- DL manuals

- Hach

- Measuring Instruments

- 2200 PCX

- User Manual

Hach 2200 PCX User Manual

Summary of 2200 PCX

Page 1

Doc023.53.80464 2200 pcx 05/2014, edition 1 user manual.

Page 3: Table of Contents

Table of contents specifications ..............................................................................................................3 general information ..................................................................................................3 safety information....................

Page 4: Troubleshooting

Clean the instrument .................................................................................................. 28 clean the cell .............................................................................................................28 complete a stain cleaning ...........................

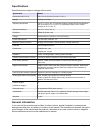

Page 5: Specifications

Specifications specifications are subject to change without notice. Specification details dimensions (w x d x h) 350 x 211 x 178 mm (13.8 x 8.3 x 7.0 in.) weight 4.89 kg (10.78 ibs) operating temperature 0 to 50 °c (32 to 122 °f); maximum relative humidity 80% for temperatures with a maximum of 31 º...

Page 6

Safety information n o t i c e the manufacturer is not responsible for any damages due to misapplication or misuse of this product including, without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent permitted under applicable law. The user is so...

Page 7

Certification canadian radio interference-causing equipment regulation, iecs-003, class a : supporting test records reside with the manufacturer. This class a digital apparatus meets all requirements of the canadian interference-causing equipment regulations. Cet appareil numérique de classe a répon...

Page 8

D a n g e r fire hazard. This product is not designed for use with flammable liquids. The 2200 pcx particle counter is used for drinking water applications. The 2200 pcx does not have data storage capability. The instrument uses a particle counting sensor with a laser-diode. The instrument converts ...

Page 9

Figure 2 system overview 1 particle counter (location “0” = influent) 5 system computer with data collection software 2 particle counter (location “1”) 6 rs485 signal converter with cable to computer 1 3 particle counter (location “2”) 7 rs485 communications cable (beldon 9841 or equivalent) 4 rs485...

Page 10: Installation

Figure 3 product components 1 particle counter with power cord 3 cleaning brush 2 cleaning solution installation w a r n i n g multiple hazards. Only qualified personnel must conduct the tasks described in this section of the document. Installation guidelines install the instrument: • as near the sa...

Page 11

This instrument is rated for an altitude of 2000 m (6562 ft) maximum. Use of this instrument at an altitude higher than 2000 m can slightly increase the potential for the insulation to breakdown, which can result in an electric shock hazard. The manufacturer recommends that users with concerns conta...

Page 12

Connect the sample stream install the sample line into a larger process pipe to minimize interference from air bubbles or pipeline bottom sediment. A sample line that goes into the center of a process pipe is best. Figure 5 shows examples of good and bad methods of sample line installation into a pr...

Page 13

13. Put the other end of the 12-in. Length of ¼-in. Black flexible tubing into the hole of the adjustment cap. Make sure that the end of the tubing is 6.4 mm (0.25 in.) inside the cap. Refer to figure 6 , item 4. 14. Install the drain line on the water weir. Install a clear ½-in. I.D. Hose over the ...

Page 14

Measure the flow rate set the distance from the overflow to the bottom of the adjustment cap to 832 mm (33 in.) for a flow rate approximately 100-ml/min. Move the adjustment cap up to decrease the flow. Move the adjustment cap down to increase the flow. The flow rate changes about 1 or 2 ml per minu...

Page 15

D a n g e r electrical shock and fire hazards. Make sure to identify the local disconnect clearly for the conduit installation. D a n g e r electrocution hazard. If this equipment is used outdoors or in potentially wet locations, a ground fault circuit interrupt (gfci/gfi) device must be used for co...

Page 16

Figure 8 wiring preparation connect rs485 communications set up an rs485 serial network to connect multiple instruments and a controlling computer. The total distance from the rs485 signal converter to the farthest instrument can be a maximum of 1219.20 m (4000 ft) without an amplifier/repeater. Ref...

Page 17

Figure 9 particle counters wiring 1 wiring for multiple instrument systems 4 rs485 signal converter with cable to computer 2 wiring for last instrument in multiple instrument system 5 rs485 shielded cable (beldon 9841 or equivalent) 3 terminated jp1 jumper configuration for last instrument 6 open jp...

Page 18

Figure 10 analog input wiring 1 connect shunt resistor between voltage input and analog ground (aingnd) 3 0 to 5 vdc or 0 to 10 vdc from other devices. Connect wires to ain2-ain7 and braided shield to aingnd. 2 voltage inputs configured to accept 4-20 ma inputs 4 4-20 ma wires from other devices. Co...

Page 19

Figure 11 analog output wiring 1 analog input card 5 optional external loop power, 15-24 vdc (150 ma) 2 jumper position (internal loop power) 6 wires from analog output terminals (out0-out7) 3 jumper position (external loop power) 7 analog connections on plc, scada 4 interconnect card english 17.

Page 20: Startup

Connect a junction box use junction boxes to connect instruments in a rs485 network. With an installed junction box, remove or install the instrument from or to the network without network integrity interruption. Connect wires from the rs485 cables (belden 9841 or equivalent) as shown in figure 12 ....

Page 21: Operation

Figure 13 front panel description 1 counting led 4 clean sensor led 2 power led 5 count display window 3 alarm led table 1 status indicators indicator description counting led comes on during the count cycle. Power led comes on when the instrument power is set to on. Alarm led comes on when the alar...

Page 22

6. Close the setup screen and go to the terminal. Note: make sure that only one instrument is connected during the setup. 7. Make sure that the correct com port is selected. 8. Click on "send lead command". Do not confirm with ok . 9. Set the instrument power to off. Wait 2 seconds and set the instr...

Page 23

Table 2 operating parameter selection (continued) menu number command line message description 5 enter lower size specify the particle size range (for front panel numerical display units only). Do not set a lower size to less than 2 microns. Enter upper size (0 for cumulative) specify the largest pa...

Page 24

Necessary to change to on again. Set the analog connection to on. Do not continue until it is on. Note: set all analog inputs to on, even if they are not in use to prevent operation problems. Configure the analog output connection it is possible to configure a maximum of eight analog output signals ...

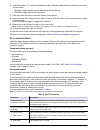

Page 25

Table 3 sample size reference table (flow = 100 ml/min) count period (seconds) sample size (ml) count period (seconds) sample size (ml) 6 10 24 40 12 20 30 50 15 25 48 80 18 30 60 100 table 4 divisors for full scale value determination (> 2µm) channel divisor channel divisor channel divisor >3µ 3.4 ...

Page 26

6. Type the number “7” to start the calibration mode. Calibration data and two instruction lines show on the monitor. • space—toggles analog outputs between 4 ma and 20 ma • return—goes back to the main menu 7. Push the space bar once to start the system (current flow). 8. Push the space bar to togg...

Page 27

Table 6 ascii commands (continued) command description “e” send eprom revision the counter sends the eprom number and revision. “k” sensor cal curve the calibration curve is put (or verified) in memory. “m” mode request the counter sends the present mode: counting, a “c” is sent. Holding, an “h” is ...

Page 28

Table 7 example for a count alarm change information description date the date information is transmitted in the third through eighth characters of the record. The second character is always a space to set apart the status character from the date characters. The date format is mmddyy (month day year...

Page 29: Maintenance

Table 8 serial communications format (continued) information type example code description analog input fields input a an0 001730 the first three characters are the tag and the remaining characters are the value for that tag. Input b an1 002481 service information calibration cal 001000 location loc...

Page 30

Clean spills c a u t i o n chemical exposure hazard. Dispose of chemicals and wastes in accordance with local, regional and national regulations. 1. Obey all facility safety protocols for spill control. 2. Discard the waste according to applicable regulations. Clean the instrument clean the exterior...

Page 31

Figure 14 cell cleaning complete a stain cleaning complete the stain cleaning procedure when the cell cleaning procedure was not successful and the clean sensor fail indicator is still on. The cell is possibly chemically stained. 1. Disconnect the instrument from the normal on-line flow path. 2. Sel...

Page 32: Troubleshooting

Replace the flow cell the flow cell is not user replaceable. Contact technical support for replacement. Replace the tubing if the sample conditions are bad, change the tubing as often as necessary. Refer to maintenance schedule on page 27 for recommendations for the tubing change. Prepare the instru...

Page 33

Problem possible cause solution instrument does not communicate to the computer. Lightning or a power surge can blow communications chips. Connect directly to the pcx with rs232 programming kit cable, disconnect from rs485 network, cycle power and scan with advanced crts. Rs485 converter or computer...

Page 34

Replacement parts (continued) description item no. Power supply, pcx standard 120 vac 770013 plunger (for cover latch) 590901 terminal strip, orange, 3 pos. 5702901 terminal strip, orange, 4 pos. 970080 terminal strip, orange, 5 pos. 970086 tubing, tygon, ¼ in. Od 1 / 8 in. Id (per ft) 960024 tubing...

Page 36

Hach company world headquarters p.O. Box 389, loveland, co 80539-0389 u.S.A. Tel. (970) 669-3050 (800) 227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com hach lange gmbh willstätterstraße 11 d-40549 düsseldorf, germany tel. +49 (0) 2 11 52 88-320 fax +49 (0) 2 11 52 88-210 info@h...