Goodman manufacturing company, l.P. 5151 san felipe, suite 500, houston, tx 77056 www.Goodmanmfg.Com © 2006-2007 goodman manufacturing company, l.P. Io-299b 7/07 i nstallation i nstructions gmh95/gch9 g as -f ired w arm a ir f urnace attention installing personnel as a professional installer you hav...

2 table of contents i. Component identification ............................................................................................................................................... 5 ii. Safety ..................................................................................................

3 xiv. Startup procedure & adjustment ............................................................................................................................. 27 h eat a nticipator s etting ............................................................................................................

4 i f the information in these instructions is not followed exactly , a fire or explosion may result causing property damage , personal injury or loss of life . - d o not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance . - what to do if you ...

5 i. Component identification 1 gas valve 2 gas line entrance (alternate) 3 pressure switch 4 gas manifold 5 combustion air intake connection / “coupling” 6 hot surface igniter 7 rollout limit 8 burners 9 flame sensor 10 flue pipe connection / “coupling” 11 flue pipe (internal) 12 primary limit 13 g...

6 or shuffle your feet, do not touch ungrounded objects, etc.). If you come in contact with an ungrounded object, repeat step 2 before touching control or wires. 4. Discharge your body to ground before removing a new control from its container. Follow steps 1 through 3 if installing the control on a...

7 the rated heating capacity of the furnace should be greater than or equal to the total heat loss of the area to be heated. The total heat loss should be calculated by an approved method or in accor- dance with “ashrae guide” or “manual j-load calculations” pub- lished by the air conditioning contr...

8 refer to the specification sheet applicable to your model for mini- mum clearances to combustible surfaces. One of the ventilation openings must be within 12 inches of the top; the other opening must be within 12 inches of the bottom of the confined space. In a typical construction, the clearance ...

9 house depressurization can cause back drafting or improper com- bustion of gas-fired appliances, thereby exposing building occu- pants to gas combustion products that could include carbon mon- oxide. If this furnace is to be installed in the same space with other gas appliances, such as a water he...

10 equipment located in confined spaces; all air from outdoors— inlet air from ventilated crawl space and outlet air to ventilated attic. See 5.3.3-b 2. When communicating with the outdoors through vertical ducts, each opening shall have a minimum free area of 1 square inch per 4,000 btu per hour of...

11 furnace water heater opening chimney or gas vent note: the single opening must have a free area of not less than one square inch per 3000 btu of the total input rating of all equip- ment in the enclosure, but not less than the sum of the areas of all vent connectors in the confined space. Alterna...

12 air discharge air discharge air discharge bottom return duct connection bottom return duct connection bottom return duct connection side return duct connection side return duct connection upflow upright upflow horizontal right air discharge upflow horizontal left air discharge alternate flue pipe...

13 t ermination l ocations notes: refer to section iv, location requirements and considerations for combustion air contaminant restrictions. The following bullets and diagram describe the restrictions con- cerning the appropriate location of vent/flue pipe and combustion air intake pipe (when applic...

14 c anadian v enting r equirements iin canada, venting must conform to the requirements of the cur- rent can/csa-b149.1-05 installation code. Use only csa-listed, ulc-s636 compliant two- or three-inch diameter pvc or abs pipe, solvent cement, and fittings throughout. The certified piping should be ...

15 and the “alternate vent/flue location” figure. Note: counterflow instructions follow the upflow instructions. 1. Remove and save the four screws securing the vent/flue coupling to the furnace top panel. Counterflow units. 1. Remove and save the four screws securing the vent/flue coupling to the f...

16 into the last joist space to penetrate the header, two 45° elbows should be used to reach the header rather than two 90° elbows. 12 " min to roof or highest anticipated snow level tee vertical termination (single pipe) 12" min. To roof or highest anticipated snow level 90º medium radius elbows al...

17 tant flashing. Both the combustion air intake and a vent/flue pipe terminations must be in the same atmospheric pressure zone. For details concerning connection of pipes to the furnace, refer to the section ix, vent/flue pipe and combustion pipe - standard furnace connections or alternate furnace...

18 alternate vent termination above anticipated snow level (dual pipe) in a basement installation, the pipes may be run between the joist spaces. If the pipes must go below the joist and then up into the last joist space to penetrate the header, two 45° elbows should be used to reach the header rath...

19 1. Remove the rubber plug from the front cover drain port (right or left side, depending on the intended drain trap mounting). 2. Secure hose a to front cover drain port with a red hose clamp. Route hose to rear side panel grommet hole. Note: for left side drainage, grommets will have to be reloc...

20 u pright d rain t rap m ounting (l eft or r ight s ide p anel ) 1. Insert drain tubes into drain trap and position the drain trap against the side panel. Note: drain tubes must reach the bottom of the drain trap. 2. Secure drain trap to side panel at the mounting holes (dimples or crosshairs on c...

21 h orizontal d rain t rap m ounting (l eft or r ight s ide p anel ) 1. Position the drain trap against side panel with drain tubes inserted into trap. Note that the trap may be orientated with the outlet facing either the furnace’s top cover or base pan. 2. Secure drain trap to side panel at the d...

22 fer to the following figure for thermostat connections to the inte- grated control module terminal strip. W w w y y y c c r r r g g w y c r g heating room thermostat heating and cooling room thermostat furnace furnace remote condensing unit thermostat diagram this furnace is equipped with a 40 va...

23 refer to the national fuel gas code, nfpa 54/ansi z223.1, and information provided by the gas supplier to determine the proper orifice size. A different pressure switch may be required at high altitude regard- less of the btu/ft 3 content of the fuel used. Contact your distributor for a tabular l...

24 • connect the furnace to the building piping by one of the following methods: – rigid metallic pipe and fittings. – semi-rigid metallic tubing and metallic fittings. Aluminum alloy tubing must not be used in exterior locations. In order to seal the grommet cabinet penetration, rigid pipe must be ...

25 e dges of sheet metal holes may be sharp . U se gloves as a precaution when removing hole plugs . Warning d irect /s tandard i nlet p iping when gas piping enters directly to the gas valve through the stan- dard inlet hole, the installer must supply straight pipe with a ground joint union to reac...

26 sizing between first and second stage regulator* maximum propane capacities listed are based on 2 psig pressure drop at 10 psig setting. Capacities in 1,000 btu/hour. Pipe or nominal pipe size tubing tubing size, o.D. Type l schedule 40 length, 3/8" 1/2" 5/8" 3/4" 7/8" 1/2" 3/4" feet 10 730 1,700...

27 600 800 1000 1200 1400 1600 2000 0453bx a 194* 194* 240 288 --- --- --- 0703bx a --- 324* 324* 324* 336 --- --- 0704cx a --- --- 291* 291* 336 384 --- 0904cx a --- --- 432* 432* 432* 432* --- 0905dx a --- --- --- 388* 388* 388* 480 1155dx a --- --- --- 486* 486* 486* 486* input_ _ a ir fl ow c oo...

28 g as s upply p ressure m easurement t o prevent unreliable operation or equipment damage , the i nlet gas supply pressure must be as specified on the unit rating plate with all other household gas fired appliances operating . Caution w hite -r odgers 36g54 g as v alve the line pressure supplied t...

29 12. Remove manometer hose from outlet pressure boss. 13. Turn outlet pressure test screw in to seal pressure port (clockwise, 7 in-lb minimum). 14. Turn on electrical power and gas supply to the system. 15. Turn on system power and energize valve. 16. Using a leak detection solution or soap suds,...

30 5. Turn on power to furnace. 6. Verify proper temperature rise as outlined in section xiv, startup procedure and adjustment - temperature rise. Orange high common/neutral medium low circulator blower speeds low red medium blue black white xv. Normal sequence of operation p ower u p the normal pow...

31 f an o nly m ode the normal operational sequence in fan only mode is as follows: • r and g thermostat contacts close, initiating a call for fan. • integrated control module performs safety circuit checks. • circulator blower is energized on low heat speed. Electronic air cleaner terminals are ene...

32 d iagnostic c hart high voltage! T o avoid personal injury or death due to electrical shock , disconnect electrical power before p erformaing any service or maintenance . Warning refer to the troubleshooting chart at the end of this manual for assistance in determining the source of unit operatio...

33 out curling, floating, or lifting off. Flames must not impinge on the sides of the heat exchanger firing tubes. I nduced d raft and c irculator b lowers the bearings in the induced draft blower and circulator blower motors are permanently lubricated by the manufacturer. No further lubrication is ...

34 xxi. Before leaving an installation • cycle the furnace with the thermostat at least three times. Verify cooling and fan only operation. • review the owner’s manual with the homeowner and discuss proper furnace operation and maintenance. • leave literature packet near furnace. Xxii. Repair & repl...

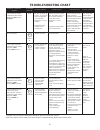

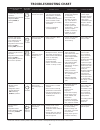

35 1 integrated control module will automatically attempt to reset from lockout after one hour. Troubleshooting chart • furnace lockout due to an excessive number of ignition “retries” (3 total) 1 . • locate and correct gas interruption. • check front cover pressure switch operation (hose, wiring, c...

36 • polarity of 115 volt ac power to furnace or integrated control module is reversed. • orange and gray wires to transformer are reversed. • poor unit ground. • circulator blower runs continuously. No furnace operation. • integrated control module diagnostic led is flashing four (4) flashes. • pri...

37 gmh95 & gch9 wiring is subject to change, always refer to the wiring diagram on the unit for the most up-to-date wiring. Wiring diagram r yl yellow or orange pu purple gn green bk black br brown wh white bl blue gy gray rd red color codes: low voltage (24v) low voltage field hi voltage (115v) hi ...