- DL manuals

- Goodman

- Furnace

- GCH9

- Installation Instructions Manual

Goodman GCH9 Installation Instructions Manual

I

NSTALLATION

I

NSTRUCTIONS

GMH95/GCH95/GME95/GCH9

G

AS

-F

IRED

W

ARM

A

IR

F

URNACE

ATTENTION INSTALLING PERSONNEL

As a professional installer you have an obligation to know the product better than the customer. This includes all safety

precautions and related items.

Prior to actual installation, thoroughly familiarize yourself with this Instruction Manual. Pay special attention to all safety

warnings. Often during installation or repair it is possible to place yourself in a position which is more hazardous than

when the unit is in operation.

Remember, it is your responsibility to install the product safely and to know it well enough to be able to instruct a customer

in its safe use.

Safety is a matter of common sense...a matter of thinking before acting. Most dealers have a list of specific good safety

practices...follow them.

The precautions listed in this Installation Manual are intended as supplemental to existing practices. However, if there is

a direct conflict between existing practices and the content of this manual, the precautions listed here take precedence.

(Type FSP CATEGORY IV Direct or Non Direct Vent Air Furnace)

RECOGNIZE THIS SYMBOL AS A SAFETY PRECAUTION.

Installer: Affix all manuals adjacent to the unit.

These furnaces comply with requirements

embodied in the American National Stan-

dard / National Standard of Canada ANSI

Z21.47·CSA-2.3 Gas Fired Central Fur-

naces.

C

US

®

NOTE: Please contact your distributor or our website

for the applicable Specification Sheet referred to in this manual.

Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com

©

2006-2011 Goodman Manufacturing Company, L.P.

IO-299O

12/11

Summary of GCH9

Page 1

I nstallation i nstructions gmh95/gch95/gme95/gch9 g as -f ired w arm a ir f urnace attention installing personnel as a professional installer you have an obligation to know the product better than the customer. This includes all safety precautions and related items. Prior to actual installation, th...

Page 2

2 table of contents i mportant n ote to the o wner regarding p roduct w arranty .................................................................................. 4 i. Component identification ..............................................................................................................

Page 3

3 warning g oodman will not be responsible for any injury or property damage arising from improper service or service procedures. I f you install or perform service on this unit, you assume responsibility for any personal injury or propery damage which may result. M any jurisdictions require a licen...

Page 4

4 i f the information in these instructions is not followed exactly , a fire or explosion may result causing property damage , personal injury or loss of life . - d o not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance . - what to do if you ...

Page 5

5 i. Component identification 1 gas valve 2 gas line entrance (alternate) 3 pressure switch 4 gas manifold 5 combustion air intake connection / “coupling” 6 hot surface igniter 7 rollout limit 8 burners 9 flame sensor 10 flue pipe connection / “coupling” 11 flue pipe (internal) 12 primary limit 13 g...

Page 6

6 or shuffle your feet, do not touch ungrounded objects, etc.). If you come in contact with an ungrounded object, repeat step 2 before touching control or wires. 4. Discharge your body to ground before removing a new control from its container. Follow steps 1 through 3 if installing the control on a...

Page 7

7 the rated heating capacity of the furnace should be greater than or equal to the total heat loss of the area to be heated. The total heat loss should be calculated by an approved method or in accor- dance with “ashrae guide” or “manual j-load calculations” pub- lished by the air conditioning contr...

Page 8

8 a furnace installed in a confined space (i.E., a closet or utility room) must have two ventilation openings with a total minimum free area of 0.25 square inches per 1,000 btu/hr of furnace input rating. Refer to the specification sheet applicable to your model for mini- mum clearances to combustib...

Page 9

9 bustion and ventilation air for gas fired and other fuel burning appli- ances. Appliances that pull air out of the house (clothes dryers, exhaust fans, fireplaces, etc.) increase the problem by starving appliances for air. House depressurization can cause back drafting or improper com- bustion of ...

Page 10

10 2. When communicating with the outdoors through vertical ducts, each opening shall have a minimum free area of 1 square inch per 4,000 btu per hour of total input rating of all equipment in the enclosure. Fu rnace water heater outlet air chimney o r gas vent note: the inlet and outlet air opening...

Page 11

11 furnace water heater opening chimney or gas vent note: the single opening must have a free area of not less than one square inch per 3000 btu of the total input rating of all equip- ment in the enclosure, but not less than the sum of the areas of all vent connectors in the confined space. Alterna...

Page 12

12 air discharge air discharge air discharge bottom return duct connection bottom return duct connection bottom return duct connection side return duct connection side return duct connection upflow upright upflow horizontal right air discharge upflow horizontal left air discharge alternate flue pipe...

Page 13

13 as an alternative to pvc pipe, primer, solvent cement, and fittings, abs materials which are in compliance with the following specifi- cations may be used. Two-or-three-inch abs schedule 40 pipe must meet astm d1527 and, if used in canada, must be csa listed. Solvent cement for abs to abs joints ...

Page 14

14 v v x direct vent terminal clearances 1 in accordance with the current csa b149.1, natural gas and propane installation code. 2 in accordance with the current ansi z223.1/nfpa 54, national fuel gas code. † a vent shall not terminate directly above a sidewalk or paved driveway that is located betw...

Page 15

15 t ermination l ocations notes: refer to section iv, location requirements and considerations for combustion air contaminant restrictions. The following bullets and diagram describe the restrictions con- cerning the appropriate location of vent/flue pipe and combustion air intake pipe (when applic...

Page 16

16 rubber coupling with worm gear clamps rubber couplings with worm gear clamps combustion air pipe (direct vent only) combustion air pipe (direct vent only) vent/flue pipe vent/flue pipe 90º pvc elbow (non-direct vent) 90º pvc elbow (non-direct vent) standard connections or or upflow counterflow a ...

Page 17

17 v ent /f lue p ipe l engths and d iameters refer to the following table for applicable length, elbows, and pipe diameter for construction of the vent/flue pipe system of a non-direct vent installation. In addition to the vent/flue pipe, a single 90° elbow should be secured to the combustion air i...

Page 18

18 tee (optional) 12 " min to roof or highest anticipated snow level vertical termination (single pipe) 12" min. To roof or highest anticipated snow level alternate vertical termination (single pipe) _______________ min. 12" from wall 12" to ground or highest anticipated snow level horizontal termin...

Page 19

19 vent/flue combustion air intake screen optional 12" min. To roof or highest anticipated snow level 12" min. Tee (optional) vertical terminations (dual pipe) horizontal terminations should be as shown in the following fig- ure. Refer to section ix, vent/flue pipe and combustion pipe - termination ...

Page 20

20 vents 24" max. 3" min. 12" min. Screen (optional) 24" max. Air intakes 90° medium radius elbows 24" max. 3" min. 3" min. 12" min. Above highest anticipated snow level horizontal venting of multiple units c oncentric v ent t ermination refer to the directions provided with the concentric vent kit ...

Page 21

21 s tandard r ight or l eft s ide d rain h ose c onnections all installations positions require the use of the drain trap, hoses, tubes, and clamps. The following quantity of hoses, tubes, and hose clamps are provided with the unit. Drain trap qty: 1 green hose clamps qty: 3 silver hose clamp qty: ...

Page 22

22 rubber elbow (externally mounted) tube 1 green hose clamps (3 places) hose b tube(s) 2 drain trap hose a front cover drain port rubber elbow drain port red hose clamp silver hose clamp a lternate v ent /f lue d rain h ose c onnections upright installations using the alternate vent/flue outlet wil...

Page 23

23 u pright i nstallations -t rap on l eft s ide note: for left side trap installation, grommets must be moved to the left side of the furnace and the plugs installed on the right side of the furnace. 1. Remove the rubber plug from the left side drain port on the front cover. 2. Secure hose a to fro...

Page 24

24 cabinet width (inches) models (kbtu_tons) "x" length to cut from long end of hose b (inches) 17 1/2 040_3, 045_30, 060_3 7 21 070_40, 080_5 3 1/2 090_50, 100_5 115_50 none 24 1/2 u pright d rain t rap m ounting (l eft or r ight s ide p anel ) 1. Insert drain tubes into drain trap and position the...

Page 25

25 l eft s ide d own horizontal installations with the left side panel down will require drain hoses to be connected to the left side front cover drain port and the side drain port on the rubber elbow. 1. Remove the rubber plug from the front cover left (down) side drain port. 2. Relocate the front ...

Page 26

26 xi. Electrical connections high voltage! T o avoid the risk of electrical shock , wiring to the unit must be polarized and grounded . Warning high voltage! T o avoid personal injury or death due to electrical shock , disconnect electrical power before servicing or changing any electrical wiring ....

Page 27

27 24 v olt t hermostat w iring note: wire routing must not interfere with circulator blower operation, filter removal, or routine maintenance. Low voltage connections can be made through either the right or left side panel. Thermostat wiring entrance holes are located in the blower compartment. Wir...

Page 28

28 if it is necessary for the installer to supply additional line voltage wiring to the inside of the furnace, the wiring must conform to all local codes, and have a minimum temperature rating of 105°c. All line voltage wire splices must be made inside the furnace junction box. The integrated contro...

Page 29

29 natural gas capacity of pipe in cubic feet of gas per hour (cfh) length of nominal black pipe size pipe in feet 1/2" 3/4" 1" 1 1/4" 1 1/2" 10 132 278 520 1050 1600 20 92 190 350 730 1100 30 73 152 285 590 980 40 63 130 245 500 760 50 56 115 215 440 670 60 50 105 195 400 610 70 46 96 180 370 560 8...

Page 30

30 horizontal [upflow model] manual shut-off valve joint pipe union) drip leg gas line hole line location manifold plug in alternate gas line hole gas valve pipe union burners plug in alternate gas line hole drip leg gas valve horizontal[counterflow model] horizontal[counterflow] gas line plug in ga...

Page 31

31 g as p iping c hecks before placing unit in operation, leak test the unit and gas connec- tions. T o avoid the possibility of explosion or fire , never use a match or open flame to test for leaks . Warning check for leaks using an approved chloride-free soap and water solution, an electronic comb...

Page 32

32 a closed return duct system must be used, with the return duct connected to the furnace. Note: ductwork must never be attached to the back of the furnace. Flexible joints may be used for supply and return connections to reduce noise transmission. To prevent the blower from interfering with combus...

Page 33

33 installed without a cooling coil, it is recommended that a remov- able access panel be provided in the outlet air duct. This opening shall be accessible when the furnace is installed and shall be of such a size that the heat exchanger can be viewed for visual light inspection or such that a sampl...

Page 34

34 5. Move the furnace gas valve manual control to the off position. 6. Wait five minutes then smell for gas. Be sure to check near the floor as some types of gas are heavier than air. 7. If you smell gas after five minutes, immediately follow the instructions on page 4 of this manual. If you do not...

Page 35

35 note: if measuring gas pressure at the drip leg or honeywell vr9205 gas valve, a field-supplied hose barb fitting must be installed prior to making the hose connection. If using the inlet pressure boss on the white-rodgers 36g54 gas valve, then use the 36g valve pressure check kit, goodman part n...

Page 36

36 2. While the furnace is operating, time and record one complete revolution of the smallest gas meter dial. 3. Calculate the number of seconds per cubic foot (sec/ ft 3 ) of gas being delivered to the furnace. If the dial is a one cubic foot dial, divide the number of seconds recorded in step 2 by...

Page 37

37 as shipped, the circulator blower fan will remain on for 150 sec- onds after the gas valve closes. When a call for cooling occurs, the circulator fan comes on and remains on for 45 seconds after the call for cooling ends. During normal heating operation, the circula- tor fan will come on approxim...

Page 38

38 • furnace operates; integrated control module monitors safety circuits continuously. • if low-stage delay period expires, control will shift operation from low-stage heating mode operation to high-stage heating mode operation. Control will energize circulator blower high heat speed and high stage...

Page 39

39 p ressure s witches the pressure switches are normally-open (closed during opera- tion), single-pole single-throw, negative air pressure-activated switches. They monitor the airflow (combustion air and flue prod- ucts) through the heat exchanger via pressure taps located on the induced draft blow...

Page 40

40 • drainage system. Check for blockage and/or leakage. Check hose connections at and internal to furnace. • wiring. Check electrical connections for tightness and/or corrosion. Check wires for damage. • filters. F ilters t o ensure proper unit performance , adhere to the filter sizes given in the ...

Page 41

41 6. Remove the recuperator coil turbulators individually by slowly pulling each turbulator forward firmly. 7. Clean the recuperator coil tubes using a long handle wire brush, such as a gun cleaning brush. 8. Clean the primary heat exchanger tubes using a wire brush attached to a length of high gra...

Page 42

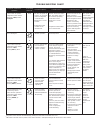

42 1 integrated control module will automatically attempt to reset from lockout after one hour. Troubleshooting chart • furnace lockout due to an excessive number of ignition “retries” (3 total) 1 . • locate and correct gas interruption. • check front cover pressure switch operation (hose, wiring, c...

Page 43

43 2 led flash code will cease if power to the control module is interrupted through the disconnect or door switch. Troubleshooting chart 4 4 flashes • circulator blower runs continuously. No furnace operation. • integrated control module diagnostic led is flashing four (4) flashes. 6 6 flashes 7 7 ...

Page 44: Gmh95

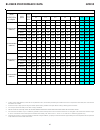

44 tons ac at 0.5" 0.6 0.7 0.8 esp cfm rise cfm rise cfm rise cfm rise cfm rise cfm cfm cfm high 3.0 1352 29 1318 30 1260 31 1202 33 1128 35 1044 955 853 gmh950453bx* med 2.5 1214 32 1172 34 1123 35 1064 37 1012 39 938 859 741 (med-hi) med-lo 2.0 997 40 994 40 960 41 923 43 884 45 817 741 611 low 1....

Page 45: Gch95 / Gch9115

45 1. Cfm in chart is without filters(s). Filters do not ship with this furnace, but must be provided by the installer. If the furnace requires two return filters, this chart assumes both filters are installed. 2. All furnaces ship as high speed cooling and medium-speed heating. Installer must adjus...

Page 46: Gme95

46 1. Cfm in chart is without filters(s). Filters do not ship with this furnace, but must be provided by the installer. If the furnace requires two return filters, this chart assumes both filters are installed. 2. All furnaces ship as high speed cooling and medium-speed heating. Installer must adjus...

Page 47: Wiring Diagram

47 wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. Wiring diagram h ig h v o lta g e ! D is co nne ct al l po wer be f o re se r v ic in g or in s t a lli n g th is uni t . M u lti p l e po wer s o u rce s ma y be pr e s en t . F ail u re t...

Page 48: Gmh95[0453,0704,0905]_Ac

48 gmh95[0453,0704,0905]_ac gmh95[0703,0904,1155]_ad wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. Wiring diagram h ig h v o lta g e ! D is co nne ct al l po wer be f o re se r v ic in g or in s t a lli n g th is uni t . M u lti p l e po ...

Page 49: Gch95_Aa / Gch9_Ac

49 gch95_aa / gch9_ac gmh950905cxa* wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. H ig h v o lta g e ! D is co nne ct al l po wer be f o re se r v ic in g or in s t a lli n g th is uni t . M u lti p l e po wer s o u rce s ma y be pr e s e...

Page 50: Gme95

50 gme95 wiring is subject to change. Always refer to the wiring diagram on the unit for the most up-to-date wiring. H ig h v o lta g e ! D is co nne ct al l po wer be f o re se r v ic in g or in s t a lli n g th is uni t . M u lti p l e po wer s o u rce s ma y be pr e s en t . F ail u re to do so m...

Page 51

51 this page left intentionally blank.

Page 52

52 goodman manufacturing company, l.P. 5151 san felipe, suite 500, houston, tx 77056 www.Goodmanmfg.Com © 2006-2011 goodman manufacturing company, l.P..