- DL manuals

- Haier

- Air Conditioner

- 3U19FS1ERA

- Service Manual

Haier 3U19FS1ERA Service Manual

Commercial Air Conditioning

SERVICE MANUAL

MULTI upgrade series

Models

Indoor: AB09CS1ERA

AB12CS1ERA

AB18CS1ERA

AB24ES1ERA

AC12CS1ERA

AC18CS1ERA

AC24CS1ERA

AD09LS1ERA

AD12LS1ERA

AD18LS1ERA

AD24LS1ERA

Outdoor: 3U19FS1ERA

4U25HS1ERA

4U30HS1ERA

5U34HS1ERA

z

DC inverter technology, high energy efficiency, higher EER A+, energy

saving for the user

z

Universal indoor units for multi upgrade series, Unitary smart DC inverter

and HAIER DAC split inverter type

z

High voltage communication, convenient wiring work

z

Multiple control types

z

10℃ constant temperature control

z

Universal power supply for 50Hz and 60Hz

z

Central control function available

z

New friendly refrigerant R410a, zero ODP, environment protection

Manual code: SYJS-017-10REV.0

Edition: 2010-12-10

Summary of 3U19FS1ERA

Page 1

Commercial air conditioning service manual multi upgrade series models indoor: ab09cs1era ab12cs1era ab18cs1era ab24es1era ac12cs1era ac18cs1era ac24cs1era ad09ls1era ad12ls1era ad18ls1era ad24ls1era outdoor: 3u19fs1era 4u25hs1era 4u30hs1era 5u34hs1era z dc inverter technology, high energy efficienc...

Page 2: Contents

>_]]vbtzr\ _^uzdz_^vb -2- contents contents……………………………………………………….....2 1. Description of products & features………………………….3 2. Specification…………………………………………………...6 3. Dimensions…………………………………………………....21 4. Pipe and wiring installation…..……………………………....26 5. Pcb photo, wiring diagram and function descri...

Page 3

-3- .9773:1506 -5: .9825;5983: 1.Description of products & features 1.1. Products code explanation 3 u 19 f s 1 e r a climate type: t1 (see table 1) frequency type: dc inverter product type: a stands for heat pump type, refrigerant is r22 b stands for heat pump type, refrigerant is r407c e stands fo...

Page 4

Commercial air conditioner -4- 1.4 product features dc inverter technology, high energy efficiency, higher eer a+, energy saving for the user the outdoor unit adopts dc inverter compressor and motor, so save power energy is just to save you have already installed the air conditioner, if you want to ...

Page 5

Commercial air conditioner -5- on the operation panel. Then according to the failure code chart, you can eliminate the failure soon. Central control function, if connected with a central controller that is convenient for building management. Weekly timing function, if connected with a weekly timer u...

Page 6

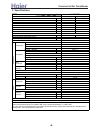

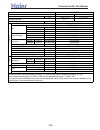

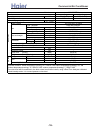

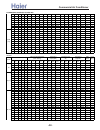

2. Specifications -6- >_]]vbtzr\ _^uzdz_^vb cooling heating w 5400 6500 w 1410 1520 a 6.13 6.6 w/w 3.84 4.28 w 1500 1800 w 500 500 w 7000 8100 w 2600 2600 a / a 11.3 11.3 99% 99% a winding resistance(at 20℃) Ω motor speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm fac...

Page 7

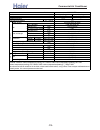

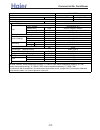

-7- >_]]vbtzr\ _^uzdz_^vb cooling heating w 7600 8600 w 2100 2060 a 9.1 9.0 w/w 3.62 4.18 w 1500 1800 w 550 550 w 9000 9500 w 3500 3500 a / a 15.2 15.2 99% 99% a winding resistance(at 20℃) Ω motor speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² external ...

Page 8

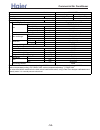

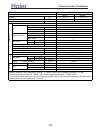

>_]]vbtzr\ _^uzdz_^vb -8- cooling heating w 8100 9800 w 2220 2430 a 9.7 10.6 w/w 3.65 4.03 w 1500 1800 w 550 550 w 9800 10500 w 3800 3800 a / a 16.5 16.5 99% 99% a winding resistance(at 20℃) Ω motor speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² externa...

Page 9

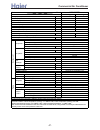

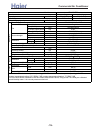

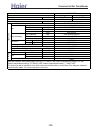

-9- >_]]vbtzr\ _^uzdz_^vb cooling heating w 10000 10700 w 2940 2850 a 12.8 12.4 w/w 3.4 3.75 w 1500 1800 w 550 550 w 11000 11500 w 4000 4000 a / a 17.4 17.4 99% 99% a winding resistance(at 20 ℃) Ω motor speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² ext...

Page 10

>_]]vbtzr\ _^uzdz_^vb -10- -7- cooling heating kw 2.6 2.9 0.71 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg external ( l×w×h) mm×mm×mm package ( l×w×h) mm×mm×mm kg / kg refrigerant mm mm norminal condition: indoor temperature (cooling): ...

Page 11

>_]]vbtzr\ _^uzdz_^vb -11- cooling heating kw 2.6 2.9 0.71 / 10‐³×m³/h r/min kw m³/h pa mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg refrigerant mm mm norminal condition: indoor temperature (cooling): 27℃db/19℃wb, indoor temperature (heating): 20℃db outdoor tempe...

Page 12

-12- >_]]vbtzr\ _^uzdz_^vb cooling heating kw 3.5(0.9--4.5) 3.7(1.0---4.8) 0.71 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg external ( l×w×h) mm×mm×mm package ( l×w×h) mm×mm×mm kg / kg refrigerant mm mm connecting method φ6.35(1/4) normin...

Page 13

>_]]vbtzr\ _^uzdz_^vb -13- cooling heating kw 3.5(0.9--4.5) 3.9(1.0---4.8) 0.71 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg refrigerant mm mm φ6.35(1/4) r410a item model ac12cs1era 1.6 1ph,220-230v 50-60hz indoor unit fan centrifugalx2 ...

Page 14

>_]]vbtzr\ _^uzdz_^vb -14- cooling heating kw 3.5(0.9--4.5) 4.0(1.0---4.8) 0.71 10‐³×m³/h r/min kw m³/h pa mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg refrigerant mm mm norminal condition: indoor temperature (cooling): 27℃db/19℃wb, indoor temperature (heating): ...

Page 15

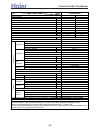

>_]]vbtzr\ _^uzdz_^vb -15- cooling heating kw 5.0(1.8--5.8) 5.2(2.0---6.5) 0.71 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg external ( l×w×h) mm×mm×mm package ( l×w×h) mm×mm×mm kg / kg refrigerant mm mm 680/620/500 inner grooved pipe/φ7...

Page 16

>_]]vbtzr\ _^uzdz_^vb -16- cooling heating kw 5.0(1.8--5.8) 5.5(2.0---6.5) 0.71 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm kw db(a) kg / kg refrigerant mm mm connecting method control type (remote /wired) liquid gas norminal condition: indoor temperatu...

Page 17

>_]]vbtzr\ _^uzdz_^vb -17- cooling heating kw 5.0(1.8---6.0) 5.5(2.0---6.2) 0.73 / 10‐³×m³/h r/min kw m³/h pa mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm db(a) kg / kg refrigerant mm mm norminal condition: indoor temperature (cooling): 27℃db/19℃wb, indoor temperature (heating): 20℃...

Page 18

>_]]vbtzr\ _^uzdz_^vb cooling heating kw 6.5(2.0---7.3) 7.1(2.5--8.0)) 0.72 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm mm db(a) kg / kg external ( l×w×h) mm×mm×mm package ( l×w×h) mm×mm×mm kg / kg refrigerant mm mm pb-950jb (white) connecting method pipin...

Page 19

>_]]vbtzr\ _^uzdz_^vb cooling heating kw 6.3(2.0-7.3) 7.1(2.5-8.0) 0.72 / 10‐³×m³/h r/min kw m³/h mm m² ℃ external (l×w×h) mm×mm×mm package (l×w×h) mm×mm×mm mm db(a) kg / kg refrigerant mm mm norminal condition: indoor temperature (cooling): 27℃db/19℃wb, indoor temperature (heating): 20℃db outdoor t...

Page 20

>_]]vbtzr\ _^uzdz_^vb cooling heating kw 6.8(2.0---7.6) 7.1(3.0---8.3) 0.72 / 10‐³×m³/h r/min kw m³/h pa mm m² ℃ external ( l×w×h) mm×mm×mm package ( l×w×h) mm×mm×mm mm db(a) kg / kg refrigerant mm mm 1ph,220-230vac,50hz 1174*549*294 1200/1050/850(white terminal 0 pa) inner grooved pipe/φ7 piping ty...

Page 21

>_]]vbtzr\ _^uzdz_^vb 3. Dimension 3u19fs1era: air outlet air inlet air inlet handle liquid pipe:Ø6.35(flared)1/4 gas pipe :Ø9.52(flared)3/8 liquid pipe:Ø6.35(flared)1/4 gas pipe :Ø9.52(flared)3/8 liquid pipe:Ø6.35(flared)1/4 gas pipe :Ø9.52(flared)3/8 } } } a unit connection b unit connection c uni...

Page 22

>_]]vbtzr\ _^uzdz_^vb 5u34hs1era: 340 6 21 49 liquid pipe Ø6.35(flared) 1/4 gas pipe Ø9.52(flared) 3/8(a,b,c,d unit) Ø12.7(flared) 1/2(e unit) d unit connection c unit connection b unit connection a unit connection handle 311 408 28 73 45 405 840 948 indoor and outdoor connect wiring hole 537 (30*48...

Page 23

>_]]vbtzr\ _^uzdz_^vb b9 a9 :;9 hgfi d >tt 7kn[^nnu z\zwnuzrvu wvsnz8 myjrujpn wrwn pjz wrwn srx\rm wrwn >@9tt 7rumvvy \ur[ mrtnuzrvu8 ?>9tt 7lnrsrup vwnurup mrtnuzrvu8 @99tt 7wjuns mrtnuzrvu8 >@9tt 7rumvvy \ur[ mrtnuzrvu8 ?>9tt 7lnrsrup vwnurup mrtnuzrvu8 @99tt 7wjuns mrtnuzrvu8 hgfi d :=9 :a9 oynz...

Page 24

>_]]vbtzr\ _^uzdz_^vb =mpqbkkbqjnm ejlfmpjnm8+ll, t u v w x y z [ \ 72. 00. 256 00. :fjkjmh dnmdfbkfe qsof rmjq8 -24- ad092ls1era ad122ls1era ad142ls1era ad182ls1era ad092ls1era ad122ls1era ad142ls1era ad182ls1era.

Page 25

>_]]vbtzr\ _^uzdz_^vb view d view b view c view c view b view d 740 (hanging position) 860~890 (ceiling hole) 740 (hanging position) 860~890 (ceiling hole) view a view a 1000 over ov er ove r ov er ove r cassette type unit: ab24 -25-.

Page 26

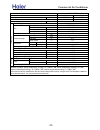

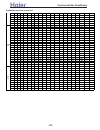

4. Pipe and wiring installation >_]]vbtzr\ _^uzdz_^vb 4.1 multi combination and the data 3u19fs1era combination and the data cooling eer (w/w) unit a unit b unit c unit a unit b unit c min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — 2...

Page 27

>_]]vbtzr\ _^uzdz_^vb 4u25hs1era combination and the data cooling eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — — 2.0 — — — 1.00 2.00 2.80 0.50 0.56 1.30 2.22 2.48 5....

Page 28

>_]]vbtzr\ _^uzdz_^vb heating eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — — 2.3 — — — 1.00 2.30 4.00 0.55 0.60 1.50 2.44 2.66 5.80 3.83 a 9 — — — 2.9 — — — 1.00 2.9...

Page 29

>_]]vbtzr\ _^uzdz_^vb 4u30hs1era combination and the data cooling eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — — 2.0 — — — 1.00 2.00 2.80 0.50 0.56 1.30 2.22 2.48 5....

Page 30

>_]]vbtzr\ _^uzdz_^vb heating eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — — 2.3 — — — 1.00 2.30 4.00 0.55 0.60 1.50 2.44 2.66 5.80 3.83 a 9 — — — 2.9 — — — 1.00 2.9...

Page 31

>_]]vbtzr\ _^uzdz_^vb 5u34hs1era combination and the data cooling eer (w/w) unit a unit b unit c unit d unit e unit a unit b unit c unit d unit e min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 — — — — 2.0 — — — — 1.00 2.00 2.80 0.50 0.65...

Page 32

>_]]vbtzr\ _^uzdz_^vb 7 9 12 12 — 1.74 2.17 3.04 3.04 — 1.80 10.00 10.80 0.55 2.96 4.00 2.50 13.13 19.00 3.38 a 7 12 12 12 — 1.60 2.80 2.80 2.80 — 1.80 10.00 11.00 0.55 2.96 4.00 2.50 13.13 19.00 3.38 a 9 9 9 9 — 2.50 2.50 2.50 2.50 — 1.80 10.00 11.00 0.55 3.01 4.00 2.50 13.35 19.00 3.32 a 9 9 9 12 ...

Page 33

>_]]vbtzr\ _^uzdz_^vb 9 12 24 — — 2.26 2.97 5.47 — — 1.50 10.70 11.50 0.55 3.01 4.00 2.50 13.35 19.00 3.55 b 12 12 12 — — 3.57 3.57 3.57 — — 1.50 10.70 11.50 0.55 3.01 4.00 2.50 13.35 19.00 3.55 b 12 12 18 — — 3.10 3.10 4.49 — — 1.50 10.70 11.50 0.55 3.01 4.00 2.50 13.35 19.00 3.55 b 12 12 24 2.78 2...

Page 34

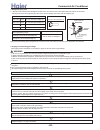

4.2. Wiring connection >_]]vbtzr\ _^uzdz_^vb 3u19fs1era -34- if this outdoor unit connects with as*s1era, the connecting cable is 1.5mm2 connect the connecting wires between indoor and outdoor units terminals match with each other. And ensure the sequence numbers on.

Page 35

>_]]vbtzr\ _^uzdz_^vb 4u25-30hs1era -35- if this outdoor unit connects with as*s1era, the connecting cable is 1.5mm2 connect the connecting wires between indoor and outdoor units terminals match with each other. And ensure the sequence numbers on.

Page 36

>_]]vbtzr\ _^uzdz_^vb 5u34hs1era: -36- if this outdoor unit connects with as*s1era, the connecting cable is 1.5mm2 connect the connecting wires between indoor and outdoor units terminals match with each other. And ensure the sequence numbers on.

Page 37

>_]]vbtzr\ _^uzdz_^vb 3u19fs1era 4.3 limitation values on pipe installation item unit description standard maximum a,b,c liquid pipe mm size of the liquid side connection pipe φ6.35 / a,b,c gas pipe mm size of the gas side connection pipe φ9.52 / l1 (one way) m max.Piping length between iu and ou of...

Page 38

>_]]vbtzr\ _^uzdz_^vb 4u25-30hs1era -38- item unit description standard maximum a,b,c, dliquid pipe mm size of the liquid side connection pipe φ6.35 / a,b,c gas pipe mm size of the gas side connection pipe φ9.52 / d gas pi[pe mm size of the gas side connection pipe φ12.7 / l1 (one way) m max.Piping ...

Page 39

>_]]vbtzr\ _^uzdz_^vb - 1- 2 5u34hs1era: -39- item uni t description standard maximum a,b,c,d,e liquid pipe mm size of the liquid side connection pipe φ6.35 / a,b,c,d gas pipe mm size of the gas side connection pipe φ9.52 / e gas pi[pe mm size of the gas side connection pipe φ12.7 / l1 (one way) m m...

Page 40

Model 3u19fs1era 5u34hs1era when there is 1 indoor,the prior stop valve is c e when there are 2 indoors,the prior stop valves are c、b e、d when there are 3 indoors,the prior stop valves are c、b、a e、d、c when there are 4 indoors,the prior stop valves are e、d、c、b when there are 5 indoors,the prior stop ...

Page 41

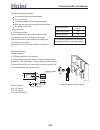

>_]]vbtzr\ _^uzdz_^vb installation figure please refers to 4u25hs1era. If there is the danger of the unit falling or overturning, fix the unit with foundation bolts, or with wire or other means. If the location does not have good drainage, place the unit on a level mounting base(or a plastic pedesta...

Page 42

>_]]vbtzr\ _^uzdz_^vb piping to each indoor unit total length of piping between al lunits outdoor unit capacity class 50m max. 3u19fs1era 25m max. 70m max. 25m max. 80m max. 25m max. 4u25hs1era 4u30hs1era 5u34hs1era 20 check the strength and level of the installation ground so that the unit will not...

Page 43: Refrigerant Piping Work

Refrigerant piping work 1. Installing outdoor unit 1) when installing the outdoor unit, refer to "precautions for selecting the location" and the "indoor/outdoor unit installation drawings". 2)if drain work is necessary, follow the procedures below. 2. Drain work 1) use drain plug for drainage. 2) i...

Page 44

>_]]vbtzr\ _^uzdz_^vb 4. Purging air and checking gas leakage warning 3. Refrigerant piping work when piping work is completed, it is necessary to purge the air and check for gas leakage. 1) do not mix any substance other than the specified refrigerant (r410a) into the refrigeration cycle. 2) when r...

Page 45

>_]]vbtzr\ _^uzdz_^vb 5. Refilling the refrigerant 6. Charging with refrigerant notes: gas pipe gas pipe insulation o.D.:9.52mm,12.7mm thickness:0.8mm i.D.:12-15mm,12.7mm thickness:13mm min. Liquid pipe liquid pipe insulation o.D.:6.35mm thickness:0.8mm i.D.:18-10mm thickness:10mm min. 7.Precautions...

Page 46

>_]]vbtzr\ _^uzdz_^vb 8.Cutting and flaring work of piping pipe cutting is carried out with a pipe cutter and burs must be removed. After inserting the flare nut, flaring work is carried out. Warning 3) use separate thermal insulation pipes for gas and liquid refrigerant pipe. It becomes high midway...

Page 47

>_]]vbtzr\ _^uzdz_^vb 1. Electric wiring the air conditioner must use special circuit , and wiring by the qualified electrician according to the wiring rules specified in national standard. The grounding wire and the neutral wire shall be strictly separated. Connect the neutral wire with grounding w...

Page 48

>_]]vbtzr\ _^uzdz_^vb wiring diagram please refers to 4u30hs1era loosen wire cover and connect the power line and communication wire of indoor unit to the terminal correspondingly. Note: when connecting power line to power supply terminal, please pay attention to the following items: do not connect ...

Page 49

>_]]vbtzr\ _^uzdz_^vb switch on all the 4 dip-switches on the outdoor unit small service pc-board as shown on the right. Then power off the unit and power on again, the system will enter the operation of "wiring error check". After 3 minutes stand-by, the unit starts for automatic wiring checking. A...

Page 50

30taha_pekj kb jjop]hh]pekj qh]_a ,3- qh]_a ]^kra pda _aehejc sdana d]ra ajkqcd ol]_a pk ]nn]jca pda qjep0 ,4- qh]_a sdana pda `n]ej]ca lela _]j ^a ]nn]jca` sahh0 ,5- qh]_a sdana ejhap ]j` kqphap ]en kb ej`kkn ]j` kqp`kkn qjep sehh jkp ^a ^hk_ga`0 ,6- ek jkp atlkoa pda qjep pk pda lh]_a sepd da]ru k...

Page 51

50 jjop]hh]pekj kb ej`kkn qjep jj _]oa kb jk _aehejc jjop]hh qjep pailkn]nehu qqp oqolaj`ejc ^n]_gap kj pda oqolaj`ejc ^khp pk d]jc pda qjep ql0 ca oqna pk qoa jqp ]j` s]odan ]p ^kpd aj` kb pda ^na]gap pk oa_qna benihu0 bbpan ejop]hh]pekj kj pda _aehejc ,3- b`fqop qjep pk epo necdp lkoepekj ,saban p...

Page 52

Voa pda `n]ej]ca dkoa ]j` _hel lnkre`a` sepd qjep0 jjoanp s]pan lela ejpk s]pan lhqc qjpeh ep na]_dao pda sdepa p]la0 uecdpaj pda _hel qjpeh da]` kb pda o_nas eo haoo pd]j 6ii bnki dkoa0 xej` pda `n]ej]ca dkoa pk pda _hel qoejc oa]h l]` bkn da]p ejoqh]pekj0 jjoqh]pa `n]ej]ca dkoa ej pda nkki0 70 d]q...

Page 53

Meiepo kb l]jah ^k]n` ejop]hh]pekj ,3-jjop]hh pda l]jah ^k]n` ej pda `ena_pekj odksj ej pda becqna0 ,4-uda ej_knna_p `ena_pekj sehh naoqhp ej s]pan ha]g]ca. Ia]jsdeha osejc ]j` oecj]h na_aerejc ]na jkp ^a _kjja_pa` oq__aoobqhhu0 dkjpnkh ^kt 90 qelejc dkjja_pekj >_]]vbtzr\ _^uzdz_^vb gep pda jqp kj ]...

Page 54

D]qpekjo bkn lelejc _kjja_pekj ek jkp pseop kn `abkni pda _kjja_pejc lela0 ek jkp iet `qopo0 uda ^aj`ejc n]`eqo od]hh ^a ]o h]nca ]o lkooe^ha0 ckpd c]o lela ]j` hemqe` lela od]hh ^a da]p ejoqh]pekj0 ok ha]g]ca ej pda bh]na0 qelejc _kjja_pekj dkjja_pejc iapdk` tia]n nabnecan]jp keh kj pda fkejpo kb l...

Page 55

Selecting the mounting position (1)do not install where there is the danger of com- bustible gas leakage. (2) do not install near heat sources. (3) if children under 10 years old may approach the unit, take preventive measures so that they cannot reach the unit. Install at a place that can withstand...

Page 56

Open the intake grill and remove the three or four or six screws.(fig. 1) remark: the main unit can be wired before the indoor unit is installed. Select the most appropriate installation order. A. Floor console type 1. Drilling for piping select piping and drain directions.(fig.2) the piping and dra...

Page 57

Select whether the drain hose will be connected to the left or right side.(fig.3) insert the drain hose into the drain pan, then secure the drain hose with a nylon fastener. (fig.6) 2. Installing drain hose (fig. 6) wrap the insulation (drain hose) around the drain hose connection. (fig.7) (fig. 7) ...

Page 58: Caution

3. Installing brackets install the brackets with nuts, washers and spring washers.(fig. 15) 4. Installing indoor unit bracket (right) bracket (left) select piping and drain directions. (fig.11) 1. Drilling for piping insert the anchor bolts into the drilled holes, and drive the pins completely into ...

Page 59

Select whether the drain hose will be connected to the left or right side.(fig.3) insert the drain hose into the drain pan, then secure the drain hose with a nylon fastener.(fig.6) wrap the insulation (drain hose)around the drain hose connection.(fig.7) be sure to arrange the drain hose correctly so...

Page 60

The maximum length and drop height of connecting pipe cautions for piping connection smear refrigerant oil on the joints of piping and flare. The bending radius shall be as large as possible. Align the pipe center when fastening, and tighten the nut, as shown in the figure. Pay attention to not mix ...