- DL manuals

- Galletti

- Air Conditioner

- FM

- User, Installation & Maintenance Manual

Galletti FM User, Installation & Maintenance Manual

Summary of FM

Page 1

Fm user, installation & maintenance manual gb n installasjon, bruk og vedlikehold vegghengt viftekonvektor high wall fan coil units.

Page 2

2 fc66003653 - rev 00 declaration of conformity galletti s.P.A. Hereby declares, under its sole responsibility, that fm high wall fan coil units series have been designed, built and tested in conformity with the specifications of european directives: 2006/42/ce, 2004/108/ce, 2006/95/ce bentivoglio, ...

Page 3

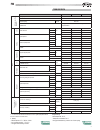

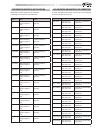

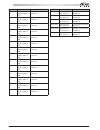

Fm 3 tekniske data fm 22/23 32/33 42/43 konfigurasjon vifte- konvektor konfigurasjon 2 rør antall vifter enkel strømforsyning (v/f/hz) 230/1/50 220/1/60 driftskontroll innebygd pcb, inkl. 1 stk. Returluftføler og 2 stk. Temperaturfølere. Ytelse luft total luftstrøm e h m 3 /h 500 645 876 m 370 445 7...

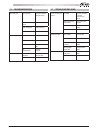

Page 4

4 fc66003653 - rev 00 units' performance table fm 22/23 32/33 42/43 unit configuration configuration 2-pipe number of fan blowers single power supply (v/ph/hz) 230/1/50 220/1/60 operation control complete function onboard pcb with integrated group control functionality, incl. 1 pc return air sensor ...

Page 5

5 contents 1 - general .....................................................................................5 2 - presentation .............................................................................6 3 - installation ................................................................................

Page 6

6 fc66003653 - rev 00 2 - presentation 2.1 - description the fm series high wall fan coil units are available in three models, complete with bldc motor and inverter, built-in on/off two or three way valve and infrared remote control. The main components and features are: • stylish casing in abs, wit...

Page 7

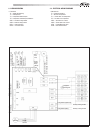

7 2.3 - overall dimensions model unit dimensions (mm) a b c d e f g h fm 22 / 23 / 32 / 33 / 42 / 43 40 105 875 55 105 r20 60 74 model unit dimensions (mm) a b c d e f g h fm 22 / 23 / 32 / 33 / 42 / 43 200 55 30 30 220 229 10 300 model unit dimensions (mm) 1 2 3 4 fm 22 / 23 / 32 / 33 / 42 / 43 665...

Page 8

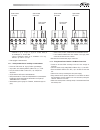

8 fc66003653 - rev 00 m30x1.5 Ø28 a c dn dn b d 2.3.1 - valve information valve dimensions (mm) dn a b c d d15 (g1/2”) 52 47 19.5 63 2-veis ventil 2 way valve body 3 way / 4 outlet differansetrykk differential pressure chart differansetrykk differential pressure chart valve dimensions (mm) valve mod...

Page 9

9 3 - installation 3.1 - choosing the location select the location for the high-wall unit with the following considerations: • the front of the air inlet and outlet should be free from any obstructions. The air should flow freely. • the wall where the unit is to be mounted should be stiff enough not...

Page 10

10 fc66003653 - rev 00 3.2 - mounting 3.2.1 - mounting plate dimensions fm 22 / 23 / 32 / 33 / 42 / 43 drill a hole on the wall anchor plastic clip expansion screw 3.2.2 - installing the mounting plate • select the structural position (e.G. A pillar or lintel) on the wall. • then temporarily fasten ...

Page 11

11 ankerbolt hull anchor bolt hole midlertidig feste temporary fastening festeplate mounting plate screw weight thread tilpass nivåstreken fit the level line pass a thread throught the cantered hole. Make sure the proper level of the plate, by hanging the thread with a weight from the central top of...

Page 12

12 fc66003653 - rev 00 3.2.3 - drilling the condensate drainage hole • ensure that the hole for condensate drainage is correctly positioned. The height should be lower than the below edge of the indoor unit. • drill a 65mm diameter hole with a descending slope. • seal it off with putty after install...

Page 13

13 4 - connections 4.1 - condensate connection • install the drain hose so that it slopes downward slightly for free drainage. • avoid installing it as shown in the below illustration marked with “x”. Slope downward 50 mm or more shield pipe drain hose på innsiden avløpsslange på utsiden inside the ...

Page 14

14 fc66003653 - rev 00 • in case that the attached (if it is attached) drain hose passes through an indoor area, insulate it with heat insulation material. • be aware of the risk of freezing in false ceilings during the winter. • the line must not have an upward slope near the outlet. 4.2 - hydrauli...

Page 15

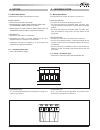

15 4.3 - electrical connections 4.3.1 - generals • the electrical connection conduits must be fixed. • class 1 appliance. • the electrical installation must be carried out in compliance with the rules in force. 4.3.2 - detail of the connection unit components are wired to the terminal block of indoo...

Page 16

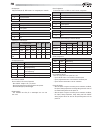

16 fc66003653 - rev 00 4.4 - electrical wiring diagrams • abbreviations ts = setting temperature tr = room air temperature ti1 = chilled water coil temperature ti2 = hot water coil temperature aux1 = hot water free contact aux2 = chilled water free contact mtv1 = chilled motorized valve mtv2 = hot m...

Page 17

17 --------- factory wiring - - - - - field wiring • dipa-s1 sw1-5: set the unit address. Sw6: set unit type: master or slave. • mode configurations: sw7=0; sw8=0; unit operates in cooling/heating. Sw7=1; sw8=0; unit operates in cooling only. • dipb-s2 sw1: occupancy contact setting. Sw2: unit confi...

Page 18

18 fc66003653 - rev 00 4.4.1 - configuration settings warning to avoid electric shock, be sure to turn the air conditioner off and disconnect the power before opening the unit. If you are installing more than 1 indor unit (up to 4) in the same room, it is necessary for you to assign each unit its ow...

Page 19

Fm 19 fc66003653 - rev 00 • unit configuration: on board dip switch on dipb are used for below configuration. Sw1 r-o contact setting 0 economy contact 1 window contact sw2 system setting 0 2-pipes system 1 4-pipes system sw4 preheat setting 1 28°c 0 36°c • motorized fan speed settings for different...

Page 20

20 fc66003653 - rev 00 5 - lift-up grille cover 5.1 - opening and closing of lift-up grille cover • open the lift-up grilled cover by lifting from the bottom position indicated by the arrow • close the lift-up grilled cover by pressing the two sides down at the position of the arrow. 5.2 - removing ...

Page 21

21 6 - starting important before doing any work on the air conditioner, make sure it is switched off and put out of bounds. Any work must be carried out by personnel qualified and authorised to work on this type of air conditioner. 6.1 - preliminary checks • make sure: - that the air handler is well...

Page 22

22 fc66003653 - rev 00 7 - name of parts and remote control unit 7.1 - led lights for all units power / operation led light (both green) unit on operation led on, power led off unit in standby power led on, operation led off installation location • we recommend this air conditioner to be installed p...

Page 23

23 eletrical requirements • before installation, check that the voltage of the electric supply in your home or office is the same as the voltage shown on the nameplate. • all wiring must conform to the local electrical codes. Consult your dealer or a qualified electrician for details. • each unit mu...

Page 24

24 fc66003653 - rev 00 fjernkontroll forsiktig når viftekonvektoren med håndsett er master, blir innstillingene automatisk sendt til slaver. "swing" kan ikke brukes. Justere temperaturen trykk pil opp eller ned for å øke eller redusere romtemperaturen. Temperaturen kan ikke settes i vifte modus. Sle...

Page 25

25 fc66003653 - rev 00 temperatur viser valgt temperatur driftsvisning viftehastighet visning av ukedag infrarød mottaker for mottak av fjernkontroll signal tastelås timer viser on/off timer eller klokke, rtc timer på timer av dag tast for valg av ukedag, søndag til lørdag. Eller for bruk i ukentlig...

Page 26

26 fc66003653 - rev 00 clock display and setting system has an accurate internal real time clock used for time indication and timer on/off function. Real time clock display area indicates internal time clock which can be set by time- or time+ button. Day display and setting the wall pad has day disp...

Page 27

27 in global control mode: • pressing master cancel button for 3 seconds will cancel all timer settings in all slave units. • timer settings will be broadcast to all slave units. Clock synchronization by master unit press time- and time+ buttons for 3 seconds to activate clock synchronization to all...

Page 28

28 fc66003653 - rev 00 networking master - slave control (only master unit wall pad can control other units on the network) • press net button to enter into networking control mode. Unit area blinking indicates the slave unit under control. Press time- or time+ to select the desired slave unit; unit...

Page 29

29 ec unit rpm setting • turn off the unit. • open wall pad’s back cover, two dip switches are appeared. • turn the dip switch 1 to “on” position. • wired wall pad led will be shown as following; this is the speed level setting. D0 means low speed d1 means medium speed d2 means high speed press para...

Page 30

30 fc66003653 - rev 00 led indication and error description for all units - operation led light (green) error description blink reason remedy electrical heater failure green led blink 1 times, stop 3 sec only for unit with eh. Eh protection switches is opened. 1. Change fan speed to high. 2. Replace...

Page 31

31 led indication on master/slave connection for master unit indicating defect status of all slave units. Error message can be found in led lights on master unit. Unit no. Blink remedy unit 2 failure red led blink 2 times, stop 3 sec check unit 2 communication plug and fix it unit 3 failure red led ...

Page 32

32 fc66003653 - rev 00 unit no. Blink remedy unit 27 failure red led blink 27 times, stop 3 sec check unit 27 communication plug and fix it unit 28 failure red led blink 28 times, stop 3 sec check unit 28 communication plug and fix it unit 29 failure red led blink 29 times, stop 3 sec check unit 29 ...

Page 33

33 control logics for 2-pipe system with thermoelectric valve configuration cool mode • mtv2, aux1 and heater are always off. • if tr ≥ ts + 1ºc (or + 4ºc if economy contact is activated), cool operation is activated, mtv1 and aux2 are turned on. Indoor fan runs at set speed. • if tr indoor fan runs...

Page 34

34 fc66003653 - rev 00 post-heat post-heat without electrical heater: • ifti1≥38ºc,mtv1andaux1areoff,indoorfancontinuestorunat set speed. • if36°c≤ti1≤38°c,whenmtv1andaux1areoff.Indoorfankeeps original state. • if ti1 • if indoor coil temperature coil is damaged, post-heat time is set for 3 minutes ...

Page 35

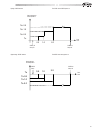

35 ts+2.0 ts+1.0 ts+0.5 ts 0.5 1.0 2.0 ts ts-0.5 ts-1.0 ts-2.0 0.5 1.0 2.0 still temperaturen set temperature sleep on sleep off hour the cool mode sleep profile is: the heat mode sleep profile is: still temperatur set temperature sleep sleep off hour sleep på sleep av time kjøling i sleep modus: op...

Page 36

36 fc66003653 - rev 00 tr ts+3c ts+2c ts+1c ts tr ts ts-1c ts-2c ts-3c high medium low low high medium low auto fan speed • in cool mode, the fan speed cannot change until it has run at this speed for more than 30 seconds. Fan speed is regulated according to the profile below. • in heat mode, the fa...

Page 37

37 louver for remote handset: • whenever indoor fan is running, louver can swing or stop at the desired position. • louver angle: 0~100º, opens clockwise with largest angle at 100º. • swing angle: 35~100º, opens clockwise to 68º. Below are the 4 fixed positions which can be set from wireless lcd han...

Page 38

38 fc66003653 - rev 00 8 - networking system 8.1 - master-slave network the control pcb can be set either as a master unit or slave unit. Master unit function • the master unit sends data on its setting to the slave unit. • the master unit settings are unit on/off, mode, fan speed, timer, clock, set...

Page 39

39 • connection wire. - if the total length of wire is more than 1000m, please use shielded wire in order to protect the signal transmission. - complete wire connection. - wire connection check: - after wire connection complete, please check the wire colour is correspondence. - check the wire contac...

Page 40

40 fc66003653 - rev 00 - check 1 and 2, 3 and 4, 5 and 6 to be sure connections correct. - if the resistance between two wire contacts is too high, please check and reconnect the wire contacts. • reconnect the communication plug to control box. 8.1.3 - using remote control handset to set master cont...

Page 41

41 8.1.4 - using wall pad to set master control unit: • connect all the units pcbs according to the wire color and type of connector. • select the master unit by setting dipa-s1 sw6 to on (=1) in the pcb. • ensure the dipa-s1 sw6 is set to off (=0) in the pcb on each slave unit. • provide each slave...

Page 42

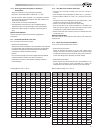

42 fc66003653 - rev 00 dipa-s1 sw6 dipa-s1 sw5 dipa-s1 sw4 dipa-s1 sw3 dipa-s1 sw2 dipa-s1 sw1 unit no. Remark 0 1 0 1 0 1 22 slave 0 1 0 1 1 0 23 slave 0 1 0 1 1 1 24 slave 0 1 1 0 0 0 25 slave 0 1 1 0 0 1 26 slave 0 1 1 0 1 0 27 slave 0 1 1 0 1 1 28 slave 0 1 1 1 0 0 29 slave 0 1 1 1 0 1 30 slave ...

Page 43

43 8.1.7 - open modbus protocol transfer mode: rtu, baud rate: 9600bps, 8 data bit, 1 stop bit, none parity bit. The communications require a delay between reading an answer and sending the next command of 80ms. All temperature is equal to reading data*10 accuracy: 0.1 degree c. Støttede funksjoner:...

Page 44

44 fc66003653 - rev 00 9 - maintenance important before doing any work on the installation, make sure it is switched off and put out of bounds. All operations must be carried out by personnel that are approved and qualified for this type of equipment. General maintenance all equipment must be proper...

Page 45

45 • cleaning: - use a vacuum cleaner to remove the dust. If the dust sticks to the filter, wash it in clear or soapy water, rise with clear water and then dry it. - replace the filter in its housing in the grille. - close the lift-up grilled cover by pressing the two sides down at the position of t...

Page 46

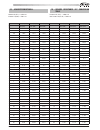

46 fc66003653 - rev 00 -30 174 182.7 191.8 4 26.11 26.9 27.71 -29 163.4 171.5 179.9 5 24.85 25.59 26.34 -28 153.6 161.1 168.9 6 23.65 24.35 25.05 -27 144.4 151.3 158.5 7 22.52 23.17 23.83 -26 135.8 142.2 148.9 8 21.45 22.06 22.68 -25 127.8 133.8 140 9 20.44 21.01 21.59 -24 120.3 125.8 131.6 10 19.48...

Page 47

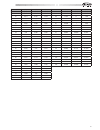

47 46 4.067 4.186 4.307 83 1.089 1.135 1.183 47 3.911 4.027 4.144 84 1.055 1.1 1.146 48 3.761 3.874 3.989 85 1.021 1.065 1.111 49 3.618 3.728 3.84 86 0.9891 1.032 1.077 50 3.481 3.588 3.697 87 0.9582 1 1.044 51 3.35 3.454 3.561 88 0.9284 0.9697 1.012 52 3.225 3.326 3.43 89 0.8998 0.9401 0.9818 53 3....

Page 48

48 fc66003653 - rev 00 11 - troubleshooting guide the fan coil does not start up no voltage check for presence of voltage; check fuse on board mains switch in the “off position place in the “on” position faulty room control check the room control faulty fan check fan motor insufficient output filter...

Page 49

Fm 51 fc66003653 - rev 00 notater.

Page 50

Fm 52 fc66003653 - rev 00 notater.

Page 51

Www.Galletti.It 40010 bentivoglio (bo) via romagnoli 12/a tel. 051/8908111 - fax. 051/8908122 azienda certificata uni en iso 9001 e ohsas 18001 / company uni en iso 9001 and ohsas 18001 certified.