- DL manuals

- Hafco

- Saw

- BS-460AS

- Instruction Manual

Hafco BS-460AS Instruction Manual

Summary of BS-460AS

Page 1

Instruction manual bs-460as dual mitre, swivel head metal cutting band saw (415v) 600 x 440mm (w x h) rectangle b035 1 instruction manual for bs-460as (b035) 31/03/2016.

Page 2

Table of contents 1 accident prevention and safety regulation .................................................................. 1 1.1 advice for the operator......................................................................................................................... 1 1.2 the electrical...

Page 3

- in the event of a power cut, the specific start-up button must be reset. 1 accident prevention and safety regulation - the machine has been tested in conformity with point 20 of en 60204 this machine has been designed to comply with national and community accident- prevention regulations. Improper...

Page 4

2 machine transportation and installation 2.1 machine dimensions 2.2 transporting the machine 2.3 minimum requirements for housing the machine - main voltage and frequency must comply with the machine’s motor requirements. - environment temperature should fall within (-10ºc to + 50 ºc). - relative h...

Page 5

Remove mobile cover by lift handle up and pull it out from the base as showing direction. 2.5 install the outlet tray, length stop device and mobile coolant trays. Install the outlet tray and stop bar on to the machine after setting up the machine already as below steps: 1. Assemble the new outlet t...

Page 6

D. Operation mode switch – selects either automatic or manual operation mode. 2.8 deactivation of machine if the machine is to be out of use for a long period, it is advisable to proceed as follows: d1. Manual operation mode – press switch d until the manual mode’s indicator light shows up. 1) disco...

Page 7

3.3 the saw bow machine parts consisting of drive members (gear motor, variable speed motor, and flywheels), tightening and guide (bladetightening slide, blade guide blocks) of tool. 3.4 the vise system a hydraulic vise is used for clamping work material. Each of the vises has a miter slot, which is...

Page 8

3.10 open blade cover safety device when blade cover is open, close the blade cover as instructed below: 1. Use one hand on the cover handle to hold the blade cover. 2. Use the other hand to push in the safety plate (fig. A), so the bracket will release (fig. B). 3. Lower the cover down slowly and c...

Page 9

4.2 thrust roller adjustment 1. Disconnect machine from the power source. 2. Loosen two hex socket cap screws (x) 3. Move guide seat (y) up or down until a clearance of .003" to .005" between back of blade and thrust roller is obtained. 4. Tighten two hex socket cap screws (x). 5. Repeat for other b...

Page 10

4.6 blade tracking adjustment (hydraulic blade tension type) this adjustment must be accomplished by qualified personnel that are familiar with this type of adjustment and the dangers associated with it. The blade tracking has been set by factory and should not require any adjustment. If a tracking ...

Page 11

- check that the saw bow is raised to clear the vise fixed vise jaw. This machine is equipped with a numeral switch q to set the saw bow an efficient return height. If cutting lots of pieces, set the saw bow’s return stroke height switch according to the work-piece’s diameter will reduce the overall...

Page 12

- disconnect the machine from power supply. - open the belt cover. Remove 4 screws from the top. Remove 1 screw from the front. Remove 8 screws from the cover. - turn the dial counter-clockwise to open the pulley discs and loosen the belt. - replace the belt. - turn the dial to pretension the belt. ...

Page 13

- remove the old blade from both wheels and out of each blade guide. Caution: even dull blades are sharp to the skin! Use extra caution handling band saw blades! - position the blade and making sure that the teeth are pointed downward in the cutting direction. - position the blade on the wheels. Twi...

Page 14

- turn off the hydraulic pump. - attach the hydraulic hose to connecter (b) and then attach the quick link connecter (j) to the 90-degree fitting. - switch on the hydraulic pump. 6 operation cycle 6.1 operation cycle 6.2 stopping or emergency stopping there are two ways to stop the machine in an eve...

Page 15

7 routine and special maintenance the maintenance jobs are listed below, divided into daily, weekly, monthly and six-month intervals. If the following operations are neglected, the result will be premature wear of the machine and poor performance. 7.1 daily maintenance - give general cleaning to the...

Page 16

8 technical characteristics 8.1 table of cutting capacity and technical details 14 8.2 noise tests the test was held under environmental noise levels of 65db. Noise measurements with the machine operating unload was 71db. Noise level during the cutting of mild carbon steel was 73db. Note: with the m...

Page 17

17 instruction manual for bs-460as (b035) 31/03/2016.

Page 18

18 instruction manual for bs-460as (b035) 31/03/2016.

Page 19

19 instruction manual for bs-460as (b035) 31/03/2016.

Page 20

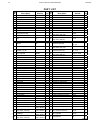

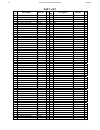

Part list part no. Description size no. Q’ty part no. Description size no. Q’ty 1 base 1 54 fuse seat 10x38-1p 2 2 hex. Cap bolt m8x20 12 55 fuse seat ask2s/(5x20-1p) 3 3 spring washer m8 12 55a fuse seat (not shown, non ce) 6x30-1p 3 4 washer m8 12 56 transformer ce-250va 1 5 supporter 1 57 relay p...

Page 21

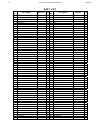

Part list part no. Description size no. Q’ty part no. Description size no. Q’ty 92 handle m8x30 1 144 hex. Socket cap screw m8x20 8 93 swiveling base 1 145 hex. Cap bolt m5x15 1 94 set screw m8x20 2 146 wire connecter 1 95 nut m8 2 147 swiveling 1 96 connect base 1 148 shaft 1 96-1 spring washer m8 ...

Page 22

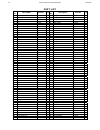

Part list part no. Description size no. Q’ty part no. Description size no. Q’ty 195 adjusting part 1 247 spring washer m10 4 196 set screw m8x8 2 248 washer m10 4 197 c ring s17 2 249 set screw m8x16 6 198 shaft 1 250 adjustable bracket-left 1 199 key 5x5x20 1 251 lock handle m12x50 2 200 cam 1 252 ...

Page 23

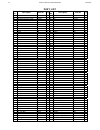

Part list part no. Description size no. Q’ty part no. Description size no. Q’ty 292 drive wheel 1 347 bearing 51203 1 293 washer 1 348 bolt sleeve 1 294 flat head hex. Soc. Screw m12x25 1 349 key 5x5x30 1 295 hex. Socket cap screw m12x70 4 350 set screw m8x10 1 296 washer 1 351 handle wheel 1 297 up...

Page 24

Part list part no. Description size no. Q’ty part no. Description size no. Q’ty 402 hex. Socket cap screw m6x20l 4 458 set screw 5/16”x5/16”l 1 403 adjusting knob 2 459 washer 1 404 spring 2 460 spring washer 3/8” 1 405 shaft 2 461 hex. Socket cap screw 3/8”x1”l 1 406 hex. Socket cap screw m8x40l 2 ...

Page 25

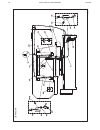

Ue-460dsa 1000307-v4 25 instruction manual for bs-460as (b035) 31/03/2016.

Page 26

Ue-460dsa 1000307-v3 26 instruction manual for bs-460as (b035) 31/03/2016.

Page 27

Ue-460dsa 1000307-v3 27 instruction manual for bs-460as (b035) 31/03/2016.

Page 28

Ue-460dsa 1000307-v3 28 instruction manual for bs-460as (b035) 31/03/2016.

Page 29

Ue-460dsa 970912-v2 29 instruction manual for bs-460as (b035) 31/03/2016.

Page 30

Ue-460dsa 1000622-v1 30 instruction manual for bs-460as (b035) 31/03/2016.