (a) and the coffee pipe (b) are positioned correctly 7.10. Coffee grinder disassembly 1 2 a b 07.

Page 36

Rev. 00 october 2009 page / 08 gaggia 07 disassembly 7.11. Grinder adjustment / assembly and disassembly 1) to remove the upper grinder support, using a hex key push down and turn clockwise to release the grinder support from the bayonet coupling 2) to remove the grinder blade from the upper support...

Page 37: Chapter 8

Rev. 00 october 2009 chapter 8 notes.

Page 38

Rev. 00 october 2009 page / 01 gaggia 08 notes 01.

Page 39: Chapter 9

Rev. 00 october 2009 chapter 9 water circuit diagram.

Page 40

Rev. 00 october 2009 page / 01 gaggia 09 water circuit diagram 9.1. Water circuit diagram steam w and pi pe fit ting rac cor do tubo vapor e sili cone tube - tubo sili cone 5x10 9972.176 (130mm) sili cone tube - tubo sili cone 5x10 9912.122 (290mm) sili cone tube - tubo sili cone 5x10 9972.176 (130m...

Page 41: Chapter 10

Rev. 00 october 2009 chapter 10 electrical diagram.

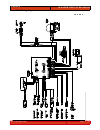

Page 42

Rev. 00 october 2009 page / 01 gaggia 10 water circuit diagram 10.1 wiring diagram 01.