- DL manuals

- H3C

- Switch

- S12500 Series

- Installation Instructions Manual

H3C S12500 Series Installation Instructions Manual

Summary of S12500 Series

Page 1

H3c s12500 series routing switches installation manual hangzhou h3c technologies co., ltd. Manual version: 5pw110-20091216.

Page 2

Copyright © 2008-2009, hangzhou h3c technologies co., ltd. And its licensors h3c technologies co., ltd., a subsidiary of 3com corporation. All rights reserved no part of this manual may be reproduced or transmitted in any form or by any means without prior written consent of hangzhou h3c technologie...

Page 3

About this manual organization h3c s12500 series routing switches installation manual is organized as follows: chapter contents chapter 1 product overview introduces the appearance, architecture and system features of the s12500 series. Chapter 2 preparing for installation lists the preparations and...

Page 4

Gui conventions convention description button names are inside angle brackets. For example, click . [ ] window names, menu items, data table and field names are inside square brackets. For example, pop up the [new user] window. / multi-level menus are separated by forward slashes. For example, [file...

Page 5

[technical support & document > software download]: provides the documentation released with the software version. Technical support customer_service@h3c.Com http://www.H3c.Com at http://www.H3cnetworks.Com documentation 1) select drivers & downloads in the support area. 2) select documentation for ...

Page 6

Z product model name, part number, and serial number z proof of purchase, if you have not pre-registered your product z a list of system hardware and software, including revision level z diagnostic error messages z details about recent configuration changes, if applicable to send a product directly ...

Page 7: Table of Contents

I table of contents 1 product overview ······································································································································1-1 overview ··················································································································...

Page 8: Product Overview

1-1 1 product overview overview the h3c s12500 series routing switches (hereinafter referred to as the s12500 series) are new-generation core routing switches developed by hangzhou h3c technologies co., ltd. (hereinafter referred to as h3c) based on its 100 g platform. The s12500 series adopt the mo...

Page 9

1-2 chassis and slots your devices might look different from the diagrams in the manual. Figure 1-1 s12508 front view (1) mpu slots (slots 0 and 1) (2) power frame front panel (3) power frame slot (4) power switch (5) upper cabling rack (6) lpu slots (slots 2 to 9) (7) lower cabling rack (8) air fil...

Page 10

1-3 figure 1-2 s12508 rear view ( 5) ( 6) ( 7) ( 8) ( 9) ( 10) (1) lower fan tray slot (2) upper fan tray slot (3) power entry module slot (4) power air exhaust vents (5) system air exhaust vents (6) switching fabric module slots (slots 10 to 18) (7) cover plate (8) air filter (9) system air intake ...

Page 11

1-4 figure 1-3 front view of the s12518 (1) mpu slots (slots 0 and 1) (2) front panel (3) two power frame slots (4) power switch (5) upper cabling rack (6) lpu slots (slots 2 to 19) (7) lower cabling rack you can open the front panel upwards so that you can see the power supply air filter and power ...

Page 12

1-5 figure 1-4 s12518 rear view ( 5) ( 6) ( 7) ( 8) ( 9) ( 10) (1) lower fan tray slot (2) upper fan tray slot (3) two power entry module slots (4) power air exhaust vents (5) system air exhaust vents (6) switching fabric module slots (slots 20 to 28) (7) cover plate (8) air filter (9) system air in...

Page 13

1-6 z auto-detects types of boards in slots. Z connects with power frames to provide distributed power supply for mpus, lpus, switching fabric modules, fan trays, and psus, and to provide monitoring channels. Power supply system ac power frame the power supply system is at the chassis top behind the...

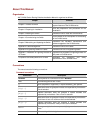

Page 14

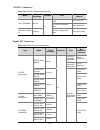

1-7 table 1-2 description of ac psu indicators indicator color status description on the power is input normally. Off no power is input. Input green blinking the input power exceeds the threshold. On the power is output normally. Off no power is output. Output green blinking the power output is over...

Page 15

1-8 table 1-4 description of pems pem description max number of supported psus lstm2pemc6 (pem-c20) applied to 110 v or 220 v single-phase three-wire ac power supply system each pem provides six standalone c20 (16a) sockets numbered in two rows, 1, 3 and 5 on the top and 2, 4 and 6 on the bottom, fr...

Page 16

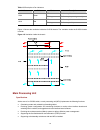

1-9 table 1-5 description of fan indicators indicator color status description off the fan tray fails. Run green blinking the fan tray is operating normally. Off the fan tray is in a normal state. Alm red blinking the fan tray is faulty. Figure 1-8 shows the ventilation inside the s12518 chassis. Th...

Page 17

1-10 table 1-6 mpu specifications item specifications model lst1mrpnc1 (for s12508 and s12518) cpu mpc8548+mpc8544 (ffdr cpu) flash 128 mb boot rom 4 mb nvram 1 mb sdram (ddr2) 1 gb (expandable to 2 gb) cf card 256 mb (expandable to 1 gb) dimensions (h × w × d) 40 × 400 × 467 mm (1.57 × 15.75 ×18.39...

Page 18

1-11 leds table 1-7 description of cf card leds led status description on the cf card is in position and idle. Do not hot-unplug it now. Blinking the cf card is in position and performing read/write operations. Do not unplug it now. Cfs off the cf card is out of position or offline. You can plug in ...

Page 19

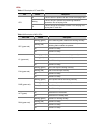

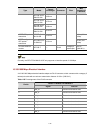

1-12 line cards specifications table 1-9 line cards specifications model item lst1xp8leb 1/lst1xp8le c1 lst1xp4leb 1/lst1xp4le c1 lst1gp48le b1/lst1gp48 lec1 lst1gt48le b1/lst1gt48 lec1 lst1xp32re b1/lst1xp32 rec1 cpu mpc8544 boot rom 2 mb sdram 512 mb dimension s (h × w × d) 40 × 400 × 467 mm (1.57...

Page 20

1-13 front panel and leds lst1xp8leb1/lst1xp8lec1 figure 1-10 lst1xp8lec1 front panel (1) 10gbase-r xfp/lc optical interfaces/10gbase-w xfp/lc optical interfaces (eight in total) (2) interface led (3) run led of the interface board the appearance of the lst1xp8leb1 is similar to that of the lst1xp8l...

Page 21

1-14 lst1xp4leb1/lst1xp4lec1 figure 1-11 lst1xp4leb1 front panel (1) 10gbase-r xfp/lc optical interfaces/10gbase-w xfp/lc optical interfaces (four in total) (2) interface led (3) run led of the interface board the appearance of the lst1xp4lec1 is similar to that of the lst1xp4leb1. For description o...

Page 22

1-15 table 1-12 description of the interface led led status description on the interface is properly connected to another interface. Off the interface is not connected to any other interface. Link/act blinking data is being sent or received through the interface. For description of the interface boa...

Page 23

1-16 lst1gt48leb1/lst1gt48lec1 figure 1-14 lst1gt48leb1 front panel (1) 10/100/1000 mbps autosensing rj-45 electrical interfaces (48 in total) (2) run led of the interface board (3) interface led the appearance of the lst1gt48lec1 is similar to that of the lst1gt48leb1. For description of the interf...

Page 24

1-17 model item lst1sf08b1 lst1sf18b1 switching capacity 320 gbps 640 gbps power consumption 36w to 45w 93w to 110w front panel and leds lst1sf08b1 figure 1-15 lst1sf08b1 front panel ( 1) (2) (3) ( 4) ( 4) (1) 10base-t interface (2) console port (3) run led (4) interface led table 1-15 description o...

Page 25

1-18 lst1sf18b1 figure 1-16 lst1sf18b1 front panel (1) 10base-t interface (2) console port (3) run led (4) interface led for description of the interface leds and board led, refer to table 1-15 and table 1-16 respectively. Interface specifications the s12500 series support the following interface ty...

Page 26

1-19 item specification baud rate 9600 bps to 115200 bps, 9600 bps by default supported services it can be connected to the serial interface of a local pc running terminal emulation software, or to an ascii terminal. Command line interface (cli) is supported. Network management interface the rj-45 n...

Page 27

1-20 table 1-20 usb interface specifications item specification connector type z usb a type connector for the host usb interface (active) z usb b type connector for the dev usb interface (standby) z currently, only active usb interfaces are supported on the s12500. Interface standard usb 2.0 (full-s...

Page 28

1-21 10g sfp+ transceiver table 1-23 10g sfp+ transceiver specifications model central wavelength connector fiber max transmission distance 62.5/125 µm multimode fiber 33 m (108.27 ft.) sfp+-sr-mm850 850 nm 50/125 µm multimode fiber 300 m (984.25 ft.) sfp-xg-lx-sm13 10 1550 nm lc 9/125 µm single mod...

Page 29

1-22 type model central wavelength connector fiber max transmissio n distance sfp-ge-lh70- sm1550-cw 1550 nm sfp-ge-lh70- sm1570-cw 1570 nm sfp-ge-lh70- sm1590-cw 1590 nm sfp-ge-lh70- sm1610-cw 1610 nm ge/fe sfp optical transceiver sfp-fe-sx-m m1310-ge 1310 nm 10 km (6.21 miles) ge/fe configurable s...

Page 30

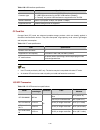

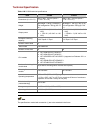

1-23 technical specification table 1-26 s12500 technical specifications item s12508 s12518 dimensions (h × w × d) 975 × 442 × 740 mm (38.39 × 17.40 × 29.13 in.) 1686 × 442 × 740 mm (66.38 × 17.40 × 29.13 in.) weight net weight: full configuration: 160 kg (352.73 lb.) net weight: full configuration: ...

Page 31: Table of Contents

I table of contents 2 preparing for installation ··························································································································2-1 safety precautions ··········································································································...

Page 32: Preparing For Installation

2-1 2 preparing for installation safety precautions installation and removal of the unit and its accessories must be carried out by qualified personnel. You must read all of the safety instructions supplied with your device before installation and operation. Installation und ausbau der anlage und ih...

Page 33

2-2 electrical safety z look carefully for possible hazards in your work area, such as ungrounded power extension cables, missing safety grounds, and moist floors. Z locate the emergency power-off switch in the room before installation. Shut the power off at once in case accident occurs. Z unplug al...

Page 34

2-3 z it is recommended to have four people work together to move the device, thus avoiding incline of the chassis. Z you can only hold the handles at both sides of the chassis when moving the switch, but not the plastic panel of the chassis, the handle of the fan tray, the handle of the psus, the h...

Page 35

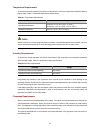

2-4 temperature requirements to ensure the normal operation of a switch, the temperature in the room should be maintained within a proper range. Table 2-1 describes temperature requirements. Table 2-1 temperature requirements temperature range operating temperature long term: 0°c to 40°c (32°f to 10...

Page 36

2-5 table 2-3 limitation on dust content and particle diameter in the equipment room mechanical active material content limit (particles/m 3 ) dust particle ≤ 3 x 10 4 (no visible dust on desk in three days) note: dust particle diameter ≥ 5 µm besides the dust specifications, the equipment room of t...

Page 37

2-6 must provide good grounding system for the switch. The resistance between the chassis and the ground must be less than 1 ohm. Power supply requirements the following tables describe the specifications for ac psus. Table 2-5 specifications for ac psus item specifications rated voltage range 100 v...

Page 38

2-7 category tool special tools esd-preventive wrist strap, cable stripper, crimping pliers, rj-45 crimping pliers, wire punch-down tool meters multimeter, 500 v meg-ohmmeter (used for measuring the insulation resistance), error detector, optical power meter, earth resistance tester the instruments ...

Page 39: Table of Contents

I table of contents 3 installing the switch ··································································································································3-1 installation flow ········································································································...

Page 40: Installing The Switch

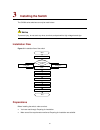

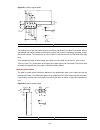

3-1 3 installing the switch the s12500 series switches can only be used indoors. To prevent injury, do not touch any wires, terminals, and parts with a high-voltage hazard sign. Installation flow figure 3-1 installation flow of the switch start connect the grounding cable install the fan tray instal...

Page 41

3-2 installing the switch in a rack installation preparation z check that the cabinet is well grounded and secured. Make sure the layout inside the rack for the switch installation is done and there is no debris left inside or around the cabinet. Z there is enough space around the cabinet for heat-d...

Page 42

3-3 the following section gives a brief description of the installation procedures. For details, refer to the installation instruction. Step1 place the switch on the support tray and slide the switch along the slide rails until the mounting brackets on the switch reach the rack posts. Step2 use moun...

Page 43

3-4 installing the switch on a workbench you can also install the switch on a clean and stable workbench or the ground. Installation preparation z the workbench or ground is sturdy enough to support the switch. Z the workbench or ground for installing the switch is reliably grounded. Installation pr...

Page 44

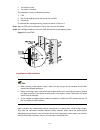

3-5 figure 3-5 install the cabling racks (1) cabling racks (2) mounting screw connecting the pgnd cable for the safety of operators and equipment, the switch must be well grounded. The resistance reading between switch chassis and the ground must be less than 1 ohm. Connection in generic grounding e...

Page 45

3-6 step1 remove the screw from the grounding hole on the switch chassis. Step2 put the supplied ot terminal of the pgnd cable on the grounding screw. Step3 insert the grounding screw into the grounding hole and screw it down. Step4 connect the other end of the pgnd cable to the grounding strip of t...

Page 46

3-7 figure 3-7 connect the pgnd cable to a grounding strip (1) grounding hole (2) grounding screw (3) pgnd cable (4) grounding strip z if an area with exposed earth is available nearby where a grounding conductor can be buried, hammer a 0.5 m (1.64 ft.) or longer angle iron or steel tube into the ea...

Page 47

3-8 figure 3-8 connect the pgnd cable to a buried grounding conductor (3) (1) (2) (4) ground surface (1) grounding hole (2) grounding screw (3) pgnd cable (4) angle iron or steel tube installing a psu installation procedures follow these steps to install a psu: step1 install a power entry module (pe...

Page 48

3-9 for connection of power cables, refer to connecting power cables. Figure 3-9 install a pem installing a psu z make sure that the psus meet the power supply requirement of the switch. Z each socket on the pem-c20 corresponds to a psu slot. Therefore, to ensure normal operation of an ac psu, you n...

Page 49

3-10 figure 3-11 install a psu 2 1 2 1 2 step4 close the panel of the psu following the direction shown in callout 2 of figure 3-11, and press the clip at the bottom left corner of the psu to lock the psu in position. The psu installation is complete, as shown in figure 3-12. Figure 3-12 complete in...

Page 50

3-11 installation preparation z put on an esd-preventive wrist strap and make sure that the esd-preventive wrist strap is properly grounded. Z remove the blank panel (if any) from the slot to be used. Installation procedures z hold a fan tray by the bottom when moving it. Do not lift the module by t...

Page 51

3-12 installing an lpu z a switch requires at least one main process unit (mpu), one lpu and six switching fabric modules. Z the s12500 does not support intermixing of the mpu, lpu, and switching fabric modules. Mpus, lpus and switching fabric modules are installed at different positions as follows:...

Page 52

3-13 z keep the removed the blank panel and protective metal box properly for future use. Z all the boards for the s12500 are hot-swappable. Installation procedures step1 remove the protective metal box before installing an mpu: z wear an esd-preventive wrist strap and then loosen the captive screws...

Page 53

3-14 you are recommended to fasten the screws of each module right after you have inserted it. Connecting interface cables cable routing recommendations interface cables and power cords should be separately routed. Reasonable cable routing can improve efficiency by facilitating installation and remo...

Page 54

3-15 connecting the console cable introduction a console cable is an 8-core shielded cable. At one end of the cable is a crimped rj-45 connector that is to be plugged into the console port of a switch. At the other end of the cable is a db-9 (female) connector. You can plug it into the 9-pin (male) ...

Page 55

3-16 connecting the aux cable you need an aux cable when configuring a switch with the remote modem dial-up approach. Introduction an aux cable is an 8-core shielded cable. At one end of the cable is an rj-45 connector that can be plugged into the aux port of the switch. At the other end is db-9 (ma...

Page 56

3-17 z the cabinet is fixed. Z the device is installed. The installation involves the following materials: z ftm z m5×10 self-tapping screws (two screws for one fmt) 2) procedures to install the fiber management tray, proceed as shown in figure 3-17. Step1 align the fmt and the installation holes on...

Page 57

3-18 figure 3-18 lc connector precautions z be sure to install the dust cover if the optical port is not connected to a fiber connector. Z some invisible rays may be emitted from the optical port if the optical port is not connected to a fiber connector or the dust cover is removed. Therefore, never...

Page 58

3-19 connecting power cables each socket on a pem (lstm2pemc6) corresponds to a psu slot. Sockets numbered 1 through 6 provide power supply for the psus in slots 1 through 6, respectively. The input current for each socket of a lstm2pemc6 can be up to 16 a. Make sure to use a matching power receptac...

Page 59

3-20 figure 3-20 pem-2n power cable (1) ot terminal (for connecting the pem-2n) (2) crimped connector (for connecting the cabinet busbar) follow these steps to connect the pem-2n power cables: step1 remove the screws from the panel of the pem-2n, align the ot terminals with the holes of the terminal...

Page 60

3-21 figure 3-22 connect the cramped connectors verifying the installation make sure that you have turned off the power before checking the installation to avoid bodily injury and device damage. After installing the switch, verify the installation against the following list. For the successful insta...

Page 61

3-22 result item yes no remarks switching fabric modules are correctly installed and have a good contact with the backplane. The console cable is correctly connected..

Page 62: Table of Contents

I table of contents 4 commissioning the switch·······················································································································4-1 setting up configuration environment·······························································································...

Page 63: Commissioning The Switch

4-1 4 commissioning the switch setting up configuration environment setting up configuration environment connect a terminal (a pc in this example) to the switch with the console cable. Setting terminal parameters this section describes how to set the terminal parameters. Step1 start the pc, and run ...

Page 64

4-2 figure 4-2 select a port for the hyperterminal connection step4 set serial port parameters. Set the bits per second to 9600, data bits to 8, parity to none, stop bits to 1, and flow control to none. Figure 4-3 set serial port parameters step5 click ok after setting the serial port parameters to ...

Page 65

4-3 figure 4-4 hyperterminal window step6 select properties in the hyperterminal window to access the properties window. Click settings in the window (as shown in figure 4-5), select vt100 for terminal emulation, and click ok. You are recommended to select the windows keys option button..

Page 66

4-4 figure 4-5 set the terminal emulation parameters powering on the switch checklist for switch power-on before powering on the switch, make sure that: z the interface cables, power cables and the grounding cable are correctly connected. Z the power outlet voltage is the same as the one indicated o...

Page 67

4-5 verifying after power-on (recommended) to ensure the configuration works that you will make on the switch, you are recommended to check the switch after powering it on to make sure that: z the cooling system is working. In this case, you can hear the noise caused by fan rotation and feel that th...

Page 68

4-6 board steady testing... [ pass ] board slotno... [ 1 ] subcard exist testing... [ fail ] dx246 testing... [ pass ] phy88e1111 testing... [ pass ] cpld1 testing... [ pass ] cpld2 testing... [ pass ] ns16550 register testing... [ pass ] the default switch's mac address... [00:e0:fc:00:95:12] cf ca...

Page 69

4-7 the s12500 series provide abundant command views. For more information about the configuration commands and the command line interface (cli), see h3c s12500 series routing switches operation manual..

Page 70: Table of Contents

I table of contents 5 maintaining and updating the switch······································································································5-1 maintaining the switch ··················································································································...

Page 71

5-1 5 maintaining and updating the switch maintaining the switch removing the psu psus for the s12500 are hot-swappable. When installing and removing a psu with the device powered on, pay attention to the operation procedures and electricity safety issues. To avoid injury, do not touch any wires, te...

Page 72

5-2 z after hot-plugging a psu, to insert the psu again, you need to wait for at least 30 seconds. Z in view of the height of the switch, make sure the switch is firmly installed and avoid incline of the switch when installing or removing a psu. Z do not touch the rotating fans on a removed psu. Rem...

Page 73

5-3 step1 loosen the captive screws on the air filter and pull the air filter out gently. Step2 wash the air filter using clean water without taking off the black mesh. Take care not to rub the air filter during cleaning and then install it back after drying the air filter. Figure 5-3 remove the air...

Page 74

5-4 figure 5-5 remove the air filter of an s12518 (1) lower fan tray (2) air filter z installing the air filter step1 hold the air filter by two edges and push it gently into the chassis. Step2 fasten the captive screws on the air filter. Figure 5-6 install the air filter of an s12518 removing an lp...

Page 75

5-5 figure 5-7 remove an mpu removing a fan tray z to avoid injury, do not touch any wires, terminals, and parts with a high-voltage hazard sign. Z fan trays are hot-swappable. To replace a fan tray with the device running, pull out the fan tray after it stop rotating. Keep your hands away from the ...

Page 76

5-6 figure 5-8 remove a fan tray removing the interface cover on the mpu currently, the smb coaxial clock interfaces are not supported; therefore, covers are installed on such interfaces to protect them for future use. You can follow these steps to remove the covers in case you may use these smb coa...

Page 77

5-7 figure 5-9 remove an interface cover (1) interface cover (2) spring clips (two) software update do not power off the switch during software update. Recommended update procedure currently the device supports two update approaches: z on the bootware menu. You can select menu items to implement app...

Page 78

5-8 updating applications on the bootware menu z never hot-plug the cf card after you enter the bootware menu. Z a cf card can be used only after the cover of the cf card is installed. Entering the bootware menu after powering on the switch, run bootware program first and the terminal will display t...

Page 79

5-9 phy88e1111 testing... [ pass ] cpld1 testing... [ pass ] cpld2 testing... [ pass ] ns16550 register testing... [ pass ] the default switch's mac address... [00:e0:fc:00:95:12] cf card testing... [ pass ] bootware validating... Press ctrl+b to enter extended boot menu... Z you must press ctrl+b i...

Page 80

5-10 menu item 9 is not supported currently. When loading the host program through the bootware menu, you must configure correct attributes of the serial interface (such as the bits per second, data bit, parity, stop bits, and flow control). Otherwise, the hyperterminal does not respond. For details...

Page 82

5-12 step6 select transfer > send file in the terminal window. Click browse in the pop-up dialog box (shown as the following figure), select the desired application, and change the protocol used for downloading to xmodem. Figure 5-10 send file dialog box step7 click send and the following interface ...

Page 83

5-13 z tftp update procedure step1 connect the switch to a pc where the desired file is located via the management ethernet port. In this case, you should know the ip address of the pc. At the same time, connect the switch to an external pc, which can be the same one that contains the desired file, ...

Page 86

5-16 modifying device working mode modification of the device working mode through the bootware menu is supported only on hosts with the version being release 1221 or above. Follow these steps to modify the device working mode through the bootware menu: step1 select 9 in the bootware menu to enter t...

Page 87

5-17 enter your choice(0-3): 3 chassis id has been changed to 2. The current chassis id is 2. Modifying system working mode follow these steps to modify the system working mode through the bootware menu: step1 select 9 in the bootware menu to enter the product special operation submenu. ============...

Page 89

5-19 updating applications at the cli after logging in to the switch z before updating the software, make sure that you have saved the configurations. Otherwise, these configurations may get lost due to system reboot. Z you must reboot the switch using the reboot command to validate the host program...

Page 90

5-20 no response from srpu serial interface check whether the serial interface cable is in good condition and if its attributes are set correctly (9600 bps). Uploading configuration file or host program using ftp fails please check that z the configuration is correct and if the ftp server is started...

Page 91: Table of Contents

I table of contents appendix a cable management················································································································· a-1 correct use of labels ·················································································································...

Page 92

A-1 appendix a cable management correct use of labels before binding the cables, you should fill in the labels for them correctly and stick them to the right position on the cables. For details, refer to the description of label usage in appendix a engineering labels for cables. Cable management req...

Page 93

A-2 figure a-2 cable binding example ii z bind the cables wherever cable bending cannot be avoided. However, the cable ties cannot be placed inside the bending area in case of the likelihood of cable core break due to excessive stress. See the following figure. Figure a-3 cable binding example iii z...

Page 94

A-3 figure a-4 cable fixing example (1) (1)(2) (3) (1) (1)(2) (3) (1) flat washer (2) spring washer (3) nut z when using a hard power cord, fix it near its terminal so as to free the terminal and the cable from stress; z do not use tapping screws to fasten the connecting terminals; z the power cords...

Page 95: Table of Contents

I table of contents appendix b engineering labels for cables······························································································ b-1 introduction to labels·······················································································································...

Page 96

B-1 appendix b engineering labels for cables engineering labels are affixed to both ends of the various cables to identify the physical positions of cables on different devices. Labels on the cables facilitate correct and orderly connection of cables, and easy maintenance after the installation. The...

Page 97

B-2 figure b-1 label for signal cables (2) 10.0 84.0 1.5 0.6 2.0 1.0 (1) 11.0 11.0 7.5 7.0 5.5 5.5 5.5 5.5 7.0 7.5 37.0 to: (2) (1) (1) dividing line (2) cut dotted line the dividing lines on the label help to specify more clearly the position of a cable. For example, there is one between the cabine...

Page 98

B-3 printing labels the contents can be printed or written on the labels. Printing is recommended for the sake of high efficiency and eye-pleasant layout. Template for the printing the word-form template is available for label printout. You can get the template from h3c local office. When using the ...

Page 99

B-4 after the page setup has been made correct, save it for future use. This page setup is only necessary in the first time you use the template to print the labels. Requirements on feeding the printer different from the ordinary paper, the label paper is composed of two pages. No matter what model ...

Page 100

B-5 figure b-4 writing direction of the label to: affixing labels after printing or writing the label, remove the label from the bottom page and affix it to the signal cable, or the identification plate of the power cable. Affixing the label to the signal cable the steps to affix the label to the ca...

Page 101

B-6 figure b-6 fold up the label cable stick side fold up cable stick side fold to right 3) after the printed part of the label has been folded up, the narrow part of the label should be covered completely, as shown in figure b-7. Figure b-7 appearance of affixed labels on signal cables to: a03 33 3...

Page 102

B-7 figure b-8 appearance of affixed labels on power cables cable to: b03 -48v2 cable to : b 03 - 48v2 information carried on labels for power cables labels for power cables are only affixed on one side of the identification plates. On the labels, there is information (the part after the mark “to:”)...

Page 103

B-8 z since the label paper is made of moistureproof and waterproof material, ink-jet printers and ink pens are forbidden for printing and writing labels. Z labels should be affixed with good order in alignment. Z cable ties should be bundled in the same position of power cables, with identification...

Page 104

B-9 3) the serial number on the hub, the network port number of the agent and the location of stand-alone server should be specified according to actual connection. Example of the label figure b-10 shows the label on the ethernet cable: figure b-10 example of the label on the ethernet cable “a01-03-...

Page 105

B-10 content meaning example mn: cabinet number b: frame number c: physical slot number d: optical interface number the meanings are the same as above. When the local device and the opposite end device are not in the same machine room, mn can be the name of the machine room. Mn-b-c-d-r/t r: optical ...

Page 106

B-11 content meaning example mn: row number and column number of odf numbered in the same rule as that of the cabinets, for example, g01 is the odf of row g and column 01 b: row number of the terminal device c: column number of the terminal device range from 01 to 99, for example, 01-01 odf-mn-b-c-r...

Page 107

B-12 table b-5 information on labels affixed to the dc power cables content meaning mn(bc)--48v1 mn(bc)--48v2 mn(bc)-bgnd mn(bc)-pgnd mn(bc): bc is written right under mn. On the loaded cabinet side, only mn is used to identify the cabinet. On the power cabinet side, mn identifies the row and column...

Page 108

B-13 z in the power distribution box (or the first power cabinet of a row in the transmission machine room), every terminal block on the -48v connector bar has a numeric identification. For example, in the above label of “a01/b08--48v2”, “08” (or sometimes “8”) is the numeric identification of the t...

Page 109

B-14 figure b-14 example of the labels on the ac power cable to: a01 ac to: b01 ac (1) (2) in figure b-14, (1) indicates the label on the loaded cabinet side, which carries the information about the position of the cable on the power socket. (2) indicates the label on the power socket side, which ca...

Page 110: Table of Contents

I table of contents appendix c installation of lightning arrester for ac power·································································· c-1.

Page 111: Power

C-1 appendix c installation of lightning arrester for ac power lightning arrester will not be shipped with the switch. You should purchase it by yourself if needed. If an outdoor ac power cord should be directly led to the switch, please serially connect the lightning arrester for ac power (socket s...

Page 112

C-2 z make sure that the arrester is well grounded before using the lightning arrester for power. Z after inserting ac power cord plug of switch into the socket of lightning arrester, if the green led is on and the red led does not alarm, it means that the lightning arrester of power is running and ...

Page 113: Table of Contents

I table of contents appendix d regulatory compliance information ···················································································· d-1 regulatory compliance standards·········································································································· d-1 euro...

Page 114

D-1 appendix d regulatory compliance information regulatory compliance standards table d-1 regulatory compliance standards discipline standards emc fcc part 15 (cfr 47) class a ices-003 class a vcci-3 class a cispr 22 class a en 55022 class a as/nzs cispr22 class a cispr 24 en 55024 en 61000-3-2 en ...

Page 115

D-2 weee directive–2002/96/ec the products this manual refers to are covered by the waste electrical & electronic equipment (weee) directive and must be disposed of in a responsible manner. Usa regulatory compliance fcc part 15 h3c s12500 series routing switches comply with part 15 of the fcc rules....

Page 116

D-3 canada regulatory compliance ices-003 this class [a] digital apparatus complies with canadian ices-003. Cet appareil numérique de la classe [a] est conforme à la norme nmb-003 du canada. Japan regulatory compliance vcci h3c s12500 series routing switches comply with the requirements of vcci clas...

Page 117: Informationen 安全信息

E-1 appendix e safety information sicherheits informationen 安全信息 overview Überblick 概述 this section introduces part of the safety precautions that should be followed during the installation and maintenance of the equipment. And for the safety statements and warnings, there followed the translations ...

Page 118

E-2 lesen sie bitte alle arbeitsanweisungen und sicherheitvorschriften sorgfältig durch, bevor sie mit dem arbeiten beginnen. Nur durch beachtung dieser hinweise lässt sich das unfallrisiko minimieren. Die in anderen handbüchern aufgeführten symbole anmerkung, achtung, warnung und gefahr beinhalten ...

Page 119

E-3 table e-1 safety symbol and description sicherheitssymbole und beschreibung 安全标识和描述 safety symbol symbole 安全标识 description erläuterung 描述 generic alarm symbol: to suggest a general safety concern alarm: hinweis auf ein generelles sicherheitsproblem 一般注意标识:用于一般安全提示 esd protection symbol: to sugge...

Page 120

E-4 z never defeat the ground conductor or operate the equipment in the absence of a suitably installed ground conductor. Contact the appropriate electrical inspection. Z betreiben sie die ausrüstung niemals ohne erdung. Trennen sie das system nicht von der erdung. Z 不允许破坏设备的接地导线或是在无接地连接的情况下操作设备,要进行...

Page 121

E-5 electricity safety elektrische sicherheit 用电安全 high voltage hochspannung 高电压 high voltage power supply offers electric power for equipment operation. Direct contact or indirect contact (via damp objects) with high voltage and ac mains supply may result in fatal danger. Die hochspannungsleitungen...

Page 122

E-6 z 在潮湿环境下进行安装时,请避免液体进入设备。 non-standard and improper high voltage operations may result in fire and electric shock. Therefore, ac cable bridging and wiring through a certain area must follow the local rules and regulations. The personnel who perform high voltage operations should be qualified for ...

Page 123

E-7 禁止安装和移动带电的线缆。因为导电体和带电的线缆,即使短暂接触,也会引起电火花或电弧,从而 导致失火或是伤害眼睛。 z before the power cable is installed or removed, the power switch must be turned off. Z das system muss stets abgeschaltet werden, bevor die zuleitung angebracht oder entfernt wird. Z 在安装、移动线缆之前,请切断电源。 z before the power cable is connect...

Page 124

E-8 thunderstorm gewitter 防雷击 high voltage and ac operations or operations on a steel tower and a mast on a thunderstorm day are prohibited. In order to prevent the equipment from being damaged by lightning, proper grounding is required. Arbeiten mit hochspannung und wechselstrom oder arbeiten auf s...

Page 125

E-9 使用不适当的电池会有爆炸的危险。更换电池时请使用厂家推荐的同类型号的电池。请根据厂家的说明 书处置废旧电池。 do not dispose of lithium battery in fire entsorgen sie die lithiumbatterien auf keinen fall durch verbrennen! 请勿将锂电池置入火中。 fuse sicherung保险丝 for the safety of continuous operation, please replace the fuse with that of the same type and ratin...

Page 126

E-10 为了产品持续操作的安全,必须更换相同型号和相同规格的保险丝。 z the ac power supply has double pole/neutral fusing。 z das mit wechselstrom betriebene modell hat eine zweiphasen-sicherung. Z ac 输入设备,n 极有保险丝。 laser laser激光辐射 the laser hazard level of this equipment is class 1. Die von diesem laser ausgehende gefahr entspricht ...