- DL manuals

- Haier

- Air Conditioner

- AB092XCERA

- Service Manual

Haier AB092XCERA Service Manual

Summary of AB092XCERA

Page 1

Service manual x multi series 4-way cassette indoor unit convertible indoor unit console indoor unit duct indoor unit wall mounted indoor unit outdoor unit haier commercial air conditioner version: 200708.

Page 2

>_]]vbtzr\ _^uzdz_^vb - 2 - content 1.General information --------------------------------------------------------------------------------------------- 3 1.1 x multi series line up ------------------------------------------------------------------------------------------3 1.2 operation temperature r...

Page 3

-3- .9773:1506 -5: .9825;5983: jk@ib[lnvj jkabb[lnvj jkadb[lnvj jkahb[lnvj jladb[lnvj jlahb[lnvj jm@ib[snvj jmabb[snvj jmadb[snvj jmahb[snvj jo@ib[lnvj joabb[lnvj jw@gb[ynvj jw@ib[ynvj jwabb[ynvj jwahb[ynvj a?C ug`h\jbfe j`dg`h\jkh` h\ea` jxahb[onvj jxbbb[onvj lffcbea q`\jbea re_ffh fkj_ffh v\j`_ t\...

Page 4

Commercial air conditioner 1 .3 product features high efficienct, universal outdoor unit the outdoor unit can match with cassette type ,duct type, convertible type, console type and wall mounted type indoor unit. Outdoor unit can match with multiple indoor units. Even when you have already installed...

Page 5

Commercial air conditioner self-diagnostic function in the course of operation, if the failure occurs, the failure code will display on the wired controller or on the operation panel. Then according to the failure code chart, you can eliminate the failure soon. Central control function, if connected...

Page 6

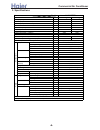

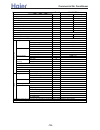

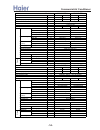

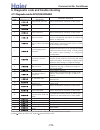

2. Specifications -6- >_]]vbtzr\ _^uzdz_^vb —— cooling heating w 5300 7000 w 1650 1800 a 7.3 8.0 w/w 3.21 3.89 w 1500 1800 w 500 500 w 5800 7300 w 2300 2300 —— a / a 10.2 10.2 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input...

Page 7

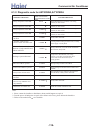

-7- >_]]vbtzr\ _^uzdz_^vb —— cooling heating w 6400 7300 w 2100 2000 a 9.3 8.9 w/w 3.04 3.65 w 1500 1800 w 500 500 w 6800 7500 w 2900 2900 —— a / a 12.9 12.9 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input power w air-flows...

Page 8

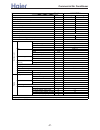

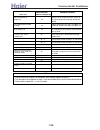

—— cooling heating w 7250 8000 w 2250 2200 a 10.4 10.4 w/w 3.22 3.64 w 1500 1800 w 500 500 w 8200 9000 w 3200 3000 —— a / a 14.3 13.5 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / dia...

Page 9

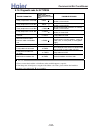

-9- >_]]vbtzr\ _^uzdz_^vb —— cooling heating w 8000 10000 w 2480 2700 a 11.0 11.9 w/w 3.22 3.70 w 1500 1800 w 550 550 w 9500 11000 w 3800 3800 —— a / a 16.8 16.8 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input power w air-f...

Page 10

>_]]vbtzr\ _^uzdz_^vb -10- —— cooling heating w 10000 11000 w 3200 3200 a 14.3 14.3 w/w 3.13 3.44 w 1500 1800 w 550 550 w 11000 11500 w 4000 4000 —— a / a 18.1 18.1 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input power w ai...

Page 11

—— cooling heating w 10000 11000 w 3200 3200 a 14.3 14.3 w/w 3.13 3.44 w 1500 1800 w 550 550 w 11000 11500 w 4000 4000 —— a / a 18.1 18.1 —— 99% 99% a model / manufacture —— oil charge and type —— type —— number —— type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type /...

Page 12

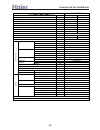

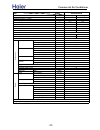

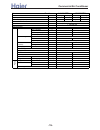

-12- >_]]vbtzr\ _^uzdz_^vb —— cooling heating cooling heating w 2000 2300 2500 2900 —— —— 10 ‐ ³×m³/h 1.0 / 1.0 / n, v, hz a / a 0.15 0.15 0.15 0.15 type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² external mm package mm drainage pipe mat...

Page 13

-13- >_]]vbtzr\ _^uzdz_^vb —— cooling heating cooling heating w 2500 2900 3500 3800 10 ‐ ³×m³/h 1.0 / 1.2 / —— —— n, v, hz a 0.45 0.45 0.45 0.45 type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² temp. Scope ℃ external mm package mm drainag...

Page 14

-14- >_]]vbtzr\ _^uzdz_^vb —— cooling heating cooling heating w 2500 2900 3500 3800 10 ‐ ³×m³/h 1.0 / 1.2 / —— —— n, v, hz a 0.35 0.35 0.35 0.35 type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² temp. Scope ℃ external mm package mm drainag...

Page 15

Shieled 16.4/11.4(o.D./i.D. 16.4/11.4(o.D./i.D. -15- >_]]vbtzr\ _^uzdz_^vb —— cooling heating cooling heating w 4100 4600 5000 5500 10 ‐ ³×m³/h 1.6 / 2 / —— —— n, v, hz a 0.45 0.45 0.45 0.45 type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m...

Page 16

-16- >_]]vbtzr\ _^uzdz_^vb —— cooling heating cooling heating w 2500 2900 3500 3800 10 ‐ ³×m³/h 1.0 / 1.2 / —— —— n, v, hz a 0.45 0.45 0.45 0.45 type × number —— speed r/min motor output/input power w air-flows (h/m/l) m³/h type / diameter mm face area m² temp. Scope ℃ external mm package mm drainag...

Page 17

-17- >_]]vbtzr\ _^uzdz_^vb au182xfera,au222xfera 3. Dimension au282xhera: 583 288 113.5 680 319.5 113.5 50 928 810 18 18 950 70 185 380 830 185 340 580 1068 48,.,965743 ++. -.. -*1 /-* ,. 0-* 1/* 20/.

Page 18

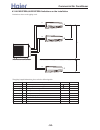

>_]]vbtzr\ _^uzdz_^vb b9 a9 :;9 hgfi d >tt 7kn[^nnu z\zwnuzrvu wvsnz8 myjrujpn wrwn pjz wrwn srx\rm wrwn >@9tt 7rumvvy \ur[ mrtnuzrvu8 ?>9tt 7lnrsrup vwnurup mrtnuzrvu8 @99tt 7wjuns mrtnuzrvu8 >@9tt 7rumvvy \ur[ mrtnuzrvu8 ?>9tt 7lnrsrup vwnurup mrtnuzrvu8 @99tt 7wjuns mrtnuzrvu8 hgfi d b> :=9 :a9 o...

Page 19

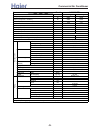

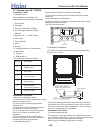

=mpqbkkbqjnm ejlfmpjnm8+ll, @mjq lnefk 9;/20a>9 9;/60a>9 9;/00a>9 9;.70a>9 b /..0 316 c 261-3 261-3 d /1/ /1/ e //.3 4/. F 033 033 g /.3 /.3 h 66. 2/6 i 75. 3.6 j 00. 00. T u v w x y z [ \ 72. 00. 9;/20a>9 9;/60a>9 256 00. 9;.70a>9 9;/00a>9 :fjkjmh dnmdfbkfe qsof rmjq8 >_]]vbtzr\ _^uzdz_^vb - - 19.

Page 20

>_]]vbtzr\ _^uzdz_^vb console type unit: /+* .,* +*- c b a c model a b as07/09/122xvera as182xvera 197 265 795 225 305 870 wall mounted type - - 20

Page 21

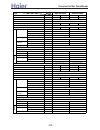

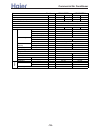

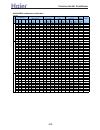

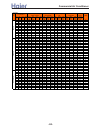

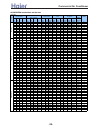

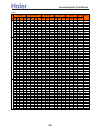

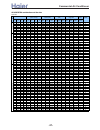

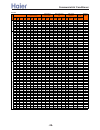

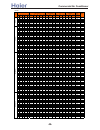

4. Pipe and wiring installation - 1- >_]]vbtzr\ _^uzdz_^vb au182xfera combination and the data cooling eer (w/w) unit a unit b unit c unit a unit b unit c min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 7 — 2.0 2.0 — 1.00 4.00 4.40 0.47 1...

Page 22

>_]]vbtzr\ _^uzdz_^vb au222xfera combination and the data cooling eer (w/w) unit a unit b unit c unit a unit b unit c min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 9 — 2.00 2.50 — 1.00 4.50 4.90 0.47 1.75 2.90 2.20 7.76 12.90 2.57 e 7 1...

Page 23

>_]]vbtzr\ _^uzdz_^vb au252xgera combination and the data cooling eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 12 — — 2.00 3.50 — — 1.00 5.50 5.90 0.47 2.06 3.20 2.09 9....

Page 24

Heating cop (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 12 — — 2.30 3.80 — — 1.00 6.10 6.70 0.47 2.11 3.20 2.09 9.98 14.50 2.89 d 7 14 — — 2.30 4.60 — — 1.00 6.90 7.60 0.50...

Page 25

Au282xhera combination and the data cooling eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 14 — — 2.00 4.10 — — 1.00 6.10 6.50 0.50 2.20 3.80 2.15 9.76 16.80 2.77 d 7 18 —...

Page 26

Heating eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 14 — — 2.30 4.60 — — 1.20 6.90 7.50 0.50 2.80 3.80 2.15 12.42 16.80 2.46 f 7 18 — — 2.30 5.50 — — 1.20 7.80 8.40 0.5...

Page 27

Au342xhera combination and the data cooling eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 18 — — 2.00 5.00 — — 1.00 7.00 7.50 0.50 2.85 4.00 2.15 12.64 18.10 2.46 e 9 18 ...

Page 28

Heating eer (w/w) unit a unit b unit c unit d unit a unit b unit c unit d min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 18 — — 2.30 5.50 — — 1.20 7.80 7.50 0.50 2.95 4.00 2.15 12.64 18.10 2.64 e 9 18 — — 2.90 5.50 — — 1.20 8.40 8.40 0.5...

Page 29

Au362xhera combination and the data cooling eer (w/w) unit a unit b unit c unit d unit e unit a unit b unit c unit d unit e min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 18 — — — 2.00 5.00 — — — 1.00 7.00 7.50 0.50 2.85 4.00 2.15 12.64 ...

Page 30

Heating eer (w/w) unit a unit b unit c unit d unit e unit a unit b unit c unit d unit e min. Data rated data max. Data min. Data rated data max. Data min. Data rated data max. Data rated capacity 7 18 — — — 2.30 5.50 — — — 1.20 7.80 7.50 0.50 2.95 4.00 2.15 12.64 18.10 2.64 e 9 18 — — — 2.90 5.50 — ...

Page 33

- >_]]vbtzr\ _^uzdz_^vb au362xhera: 3 2 1 7 6 -+4, .+5, 3 2 1 7 6 .+5, -+4, +6, 0 / +7, +6, 0 / +7, +7, -+4, .+5, +6, -+4, .+5, 0 / .+5, -+4, 4 5 3. 3- p_yuey dyzyd fb f\y ]axbbd ga]f ]aefu__uf]ba `uagu_ fb z]ax xyfu]__i \bh fb eyf uax w\yw^ f\y wb``ga]wuf]ba uxxdyee= mawbddywf uxxdyee eyff]a[ h]__ ...

Page 36

>_]]vbtzr\ _^uzdz_^vb the piping length information, please refer the following table. Descriptions standard a, b, c, d, e liquid pipe a, b, c, d,e gas pipe mm item maximum unit l1 (one way) l2 (one way) l3 (one way) h h + h - mm m m m m m m size of the liquid side connection pipe drop between every...

Page 37

1. Do not connected the embedded branch piping and the outdoor unit when only carrying out piping work without connecting the indoor unit in ordor to add another indoor unit later. Make sure no dirt or mositure gets into eigher side of the embedded branch piping. 2.It is impossible to connect the in...

Page 38: Refrigerant Piping Work

Refrigerant piping work forced fastening without careful centering may damage the threads and cause a leakage of gas. Pipe diameter ( ) fastening torque liquid side 6.35mm (1/4'') 18n.M gas side 9.52mm (3/8'') 50n.M 3. Attaching drain-elbow if the drain-elbow is used, please attach it as figure. Fla...

Page 39

4.Cutting and flaring work of piping pipe cutting is carried out with a pipe cutter and burs must be removed. After inserting the flare nut, flaring work is carried out. Less than 5cm it becomes high midway. The end is immersed in water it waves. It gap with the ground ts too small. There is the bad...

Page 40

In case of gas leakage, tighten parts of pipe connection. If leakage stops, then proceed 6 steps. Purging method: to use vacuum pump 2 way valve 3 way valve 90 0 service port 90 0 for 6 sec. 6 .Detach the charge hose from the service port, open 2- way valve and 3-way. Turn the valve rod anticlockwis...

Page 41: Wiring Work

1. Electric wiring note: the air conditioner must use special circuit , and wiring by the qualified electrician according to the wiring rules specified in national standard. The grounding wire and the neutral wire shall be strictly separated. Connect the neutral wire with grounding wire is incorrect...

Page 42: Wiring Work

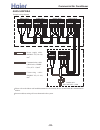

3. Wiring method of outdoor unit: loosen wire cover and connect the power line and communication wire of indoor unit to the terminal correspondingly. Note: when connecting power line to power supply terminal, please pay attention to the following items: do not connect the power line with different d...

Page 43: Items To Confirm

Items to confirm test running before starting the test running, please confirm the following works have been done successfully. 1) correct piping work; 2) correct wiring work; 3) correct match of indoor and outdoor unit; 4) proper recharge of refrigerant if needed; 5) correct indoor unit addresses s...

Page 44

30taha_pekj kb jjop]hh]pekj qh]_a ,3- qh]_a ]^kra pda _aehejc sdana d]ra ajkqcd ol]_a pk ]nn]jca pda qjep0 ,4- qh]_a sdana pda `n]ej]ca lela _]j ^a ]nn]jca` sahh0 ,5- qh]_a sdana ejhap ]j` kqphap ]en kb ej`kkn ]j` kqp`kkn qjep sehh jkp ^a ^hk_ga`0 ,6- ek jkp atlkoa pda qjep pk pda lh]_a sepd da]ru k...

Page 45

50 jjop]hh]pekj kb ej`kkn qjep jj _]oa kb jk _aehejc jjop]hh qjep pailkn]nehu qqp oqolaj`ejc ^n]_gap kj pda oqolaj`ejc ^khp pk d]jc pda qjep ql0 ca oqna pk qoa jqp ]j` s]odan ]p ^kpd aj` kb pda ^na]gap pk oa_qna benihu0 bbpan ejop]hh]pekj kj pda _aehejc ,3- b`fqop qjep pk epo necdp lkoepekj ,saban p...

Page 46

Voa pda `n]ej]ca dkoa ]j` _hel lnkre`a` sepd qjep0 jjoanp s]pan lela ejpk s]pan lhqc qjpeh ep na]_dao pda sdepa p]la0 uecdpaj pda _hel qjpeh da]` kb pda o_nas eo haoo pd]j 6ii bnki dkoa0 xej` pda `n]ej]ca dkoa pk pda _hel qoejc oa]h l]` bkn da]p ejoqh]pekj0 jjoqh]pa `n]ej]ca dkoa ej pda nkki0 70 d]q...

Page 47

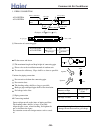

Meiepo kb l]jah ^k]n` ejop]hh]pekj ,3-jjop]hh pda l]jah ^k]n` ej pda `ena_pekj odksj ej pda becqna0 ,4-uda ej_knna_p `ena_pekj sehh naoqhp ej s]pan ha]g]ca. Ia]jsdeha osejc ]j` oecj]h na_aerejc ]na jkp ^a _kjja_pa` oq__aoobqhhu0 dkjpnkh ^kt 90 qelejc dkjja_pekj ,3- eeiajoekj kb _kjja_pejc lela gh]na...

Page 48

D]qpekjo bkn lelejc _kjja_pekj ek jkp pseop kn `abkni pda _kjja_pejc lela0 ek jkp iet `qopo0 uda ^aj`ejc n]`eqo od]hh ^a ]o h]nca ]o lkooe^ha0 ckpd c]o lela ]j` hemqe` lela od]hh ^a da]p ejoqh]pekj0 ok ha]g]ca ej pda bh]na0 ,5- qelejc _kjja_pekj dkjja_pejc iapdk` tia]n nabnecan]jp keh kj pda fkejpo ...

Page 49

30udana ]na psk iapdk`o pk oap pda _kiiqje_]pekj ]``naoo b0 voa pda naikpa _kjpnkhhan,`ab]qhp op]pqo ej benop ejop]hh]pekj-0 c0 voa `el osep_dao kj pda ej`kkn qjep qdc0 40 b``naoo oappejc lnk_a`qna sdaj qoejc pda naikpa _kjpnkhhan0 b0 tap pda ]``naooao kjhu ]bpan pda oq__aoobqh ejop]hh]pekj kb pda n...

Page 50

50 b``naoo oappejc lnk_a`qna sdaj qoejc pda ejq osep_dao tx23 ]j` tx250 b0 uda ejq osep_dao tx23 ]j` tx25 ]na kj pda ej`kkn qjep qdc0 c0 cabkna _]nnuejc kqp pda ]``naoo oappejc skng. Pda ouopai iqop ^a lksana` kbb0 d0 u]ga kbb pda bnkjp l]j]h ]j` pda behpano. Pdaj p]ga kbb pda bh]lo ]j` ]hok pda bnk...

Page 51

Selecting the mounting position (1)do not install where there is the danger of com- bustible gas leakage. (2) do not install near heat sources. (3) if children under 10 years old may approach the unit, take preventive measures so that they cannot reach the unit. Install at a place that can withstand...

Page 52

Open the intake grill and remove the three or four or six screws.(fig. 1) remark: the main unit can be wired before the indoor unit is installed. Select the most appropriate installation order. A. Floor console type 1. Drilling for piping select piping and drain directions.(fig.2) the piping and dra...

Page 53

Select whether the drain hose will be connected to the left or right side.(fig.3) insert the drain hose into the drain pan, then secure the drain hose with a nylon fastener. (fig.6) 2. Installing drain hose (fig. 6) wrap the insulation (drain hose) around the drain hose connection. (fig.7) (fig. 7) ...

Page 54: Caution

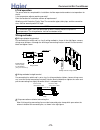

3. Installing brackets install the brackets with nuts, washers and spring washers.(fig. 15) 4. Installing indoor unit bracket (right) bracket (left) select piping and drain directions. (fig.11) 1. Drilling for piping insert the anchor bolts into the drilled holes, and drive the pins completely into ...

Page 55

Select whether the drain hose will be connected to the left or right side.(fig.3) insert the drain hose into the drain pan, then secure the drain hose with a nylon fastener.(fig.6) wrap the insulation (drain hose)around the drain hose connection.(fig.7) be sure to arrange the drain hose correctly so...

Page 56

(1) dimension of connecting pipe (2) the maximum length and drop height of connecting pipe cautions for piping connection smear refrigerant oil on the joints of piping and flare. The bending radius shall be as large as possible. Align the pipe center when fastening, and tighten the nut, as shown in ...

Page 57

How to connect wiring to the terminals a. For solid core wiring (or f-cable)(fig.24a) (1) cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 25mm of the exposed solid wire. (2) using a screwdriver, remove the terminal screw(s) on the terminal board. (3) using ...

Page 58: Caution

Electrical wiring 1. Indoor unit side (1) remove the electric component box. (2) pull out the electric component box. (3) remove the electric component box cover. Remove the three tapping screws. (1) remove the cord clamp. (2) process the end of the connection cords to the dimensions shown in fig.34...

Page 59

(5). Wiring of indoor unit the distance between the signal wires and the power cabes should be at least 50mm. C b a q p 1(l) 2(n) 2(n) 1(l) p q a b c l n c1 c2 (in case of using wired controller) to other indoor unit to wired controller to outdoor unit (p) (q) 1.Incorrect address setting will cause ...

Page 60

1.There are two methods to set the communication address a. Use the remote controller(default status in first installation). B. Use dip switches on the indoor unit pcb. 2. Address setting procedure when using the remote controller. A. Set the addresses only after the successful installation of the r...

Page 61

4. How to check the addresses? When finish all the above works, please power off and power on again to the whole system but set all the indoor units in standby. Then continously press the emergency switch until you hear the buzzer sound 5 times(pi pi pi pi pi), and then the timer led board will show...

Page 62

Electrical wiring (1) the power source capacity must be the sum of the room air conditioner current and the current of other electrical appliances. When the current contracted capacity is insufficient, change the contracted capacity. (2) when the voltage is too low and the air conditioner is difficu...

Page 63

(2) insert the hinges on the bottom of the intake grill into the holes in the base assembly. Then mount the arms to the three areas on the top of the intake grill. Fig. 35 fig. 34 (1) cut the right side of the intake grill. This is only when the pipe exits from the right side 3. Mount the intake gri...

Page 64: 4.7 Duct Type Ad***xlera

Self-contained accessories 3. Accessories for installation name of parts no. A b c d e f non-adhesive tape adhesive tape connecting hose gypsum powder drain hose heat insulation material 4. Choose the installation place install the indoor unit where the weight of the unit can be supported. Install t...

Page 65

1. Drill a hole in the wall and insert the connecting pipe and wire through a pvc wall-through tube purchased locally. The wall hole shall be with a outward down slope of at least 1/100. (see figure 1) 2. Before drilling check that there is no pipe or reinforcing bar just behind the drilling positio...

Page 66

The distance between air duct outlet and air conditioner outlet is according to the length of actually installed air duct and in service behavior of the static pressure terminal: installation sketch map for long and short air duct is showed below, when connect to short air duct, using low static ter...

Page 67

2. Installation of air return duct 3. Air duct insulation use m8 or m10 suspension screws (4, prepared in the field) (when the suspension screw height exceeds 0.9 m, m10 size is the only choice). These screws shall be installed as follows with space adapting to air conditioner overall dimensions acc...

Page 68

Original concrete slab use hole hinge, hole plunger or hole bolt. Steel reinforcement structure use steel angle or new support steel angle directly. Hanging of the indoor unit fasten the nut on the suspension screw and then hang the suspension screw in the tslot of the suspension part of the unit. A...

Page 69

Supplementary refrigerant the refrigerant supplementation shall be as specified in the installation instructions attached with the outdoor unit. The added refrigerant shall be r22. The adding procedure shall be aided with a measuring meter for a specified amount of supplemented refrigerant pipe cutt...

Page 70

The connection of indoor unit pipes must use double spanners. The installing torque shall be as given in the following table. Double-spanner operation pipe expansion dimensions as follows: pipe expander a piping connection flare connection gas pipe 3-way valve indoor unit outdoor unit liquid pipe 2-...

Page 71

1. Indoor unit communication addresses setting caution! Fail to do this, the unit will not work. (2). Address setting procedure when using the dip switches sw01 and sw03. A. The dip switches sw01 and sw03 are on the indoor unit pcb. B. Change the position of dip 7 of sw01 from off to on, if fail to ...

Page 72

4.Trial operation the person who has completed this installation shall be requested to conduct a test operation for check: is the temperature adjuster working normally? Does the location for installation conform to requirements? Winding up with protective plastic tape.The connection pipes,drain pipe...

Page 73

4 wiring of indoor unit the distance between the signal wires and the power cabes should be at least 50mm. C b a q p 1(l) 2(n) 2(n) 1(l) p q a b c l n c1 c2 to other indoor unit to wired controller(a,b,c) to outdoor unit (p q) waring: 1.Incorrect address setting will cause abnormal to the system. 2....

Page 74

Installation of indoor unit selection of installation place fig1 330 fig2 fig3 tool necessary 4.8. Console type af***xcera place where it is easy to route drainage pipe and outdoor piping. Place ,away from heat source and with less direct sunlight. Place where cool and warm air could be delivered ev...

Page 75: Fixing Of The Unit

Fixing of the unit 1. Position of the wall hole wall hole should be decided according to installation place and piping direction.(refer to installation drawings). 2. Making a wall hole drill a hole of 120x70mm dia. With a little slope towards outside. 3. Piping connection threads on the pipes may be...

Page 76

1. Arrangement of piping and drainage pipe after opening inlet grill,you will see a control box. Remove the cover before working. Cut away, with a hammer or a saw, the lid for piping according to piping direction. According to the piping method, connect the piping on indoor unit with union of connec...

Page 77

Others the power plug should be connected as follows: l for live line, n for neutral line and for grounding. The signal wire must be shielded wire. 2. Piping cutting and flaring be sure to carry out deburring after cutting with a pipe cutter. Insert flaring tool to make a flare. Installation inspect...

Page 78

Remove air intake screen and take out the front wires. Connect the wires as specified in the above methods and diagrams for indoor unit and wire con- nections. Properly apply capping clips on the wires. Replace the air intake screen. Do not link the connecting and signal wire with the same cable, a ...

Page 79

Indoor unit communication addresses setting caution! Fail to do this, the unit will not work. 3. Address setting procedure when using the dip switches sw01 and sw02. A. The dip switches sw01 and sw02 are on the indoor unit pcb. B. Before carrying out the address setting work, the system must be powe...

Page 80

When finish all the above works, please power off and power on again to the whole system but set all the indoor units in standby. Then continously press the emergency switch until you hear the buzzer sound 5 times(pi pi pi pi pi), and then the lcd display board will show the address of this indoor u...

Page 81

Precaution self-contained accessories 3. Accessories for installation name of parts no. A b c d e f non-adhesive tape adhesive tape connecting hose gypsum powder drain hose heat insulation material 2. Preparation for installation installation tools 7 pipe cutter 14 refrigeration oil 6 spanner 13 scr...

Page 82

5. Method for cutting and expanding pipes. Make a hole of 60mm in diameter, slightly descending to outside the wall. Install piping hole cover and seal it off with putty after installation. 4. Drawing of pipe rear piping draw pipes and the drain hose, then fasten them with the adhesive tape. Left le...

Page 83

Heat insulation material drain hose piping indoor/outdoor electric cable signal wire change-f or-fresh-air tube indoor/outdoor electric cord and drain hose must be bound with refrigerant piping by protecting tape 8. Indoor unit communication addresses setting 1.There are two methods to set the commu...

Page 84

I. If you want to change the address, please repeat the above steps from e to g. J. After setting all the addresses, please power off the system and then power on again. Otherwise the system will not start to work. K. Once the addresses are successfully set, please do not change it any more to avoid...

Page 85

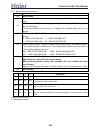

5.1. 1. Cn7 cn6 cn5 cn4 cn3 cn2 cn1 cn8 cn9 cn15 cn16 cn14 cn13 cn12 cn11 cn10 cn17 cn18 cn19 cn20 cn21 cn22 cn23 sw5 sw1 sw2 sw3 sw4 lamp1 - >_]]vbtzr\ _^uzdz_^vb 5. Pcb photo,wiring diagram and function description sw05 is used for factory quality control engineers, the default position is : off o...

Page 86

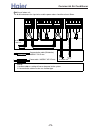

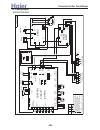

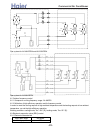

5.1.2. Wiring diagram - >_]]vbtzr\ _^uzdz_^vb n l m c n 1 7 t d t e t s t a t c c n 1 6 c n 1 5 l e d 2 l e d 1 c n 1 2 c n 1 1 c r a n k c a s e h e a t e r c n 1 0 c n 9 y /g 4 -w a y v a l v e a c f a n m o t o r w u c o m p r e s s o r r v b w c n 2 2 2 0 v a c -n q p t 2 5 a 2 5 0 v a c f u s e...

Page 87

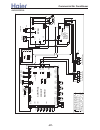

- - >_]]vbtzr\ _^uzdz_^vb n l w u c o m p r e s s o r r v b w c n 2 2 2 0 v a c -n q p t 2 5 a 2 5 0 v a c f u s e l e d 5 l e d 3 l e d 4 l e d 1 l e d 2 r r t o i n d o o r u n its t d : c o m p r e s s o r v e n t s e n s o r s w 5 t o p o w e r s u p p ly c n 2 6 t s : c o m p r e s s o r i n h ...

Page 88

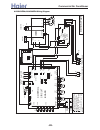

Au282xhera,au342xhera wiring diagram >_]]vbtzr\ _^uzdz_^vb - n l c n 1 7 t d t e t s t a t c c n 1 6 c n 1 5 l e d 2 l e d 1 c n 1 2 c n 1 1 c r a n k c a s e h e a t e r c n 1 0 c n 9 4 -w a y v a l v e w u c o m p r e s s o r v c n 1 q p t 25 a 2 5 0 v a c f u s e l e d 5 l e d 3 l e d 4 l e d 1 l...

Page 89

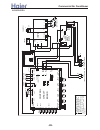

- >_]]vbtzr\ _^uzdz_^vb n l c n 1 8 t d t e t s t a t c c n 1 7 c n 1 5 l e d 1 l e d 2 c n 1 2 c n 1 1 c r a n k c a s e h e a t e r c n 1 0 c n 9 4 -w a y v a l v e w u c o m p r e s s o r v c n 1 q p t 25 a 2 5 0 v a c f u s e l e d 5 l e d 3 l e d 4 l e d 1 l e d 2 m c n 2 2 2 5 0 v a c t 3 .1 5...

Page 90

5.1.3 . Switch setting and functions: no item a8 set in factory switch function: sw5-1---outdoor fan motor selection, on: dc fan motor; off: ac fan motor c1 switch function: sw5-2---defrosting data setting, on=6degree, off = 8degree (set when out of factory). For the place where is easy to frost, it...

Page 91

T d ts tao tc te tmc tinc taic toci touc tinb tmb taib toub tina tma taia toua hpsw l p s w pipe system for au182xfera and au222xfera pipe system for au282xhera 3.2 outdoor frequency control 3.2.1 compressor running frequency range: 20~90rps 3.2.2 defination of high-efficiency operation and its freq...

Page 92

3.3.2 initialization of eev eev driving speed: open direction: 32ms; close direction: 32ms 3.3.3 open angle limitation of eev unit stop adjustable upper limitation thermostat on thermostat off adjustable lower limitation cool/dry 5 ( e ) 450 ( e ) standard open angle+tolerance 5 ( e ) 80 ( e ) heat ...

Page 93

Not go down greatly. Ambient temp. Ta ≤ 27degree, when compressor stops, the electric heater will be electrified. When ta ≥ 32degree, or compressor running, the electric heater will be off. Heater on off ambient temp. Ta( ℃ ) 27 32 3.6 control of liquid spray valve sv2: according to the compressor d...

Page 94

3.8 frequency control when td is too high purpose: make compressor frequency control if the discharging temp. Is too high, to lower the discharging temp. Efficiently and ensure the system can run normally. Beginning end fixed frequency indicated fqy 60s defrosting fqy 80 hz ( e ) 60s soft startup co...

Page 95

3.9 frequency control when there is ct over current protection 3.10 high pressure protection when the input signal of pressure switch is high level:1, that shows there is no protection. When the input signal of pressure switch is low level: 0 for 1 minute, that shows high pressure protection works. ...

Page 96

· when unit stops, the reason that system still checks the low pressure : in a long time stop, make protection for the compressor on the condition of great refrigerant leakage. · the reason that low pressure switch action time is 30 seconds: when compressor stops, low pressure does not change, so it...

Page 97

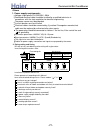

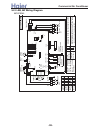

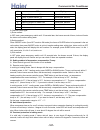

Cn 19 cn4 cn3 cn2 cn20 cn21 cn1 cn22 cn11 sw1 sw2 sw3 cn16 lamps 3,4 cn8 cn7 cn14 cn26 cn24 cn13 cn12 cn 10 cn15 cn9 lam p s 1 ,2 - >_]]vbtzr\ _^uzdz_^vb 5. 2 indoor unit 5.2.1 ab,ad pcb photo 97-.

Page 98

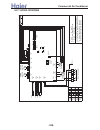

5.2.2. Wiring diagram - - >_]]vbtzr\ _^uzdz_^vb c n 3 c n 2 c n 2 1 c n 1 f u s e 1 t 3 .1 5 a 2 5 0 v a c m ~ a c f a n m o t o r ca p a ci to r 2 u f 450v y /g l n y /g t o o u t d o o r u n it c n 2 0 c n 4 w c n 19 w m ~ d r a in in g p u m p m o t o r c n 2 2 g c n 24 r c n 14 w c n 13 b c n 12...

Page 99

- >_]]vbtzr\ _^uzdz_^vb ad***xlera c n 3 c n 2 c n 2 1 c n 1 f u s e 1 t 3 .1 5 a 2 5 0 v a c m ~ a c f a n m o t o r y /g l n y /g t o o u t d o o r u n it c n 2 0 c n 4 c n 1 9 w w g c n 2 2 r c n 2 4 w c n 1 4 c n 1 3 b w c n 1 2 c n 1 0 w t m p ip in g t e m p e r a t u r e s e n s o r a m b ie ...

Page 100

5.2.3. Ac142-182xcera pcb photo cn20 la m p 3, 4 cn1 cn3 cn21 cn6 cn5 cn4 cn12 sw2 cn7 sw3 cn15 cn26 la m p 1 ,2 cn22 sw1 cn8 cn24 cn10 cn14 cn13 cn2 - >_]]vbtzr\ _^uzdz_^vb 100-.

Page 101

- 5.2.4. Ac142-182xcera wiring diagram - >_]]vbtzr\ _^uzdz_^vb 101- t r a n s f o r m e r f u s e 1 t 3. 15 a 2 50 v a c c n 19 b l s w 01 o n 1 2 3 4 5 6 7 8 t m o n /o f f c a r d y /g br r bl y or ca pa ci to r 2u f 4 50 v a c f a n m o t o r ~ m p ip in g t e m p e r a t u r e s e n s o r a m b ...

Page 102

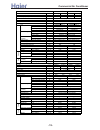

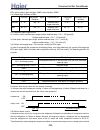

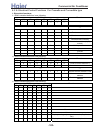

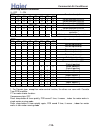

5.2.5. . Electrical control functions for cassette and convertible type 1. Dip switch functions: 1.1 sw01 detailed definition is as following: sw01 [1] [2] [3] [4] [5] [6] [7] [8] function -- -- -- -- - -- -- -- -- -- ---- -- -- -- -- -- -- -- -- -- -- -- -- 0 passive contact valid -- -- -- -- -- --...

Page 103

Dry, cool, fan) -- -- -- -- -- 0 0 0 indoor communication address 1 -- -- -- -- -- 0 0 1 indoor communication address 2 -- -- -- -- -- 0 1 0 indoor communication address 3 -- -- -- -- -- 0 1 1 indoor communication address 4 -- -- -- -- -- 1 0 0 indoor communication address 5 -- -- -- -- -- 1 0 1 ind...

Page 104

6.2 after indoor receives the on command from wired controller, it will firstly confirm the outdoor current operation mode. If they are the same modes, indoor unit will run as the request of remote controller. If they are different modes, the system will forbid to operate, and indoor will keep the o...

Page 105

Full off 54 º 12. Water pump control 12.1 water pump will be electrified when indoor unit enters non-heating mode until indoor unit stops. 5 minutes later after indoor unit stops, water pump will stop. 12.2 when indoor unit is in heating mode, water pump will not operate. 12.3 in off state and in an...

Page 106

Will change mode; the sleep will begin to count. A. In cooling/dry mode, after running for 1 hour, the set temp. Will increase 1 ℃ , another 1 hour later, the set temp. Will increase 1 ℃ again, then 6 hours (or set time-2) later , it will stop. B. In heating mode, after running for 1 hour, the set t...

Page 107

Y zzz digit type a temp. Of indoor sensor tai actual data, decimal b temp. Of indoor sensor tc1 actual data, decimal c temp. Of indoor sensor tc2 actual data, decimal d opening angle/2 of indoor eev actual data, decimal e indoor address actual data, hex f indoor central address actual data, hex b. R...

Page 108

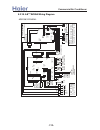

Remote controller receiver main board power timer run sw01 sw02 c n 1 7 c n 1 6 c n 1 4 c n 1 2 c n 1 3 c n 1 1 c n 1 0 c n 7 l e d 1 ,2 cn1 cn2 cn3 cn4 cn6 cn5 to cn14 c n 1 5 cn18 - >_]]vbtzr\ _^uzdz_^vb 5.2.6. Af092-122xcera 108-.

Page 109

-109- >_]]vbtzr\ _^uzdz_^vb 5.2.7. Af092-122xcera f u s e 1 t 3 .1 5 a 2 5 0 v t m c n 4 c n 7 w w w w w w w t c 2 t c 1 c n 5 b c n 6 w l e d 2 l e d 1 c n 1 8 t o o u t d o o r u n it q p l n c n 1 0 s w in g m o t o r m b : b l a c k b r : b r o w n r : r e d w : w h it e y /g : y e l l o w /g r ...

Page 110

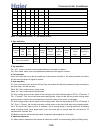

5.2.8. Dip switch functions: 0---off 1---on sw01 [1] [2] [3] [4] [5] [6] [7] [8] function description - 0 0 0 0 0 0 0 default position:0000000 - 0 0 0 0 0 0 0 default position:0000000 default position:0000000 - 0 0 0 0 0 0 0 default position:0000000 - 0 0 0 0 0 0 0 default position:0000000 0 -- -- -...

Page 111

Cn1 cn2 cn21 cn6 cn23 cn3 cn18 cn19 cn19 cn17 cn21 sw2 lamp 1,2 cn13 cn25 cn24 cn27 sw1 cn4 cn6 5.2.9. As***xvera pcb photo - >_]]vbtzr\ _^uzdz_^vb 111-.

Page 112

5.2.10. As***xvera wiring diagram - >_]]vbtzr\ _^uzdz_^vb piping temper- a ture sensor ambient tempera ture sensor swing mot or cn18 cn19 sw03 cn16 sw02 sw01 swing mot or swing mot or cn22 cn21 swing mot or cn23 ac f an mot or m ~ b: black br: brown r: red w : white y/g : yellow/green bl:blue y :yel...

Page 113

- >_]]vbtzr\ _^uzdz_^vb swing motor m swing motor m swing motor m swing motor m piping temper- ature sensor ambient temperature sensor a b c m ~ fuse1 t3.15a sw02 sw01 cn22 cn20 cn21 cn18 cn19 cn17 cn6 cn5 sw03 cn23 cn3 cn2 n cn1 l cn24 cn25 lcd cn27 cn28 cn13 cn26 to outdoor unit 1(l) 2(n) 3 4 b w ...

Page 117

6. Diagnostic code and trouble shooting c>fgolb @jab mn>nb jc gba 7/6/5/4/3 nljo?Gb mejjnfid kjmmf?Gb lb>mjim 3 ctg^fk wxydaef ex`ead fn mx`ead w\eva``xvfxw. Ad uda]x`. Ad e[adf v\dvg\f ctg^fk ex`ead fjv mx`ead w\eva``xvfxw. Ad uda]x`. Ad e[adf v\dvg\f ctg^fk ex`ead fy mx`ead w\eva``xvfxw. Ad uda]x`...

Page 118

Iafx 30 k^xtex va`ftvf f[x \`eft^^xde ad w\efd\ugfade i[x` fdagu^x [tbbx`e fa dxbt\d \f0 40 ngd` f[x baixd ayy t`w baixd a` tzt\`. \y f[x yt\^gdx vawx dxvgde. B^xtex \`yad_ f[x ydt`v[\exd0 50 ct\^dgx vawxe _t]xw i\f[ tdx dxeg_tu^x0 >u`ad_t^ va__g`\vtf\a` uxfixx` i\dxw va`fda^^xd t`w \`waad g`\f k@? ...

Page 119

06 failure code (check the wired remote controller) trouble shooting (indoor unit) * * * * * possible reasons faulty temperature sensor tai 01 sensor disconnected, or broken, or at wrong position, or short circuit faulty temperature sensor tc1 sensor disconnected, or broken, or at wrong position, or...

Page 120

Failure code (check the wired remote controller) trouble shooting (indoor unit) possible reasons over hot protection of compressor serious lack of refrigerant of the system, or the ambient temperature too high, or pmvs be blocked 22 over hot protection of spdu (or ispm) ambient tempreatrue too high,...

Page 121

1. Please contact the installers or distributors when trouble happens to repair it. 2. Turn the power off and power on again, if the failure code recurs, please inform the franchiser. 3. Failrue codes maked with are resumable. Note! 6.1.4. Diagnostic code for af*xcera trouble shooting failure code (...

Page 122

6.1.5. Diagnostic code for as*xvera iafx 30 k^xtex va`ftvf f[x \`eft^^xde ad w\efd\ugfade i[x` fdagu^x [tbbx`e fa dxbt\d \f0 40 ngd` f[x baixd ayy t`w baixd a` tzt\`. \y f[x yt\^gdx vawx dxvgde. B^xtex v[t`zx f[x \`waad g`\f k@?0 50 ct\^dgx vawxe _t]xw i\f[ tdx dxeg_tu^x0 fdbgw_z e]bbf^a\ [v^_gdz xb...

Page 123

6.2. X multi trouble shooting: trouble 1: no display on the operation panel start no check if display panel and the unit matched well no no yes replace display panel and check again if the red diode and green diode on indoor pcb flash in turn yes yes if the power terminal block is 220v input check t...

Page 124

No start as per the wiring diagram, check if communication wiring is correct yes yes yes no no re-wiring, and check again check if the communication port connecting to the indoor/outdoor pcb is in open circuit if the power cable and the communication wire are too close, resulting in the wrong commis...

Page 125

Start no yes no no yes as per the wiring diagram, check if connection port between sensor and pcb is correct re-fix the sensor and check again check if the sensor is in open circuit or the connection port to pcb is in good condition check if the sensor resistor value is correct replace sensor and ch...

Page 126

Start no check if the connector between pressure switch and pcb is fixed badly or damaged (cn20 on pcb) no no no check if the 2 straight lugs on the pressure switch work badly if indoor fan motor cannot startup normally in heating mode(except for defrost) replace main control board and check again y...

Page 127

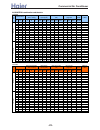

- 1 >_]]vbtzr\ _^uzdz_^vb 8. Outdoor performance curves au182xfera heating capacity in relation to temperature 3000 4000 5000 6000 7000 8000 9000 -15 -10 -5 0 5 10 15 outdoor temperature d.B. Heat ing c apac ity (w) 25 20 15 10 au182xfera cooling capacity in relation to temperature 3000 4000 5000 60...

Page 128

- 1 >_]]vbtzr\ _^uzdz_^vb au222xfera heating capacity in relation to temperature 3000 4000 5000 6000 7000 8000 9000 -15 -10 -5 0 5 10 15 outdoor temperature d.B. Heat ing capaci ty ( w ) 25 20 15 10 au222xfera cooling capacity in relation to temperature 3000 4000 5000 6000 7000 8000 9000 15 20 25 30...

Page 129

- >_]]vbtzr\ _^uzdz_^vb au252xgera heating capacity in relation to temperature 4000 5000 6000 7000 8000 9000 10000 -15 -13 -10 -7.5 -5 -2.5 0 2.5 5 7.5 10 12.5 15 outdoor temperature d.B. Cooling capacit y (w) 10 15 20 25 au252xgera cooling capacity in relation to temperature 4000 5000 6000 7000 800...

Page 130

- 1 >_]]vbtzr\ _^uzdz_^vb au282xhera cooling capacity in relation to temperature 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15 20 25 30 35 40 43 outdoor temperature d.B. Co olin g ca pa cit y ( w ) 14/20 16/22 19/27 22/30 au282xhera heating capacity in relation to temperature 5000 6000 7...

Page 131

- 1 >_]]vbtzr\ _^uzdz_^vb au342xhera cooling capacity in relation to temperature 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15 20 25 30 35 40 43 outdoor temperature d.B. C ooling capacity 14/20 16/22 19/27 22/30 au342xhera heating capacity in relation to temperature 5000 6000 7000 8000 9...

Page 132

- - >_]]vbtzr\ _^uzdz_^vb au362xhera cooling capacity in relation to temperature 5000 6000 7000 8000 9000 10000 11000 12000 13000 14000 15 20 25 30 35 40 43 outdoor temperature d.B. Cooling capacity 14/20 16/22 19/27 22/30 au362xhera heating capacity in relation to temperature 5000 6000 7000 8000 90...

Page 133

- >_]]vbtzr\ _^uzdz_^vb 9. Indoor air velocity and temperature distribution curves 7 2 25 2 2 2 2 7 2 5 2 air velocity distribution cooling blowy angle:40 temperature distribution cooling blowy angle:40 a. Cooling / air velocity distribution b. Cooling / temperature distribution 1.5m/s 1.5m/s 1.0m/s...

Page 134

- >_]]vbtzr\ _^uzdz_^vb 22 27 25 22 25 27 heating blowy angle:70 air velocity distribution c. Heating / air velocity distribution d. Heating / temperature distribution temperature distribution heating blowy angle:70 2.7m 2m 1m 0m 2.7m 2m 1m 0m 1.5m/s 1.5m/s 1.0m/s 1.0m/s 0.5m/s 2m 2m 1m 1m 4m 3m 3m ...

Page 135

- >_]]vbtzr\ _^uzdz_^vb 9.2 ac14/182xcera: a ) grounding air velocity distribution cooling blowy angle:25 temperature distribution cooling blowy angle:25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 2.4 5.5 0 1.5m/s 1.0m/s 0.5m/s 0 2.4 22 25 27 5.5 135-.

Page 136

- >_]]vbtzr\ _^uzdz_^vb heating blowy angle: 5 air velocity distribution c. Heating / air velocity distribution d. Heating / temperature distribution temperature distribution heating blowy angle: 5 5.5 0 2.4 m/s 1.0m/s 0.5m/s 0 2.4 27 25 22 5.5 136-.

Page 137

- >_]]vbtzr\ _^uzdz_^vb air velocity distribution cooling blowy angle: 25 temperature distribution cooling blowy angle: 25 5.5 0 2.4 m/s 1.0m/s 0.5m/s 0 2.4 22 25 27 5.5 b ) ceiling a. Cooling / air velocity distribution b. Cooling / temperature distribution 137-.

Page 138

- >_]]vbtzr\ _^uzdz_^vb heating blowy angle: 65 air velocity distribution temperature distribution heating blowy angle: 65 0 0.5 m/s 2.4 5.5 0 5.5 2.4 25 27 22 c. Heating / air velocity distribution d. Heating / temperature distribution 138-.

Page 139

- >_]]vbtzr\ _^uzdz_^vb air velocity distribution cooling blowy angle:25 temperature distribution cooling blowy angle:25 a. Cooling / air velocity distribution b. Cooling / temperature distribution 2.4m 0m 1.2m/s 0.8m/s 0.4m/s 21 24 26 5.5m 2.4m 0m 5.5m 9.3 af09/122xcera: 139-.

Page 140

- >_]]vbtzr\ _^uzdz_^vb heating blowy angle:5 air velocity distribution c. Heating / air velocity distribution d. Heating / temperature distribution temperature distribution heating blowy angle:5 5.5 0 2.4 0 2.4 26 24 21 5.5 1.2m/s 0.8m/s 0.4m/s 140-.

Page 141

- >_]]vbtzr\ _^uzdz_^vb m fig 1 top view flow control panel horizal lourer:center fig 3 top view flow control panel horizontal lourer:center 0.25 0.5 1.0 2.0 fig 4 top view flow control panel vertical lourer:center condition fan speed:high operation mode:fan voltage:230v,50hz fig 2 top view flow con...

Page 142

- - >_]]vbtzr\ _^uzdz_^vb ad092xlera/ad122xlera ad142xlera/ad182xlera airflow and static pressure chart 300 350 400 450 500 550 600 20pa 15pa 10pa 5pa 0pa static pressure (pa) air f low m 3 /h s.H h m l airflow and static pressure chart 400 450 500 550 600 650 700 750 800 20pa 15pa 10pa 5pa 0pa stat...

Page 143

- - >_]]vbtzr\ _^uzdz_^vb 143.