Summary of PH40V

Page 1

Instruction manual - ph40v - ph45v.

Page 2

Contects 1. ! Safety)...............................................................................................................................)1! 2. ! Introduction)..............................................................................................................)2! 3. ! Specificati...

Page 3

! 1. S afety please make sure to read this manual for safety in operation before using this product. Take good care of this manual and keep it where you can always find it. This manual contains cautions and warnings in order to prevent harm to the purchaser and other persons, lives, or the damage to...

Page 4

2 2. I ntroduction your new folder is a table top automatic folding machine which will efficiently solve all your folding problems over many years if your handle if carefully and with care. Thanks to new advances in production technology. The machine offers you outstanding capacity at reasonable cos...

Page 5

3 the model number shows the machine configuration, for example: ph-40 df-30 feed width of 300mm 4 4-plate folding machine v vertical stacker c counter df-45 feed width of 350mm 4 4-plate folding machine v vertical stacker b batch-counter note: 1. For all 4-plate folding machine unit configurations,...

Page 6

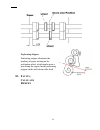

4 3. S pecification & c omponents model ph40v ph45v max. Paper size (mm) 300(w)x 500(l) 350(w)x 540(l) min. Paper size (mm) 80(w) x 100(l) folding paper weight (gsm) 45 to 150 min. Folding size (mm) 24 dimension (lxwxh in mm) 1100x525x510 1100x570x510 weight (kg) 68kg 71kg 1 feed table 2 feed guide ...

Page 7

5 a. Feed table hook in the feed table. First place it on the support shaft, slide it down at an angle until the lower slots engage with the pins on the side panels. The upper slots must engage with the support shaft. After which, install the two bracket guides. B. Folding plates hook the folding pl...

Page 8

6 below are some of the common folds and setup guide that you will come across during your folding. With the 4-plate machine, there more combinations essentially based on these principal and setup. Basic fold style fold style setting guide type of fold fold plate set to paper length a4 a3 single 1 1...

Page 9

7 2 1/4 74 105 3 - - - 4 - - - triple parallel (8-page) 1 1/2 148 210 2 1/4 74 105 3 - - - 4 1/8 37 52 zig-zag/accordion** 1 1/3 99 140 2 1/3 100 140 3 - - - 4 - - - 1 1/4 74 105 2 1/4 75 105 3 1/4 76 105 4 - - - * the dash line – means to insert the fold plate with the paper deflector side into the...

Page 10

8 • paper thickness adjusting knob: variable adjustment for thickness of papers between 45-150 gsm. • feeder: with adjustable infeed pressure roller. • folding plates: with micro-adjust for length and angle setting, fitted with scales. • vertical stacker: adjust the stacker wheels according to the p...

Page 11

9 please remove the hand wheel before switching on the machine. Adjust paper thickness paper thickness is to be adjusted so that the feeder only feeds one piece of paper at a time. By adjusting to the pressure roller, you can limit the passage gap to any paper thickness. Set the gap between feed rol...

Page 12

10 adjust feed guide first align the left feed bracket guide (1) so that the sheet is fed centered on the table as far as possible. A notch (2) in the table under the removable center panel marks table center, but you can also align the sheet using the feed or pressure roller as gauge. To shift the ...

Page 13

11 paper stack it is important to fan the paper stack before placing it on the feed table: grip the left end of the paper with your left hand and bend it towards the right. Press on the right side of the paper with your right hand, and then release your left hand. The paper stack will snap back and ...

Page 14

12 feeder pressure to adjust the feed pressure, first place the feeder unit at its rest position (infeed roller raised). Set the pressure of roller on feeder with the knurled nut (1). For paper weight from 60gsm to 90gsm, place the nut in the middle, neutral position. For over 90gsm paper, loosen th...

Page 15

13 when the pressure is set, place the feeder to its work position. To sum up, set paper feed in the following steps: • set gap between feed and pressure roller approximately to paper thickness. • align guides. • set infeed roller contact pressure with the knurled nut on the feeder. Setting the fold...

Page 16

14 needed, take it out and fit it reversely with the deflector (6) end into the machine. When the setting is completed, please test folding several papers first. You can fine-tune the stops for length and angle with the knurled screws. Angle micro-adjustment (2) vertical micro-adjustment (3) connect...

Page 17

15 vertical stacker installation of the vertical stacker insert the vertical stacker into the support shaft in the rear of folding machine using the groove (1) provided. Adjustment of the vertical stacker belts adjust the belts according to the width of the folded paper. The belt should have at leas...

Page 18

16 maximum fold size adjustment position the maximum size folded paper at the center of the stacker. Adjust the upper outer belt to space 1/4 of the paper length from the centre. The lower outer belt should be positioned as such that it leaves around 10~15mm to the edge of the paper. Adjustment of t...

Page 19

17 for this reason, it is advisable to place your left hand on the stack before switching on the power. Release the paper only when the machine has run up to the selected speed (you will hear the steady hum). The same applies when you switch the machine off with sheets of paper remain on the feed ta...

Page 20

18 7. O peration and folds 1. Choice between auto/manual for counter mode 2. Choice between increment or decrement count 3. Set batch count quantity enter button once setting is completed under count mode, press enter to store memory in count mode • press to increase the display number • select auto...

Page 21

19 in count mode • press to move left for digit position • digit flashes indicating the current position in count mode • press to move right for digit position • digit flashes indicating the current position when the counter is set and machine at the stop position, press right button to perform test...

Page 22

20 1. Press to enter count mode. Auto and manual led will blink. Press to select auto mode. Add and sub led will blink. Press to select sub for decrement count style use the direction buttons to set the number of sheets to fold. 2. Press to store setting 3. Press to determine machine speed 4. Press ...

Page 23

21 mark the first sheet you run through the machine with a cross on the top side, so that you know in which direction it has been fed. If it leaves the machine with the fold diagonally shifted from the straight line, first fold it by hand to an even more acute diagonal offset from the straight, then...

Page 24

22 tape to the table. Place the fanned stack on top, holding it in position with your left hand and guiding it with the right. Cautiously slide the stack up to the feed roller working range so that the fanning will not collapse again. As the top sheet must be seized first, slide it closest to the fe...

Page 25

23 turn the adjustment nut (1) anti-clockwise: this action will push the rod and close the gap between the rollers. This step is to increase pressure on the fold rollers 9. O ptional accessories a. Scoring!Or!Perforating!Wheel! First, mark the scoring position on a test paper then adjust the ejector...

Page 26

24 10. F aults , c ause and r emedy perforating stripper perforating stripper eliminates the tendency of paper sticking on the perforating wheel, which might cause a jam during the output. Install perforating stripper on the hold - down roller shaft..

Page 27

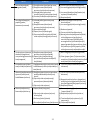

25 ( fault cause remedy intermittent(and( irregular(feed( 1.(feed(bracket(set(too(narrow( 2.(gap(between(feed(and( pressure(roller(too(narrow( 3.(infeed(roller(pressure( insufficient(or(roller(worn(out( 4.(feeder(shaft(drive(belt(worn( 1.(loosen(the(bracket(by(a(little( 2.(increase(gap(with(setting(...

Page 28

26.