- DL manuals

- Gamma

- Stringing Machines

- 6500 Els

- Owner's Manual

Gamma 6500 Els Owner's Manual

Summary of 6500 Els

Page 1

Owner's manual issue 1 - july 2006 stringing machine 6500 els 2 point mounting.

Page 2: Limited Warranty

1 limited warranty gamma sports ("gamma") warrants to the original purchaser that the gamma stringing machine ("equipment") purchased is free from defects in materials and workmanship for a period of five (5) years from the date of original purchase for mechanical parts (excluding electronic parts a...

Page 3: 6500 Els

2 6500 els key product features 1. Electric constant pull string tensioner w/ diamond coated string gripper (10-90 lbs tension range in 0.5 lbs increments) 2. Control panel w/ calibration, lbs/kgs, pulling speed & string length functions 3. String reel holder 4. Electronic string length meter 5. 2-p...

Page 4: 6500 Els

3 6500 els unpacking instructions & contents instructions for unpacking and preparing for assembly the 6500 els is shipped in three cartons, a large carton for the stringing machine and accessories, a medium carton with the turntable and mounting system and a smaller carton for the post and base leg...

Page 5: Assembly Instructions

4 base leg assembly the stringing machine uses a four leg base design. The legs must be assembled to the support post before use. Remove the lower column support, the upper column support, four (4) legs, four (4) socket head cap screws and four (4) flat head cap screws from the small shipping carton...

Page 6: Assembly Instructions

5 stand upper post installation remove the four (4) button head cap screws from the base of the assembly. Assembly instructions stand upper post installation (cont.) with the height adjustment cap screw on the upper post facing the left side of the tensioner, align the four (4) holes in the upper po...

Page 7: Assembly Instructions

6 clamp head installation the post of the string clamp head and the tube of the string clamp base are treated with grease to provide protection against corrosion during shipping. Remove any excessive grease with a clean cloth prior to use. The post and tube may also be cleaned with isopropyl alcohol...

Page 8

String reel holder installation the string reel holder pin is an 8 mm rod with threads on both ends, and flat surfaces machined on one end. Thread the end of the pin without the flat surfaces into the threaded boss on the right side of the lower column support. Using the m6 open end wrench positione...

Page 9

Slm face plate installation remove the tape covering the opening on the front side of the bottom cover to expose the string length meter. Position the face plate assembly over the opening in the bottom cover, and align the two countersunk end holes of the face plate with the threaded attachment hole...

Page 10

Instructions for power connection (refer to figure 1) caution ! Before connecting to the power supply, check the voltage supply switch setting located on the side panel as shown in figure 1. To change from 115 volts service to 230 volt service simply slide the switch fully to the top or to the botto...

Page 11: Features

Control panel fuctions and features release button - returns winder to starting position and releases tension on string. 10 three digit (xx.X) led display - displays tension settings or string length. Lbs/kgs button - changes tension display from lbs to kgs. Each press of the button toggles back and...

Page 12

String length meter operation to enable the string length meter (slm) function, press the string length function key on the keypad. When the string length button is pressed, one of the red led indicators below “m” or “ft” will light up to indicate that the slm function is enabled. Pressing the strin...

Page 13

Clamp head operation to clamp a string, lift the clamp head and place the string between the jaws and de- press the clamp head lever to secure the string. The clamping pressure applied to the string should be adjusted to provide suffi- cient pressure to secure the string when subjected to the desire...

Page 14: String Gripper Operation

13 string gripper operation string gripper operation to insert the string in the split drum string gripper, wrap the free end of the string clock- wise around the gripper drum and position the string between the gripper jaws as shown in the illustration. The string must pass over the top half of the...

Page 15: Mounting The Frame

Mounting the frame 14 installing the racquet hold down with the lever in the up position, insert the racquet hold down into the hole in the center of the mounting post. Mounting post adjustment place the racquet frame over the white racquet supports. Screw the the post out- ward until the racquet su...

Page 16: Mounting The Frame

15 mounting the frame stringing the frame installing the cross strings weave the cross strings over and under the main strings being careful to alternate the weave direction of each consecutive cross string so as to be opposite of the previously installed cross string. Once the final cross string is...

Page 17: Patherfinder Awl Operation

16 patherfinder awl operation the machine includes the pathfinder string- ing awl which creates a pathway between or around strings to make inserting a string through tight grommets easier and quicker. Insert the awl through the grommet hole in the same manner as for traditional awls. The pathfinder...

Page 18: Tensioner Calibration

Each stringing machine has been checked and calibrated at the factory using accurate load sensing devices to ensure that the machine pulls at the correct tension. However, if you suspect that your machine is not pulling at the correct tension, or if you would like to check the pulling tension using ...

Page 19: Cleaning Instructions

Cleaning instructions to thoroughly clean the diamond coated surfaces of the clamp heads, remove the adjustment knob screw to expose the inside surfaces of the clamps. Using the cleaning stone provided with your machine (you can also use a small tooth brush or a sharpening stone for knives), scrub t...

Page 20: Troubleshooting Tips

19 troubleshooting tips problem solution string slips in clamps string slips in string gripper to check fuse, remove the power cord and pull the fuse holder straight out. Remove the fuse from the clips and examine it. If it is burned out, replace it with the spare fuse and replace the fuse holder in...

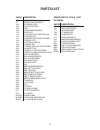

Page 21: Parts Summary

20 114 208 131 199 236 237 241 239 mrsgd 127 210 211 101 102 195 194 240 inside cover 222 223 inside cover 221 mdcsc mqac 121 6b 115 212 5 103 238 106 304 parts summary 311 312 310 309.

Page 22: Parts List

Spare parts & tools (not pictured) part# description 109 needle nose pliers 110 bent nose pliers 171 cutting pliers 194 tt brake pad 206 17mm socket 221 slm clamp pads 224 6mm open end wrench 251 long hex wrench set ma stringer’s awl mbfc bad. Flying clamp set mpg starting clamp mps grip./clamp clea...