- DL manuals

- Garmin

- GPS

- G3X Touch

- Installation Manual

Garmin G3X Touch Installation Manual

Summary of G3X Touch

Page 1

190-01115-01 october, 2010 revision e g3x installation manual.

Page 2

Page a g3x installation manual revision e 190-01115-01 © copyright 2010 garmin ltd. Or its subsidiaries all rights reserved except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted, disseminated, downloaded or stored in any storage medium, for any purpose wi...

Page 3

G3x installation manual page i 190-01115-01 revision e information subject to export control laws this document may contain information which is subject to the export administration regulations (“ear”) issued by the united states department of commerce (15 cfr, chapter vii subchapter c) and which ma...

Page 4

Page ii g3x installation manual revision e 190-01115-01 warning this product, its packaging, and its components contain chemicals known to the state of california to cause cancer, birth defects, or reproductive harm. This notice is being provided in accordance with california's proposition 65. If yo...

Page 5

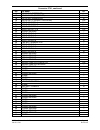

G3x installation manual page iii 190-01115-01 revision e table of contents paragraph page 1 installation overview .......................................................................................................................1-1 1.1 unpacking unit ...............................................

Page 6

Page iv g3x installation manual revision e 190-01115-01 paragraph page 5 gtp 59 .............................................................................................................................................5-1 5.1 equipment description.....................................................

Page 7

G3x installation manual page v 190-01115-01 revision e paragraph page 10.6 post installation calibration procedures ........................................................................................10-8 10.7 gsu 73 data logging......................................................................

Page 8

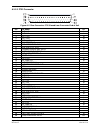

Page vi g3x installation manual revision e 190-01115-01 list of illustrations figure page 1-1 g3x interconnect example..............................................................................................................1-2 1-2 configuration module ..............................................

Page 9

G3x installation manual page vii 190-01115-01 revision e figure page 6-26 example bracket antenna mounting under glareshield...............................................................6-26 6-27 example non-structural antenna mounting under glareshield.................................................

Page 10

Page viii g3x installation manual revision e 190-01115-01 figure page a-1 view of j3701 connector from back of unit ................................................................................. A-1 a-2 view of j441 connector looking at rear of unit ..................................................

Page 11

G3x installation manual page ix 190-01115-01 revision e figure page c-24 alignment of magnetometer cutout with aircraft’s forward direction .................................... C-15 c-25 alignment of mag cutout w/aircraft’s forward direction w/offset mag cutout ..................... C-16 c-26 magnet...

Page 12

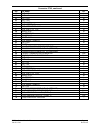

Page x g3x installation manual revision e 190-01115-01 list of tables table page 1-1 g3x lru part numbers ..................................................................................................................1-5 1-2 contents of gdu 37x assembly (010-00667-xx)................................

Page 13

G3x installation manual page xi 190-01115-01 revision e table page 6-5 xm satellite radio antenna minimum requirements ....................................................................6-3 6-6 teardrop footprint antenna doubler design and installation..................................................

Page 14

Page xii g3x installation manual revision e 190-01115-01 limited warranty for garmin gmu 44 and gtp 59 products the garmin products gmu 44 and gtp 59 are warranted to be free from defects in materials or workmanship for two years from the date of purchase. Within the applicable period, garmin will, ...

Page 15

G3x installation manual page xiii 190-01115-01 revision e limited warranty for gsu 73 and gdu 37x products the garmin products gsu 73 and gdu 37x are warranted to be free from defects in materials or workmanship for one year from the date of purchase. Within the applicable period, garmin will, at it...

Page 16

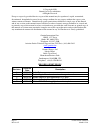

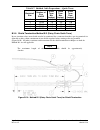

Page xiv g3x installation manual revision e 190-01115-01 gsu 73 hardware mod level history the following table identifies hardware modification (mod) levels for the gsu 73 lru. Mod levels are listed with the associated service bulletin number, service bulletin date, and the purpose of the modificati...

Page 17

G3x installation manual – installation overview page 1-1 190-01115-01 revision e 1 installation overview 1.1 unpacking unit carefully unpack the equipment and make a visual inspection of the unit for evidence of damage incurred during shipment. If any component of the g3x system is damaged, notify t...

Page 18

Page 1-2 g3x installation manual –installation overview revision e 190-01115-01 1.3 system overview the g3x is an advanced technology avionics suite designed to integrate pilot/aircraft interaction into one central system. The system combines primary flight instrumentation, aircraft systems instrume...

Page 19

G3x installation manual – installation overview page 1-3 190-01115-01 revision e 1.3.2 configuration modules the g3x system is designed to store configuration and calibration data in multiple locations to retain the configuration of the system during maintenance. Figure 1-2 shows the configuration m...

Page 20

Page 1-4 g3x installation manual –installation overview revision e 190-01115-01 1.3.3 external navigators (optional) the g3x can interface with the sl30 nav/comm transceiver and the gns 400/500 series units (figure 1-1) for use as external navigators. In a configuration which includes one or more ex...

Page 21

G3x installation manual – installation overview page 1-5 190-01115-01 revision e 1.4 general lru specifications 1.4.1 garmin lru part numbers table 1-1 lists the available g3x lrus. The gdu 37x assembly part numbers (010-00667-xx) include the gdu and all items listed in table 1-2. Other lrus listed ...

Page 22

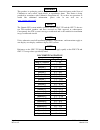

Page 1-6 g3x installation manual –installation overview revision e 190-01115-01 1.4.3 physical specifications all width, height, and depth measurements are taken with unit rack (if applicable) and connectors. Table 1-4. G3x lru physical specifications lru width height depth (gmu 44 diameter, includi...

Page 23

G3x installation manual – installation overview page 1-7 190-01115-01 revision e 1.5 installation requirements one gdu 37x assembly (listed in table 1-1) is required, dependent upon customer’s desired database region. Each gdu 37x (010-00667-xx) comes with all equipment needed for installation. 1.5....

Page 24

Page 1-8 g3x installation manual –installation overview revision e 190-01115-01 1.7.1 wiring harness installation allow adequate space for installation of cables and connectors. Ensure that routing of the wiring does not come in contact with sources of heat, rf or emi interference. Analog input wire...

Page 25

G3x installation manual – installation overview page 1-9 190-01115-01 revision e 1.7.2 cable location considerations use cable meeting the applicable aviation regulation for the interconnect wiring. Any cable meeting specifications is acceptable for the installation. When routing cables, observe the...

Page 26

Page 1-10 g3x installation manual –installation overview revision e 190-01115-01 figure 1-4 tnc connector installation 1.7.4 backshell assemblies connector kits include backshell assemblies. The backshell assembly houses the configuration module and a thermocouple reference junction (if applicable, ...

Page 27

G3x installation manual – gdu 37x page 2-1 190-01115-01 revision e 2 gdu 37x figure 2-1. Gdu 37x unit view 2.1 equipment description note there is no tso/etso applicable to the gdu g37x. The gdu 37x provides a central display and user interface for the g3x system. The display is mounted flush to the...

Page 28

Page 2-2 g3x installation manual – gdu 37x revision e 190-01115-01 2.1.2 interface summary the gdu 37x uses can and rs-232 communications interfaces. The gdu 37x communicates with the following garmin lrus: • other gdu 37x • gsu 73 • sl30 nav/comm transceiver • sl40 comm transceiver • gns 400/500 se...

Page 29

G3x installation manual – gdu 37x page 2-3 190-01115-01 revision e 2.2.4 antennas refer to section 6 for antenna information 2.3 environmental specifications the gdu 37x has an operating temperature range of -20°c to +60°c. 2.4 installation requirements 2.4.1 accessories the gdu 37x connector kit is...

Page 30

Page 2-4 g3x installation manual – gdu 37x revision e 190-01115-01 2.4.2 additional equipment a 3/32” hex drive tool is required to secure the gdu 37x to the panel as described in section 2.7 unit installation. Gdu 37x unit 011-01747-( ) connector kit 011-01921-00 figure 2-2. Gdu 37x mounting access...

Page 31

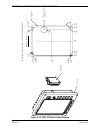

G3x installation manual – gdu 37x page 2-5 190-01115-01 revision e 2.6 mounting requirements refer to appendix d for outline and installation drawings. 2.7 unit installation the gdu 37x is installed by holding the unit flush with the instrument panel and fastening the four captured 3/32” hex socket ...

Page 32

Page 2-6 g3x installation manual – gdu 37x revision e 190-01115-01 2.9 panel cutout template figure 2-3 can be used as a template when marking the panel for cutout. Dimensions below are to verify accuracy of printout only, see figure d-1.2 for complete dimensions. Gdu 37x panel cutout template 5.57 ...

Page 33

G3x installation manual – gmu 44 page 3-1 190-01115-01 revision e 3. Gmu 44 figure 3-1. Gmu 44 unit view 3.1 equipment description the garmin gmu 44 magnetometer is a remote mounted device that interfaces with a garmin gsu 73 to provide flight attitude and heading data for flight instrumentation. An...

Page 34

Page 3-2 g3x installation manual – gmu 44 revision e 190-01115-01 3.3 environmental specifications table 3-2 lists general environmental specifications. Table 3-2. Gmu 44 environmental specifications specification characteristic regulatory compliance rtca/do-160d environmental conditions and eurocae...

Page 35

G3x installation manual – gmu 44 page 3-3 190-01115-01 revision e 3.5 installation requirements 3.5.1 equipment available table 3-5. Gmu 44 part numbers model catalog part number unit part number installation rack gmu 44 010-00296-10* 011-00870-10 no *included in g3x lru kit (k10-00016-00) table 3-6...

Page 36

Page 3-4 g3x installation manual – gmu 44 revision e 190-01115-01 table 3-7. Required distance from magnetic disturbances disturbance source minimum distance from gmu 44 electric motors and relays, including servo motors 10 feet (3.0 meters) ferromagnetic structure greater than 1 kg total (iron, ste...

Page 37

G3x installation manual – gmu 44 page 3-5 190-01115-01 revision e 3.6.1 consideration for wing grounded lighting fixtures the following installation practices are recommended if the required gmu 44 mounting bracket is located in the wing. 1. The wing tip lights should not have a power ground referen...

Page 38

Page 3-6 g3x installation manual – gmu 44 revision e 190-01115-01 3.8 mounting instructions after evaluation of the mounting location has been completed and ensuring that requirements are met, assemble the gmu 44 mounting plate kits according to the dimensions given in appendix d. Install the unit a...

Page 39

G3x installation manual – gsu 73 page 4-1 190-01115-01 revision e 4 gsu 73 4.1 equipment description note there is no tso/etso applicable to the gsu 73. The gsu 73 is intended for the lsa (light sport aircraft) and experimental aircraft markets. The garmin gsu 73 sensor unit is not a tso-certified p...

Page 40

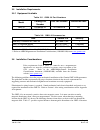

Page 4-2 g3x installation manual – gsu 73 revision e 190-01115-01 4.1.1 features summary air data interfaces pressure altitude can (1) density altitude rs-232 (2 tx/2 rx) vertical speed arinc 429 (4 rx/2 tx) mach number oat probe (gtp 59) indicated airspeed magnetometer (gmu 44) (1 rs-232 tx/ 1 rs-4...

Page 41

G3x installation manual – gsu 73 page 4-3 190-01115-01 revision e 4.3 environmental specifications table 4-2 lists general environmental specifications. Note the gsu 73 may require a warm-up period of 15 minutes to reach full air data accuracy (30 minutes if the environmental temperature is less tha...

Page 42

Page 4-4 g3x installation manual – gsu 73 revision e 190-01115-01 table 4-5. Contents of p732 connector kit (011-01818-01)** item garmin p/n quantity sub-assy,backshell w/hdw,jackscrew 011-01855-04 1 connector ,hi dens, d-sub, mil crimp 78ck 330-00185-78 1 contact pin, mil crimp, size 22d 336-00021-...

Page 43

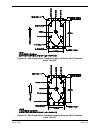

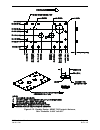

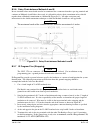

G3x installation manual – gsu 73 page 4-5 190-01115-01 revision e 4.5.1 pneumatic plumbing the gsu 73 has two ports that are connected to the aircraft’s pitot pressure source and static pressure source. The two ports are labeled on the unit (see figure 4-2). The pressure ports have 1/8-27 anpt femal...

Page 44

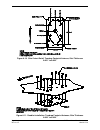

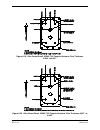

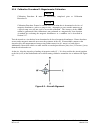

Page 4-6 g3x installation manual – gsu 73 revision e 190-01115-01 4.6 mounting requirements mount the gsu 73 with the connectors aligned within 1.0 deg of either the longitudinal or lateral axis of the aircraft. The direction of the unit will be accounted for during the calibration procedure as show...

Page 45

G3x installation manual – gsu 73 page 4-7 190-01115-01 revision e the gsu 73 includes an extremely sensitive strap-down inertial measurement unit. It must be mounted rigidly to the aircraft primary structure, preferably to a metallic structure to conduct heat away from the unit. Do not mount the gsu...

Page 46

Page 4-8 g3x installation manual – gsu 73 revision e 190-01115-01 4.8 maintenance per part 43 appendix e, paragraph (b)(2), garmin specifies a test procedure equivalent to part 43 appendix e, paragraph (b)(1) with two exceptions. The tests of sub-paragraph (iv)(friction) and (vi) (barometric scale e...

Page 47

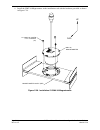

G3x installation manual – gtp 59 page 5-1 190-01115-01 revision e 5 gtp 59 figure 5-1. Gtp 59 5.1 equipment description the garmin gtp 59 is an outside mounted temperature probe that provides raw air temperature data. The temperature input device is a three-wire temperature probe interface. Oat powe...

Page 48

Page 5-2 g3x installation manual – gtp 59 revision e 190-01115-01 5.2.1 additional equipment required • cables - the installer will supply all system cables. 5.3 tso/etso compliance the following table provides a list of applicable tso/etsos for the gtp 59. Table 5-3. Applicable tso/etsos for the gt...

Page 49

G3x installation manual – gtp 59 page 5-3 190-01115-01 revision e 5.4 installation considerations 5.4.1 gtp 59 icing the gtp 59 oat probe has no icing protection. If ice accumulates on the gtp 59 oat probe, its accuracy is unknown. Consequently, air temperature measurements may be incorrect if ice a...

Page 50

Page 5-4 g3x installation manual – gtp 59 revision e 190-01115-01 5. Strip back 1/8” (0.125”) of insulation and crimp pins to each of the conductors in the shielded cable. 6. Cut an awg #16 wire to 3” long. Strip back 0.5” of insulation from this cable. Connect the shield of the oat probe cable (2) ...

Page 51

G3x installation manual – antennas page 6-1 190-01115-01 revision e 6 gps/xm antennas in an installation with multiple gdu 37x units, each gdu can be configured to use its own internal gps receiver, or to receive gps data transmitted by another gdu. At least one gdu must be equipped with a gps anten...

Page 52

Page 6-2 g3x installation manual – antennas revision e 190-01115-01 6.2 garmin gps antennas if using a garmin ga 26c or ga 26xm, refer to the accompanying installation instructions (190-00082-00 or 190-00522-03). For ga 55/55a, or ga 56 or ga 57x antennas, refer to this section and the drawings in a...

Page 53

G3x installation manual – antennas page 6-3 190-01115-01 revision e 6.3 garmin xm antennas table 6-4. Xm antennas model part number description weight mounting configuration ga 26xm 013-00268-10 xm antenna na flange, magnetic, or suction cup mount (for in-cabin mounting) ga 55 011-01033-00 xm antenn...

Page 54

Page 6-4 g3x installation manual – antennas revision e 190-01115-01 6.4 antenna mounting considerations the information in this section does not pertain to in-cabin (internal) mounted antennas such as the ga 26c, refer to the accompanying installation instructions (190-00082-00). No special precauti...

Page 55

G3x installation manual – antennas page 6-5 190-01115-01 revision e 6.4.2 gps/xm antenna mounting location the gps antenna is a key element in the overall system performance and integrity for a gps navigation system. The mounting location, geometry, and surroundings of the antenna can affect the sys...

Page 56

Page 6-6 g3x installation manual – antennas revision e 190-01115-01 figure 6-1 shows the recommended placement of antennas. 4 figure 6-1. Recommended antenna placement.

Page 57

G3x installation manual – antennas page 6-7 190-01115-01 revision e 6.4.3 buried antenna (below the skin covering or glareshield) mounting there are potential performance issues related to buried antennas that the kit builder/installer should be aware of prior to electing to install a buried antenna...

Page 58

Page 6-8 g3x installation manual – antennas revision e 190-01115-01 mounting the antenna under the glare shield (figure 6-3) is a good option for xm – fis antennas, although it is not typically the best option for a gps antenna. This location results in the aft fuselage shading the antenna. Figure 6...

Page 59

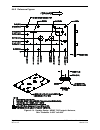

G3x installation manual – antennas page 6-9 190-01115-01 revision e 6.5 teardrop footprint antenna installation (ga 55 and ga 56) this section describes the structural mounting of the teardrop footprint antenna installation. An acceptable installation method is to use garmin p/n: 115-00846-10 double...

Page 60

Page 6-10 g3x installation manual – antennas revision e 190-01115-01 6.5.2 antenna installation instructions 1. Refer to table 6-6 and the drawings in appendix d for guidance on selecting the appropriate mounting cutout. Drill or punch the holes to match the mating part (doubler). 2. Install a doubl...

Page 61

G3x installation manual – antennas page 6-11 190-01115-01 revision e 6.5.3 reference figures figure 6-4. Doubler design, teardrop footprint antenna, skin thickness 0.032" to 0.049" figure 6-5. Doubler design, teardrop footprint antenna, skin thickness 0.049" to 0.051".

Page 62

Page 6-12 g3x installation manual – antennas revision e 190-01115-01 figure 6-6. Doubler design, teardrop footprint antenna, skin thickness 0.051" to 0.063" figure 6-7. Sample doubler location, teardrop footprint antenna, metal skin aircraft.

Page 63

G3x installation manual – antennas page 6-13 190-01115-01 revision e figure 6-8. Skin cutout detail, teardrop footprint antenna, skin thickness 0.032" to 0.049" figure 6-9. Skin cutout detail, teardrop footprint antenna, skin thickness 0.049" to 0.051".

Page 64

Page 6-14 g3x installation manual – antennas revision e 190-01115-01 figure 6-10. Skin cutout detail, teardrop footprint antenna, skin thickness 0.051" to 0.063" figure 6-11. Doubler installation, teardrop footprint antenna, skin thickness 0.032" to 0.049".

Page 65

G3x installation manual – antennas page 6-15 190-01115-01 revision e figure 6-12. Doubler installation, teardrop footprint antenna, skin thickness 0.049" to 0.051" figure 6-13. Doubler installation, teardrop footprint antenna, skin thickness 0.051" to 0.063".

Page 66

Page 6-16 g3x installation manual – antennas revision e 190-01115-01 6.6 arinc 743 footprint antenna installation (ga 55a, ga 57x) this section describes the structural mounting of the arinc 743 footprint antenna (ga 55a, ga 57x) installation. One acceptable method is to use garmin p/n: 115-00846-00...

Page 67

G3x installation manual – antennas page 6-17 190-01115-01 revision e 6.6.2 antenna installation instructions 1. Refer to table 6-7 (and to figures in appendix c) for guidance on selecting the appropriate mounting cutout. Drill or punch the holes to match the mating part (doubler). 2. Install a doubl...

Page 68

Page 6-18 g3x installation manual – antennas revision e 190-01115-01 6.6.3 reference figures figure 6-14. Doubler design, arinc 743 footprint antenna, skin thickness 0.032" to 0.049".

Page 69

G3x installation manual – antennas page 6-19 190-01115-01 revision e figure 6-15. Doubler design, arinc 743 footprint antenna, skin thickness 0.049" to 0.051".

Page 70

Page 6-20 g3x installation manual – antennas revision e 190-01115-01 figure 6-16. Doubler design, arinc 743 footprint antenna, skin thickness 0.051" to 0.063".

Page 71

G3x installation manual – antennas page 6-21 190-01115-01 revision e figure 6-17. Sample doubler location, arinc 743 antenna, metal skin aircraft figure 6-18. Skin cutout detail, arinc 743 footprint antenna, skin thickness 0.032" to 0.049".

Page 72

Page 6-22 g3x installation manual – antennas revision e 190-01115-01 figure 6-19. Skin cutout detail, arinc 743 footprint antenna, skin thickness 0.049" to 0.051" figure 6-20. Skin cutout detail, arinc 743 footprint antenna, skin thickness 0.051" to 0.063".

Page 73

G3x installation manual – antennas page 6-23 190-01115-01 revision e figure 6-21. Doubler installation, arinc 743 footprint antenna, skin thickness 0.032" to 0.049" figure 6-22. Doubler installation, arinc 743 footprint antenna, skin thickness 0.049" to 0.051".

Page 74

Page 6-24 g3x installation manual – antennas revision e 190-01115-01 figure 6-23. Doubler installation, arinc 743 footprint, skin thickness 0.051" to 0.063" figure 6-24. Installation of arinc 743 footprint antenna.

Page 75

G3x installation manual – antennas page 6-25 190-01115-01 revision e 6.7 non-structural mount installation this section provides installation examples and considerations for non-structural mounting of teardrop and arinc 743 footprint antennas. Typical installations may be below a non-metallic glares...

Page 76

Page 6-26 g3x installation manual – antennas revision e 190-01115-01 6.7.2 considerations for non-structural mounting external mounting of the antenna is preferred, although the antenna can be mounted inside the aircraft. When mounted internally, the antenna does not have to be aligned with the airc...

Page 77

G3x installation manual – antennas page 6-27 190-01115-01 revision e figure 6-27. Example non-structural antenna mounting under glareshield.

Page 78

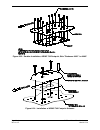

Page 6-28 g3x installation manual – antennas revision e 190-01115-01 6.7.4 non-structural installation to airframe internal non-structural installation figure 6-28 and figure 6-29 show examples of under the fabric skin non-structural mounting of the antenna to the airframe of a tube-and-fabric aircr...

Page 79

G3x installation manual – antennas page 6-29 190-01115-01 revision e external non-structural installation figure 6-30 is an example of an external, non-structural mounting of the antenna in a tube-and-fabric aircraft. The antenna support bracket shown should be made of 2024-t3 alu with a minimum mat...

Page 80

Page 6-30 g3x installation manual – antennas revision e 190-01115-01 minimum distance from metal tube structure requirements figure 6-31 shows minimum distance from metal tube structure requirements for internal, non-structural mounting of the antenna. Table 6-8 presents minimum distance requirement...

Page 81

G3x installation manual – software, configuration, databases, and xm activation page 7-1 190-01115-01 revision e 7 software, configuration, databases, and xm activation 7.1 software, database, and audio data identification for gdu 37x software version 2.70 and later, the gdu 37x software, bootblock,...

Page 82

Page 7-2 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.2 software loading procedure gdu software loading can be performed in either normal or configuration mode (section 7.3), while gsu software loading is performed only in configuration mo...

Page 83

G3x installation manual – software, configuration, databases, and xm activation page 7-3 190-01115-01 revision e 3. The unit will reboot, then gdu software update will begin automatically. 4. Ensure power is not removed while the update is being performed. 5. The unit will reboot after the update is...

Page 84

Page 7-4 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 4. Allow the software load to complete. Note a software update may include multiple gsu 73 software regions, ensure all updates are completed successfully. If a region fails to load, retr...

Page 85

G3x installation manual – software, configuration, databases, and xm activation page 7-5 190-01115-01 revision e 7.3 configuration mode some of the software loading, and all of the configuration settings are performed in the configuration mode. To enter configuration mode, hold down the left-hand so...

Page 86

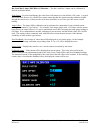

Page 7-6 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.4.1 main configuration page the main configuration page is used to display lru (device) specific information such as software version, unit id’s, system id’s, and database information f...

Page 87

G3x installation manual – software, configuration, databases, and xm activation page 7-7 190-01115-01 revision e 7.4.2 gsu configuration page if an sd card is inserted into the gdu 37x, a save log softkey is displayed at the bottom of the gsu page. Pressing this softkey writes gsu log data to the ga...

Page 88

Page 7-8 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 2. Use the fms joystick to select the desired configurable item and make the desired change. Then press the ent key or use the fms joystick to select the next item. Press the fms joystick...

Page 89

G3x installation manual – software, configuration, databases, and xm activation page 7-9 190-01115-01 revision e 7.4.4 w/b (weight/balance) configuration page the w/b configuration page allows setting the weight and balance parameters for the airplane. These parameters are then used on the main menu...

Page 90

Page 7-10 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.4.5 units configuration page the units configuration page allows selection of the desired displayed units for the listed items in the units configuration window. The various settings f...

Page 91

G3x installation manual – software, configuration, databases, and xm activation page 7-11 190-01115-01 revision e 7.4.6 dspl (display) configuration page the dspl configuration page allows setting the parameters for display and backlight control configuration. The aircraft lighting bus voltage can b...

Page 92

Page 7-12 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 display configuration window: backlight intensity : can be set to auto or manual. The backlight intensity setting can also be accessed/changed in normal mode on the display setup page. E...

Page 93

G3x installation manual – software, configuration, databases, and xm activation page 7-13 190-01115-01 revision e options softkey: press the option softkey to adjust the following non-backlight-related display options. Press the backlight softkey to return to the dspl configuration page. Eis display...

Page 94

Page 7-14 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.4.7 sound configuration page the sound configuration page allows setting the parameters for various alert and message tones. 1. In configuration mode, use the fms joystick to select th...

Page 95

G3x installation manual – software, configuration, databases, and xm activation page 7-15 190-01115-01 revision e 7.4.8 comm configuration page the comm configuration page allows setting the parameters for the communication ports. 1. In configuration mode, use the fms joystick to select the comm pag...

Page 96

Page 7-16 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 a green checkbox will appear next to the name of each comm port when it is receiving valid data, or a red x if data reception has been interrupted or has timed out. G3x installations wit...

Page 97

G3x installation manual – software, configuration, databases, and xm activation page 7-17 190-01115-01 revision e tis in/nmea & vhf out - receives tis data and transmits out both nmea data, at 9600 baud, and vhf frequency tuning information to a garmin nav/comm radio. Sl30 nav/comm - outputs frequen...

Page 98

Page 7-18 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 autopilot - for use with autopilots that use both rs-232 and arinc 429 data. The transmitted labels are as follows: 001 distance to waypoint (bcd) 012 ground speed (bcd) 100p selected co...

Page 99

G3x installation manual – software, configuration, databases, and xm activation page 7-19 190-01115-01 revision e 7.4.10 log configuration page the data logging configuration page enables the storage of flight data as .Csv files to the "data_log" folder on an sd card. If data logging is enabled, the...

Page 100

Page 7-20 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.5 garmin database updates the g3x mfd database updates can be obtained by visiting the ‘flygarmin’ website ( www.Fly.Garmin.Com ). The ‘flygarmin’ website requires the unit’s system id...

Page 101

G3x installation manual – software, configuration, databases, and xm activation page 7-21 190-01115-01 revision e 4. The database(s) can be updated by either highlighting update all and pressing the ent key; or by using the fms joystick to highlight a single database and pressing the ent key. 5. Whe...

Page 102

Page 7-22 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 basemap the basemap contains data for the topography and land features, such as rivers, lakes, and towns. It is updated only periodically, with no set schedule. There is no expiration da...

Page 103

G3x installation manual – software, configuration, databases, and xm activation page 7-23 190-01115-01 revision e 7.6 xm activation instructions (gdu 375 only) follow the below instructions to activate the xm receiver in the gdu 375. Before xm satellite weather can be used, the service must be activ...

Page 104

Page 7-24 g3x installation manual – software, configuration, databases, and xm activation revision e 190-01115-01 7.8 checklist editor the aviation checklist editor (ace) is available for free download from the garmin website www.Garmin.Com . Click on the software link on the g3x product page and fo...

Page 105

G3x installation manual – engine sensor installation and configuration page 8-1 190-01115-01 revision e 8 engine/airframe sensor installation and configuration 8.1 engine/airframe sensor options table 8-1 lists the types of engine/airframe sensors that may be used for the various engine/airframe inp...

Page 106

Page 8-2 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 table 8-1. Compatible engine/airframe input sensors (continued) sensor type compatible sensors garmin part number* uma 1a3c-2 n/a uma t1a9-1 (slick mag) 494-50005-00 uma t1a9-2 (bendix mag) 494-50...

Page 107

G3x installation manual – engine sensor installation and configuration page 8-3 190-01115-01 revision e the engine inputs being monitored are displayed as gauges on the eis display (figure 8-1) and also on the mfd’s engine page. Figure 8-1. Eis display (engine bar) the following list of gauges, (if ...

Page 108

Page 8-4 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 table 8-3. Contents of g3x sensor kit, 6 cylinder lycoming/continental (k00-00513-00) item garmin p/n quantity fuel flow transducer, ei ft-60 494-10001-00 1 oil pressure transducer, powered, 150 p...

Page 109

G3x installation manual – engine sensor installation and configuration page 8-5 190-01115-01 revision e 8.2.2.1 lycoming and continental engine installation general installation guidance – to maintain measurement accuracy, thermocouple (tc) wire must be connected directly to the inputs of the gsu 73...

Page 110

Page 8-6 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 figure 8-4. One piece cht probe installed 8.2.3 egt (exhaust gas temperature) sensor description – type k grounded thermocouple probe with integrated clamp for mounting in an exhaust pipe. Note if...

Page 111

G3x installation manual – engine sensor installation and configuration page 8-7 190-01115-01 revision e perform the following steps and refer to figures 8-5, 8-6, and 8-7 to install an egt sensor. 1. Egt probes (figure 8-5) should optimally be mounted between 2 and 4 inches from the cylinder head on...

Page 112

Page 8-8 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 figure 8-6. Exhaust pipe drilled figure 8-7. Installed egt probe orientation.

Page 113

G3x installation manual – engine sensor installation and configuration page 8-9 190-01115-01 revision e 8.2.4 oil temperature threaded 5/8-18 platinum resistance temperature detector (rtd) probe - this sensor is applicable to the lycoming and continental engines. Rotax 965531 oil temperature sensor ...

Page 114

Page 8-10 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.2.5 pressure (fuel, manifold, oil, and coolant) general installation guidance – the specified pressure transducers provide for two different mounting options: figure 8-11. Uma pressure sensor f...

Page 115

G3x installation manual – engine sensor installation and configuration page 8-11 190-01115-01 revision e 8.2.5.1 fuel pressure sensor kavlico p4055-15g-e4a - 0 – 15 psig pressure transducer for all carbureted engines. Kavlico p4055-50g-e4a - 0 – 50 psig pressure transducer for all fuel injected engi...

Page 116

Page 8-12 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.2.6.1 lycoming and continental engine installation general installation guidance electronic ignition - refer to vendor documentation for proper installation. Uma 1a3c-2 1. Remove the cap from t...

Page 117

G3x installation manual – engine sensor installation and configuration page 8-13 190-01115-01 revision e uma n/t1a9-x the magnetic pickup tach sensor is installed in the magneto bleed port. It is recommended that it be installed in the non-impulse magneto, but it can be installed in the impulse magn...

Page 118

Page 8-14 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.2.7 fuel quantity 8.2.7.1 resistive type fuel quantity sensors resistive type fuel quantity sensors with a 0–500 Ω range are currently supported. Wiring methods vary based on the gsu 73 channel...

Page 119

G3x installation manual – engine sensor installation and configuration page 8-15 190-01115-01 revision e 8.2.10 bus current 8.2.10.1 hall effect ammeter sensor sensor description – hall effect: amploc key100, +/- 100 amp or equivalent. Sensor output is 15.9 mv/amp. This type of sensor is applicable ...

Page 120

Page 8-16 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.2.11 fuel flow electronics international ft-60 (red cube) - this sensor is applicable to all engines. Refer to the electronics international ft-60 flow transducer (red cube) document # 1030032 ...

Page 121

G3x installation manual – engine sensor installation and configuration page 8-17 190-01115-01 revision e 8.2.11.1 k-factor for floscan 201b-6 the floscan 201b-6 (201-030-000) fuel flow sensor ranges from 28,000 to 31,000 pulses/gallon. The g3x default k factor for the 201b-6 is set to 29,500 pulses/...

Page 122

Page 8-18 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.2.12 carburetor temperature sensor uma 1b10r - threaded ¼-28 platinum resistance temperature detector (rtd) probe. This sensor is applicable to all carbureted lycoming and continental engines. ...

Page 123

G3x installation manual – engine sensor installation and configuration page 8-19 190-01115-01 revision e 8.3 engine/airframe input configuration the engine/airframe input configuration section of the engine configuration page allows enabling/disabling and customization of the engine/airframe input o...

Page 124

Page 8-20 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 for factory-installed systems, the engine/airframe input configuration section is replaced with an eis configuration page that allows access to calibration functions and time adjustments, but doe...

Page 125

G3x installation manual – engine sensor installation and configuration page 8-21 190-01115-01 revision e 8.3.1 common configuration options many of the items listed in the engine/airframe input configuration section of the engine configuration page have the same (or similar) configuration options, t...

Page 126

Page 8-22 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 the below screenshot of the cht input configuration page shows an example of the gauge display range and gauge markings settings and the resultant cht gauge. Dual gauge the eis display will show ...

Page 127

G3x installation manual – engine sensor installation and configuration page 8-23 190-01115-01 revision e eis display – the hide setting removes the item from the eis display, although the item will be displayed on the mfd eng page. The auto setting displays items based upon hierarchy and the availab...

Page 128

Page 8-24 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 oil temperature input configuration – select none, uma 1b3-2.5r, rotax 965531, or jabiru as applicable to the aircraft’s engine. Or oil pressure input configuration – select none, kavlico p4055-1...

Page 129

G3x installation manual – engine sensor installation and configuration page 8-25 190-01115-01 revision e rpm input configuration – select none, mechanical sensor (uma 1a3c), 4 cylinder mag port (uma t1a9), 6-cylinder mag port (uma t1a9), 4 cylinder electronic ignition, 6 cylinder electronic ignition...

Page 130

Page 8-26 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 position inputs – the position 1-5 inputs can be configured for several different inputs. Pos 1 – 5 – position inputs 1 – 5 can be used for elevator trim, aileron trim, rudder trim, and flap posi...

Page 131

G3x installation manual – engine sensor installation and configuration page 8-27 190-01115-01 revision e misc temp (temperature) input – carb temp (uma 1b10r), rotax carb temp (965531), and rotax coolant temp (965531) settings are available. Egt 6 – if the user has selected the 6 cylinders option fo...

Page 132

Page 8-28 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 shunt 1 and shunt 2 – choices for shunt 1 are none, bus 1 amps, and main bus amps. Choices for shunt 2 are none, bus 2 amps, and essential bus amps. The shunt 1 and shunt 2 inputs can be calibrat...

Page 133

G3x installation manual – engine sensor installation and configuration page 8-29 190-01115-01 revision e fuel flow 2 input – the fuel flow 2 input selections are fuel return (ei ft-60) and fuel return (floscan 201b-6). This input can be used for a second fuel flow sensor to measure differential fuel...

Page 134

Page 8-30 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 enter the engine's max rated power and rpm (e.G. 180 horsepower @ 2750 rpm). For a turbocharged engine, enter the manifold pressure for max rated power. Max manifold pressure is not entered for a...

Page 135

G3x installation manual – engine sensor installation and configuration page 8-31 190-01115-01 revision e total time – the total time displays the total operating time in hours of the aircraft. This time is displayed on both the engine configuration page and the total time configuration page. The tot...

Page 136

Page 8-32 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 8.3.3 input configuration items requiring calibration fuel input calibration – the fuel 1–4 and cap fuel 1–2 inputs require calibration. To perform the fuel quantity calibration: 1. Press the cal...

Page 137

G3x installation manual – engine sensor installation and configuration page 8-33 190-01115-01 revision e the cap (capacitive) fuel inputs are calibrated in the same manner as the resistive fuel inputs, except that the resulting frequency (in khz) from the sensor is displayed instead of the voltage. ...

Page 138

Page 8-34 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 fuel flow calibration – the fuel flow input requires calibration as detailed below. K-factor – enter the ‘k’ factor for the fuel flow sensor (section 8.2.11). When installing the fuel flow sensor...

Page 139

G3x installation manual – engine sensor installation and configuration page 8-35 190-01115-01 revision e trim/flap position input calibration – the pos 1 – 5 inputs require calibration if configured for any of the trim positions (elevator, aileron, rudder) or flap position. To perform the trim/flap ...

Page 140

Page 8-36 g3x installation manual – engine sensor installation and configuration revision e 190-01115-01 bus 1 and bus 2 amps (hall effect) calibration – the bus 1 and bus 2 inputs can be calibrated (if desired) as detailed below. Scale factor – for most installations, the scale factor will remain s...

Page 141

G3x installation manual – post installation checkout and calibration procedures page 9-1 190-01115-01 revision e 9. Post-installation checkout and calibration procedures the checkout procedures in this section are recommended to be performed after installing the g3x. The calibration procedures are r...

Page 142

Page 9-2 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.1 recommended test equipment the following test equipment is recommended to conduct and complete all post installation checkout procedures in this section: (all test equipment should ha...

Page 143

G3x installation manual – post installation checkout and calibration procedures page 9-3 190-01115-01 revision e test the xm receiver (if applicable): 1. Power on unit and use the fms joystick to select the xm page. 2. Verify that the xm receiver is functioning correctly as indicated by the green si...

Page 144

Page 9-4 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.3 gsu 73/gmu 44 post-installation calibration procedures after mechanical and electrical installation of the gsu 73 ahrs and gmu 44 magnetometer have been completed, prior to operation,...

Page 145

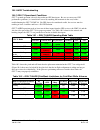

G3x installation manual – post installation checkout and calibration procedures page 9-5 190-01115-01 revision e for each calibration procedure, table 9-2 lists the lru’s that require valid calibration data. Table 9-2. Data validity requirements for ahrs calibration procedures ahrs calibration proce...

Page 146

Page 9-6 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 furthermore, electrical changes to the installation that affect components within 10.0 feet of the gmu 44 magnetometer after the magnetometer calibration and magnetometer interference pro...

Page 147

G3x installation manual – post installation checkout and calibration procedures page 9-7 190-01115-01 revision e 6. Use the fms joystick to select the direction of the gsu 73 connectors per the on-screen instructions, select ok and press the ent key to continue. 7. After a few minutes the calibratio...

Page 148

Page 9-8 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.3.2 calibration procedure b: pitch/roll offset compensation by aircraft leveling note this procedure requires orienting the aircraft to normal flight attitude (can be done by using jack...

Page 149

G3x installation manual – post installation checkout and calibration procedures page 9-9 190-01115-01 revision e 5. Use the fms joystick to select pitch/roll offset. 6. Use the fms joystick to highlight the calibrate button, press the ent key. 7. Ensure that the aircraft has been properly leveled pe...

Page 150

Page 9-10 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9. Verify that the 3 on-screen statements are true. If either tilt angle is greater than 3.0 degrees, "out of spec" is displayed. Note to accommodate multiple mounting orientations, the ...

Page 151

G3x installation manual – post installation checkout and calibration procedures page 9-11 190-01115-01 revision e 9.3.3 calibration procedure c: magnetometer interference test note calibration procedure c is only required for initial installation verification. This test should also be repeated to ve...

Page 152

Page 9-12 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 5. Use the fms joystick to select mag interference test. 6. Use the fms joystick to highlight the calibrate button, press the ent key. 7. Ensure that the aircraft has been properly prepa...

Page 153

G3x installation manual – post installation checkout and calibration procedures page 9-13 190-01115-01 revision e 8. Use the fms joystick to highlight the calibrate button at the bottom of the display, press the ent key to begin the calibration. 9. The operator should carry out the actions called fo...

Page 154

Page 9-14 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 10. After the calibration is finished, press the ok softkey, a done key will appear at the bottom of the display. Ensure that a mag interference test passed message appears at the bottom...

Page 155

G3x installation manual – post installation checkout and calibration procedures page 9-15 190-01115-01 revision e table 9-4. Magnetometer interference test sequence example (continued) elapsed time since start of test (min:secs) action 2:10 flaps up 2:20 autopilot on 2: 3 0 autopilot off 2:40 landin...

Page 156

Page 9-16 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.3.4 calibration procedure d: magnetometer calibration note calibration procedure b must be successfully completed prior to calibration procedure d. Note calibration procedure d must be...

Page 157

G3x installation manual – post installation checkout and calibration procedures page 9-17 190-01115-01 revision e with the aircraft stationary, initiate the gsu 73 ahrs magnetometer calibration procedure as follows: 1. Enter configuration mode by holding down the left-hand softkey while powering on ...

Page 158

Page 9-18 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 7. Ensure that the aircraft has been properly positioned per the on-screen instructions. 8. Use the fms joystick to highlight the calibrate button at the bottom of the display, press the...

Page 159

G3x installation manual – post installation checkout and calibration procedures page 9-19 190-01115-01 revision e 11. The pfd guides the operator to dwell at multiple headings around a complete circle. Note due to high winds or excessive airframe vibration, the operator may encounter a condition whe...

Page 160

Page 9-20 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.3.5 calibration procedure e: engine run-up vibration test note calibration procedure e is required for all installations to validate the vibration characteristics of the installation. ...

Page 161

G3x installation manual – post installation checkout and calibration procedures page 9-21 190-01115-01 revision e 6. Use the fms joystick to highlight the calibrate button, press the ent key. 7. Ensure that the aircraft has been properly positioned per the on-screen instructions. 8. Use the fms joys...

Page 162

Page 9-22 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 note if failures are indicated, the engine run-up test may be repeated up to three times. If the test does not pass after three attempts, the installation should be considered unreliable...

Page 163

G3x installation manual – post installation checkout and calibration procedures page 9-23 190-01115-01 revision e c) mounting of gsu 73 at a location that is subject to severe vibrations (example; close to an engine mount.) d) mounting screws and other hardware for gsu 73 and/or gmu 44 not firmly at...

Page 164

Page 9-24 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.3.6 calibration procedure f: heading offset compensation this procedure is optional, and generally not recommended as it is difficult to orient the entire aircraft with an absolute acc...

Page 165

G3x installation manual – post installation checkout and calibration procedures page 9-25 190-01115-01 revision e 6. Use the fms joystick to highlight the calibrate button, press the ent key. 7. Ensure that the aircraft has been properly positioned per the on-screen instructions. 8. Use the fms joys...

Page 166

Page 9-26 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 11. After the complete calibration is finished, a done button will appear at the bottom of the display, ensure that a calibration successful message appears at the bottom of the display,...

Page 167

G3x installation manual – post installation checkout and calibration procedures page 9-27 190-01115-01 revision e if, upon completion of the magnetometer calibration procedure in both the clockwise and counter- clockwise directions, the pfd displays the “calibration successful / site is clean” messa...

Page 168

Page 9-28 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.4 external interface configuration (garmin units only) refer to appendix f for wiring the interface connections between gdu 37x lrus and any external garmin units such as the gns 4xx/5...

Page 169

G3x installation manual – post installation checkout and calibration procedures page 9-29 190-01115-01 revision e installation configuration pages the configuration pages are in the order found when rotating the right small knob clockwise starting at the main arinc 429 config page. Follow the preced...

Page 170

Page 9-30 g3x installation manual – post installation checkout and calibration procedures revision e 190-01115-01 9.4.2 gtx 327/330 transponder configuration mode operations holding down the func key and pressing the on key provides access to the configuration pages. The func key sequences forward t...

Page 171

G3x installation manual - troubleshooting page 10-1 190-01115-01 revision e 10 troubleshooting in this section the term ‘red-x’ refers to a red “x” that appears on different areas of the display to indicate the failure of that particular function. Refer to the g3x pilot’s guide (190-01115-00) for a ...

Page 172

Page 10-2 g3x installation manual –troubleshooting revision e 190-01115-01 8. Inspect the wire harness clamp on the rear of the connector to verify that it is not too tight and smashing/shorting the wires. If the wire clamp is installed upside down, it has sharp edges that can cut into the wires. Ve...

Page 173

G3x installation manual - troubleshooting page 10-3 190-01115-01 revision e 10.3 air data troubleshooting under normal operating conditions, the gsu 73 provides the following air data information: • total air temperature is measured • outside air temperature (oat) • indicated airspeed (ias) • true a...

Page 174

Page 10-4 g3x installation manual –troubleshooting revision e 190-01115-01 1. Inspect gsu73 pitot/static plumbing integrity. 2. Inspect pitot/static ports and associated equipment. 3. If the problem persists replace the gsu 73 with a known good unit. 10.4 engine indication troubleshooting to trouble...

Page 175

G3x installation manual - troubleshooting page 10-5 190-01115-01 revision e 10.5 ahrs troubleshooting 10.5.1 gsu 73 operational conditions gsu 73 ground operation is heavily dependent on gps data inputs. Be sure to correct any gps performance problems (i.E. Interference caused by anything that trans...

Page 176

Page 10-6 g3x installation manual –troubleshooting revision e 190-01115-01 figure 10-4 – ahrs align message (pfd) 10.5.2 heading red-x figure 10-5 – heading failure indication (full-screen pfd) if a red-x (steady or intermittent) is displayed on the heading (figure 10-5), check the following while t...

Page 177

G3x installation manual - troubleshooting page 10-7 190-01115-01 revision e 4. While a magnetic anomaly is detected and the aircraft is determined to be stationary, the value of the heading output is frozen. When either the aircraft is determined to be no longer stationary or the magnetic anomaly ce...

Page 178

Page 10-8 g3x installation manual –troubleshooting revision e 190-01115-01 5. Was the problem correlated with a specific maneuver or a specific geographic area? 6. Can the problem be repeated reliably? 7. Were any of the following message advisory alerts observed (must navigate to the info page and ...

Page 179

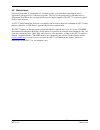

G3x installation manual - troubleshooting page 10-9 190-01115-01 revision e 10.7 gsu 73 data logging the gsu 73 data logger may be used to help troubleshoot g3x issues. Operational data can be gathered from the gsu 73 during flight or on ground, and stored in a data file on a pc. The data file can t...

Page 180

Page 10-10 g3x installation manual –troubleshooting revision e 190-01115-01 4. The data logger requests product data, then downloads 7 regions from the gsu 73 to the pc. The full path is displayed on the user interface of the logging tool. The log file name includes the date and time when the loggin...

Page 181

G3x installation manual - troubleshooting page 10-11 190-01115-01 revision e 7. If the logging tool loses data connection to the gsu 73, it will continuously check to see if the connection has been reestablished. This allows the tool to auto- restart, and eliminates the need for pilots to interact w...

Page 182

Page 10-12 g3x installation manual –troubleshooting revision e 190-01115-01 this page intentionally left blank.

Page 183

G3x installation manual – return to service page 11-1 190-01115-01 revision e 11 return to service information these return to service procedures are intended to verify the serviceability of the appliance only. These tests alone do not verify or otherwise validate the airworthiness of the installati...

Page 184

Page 11-2 g3x installation manual – return to service revision e 190-01115-01 11.2.2 new gsu 73 installed if a new gsu 73 is installed (new serial number), verify the correct software version on the main page in configuration mode. If the correct software version is not installed, load the gsu 73 so...

Page 185

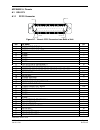

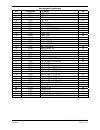

G3x installation manual – pinouts page a-1 190-01115-01 revision e appendix a pinouts a.1 gdu 37x a.1.1 p3701 connector pin 1 pin 17 pin 18 pin 33 pin 34 pin 50 figure a-1. View of j3701 connector from back of unit pin pin name i/o 1 mono audio out hi out 2 stereo audio out lo -- 3 stereo audio out ...

Page 186

Page a-2 g3x installation manual – pinouts revision e 190-01115-01 connector p3701, continued pin pin name i/o 33 config module clock i/o 34 signal ground -- 35 signal ground -- 36 signal ground -- 37 signal ground -- 38 spare -- 39 spare -- 40 spare -- 41 spare -- 42 cdu system id program* 4 in 43 ...

Page 187

G3x installation manual – pinouts page a-3 190-01115-01 revision e a.1.3 mode selections configure the gdu 37x units per the following tables. A gdu 37x can be manually placed in reversionary mode by wiring pin 25 to a two pole switch that toggles between open and ground. When the switch is open, th...

Page 188

Page a-4 g3x installation manual – pinouts revision e 190-01115-01 a.1.4.3 configuration module in multiple gdu 37x installations, it is only necessary to connect a configuration module to pfd1. Pin name connector pin i/o config module clock p3701 33 i/o config module data p3701 50 i/o config module...

Page 189

G3x installation manual – pinouts page a-5 190-01115-01 revision e a.2 gmu 44 a.2.1 p441 connector figure a-2. View of j441 connector looking at rear of unit pin pin name i/o 1 signal ground -- 2 rs-485 out b out 3 signal ground -- 4 rs-485 out a out 5 spare -- 6 power ground -- 7 spare -- 8 rs-232 ...

Page 190

Page a-6 g3x installation manual – pinouts revision e 190-01115-01 a.3 gsu 73 a.3.1 connector description the gsu 73 has one 62-pin connector (j731) and one 78-pin connector (j732) located on the connector end of the unit, as shown below. J731 and j732 are clearly marked on the connector end plate. ...

Page 191

G3x installation manual – pinouts page a-7 190-01115-01 revision e connector p731, continued pin pin name i/o 16 rs-232 in 2 (reserved) in 17 rs-232 out 2 (reserved) out 18 rs-232 in 3 (reserved) in 19 rs-232 out 3 (gps/alt encoder) out 20 arinc 429 out 1 a out 21 arinc 429 out 1 b out 22 arinc 429 ...

Page 192

Page a-8 g3x installation manual – pinouts revision e 190-01115-01 a.3.2.2 p732 connector figure a-5 rear connector j732 viewed from connector end of unit pin pin name i/o 1 cht 2 lo in 2 cht 3 hi in 3 egt 2 lo in 4 egt 3 lo in 5 fuel 1 lo in 6 man press lo in 7 pos 3/gp 3/fuel 3 lo in 8 pos 2/gp 2/...

Page 193

G3x installation manual – pinouts page a-9 190-01115-01 revision e connector p732, continued pin pin name i/o 40 cht 4 lo in 41 cht 1 lo in 42 egt 4 lo in 43 egt 1 lo in 44 fuel 2 lo in 45 fuel press lo in 46 pos 4/gp 4/fuel 4 lo in 47 pos 1/gp 1/tit 1 hi in 48 shunt 2 hi in 49 oil press lo in 50 sh...

Page 194

Page a-10 g3x installation manual – pinouts revision e 190-01115-01 a.3.3 power i/o a.3.3.1 aircraft power the gsu 73 has four inputs for aircraft power bus inputs of 14/28vdc. Aircraft power 2 is for connecting to an alternate power source, such as on aircraft with two electrical buses. Pin connect...

Page 195

G3x installation manual – pinouts page a-11 190-01115-01 revision e a.3.5 serial data electrical characteristics a.3.5.1 arinc 429 input/output the arinc 429 outputs conform to arinc 429 electrical specifications when loaded with up to 5 standard arinc 429 receivers. Pin connector pin name i/o 20 p7...

Page 196

Page a-12 g3x installation manual – pinouts revision e 190-01115-01 a.3.5.3 rs-485 input the gsu 73 contains one channel of rs-485 serial data communications. Pin connector pin name i/o 1 p731 magnetometer rs-485 in b in 2 p731 magnetometer rs-485 in a in a.3.5.4 can bus this data bus conforms to th...

Page 197

G3x installation manual – pinouts page a-13 190-01115-01 revision e a.3.6.2 discrete outputs the gsu 73 has 2 annunciator outputs, these outputs do not require any configuration and can be optionally wired to an external annunciator. Discrete out 1 acts as a master warning annunciator and is active ...

Page 198

Page a-14 g3x installation manual – pinouts revision e 190-01115-01 analog inputs (continued) pin connector pin name i/o 4 p732 egt 3 lo in 62 p732 egt 4 hi in 42 p732 egt 4 lo in 30 p732 egt 5 hi in 29 p732 egt 5 lo in 34 p732 oil temp hi in 14 p732 oil temp lo in 72 p732 pos 5 / misc temp hi in 52...

Page 199

G3x installation manual – pinouts page a-15 190-01115-01 revision e a.3.8 temperature inputs temperature input is used for outside air temperature (oat) computations. The temperature input is a three-wire temperature probe interface. Oat power out and oat high are connected internally at the oat pro...

Page 200

Page a-16 g3x installation manual – pinouts revision e 190-01115-01 this page intentionally left blank.

Page 201

G3x installation manual – connector installation instructions page b-1 190-01115-01 revision e appendix b connector installation instructions b.1 thermocouple installation into a backshell table b-1 lists parts needed to install a thermocouple. Parts for this installation are included in the thermoc...

Page 202

Page b-2 g3x installation manual – connector installation instructions revision e 190-01115-01 figure b-2. Jackscrew backshell thermocouple installation.

Page 203

G3x installation manual – connector installation instructions page b-3 190-01115-01 revision e b.2 jackscrew configuration module installation into a jackscrew backshell tables b-2 & b-3 list parts needed to install a jackscrew configuration module with pins or with sockets. Parts for these installa...

Page 204

Page b-4 g3x installation manual – connector installation instructions revision e 190-01115-01 notes for the following steps please refer to figures b-3 & b-4. 1. Strip back approximately 0.17 inches of insulation from each wire of the four conductor wire harness (item 3) and crimp either a pin (ite...

Page 205

G3x installation manual – connector installation instructions page b-5 190-01115-01 revision e figure b-4. Jackscrew backshell installation.

Page 206

Page b-6 g3x installation manual – connector installation instructions revision e 190-01115-01 b.3 jackscrew backshell installation instructions b.3.1 shield block installation parts tables b-4 and b-5 list the parts needed to install a shield block. Parts listed in table b-4 are supplied in the gdu...

Page 207

G3x installation manual – connector installation instructions page b-7 190-01115-01 revision e note in figure b-5, “ar” denotes quantity “as required” for the particular installation. Figure b-5. Shield install onto a jackscrew backshell (78 pin example).

Page 208

Page b-8 g3x installation manual – connector installation instructions revision e 190-01115-01 b.3.2 shield termination technique – method a.1 (standard) note for the following steps please refer to the drawings showing the installation of a jackscrew backshell. 1. The appropriate number of jackscre...

Page 209

G3x installation manual – connector installation instructions page b-9 190-01115-01 revision e 3. Connect a flat braid (item 4) to the shield exposed through the window of the prepared cable assembly (item 2) from step 2. The flat braid should go out the front of the termination towards the connecto...

Page 210

Page b-10 g3x installation manual – connector installation instructions revision e 190-01115-01 secondary method: solder a flat braid (item 4) to the shield exposed through the window of the prepared cable assembly (item 2). Ensure a solid electrical connection through the use of acceptable solderin...

Page 211

G3x installation manual – connector installation instructions page b-11 190-01115-01 revision e 6. Insert newly crimped pins and wires into the appropriate connector housing location as specified by the installation wiring diagrams. 7. Cut the flat braid (item 4) to a length that, with the addition ...

Page 212

Page b-12 g3x installation manual – connector installation instructions revision e 190-01115-01 b.3.3 shield termination technique - method a.2 (daisy chain) in rare situations where more braids need to be terminated for a connector than three per ring terminal it is allowable to daisy chain a maxim...

Page 213

G3x installation manual – connector installation instructions page b-13 190-01115-01 revision e connect a flat braid (item 4) to the folded back shield of the prepared cable assembly. The flat braid should go out the front of the termination towards the connector. It is not permitted to exit the rea...

Page 214

Page b-14 g3x installation manual – connector installation instructions revision e 190-01115-01 table b-7. Shielded cable preparations – (quick term) backshell size number of pins std/hd quick term min (inches) quick term max (inches) quick term float (inches) 1 9/15 1.25 2.25 1.75 2 15/26 1.5 2.5 2...

Page 215

G3x installation manual – connector installation instructions page b-15 190-01115-01 revision e b.3.6. Daisy chain between methods a and b in rare situations where more braids need to be terminated for a connector than three per ring terminal and a mixture of methods a and b have been used, it is al...

Page 216

Page b-16 g3x installation manual – connector installation instructions revision e 190-01115-01 b.3.8 splicing signal wires notes figure b-12 illustrates that a splice must be made within a 3 inch window from outside the edge of clamp to the end of the 3 inch max mark. Warning keep the splice out of...

Page 217

G3x installation manual – airframe specific installation guidance page c-1 190-01115-01 revision e appendix c airframe specific installation guidance c.1 introduction garmin has included in this manual some installation guidelines to aid the builder in the placement of various units which make up th...

Page 218

Page c-2 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 c.2 van’s aircraft c.2.1 rv-7/9 c.2.1.1 gmu 44 mounting bracket an rv-7/9 gmu 44 mounting bracket kit is available under garmin part number 011-01796-00, see figure c-1. The aft deck was chosen as an i...

Page 219

G3x installation manual – airframe specific installation guidance page c-3 190-01115-01 revision e 4. Securely clamp the mounting bracket to the aft deck so that no movement occurs with the front edge flush with the vertical portion of the f-714 aft deck. 5. Drill the six attach points with a #30 dr...

Page 220

Page c-4 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 c.3 lancair aircraft c.3.1 lancair iv/iv-p differences exist between the lancair iv/iv-p and the es series aircraft that result in different mounting techniques for the gmu 44. C.3.1.1 gmu 44 mounting ...

Page 221

G3x installation manual – airframe specific installation guidance page c-5 190-01115-01 revision e 1. Rivet the gmu 44 installation rack (115-00481-00) to the top bracket assembly (115-01052-00) as shown in figure c-4. Figure c-4. Lancair iv/iv-p gmu 44 mounting bracket 2. Attach the gmu 44 to the t...

Page 222

Page c-6 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 3. Attach the top bracket assembly (115-01052-00) to the bottom bracket assembly (115-01052-01) as shown in figure c-6. Figure c-6. Lancair iv/iv-p gmu 44 mounting bracket 4. After the installation, th...

Page 223

G3x installation manual – airframe specific installation guidance page c-7 190-01115-01 revision e c.3.2 lancair es/es-p c.3.2.1 gmu 44 mounting bracket the lancair es/es-p uses the g3x generic gmu 44 mount. The mount is comprised of two sheet metal parts, a bottom bracket (garmin part number 115-00...

Page 224

Page c-8 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 1. Clamp the gmu 44 installation rack (figure c-8) in place and match drill the gmu 44 bracket through three countersunk mounting holes. 2. Mark the center of the three mounting screw holes. 3. Remove ...

Page 225

G3x installation manual – airframe specific installation guidance page c-9 190-01115-01 revision e 6. Rivet the top bracket assembly (115-01017-00) to the universal bracket assembly (115-00939-00) as shown in figures c-10 and c-11. Figure c-10. Lancair iv/iv-p gmu 44 mounting bracket assembly note t...

Page 226

Page c-10 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 7. With the gmu 44 mount setup for installation in the right wing, shift the bracket to the minus 2 degree setting and rivet it in place using six 1/8” button head rivets as illustrated in figure c-12...

Page 227

G3x installation manual – airframe specific installation guidance page c-11 190-01115-01 revision e 9. Fabricate two disks from 2 bid sheet to the dimensions shown in figure c-14. Figure c-14. 2 bid sheet disk 10. Align one stainless steel nutplate ms21048-3 (or k1001-3) to each disk using the cente...

Page 228

Page c-12 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 15. Apply a small amount of release agent on the stainless steel ms51958 screw threads. 16. Attach gmu assembly to wing rib as shown in figure c-18. Figure c-18. Magnetometer assembly attached to wing...

Page 229

G3x installation manual – airframe specific installation guidance page c-13 190-01115-01 revision e c.3.3 lancair legacy c.3.3.1 gmu 44 magnetometer installation guidance 1. A possible mounting location is in the upper section of the fuselage cavity, just forward of the vertical tail section. The re...

Page 230

Page c-14 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 3. Measure the fuselage in multiple locations to determine the size of the shelf. The shelf will have an approximate trapezoidal shape and should have a depth of at least 4.0 in. Cut the shelf from 0....

Page 231

G3x installation manual – airframe specific installation guidance page c-15 190-01115-01 revision e 5. Secure the shelf to the fuselage with one layer of 3.0 in. Wide, 2 bid strips at each corner above and below the shelf. The lay up is shown in figure c-23. Magnetometer shelf 3" wide, 2 bid strips,...

Page 232

Page c-16 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 alternately, if the 2.50 in. Diameter hole is drilled off of centerline as indicated in figure c-25, project a parallel line to the aircraft’s centerline reference using the elevator control tube as a...

Page 233

G3x installation manual – airframe specific installation guidance page c-17 190-01115-01 revision e 60° typ mark location Ø0.203 3 places match drill Ø0.164 3 places fwd 115-00481-00 gmu 44 installation rack figure c-26. Magnetometer shelf with hole pattern for gmu 44 installation rack 7. Assemble t...

Page 234

Page c-18 g3x installation manual – airframe specific installation guidance revision e 190-01115-01 8. Install the gmu 44 magnetometer in the installation rack with the hardware provided as shown in figure c-28. Gmu 44 magnetometer 211-60037-08 screw 6-32 x .25 brass (3x) magnetometer shelf (ref) up...

Page 235

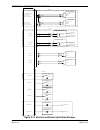

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-1 190-01115-01 revision e 77. 83 19 8. 8 6. 04 15 3. 4 2. 98 75 .8 3. 89 98 .7 2x 1. 72 43 .7 .0 04 0.1 1. 09 27 .7 [8 6. 7] 3. 41 .5 9 15 .0 1. 08 27 .5 # 6- 32 c a pt iv e sc re w (4 p lc ...

Page 236

Appendix d outline & installation drawings page d-2 g3x installation manual – outline & installation drawings revision e 190-01115-01 drawing is not to scale! Use for dimensions only. 4x 4x 45 ° 45° 4x 4x .1 60 .160 4. 1 4.1 r r .3 9 .39 typ . Typ. 10 .0 10.0 .19 .19 typ. 4.9 1.24 31.5 0 0 0.0 0.0 1...

Page 237

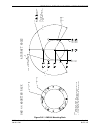

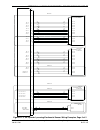

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-3 190-01115-01 revision e 2.520 64.01 3.370 85.60 gmu 44 mounting rack note : 1. Dimensions in inches [mm] 2. See sections 3 and 4 for mounting instructions of the gsu 73 ahrs and gmu 44 mag...

Page 238

Appendix d outline & installation drawings page d-4 g3x installation manual – outline & installation drawings revision e 190-01115-01 3.37 85.60 2.10 53.34 2.38 60.33 1.84 46.61 8.4 214 .3 8 aircraft mounting surface notes: 1. Dimensions in inches [mm] gmu 44 installation from above (preferred) gmu ...

Page 239

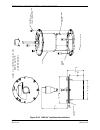

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-5 190-01115-01 revision e gmu 44 6-32 100 flat head brass scre ws required 6-32 pan head brass screws 0.24 [6.1] max thread length without clearance holes aircraft mounting rack 2.23 56.52 2...

Page 240

Appendix d outline & installation drawings page d-6 g3x installation manual – outline & installation drawings revision e 190-01115-01 note: 1. Bubble numbers in this dra wing refer to reference numbers listed in tables 3-8 and 3-9. Figure d-2.4 gmu 44 wiring detail.

Page 241

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-7 190-01115-01 revision e 2.8 71 1.8 46 3.2 81 4.46 113.2 notes: dimensions: inches[mm]. 1. Dimensions are shown for reference only. 2. Mounting holes for #10 pan head or hex head fasteners....

Page 242

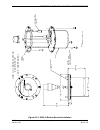

Appendix d outline & installation drawings page d-8 g3x installation manual – outline & installation drawings revision e 190-01115-01 .563 -.012 +.000 notes: 2. Max height of incomplete thread: 0.050 1. Dimensions: inches 3. Cable: m27500-22 te3v14. Cable len gth to be 10 feet 6 inches 4. 16 awg wir...

Page 243

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-9 190-01115-01 revision e aircraft skin forwar d fabricate and install doubler plate torque 20 to 25 in-lbs 011-01153-00 as required to comply with applicable ga 55a xm antenna #10-32 php x ...

Page 244

Appendix d outline & installation drawings page d-10 g3x installation manual – outline & installation drawings revision e 190-01115-01 3.00 76.2 2x 1.25 31.8 5.00127.0 forward backing plate outlin e .83 [21.1] 2.59 65.8 .6015.2 bnc connecto r front vie w 011-00134-0 0 antenna, aviation , ga 56 253-0...

Page 245

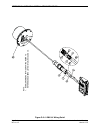

Appendix d outline and installation drawings g3x installation manual – outline & installation drawings page d-11 190-01115-01 revision e .25 6.4 2.35 59.7 2x0 2x1.600 40.64 2x 0 1.000 25.40 2.350 59.69 2x 3.300 83.82 .70 17.8 .6516.5 2x.800 20.3 .49 12.3 xm gps bnc connector tnc connector forward 4....

Page 246

Appendix d outline & installation drawings page d-12 g3x installation manual – outline & installation drawings revision e 190-01115-01 this page intentionally left blank.

Page 247

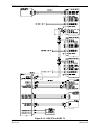

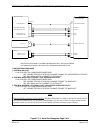

Appendix e g3x core interconnect drawings g3x installation manual – g3x core interconnect drawings page e-1 190-01115-01 revision e figure e-1.1 notes and 2 display can bus.

Page 248

Appendix e g3x core interconnect drawings page e-2 g3x installation manual – g3x core interconnect drawings revision e 190-01115-01 figure e-1.2 gdu 37x and gsu 73.

Page 249

Appendix e g3x core interconnect drawings g3x installation manual – g3x core interconnect drawings page e-3 190-01115-01 revision e figure e-1.3 14v power and antennas.

Page 250

Appendix e g3x core interconnect drawings page e-4 g3x installation manual – g3x core interconnect drawings revision e 190-01115-01 this page intentionally left blank.

Page 251

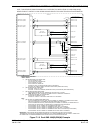

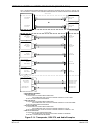

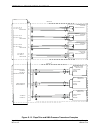

Appendix f external interface drawings (example only) g3x installation manual – external interface drawings page f-1 190-01115-01 revision e shield terminated to ground twisted shielded 3 conductor shield floats twisted shielded 3 conductor 4. Symbol designations twisted shielded pair shield termina...

Page 252

Appendix f external interface drawings (example only) page f-2 g3x installation manual – external interface drawings revision e 190-01115-01 configuration guidance 1. Gns 430w/530w a. On the main arinc 429 config page set in 1 speed to "low" set in 1 data to "efis/air data" set out speed to "low" se...

Page 253

Appendix f external interface drawings (example only) g3x installation manual – external interface drawings page f-3 190-01115-01 revision e configuration guidance 1. Gns #1 and #2 a. On the main arinc 429 config page set in 1 speed to "low" set in 1 data to "efis/air data" set out speed to "low" se...

Page 254

Appendix f external interface drawings (example only) page f-4 g3x installation manual – external interface drawings revision e 190-01115-01 configuration guidance 1. Gdu 37x to sl40 a.On the gdu 37x comm config mode page set connected gdu 37x rs-232 channel format to "sl40 comm" b.No sl40 configura...

Page 255

Appendix f external interface drawings (example only) g3x installation manual – external interface drawings page f-5 190-01115-01 revision e autopilot interconnects shown for reference only. Autopilot vendor documentation should be consulted for proper pin connections. Trutrak 17 primary serial inpu...

Page 256