- DL manuals

- H.E.R.O.

- Paint Sprayer

- H2K 3819

- Owner's Manual

H.E.R.O. H2K 3819 Owner's Manual

Owner’s Manual

HK3819 / HK5523

Page 1

TABLE OF CONTENTS

Warranty Information

2

Important Safety Precautions

3

Introduction

4

Set Up, Priming, Spraying

5

Flushing & Priming

5

Shut Down and Pressure Relief Procedures

6

Airless Spray Painting Suggestions

7-8

Tip Selection

8-9

Troubleshooting

9

Repair Procedures

10-11

Piston Cartridge Assembly Repairs

12-13

Pressure Control Calibration

14

Prime Valve Service

14-15

Unit Parts Breakdown

16

Cart Parts Breakdown

17

Wiring Schematic

18

Parts List and Descriptions

19-22

Summary of H2K 3819

Page 1

Owner’s manual hk3819 / hk5523 page 1 table of contents warranty information 2 important safety precautions 3 introduction 4 set up, priming, spraying 5 flushing & priming 5 shut down and pressure relief procedures 6 airless spray painting suggestions 7-8 tip selection 8-9 troubleshooting 9 repair p...

Page 2: Warranty

Owner’s manual hk3819 / hk5523 page 2 h.E.R.O. Warranty h.E.R.O., guarantees this airless pump to be free of defects in materials and workmanship to the original owner, for a period of one full year from the date of purchase. The warranty entitles the owner to parts replacement at no charge. The par...

Page 3: Important

Owner’s manual hk3819 / hk5523 page 3 important as with all mechanical equipment, proper operating and maintenance procedures are required to keep your h.E.R.O. Airless pump performing to your satisfaction. The following safety, operating and maintenance instructions are important. Read and understa...

Page 4: Introduction & Unpacking

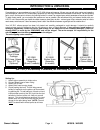

Owner’s manual hk3819 / hk5523 page 4 set up, flushing, priming, spraying, shut down setting up: 1. Attach siphon assembly to intake valve. 2. Connect bleed hose to return fitting. 3. Attach gun to hose. 4. Attach paint hose to outgo nipple. 5. Check packing lubricant. This will help prevent buildup...

Page 5

Owner’s manual hk3819 / hk5523 page 5 flushing: 1. Have two pails ready; one for flushing fluid and one for waste. 2. If you are using latex paint, fill the flushing pail with approximately 1 gallon of warm soapy water. For oil based paints, use approximately 1 gallon of mineral spirits. 3. Place th...

Page 6: Spraying & Shut Down

Owner’s manual hk3819 / hk5523 page 6 spraying: 1. Turn unit on. 2. Trigger gun, and increase pressure slowly. Continue to increase the pressure until the spray pattern is uniformed from top to bottom, with no heavy areas. If heavy areas are still visible at maximum pressure settings, thin paint wit...

Page 7

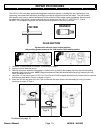

Owner’s manual hk3819 / hk5523 page 7 airless spray painting suggestions poor good tailing good pattern fog, overspray fig. 1 a good airless spray application is the result of many factors. Surface preparation, which includes cleaning and degreasing, priming, material compatibility, quality finish p...

Page 8: Spray Tip Selection

Owner’s manual hk3819 / hk5523 page 8 airless spray painting suggestions fig. 3 fig. 4 fig. 5 spray tip selection it is advisable to obtain a spray tip recommendation from the supplier of the material to be sprayed. The following table is a general guide and will assist in selecting the optimum tip ...

Page 9: Spray Tip Selection

Owner’s manual hk3819 / hk5523 page 9 orifice size all tips are rated by the size of the orifice or bore size. The bore size is measured in thousandths of an inch ( .017 = 17 thousandths of an inch ). The size of tip required is based on the consistency of the material to be sprayed. The thicker the...

Page 10: Repair Procedures

Owner’s manual hk3819 / hk5523 page 10 the h.E.R.O. H2k units were specifically designed to assist the operator in dealing with the inconvenient, time consuming, and some times technically challenging concept of equipment service and repair. The h2k models offer simple, quick, easy to perform proced...

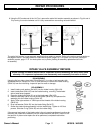

Page 11: Repair Procedures

Owner’s manual hk3819 / hk5523 page 11 fig # 4 fig # 6 fig # 5 6. Using the 5/8” socket end of the uni-tool, remove the entire fluid section assembly as shown in fig # 4 and # 5 by turning it counter clockwise until it is fully removed from connecting rod and manifold. The entire fluid section is no...

Page 12: Repair Procedures

Owner’s manual hk3819 / hk5523 page 12 repair procedures piston cartridge assembly repairs – dismantling the piston cartridge assembly is available as a complete, pre-assembled cartridge for quick, on site, unit repairs. Items are also available individually for more economical repairs when time is ...

Page 13: Repair Procedures

Owner’s manual hk3819 / hk5523 page 13 repair procedures 1. Slide o-rings (ref # 14 & 15) onto the piston valve body (ref # 13). It is recommended to lubricate with a common grease or piston lube before sliding on. 2. Drop ball (ref # 16) into piston valve. 3. Insert piston valve washer (ref # 17) i...

Page 14: Prime Valve Service

Owner’s manual hk3819 / hk5523 page 14 pressure control calibration if any component relating to pressure control is repaired or replaced, a pressure calibration must be performed. For illustration purposes, the gear housing is shown without the cover and con-rod assembly. The cover does not have to...

Page 15: Prime Valve Service

Owner’s manual hk3819 / hk5523 page 15 prime valve service part # hk-3500b ( older version ) removal place 5/8” wrench on flats of bleed valve housing (ref # 4) and remove valve assembly from the manifold (ref # 39). Remove the ball (ref # 3) seat (ref # 2) and the crush washer (ref # 1) from the ma...

Page 16: Parts Breakdown

Owner’s manual hk3819 / hk5523 page 16 parts breakdown.

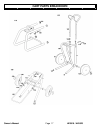

Page 17: Cart Parts Breakdown

Owner’s manual hk3819 / hk5523 page 17 cart parts breakdown.

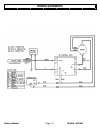

Page 18: Wiring Schematic

Owner’s manual hk3819 / hk5523 page 18 wiring schematic.

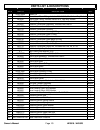

Page 19: Parts List & Descriptions

Owner’s manual hk3819 / hk5523 page 19 parts list & descriptions ref# part # description qty 1 hk2560 siphon hose assembly, sled and low boy models, includes ref # 1,3 -7,9,10 1 2 hk2600 siphon hose assembly, high boy models, includes ref # 2 - 6,8 -10 1 3 187f siphon screen, fine mesh 1 4 hk2035 o-...

Page 20: Parts List & Descriptions

Owner’s manual hk3819 / hk5523 page 20 parts list & descriptions ref# part # description qty 41 05-40-5020 dowel pin 1 42 hk3025 prime hose elbow fitting, includes ref #9 &10, sled & low boy models 1 43 hk3035 prime hose fitting, includes ref #9 &10, high boy models 1 44 14a outlet fitting 1 45 hk56...

Page 21: Parts List & Descriptions

Owner’s manual hk3819 / hk5523 page 21 parts list & descriptions ref# part # description qty 83 05-40-5012 thrust washer 1 84 hk5525 hk5530 crankshaft gear assembly, 3819 models crankshaft gear assembly, 5523 models assy assy 85 05-40-5015 thrust washer 1 86 hk5155 dowel pin 2 87 hk5055 thrust washe...

Page 22: Parts List & Descriptions

Owner’s manual hk3819 / hk5523 page 22 ref# part # description qty 115 hk6535 hk6540 gear housing cover with decal, 3819 models gear housing cover with decal, 5523 models 1 1 116 dec-3819 dec-5523 front label, 3819 models front label, 3819 models 1 1 117 hw3021 capscrew, socket head, 8/32” x 1/2” 4 ...

Page 23

Owner’s manual hk3819 / hk5523 page 23 manufactured by: h.E.R.O. 2719 lake city way burnaby, b.C. Canada phone: 604-420-6543 800-494-4376 fax: 604-420-8725 purchased from __________________________ __________________________ __________________________ __________________________ model: ______________...

Page 24

Owner’s manual hk3819 / hk5523 page 24 factory located at: 2719 lake city way burnaby, b.C. Canada v5a 2z6 u.S.A correspondence p.O. Box 75 custer, washington 98240-0075 warning: do not operate this equipment without reading and understanding all safety and operating instructions see page 2 - 3 owne...