- DL manuals

- Hach

- Laboratory Equipment

- TU5200

- User Manual

Hach TU5200 User Manual

Summary of TU5200

Page 1

Doc342.53.80489 tu5200 03/2017, edition 3 user manual.

Page 3: Table of Contents

Table of contents specifications .............................................................................................................. 3 general information .................................................................................................. 4 safety information..................

Page 4: Verification

Calibrate the instrument ............................................................................................. 26 verification .................................................................................................................. 27 configure the verification settings ..............

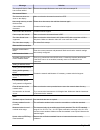

Page 5: Specifications

Specifications specifications are subject to change without notice. Specification details measurement method nephelometry with the scattered light collected at a 90° angle to the incident light and 360° around the sample vial. Primary compliance method din en iso 7027 dimensions (w x d x h) 41 x 28 ...

Page 6: General Information

Specification details verification (rfid or link2sc ® ) process and laboratory measurements are compared with rfid or link2sc for verification of the measurement value. Certifications ce compliant; us fda accession number: 1420492-xxx. This product complies with iec/en 60825-1 and to 21 cfr 1040.10 ...

Page 7

Precautionary labels read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary statement. Electrical equipment marked with this symbol may not be disposed o...

Page 8

This instrument is a class 1 laser product. There is invisible laser radiation when the instrument is defective and when the instrument lid is open. This product complies with en 61010-1, "safety requirements for electrical equipment for measurement, control and laboratory use" and with iec/en 60825...

Page 9

Table 1 registration information parameter value fcc identification number (fcc id) yuh-qr15hl ic 9278a-qr15hl frequency 13.56 mhz certification canadian radio interference-causing equipment regulation, iecs-003, class a: supporting test records reside with the manufacturer. This class a digital app...

Page 10

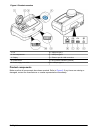

Figure 1 product overview 1 lid 6 usb port type a 2 vial compartment 7 usb port type b 3 display 8 ethernet port for lan connection 4 power button 9 rfid module indicator (optional) 5 power supply connection 10 usb port type a product components make sure that all components have been received. Refe...

Page 11: Installation

Figure 2 product components 1 tu5200 4 power supply with adapters 2 stablcal kit, sealed vials with rfid (10, 20 and 600 ntu) 5 dust cover 3 sample vials 6 vial stand installation c a u t i o n multiple hazards. Only qualified personnel must conduct the tasks described in this section of the documen...

Page 12

Usb type a port—connect to a printer, barcode handset scanner, usb flash drive, keyboard 2 or sip 10 module. Usb type b port—not used. Ethernet port—connect to a lan with a shielded cable (e.G., stp, ftp, s/ftp). The maximum length of the shielded cable is 20 m (65.6 ft). To identify if a lan connec...

Page 13: Startup

Table 2 sidebar menu icons icon description login logs in or logs out an operator. To log in, select an operator id and then push login. To log out, push logout. Note: when an operator is logged in, the login icon changes to the icon selected for the operator id (e.G., fish, butterfly or soccer ball...

Page 14: Operation

C a u t i o n personal injury hazard. Do not look into the vial compartment when the instrument is connected to power. Refer to the illustrated steps that follow to connect power to the instrument and start the instrument. When the language menu shows, select the language and then push ok. The self-...

Page 15

Option description network & peripherals shows the connection status of the devices that are directly connected to the instrument and connected to the instrument by lan (local area network). • printer—local printer or network printer • network—lan connection • controller—sc controller(s) • pc • usb ...

Page 16

Configure an operator rfid tag (optional) to use an operator rfid tag to log in to the instrument, save the applicable operator id to an operator rfid tag as follows: 1. Push login. 2. Select the operator id, then push options>initialize rfid tag. 3. Enter the password for the operator id as necessa...

Page 17

1;aeration;13.09.2015 10:03 2;outlet;13.09.2015 06:30 3;feed;13.09.2015 18:00 note: the date of sample collection is optional. 4. Make a new folder on a usb flash drive. Give the folder the name "sampleid". 5. Save the spreadsheet file to the sampleid folder as a csv (comma-separated value) or txt (...

Page 18

4. Select an option. Option description % sets the acceptance range to a percentage (1 to 99%). Ntu sets the acceptance range to ntu units (0.015 to 100.00 ntu). 5. Push value, then enter the acceptance range. Set up a lan connection the manufacturer recommends that a network administrator does this...

Page 19

4. Push network server. 5. To connect to a folder on an ftp server, do the steps that follow. A. Select ftp. B. Push ftp server. 6. To connect to a folder on a netdrive, do the steps that follow. A. Select netdrive. B. Push netdrive setup. 7. Select an option. Option description ip-address selects t...

Page 20

4. Push add. 5. To enter the ip address of the sc controller, do the steps that follow. A. Select ip-address. B. Push ip-address, then enter the ip address of the sc controller. 6. To enter the host name of the sc controller, do the steps that follow. A. Select hostname. B. Push hostname, then enter...

Page 21

Figure 4 sample vial overview 1 measurement surface—do not touch. Prepare a sample vial c a u t i o n chemical exposure hazard. Dispose of chemicals and wastes in accordance with local, regional and national regulations. N o t i c e always put a cap on the sample vial to prevent spills in the vial c...

Page 22

Put the vial in the instrument c a u t i o n personal injury hazard. Never remove covers from the instrument. This is a laser-based instrument and the user risks injury if exposed to the laser. C a u t i o n personal injury hazard. Do not look into the vial compartment when the instrument is connect...

Page 23

Measure the sample 1. Push read if a measurement does not start automatically when the lid is closed. 2. When the measurement is complete, push options>store to record the measurement to the reading log as necessary. Note: if the auto save setting is set to on, "data stored" shows on the display and...

Page 24

• glass sample bottle with a sample rfid sticker • operator rfid tag (optional) 1. At the process instrument, put the operator rfid tag (if available) near the rfid module. 2. Put a sample rfid sticker on the sample bottle. 3. Collect a grab sample. Refer to collect a grab sample on page 21. 4. At t...

Page 25

1. Collect a grab sample. Refer to collect a grab sample on page 21. 2. If the sc controller and laboratory instrument do not have a lan connection, install the sd card in the sc controller. Refer to the sc controller documentation to install the sd card. 3. At the sc controller, make a link2sc job ...

Page 26

Configure the link2sc settings select the acceptance range permitted when process and laboratory measurements are compared with link2sc. 1. Push menu. 2. Select sensor setup>tu5x00 sc>link2sc. 3. Select an option. Option description accept. Unit sets the units used to compare the process and laborat...

Page 27

B. Select an option. Option description delete removes one of the items that follow. • the selected log entry • the log entries for a time interval • the log entries with a specific operator id • the log entries with a specific sample id 8 • all the entries in the selected log send data sends one of...

Page 28: Calibration

Calibration w a r n i n g chemical exposure hazard. Obey laboratory safety procedures and wear all of the personal protective equipment appropriate to the chemicals that are handled. Refer to the current safety data sheets (msds/sds) for safety protocols. The instrument is factory calibrated and the...

Page 29: Verification

4. Clean the vial with a no-lint cloth to remove contamination. Keep contamination off the glass. Refer to prevent vial contamination on page 18. 5. Dry the external surfaces of the vial with a no-lint cloth. Make sure to dry the bottom of the vial. 6. Carefully invert at least three times. Refer to...

Page 30: Maintenance

Option description verify after cal. Sets the instrument to start a verification immediately after the instrument is calibrated. When set to on, the verification standard is measured immediately after a calibration is done. Default: on. Acceptance range sets the maximum difference permitted between ...

Page 31

C a u t i o n personal injury hazard. Never remove covers from the instrument. This is a laser-based instrument and the user risks injury if exposed to the laser. N o t i c e do not disassemble the instrument for maintenance. If the internal components must be cleaned or repaired, contact the manufa...

Page 32: Troubleshooting

6. For storage, fill the sample vial with distilled or demineralized water. Note: if the sample vial is used to measure low range turbidity samples or dilution water, fill the sample vial with dilution water (not distilled or deionized water). 7. Immediately put the cap on the sample vial to keep th...

Page 33

Message solution next calibration is due! Calibrate the instrument. Refer to calibrate the instrument on page 26. Note: the calibration reminder is set to on. Refer to configure the calibration settings on page 26. Next service is due! Contact technical support. Note: the service reminder is set to ...

Page 34

Message solution instrument update copy from usb memory failed remove large files from the usb flash drive that use too much space. Start the instrument update procedure again. Remove the instrument update files from the usb flash drive. Save the instrument update files again to the usb flash drive....

Page 35

Message solution the sample id list full. Data has not been added remove the sample ids that are not used. Add a new sample id. Documents/videos the document does not show on the display. Make sure that the document is saved as a pdf. Not enough memory to store the document. Delete other documents, ...

Page 36

Message solution measured with different calibration. Read standard? The verification standard was measured for a different calibration curve (e.G., stablcal, formazin, sdvb, degrees or custom). Measured with different instrument type. Read standard? The verification standard was measured on a diffe...

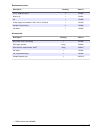

Page 37

Replacement parts description quantity item no. Cover, usb port type a 1 lzv881 dust cover 1 lzv947 lid 1 lzv968 power supply with adapters, 100 to 240 v, 50/60 hz 1 lzv798 sample vials with caps 2 lzv946 vial stand 1 lzv952 accessories description quantity item no. Micro fiber cloth, vial cleaning ...

Page 38

36 english.

Page 40

Hach company world headquarters p.O. Box 389, loveland, co 80539-0389 u.S.A. Tel. (970) 669-3050 (800) 227-4224 (u.S.A. Only) fax (970) 669-2932 orders@hach.Com www.Hach.Com hach lange gmbh willstätterstraße 11 d-40549 düsseldorf, germany tel. +49 (0) 2 11 52 88-320 fax +49 (0) 2 11 52 88-210 info-d...