- DL manuals

- Haier

- Heat Pump

- AU48NFIERA

- Installation & maintenance instructions manual

Haier AU48NFIERA Installation & maintenance instructions manual

Summary of AU48NFIERA

Page 1

Syjs-11-2015rev.D edition: 11-2015 r410a heat pump mrviii-s (g) design, installation & maintenance instruction au282fhera au482fiera (g) au48nfiera (g) au60nfiera (g).

Page 2

Contents 1. General information .................................................................................................................. 1 2. Specification ............................................................................................................................. 2 3. Ind...

Page 3

1 1. General information mrvlli-s adopts refrigerant r410a, which is the new generation of h-mrv. It is with dc inverter technology, high efficiency and energy saving, intelligent control, etc. All indoor units are with eev to adjust the refrigerant flow, collect the data by the precise temp. Sensor...

Page 4

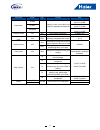

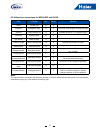

2 2. Specification model au282fhera au482fiera (g) power supply ph/v/hz 1/220~230/50 1/220~230/50/60 cooling rated capacity kw 8 15 rated capacity kbtu/h 27.3 51.2 rated power input kw 2.2 4.2 max. Power input kw 4.1 6.2 eer 3.64 3.57 rated current a 10.5 21.2 max. Current a 20.7 31.3 heating rated ...

Page 5

3 model au282fhera au482fiera (g) outdoor coil number of rows 2 2 tube pitch (a)×row pitch (b) mm 19.05×22 19.05×22 fin spacing mm 1.70 1.5 fin type (code) hydrophilic aluminium hydrophilic aluminium fin coating type optional clear lacquer clear lacquer salt spray test duration hour 168 168 tube out...

Page 6

4 model au48nfiera (g) au60nfiera (g) power supply ph/v/hz 3/380~400/50/60 3/380~400/50/60 cooling rated capacity kw 15 18 rated capacity kbtu/h 51.2 61.4 rated power input kw 4.2 5.5 max. Power input kw 6.2 7.3 eer 3.57 3.27 rated current a 6.7 9.8 max. Current a 10 13 heating rated capacity kw 17 ...

Page 7

5 model au48nfiera (g) au60nfiera (g) outdoor coil number of rows 2 2 tube pitch (a)×row pitch (b) mm 19.05×22 19.05×22 fin spacing mm 1.5 1.5 fin type (code) hydrophilic aluminium hydrophilic aluminium fin coating type optional clear lacquer clear lacquer salt spray test duration hour 168 168 tube ...

Page 8

6 3. Indoor model list 4-way cassette type/pb-700lb ab092mcera ab122mcera ab162mcera high wall eev inside as072mgera as162mgera as092mgera as182mgera as122mgera as242mgera 4-way cassette type/pb-950jb ab182mcera ab242mcera ab282mcera ab302mcera ab382mcera ab482mcera med esp duct type (80/120pa) ad18...

Page 9

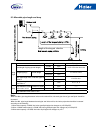

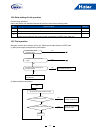

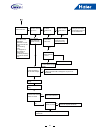

7 4. Refrigerant circuit ta liquid pipe tc strainer p mv strainer strainer te s 4-way valve gas pipe oil segregator sv1 op oil return capillary ts td compressor lp gas-liquid segregator legend connected disconnected 2 c t pmv outdoor unit ta indoor unit tc1 strainer strainer strainer au282fhera sv2.

Page 10

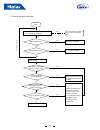

8 ta one-way valve liquid pipe 室外 hex t e tc strainer strainer pmv strainer s accumulator 4-way valve gas pipe strainer sv1 strainer oil segregator strainer op oil return capillary td ts lp gas-liquid segregator legend connected pmv tc2 disconnected ta tc1 outdoor indoor compressor t au482fiera (g),...

Page 11

9 g part name model sign function date compressor au282 capacity control, meet indoor load request by adjusting the frequency motor resistance (at 20°c): 0.88Ω au482 motor resistance (at 20°c): 0.29Ω au48/60n motor resistance (at 20°c): 0.53Ω pressure switch all hp high pressure protection 4.15mpa, ...

Page 12

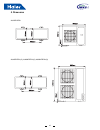

10 5. Dimension au282fhera au482fiera (g), au48nfiera (g), au60nfiera (g).

Page 13

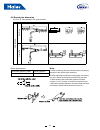

11 1. Single unit scenario over over over over over over over over over over over the top and two side surfaces must be exposed to open space, and obstacles on at least one side of the front and back shall be lower than the outdoor unit. ※ 2. Multiple units scenario: over over over over over over ov...

Page 14

12 6. Wiring diagram control boar d i p m noise filter cn11 cn 6 no co m cn 5 ln cn 1 cn 2 cn 3 cn4(ptc ) con2 con3 cn 2 cn 1 hp lp cn 5 cn 4 cn 7 cn 6 cn 3 tc te td ts ta (out/in_com )cn2 1 p q pm v cn 8 module_co m cn1 0 4-wa ys v2 heate r cn1 4 acfan 1 fan moto r startup capacitor cn 9 cn 2c n1 c...

Page 15

13 au482fiera (g) p sv2 p q sv 1 4wv heater p l n 1 6 2 3 4 5 l n cn60 3 cn609 v w l acl acn l l n line load l n + u y/ g u v w r w b . C u r r en t b w b w ac l ac n ptc up m dcfa n sw01 cn20 cn8 cn24 cn11 eev m led_displa y module_com cn21 cn7 cn6 cn5 cn4 cn3 cn2 out/in ts te td lp cn1 cn1 9 cn1 8...

Page 16

14 au48nfiera (g), au60nfiera (g) sw 02 t s r dc+l2 l1 dc-t s r cn604 led601 led602 igbt r w b bl y /g e n l3 l2 l1 noise filter e n l3 l2 l1 p q r s t n w b g r w w w sw01 sw02 ! u r v w w b comp p w v u n cn607 + cd +c d p p m m cn 12 (d o w n ) (d o w n ) (u p) (u p) m c n 7 ta c n 6 ts c n 2 lp ...

Page 17

15 7. Performance curves 7.1 running range note : au282fhera lowest cooling temperature is 10. 7.2 calculation method (1) calculation method of refrigerating capacity---refrigerating capacity to be known =refrigerating capacity×(a×b×c×d×e) w.

Page 18

16 (2) calculation method of heating capacity---heating capacity to be known = heating capacity×(a×b×c×d×e×f) w outdoor modified capacity with a single indoor running = outdoor modified capacity * (3) calculation method of refrigerating capacity---only one indoor unit running (outdoor modified capac...

Page 19

17 20 30 40 50 60 80 70 au282fhera 1252 50 500 1000 2000 4000 8000 63 nc-20 nc-30 nc-40 nc-50 nc-60 nc-70 octave band center frequency octave band sound pressure level db limit of audible continuous noise 20 30 40 50 60 80 70 au482fiera(g) 63 1252 50 500 1000 2000 4000 8000 nc-20 nc-30 nc-40 nc-50 n...

Page 20

18 8. Outdoor installation 8.1 installation cautions safety precautions ■ please read these "safety precautions" firstly then accurately execute the installation work. ■ though the precautionary points indicated herein are divided under two headings, "warning" and "caution", those points which are r...

Page 21

19 catuion ■ execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightening rod or a telephone ground wire. ■ improper placement of ground wires can result in electric shock. ■ the installation of an earth leakage breaker is necessary depending on the established loca...

Page 22

20 c. Pipe "c" diameter (main pipe, between outdoor gather pipe and the first branch pipe) model gas pipe side liquid pipe side diameter connecting method diameter connecting method au282fhera φ15.88 flared joint φ9.52 flared joint au482/nfiera (g) φ19.05 φ9.52 au60nfiera (g) φ19.05 φ9.52 d. Copper ...

Page 23

21 8.3 allowable pipe length and drop indoor unit length of the longest after the piping length model allowable value piping part total length of piping (actual length) au282 50m l1+l2+l3+l4+a+b+c+d+e au48~60 100m longest piping l actual length au282 35m l1+l2+l3+l4+e au48~60 70m max. Pipe length fr...

Page 24

22 8.4 branch pipe dimension unit: mm; id: inner diameter; od: outer diameter side gas side changing pipe fqg-b335a gas pipe liquid pip branch pipe selection: total indoor capacity (100w) model (optional) less than 335 fqg-b335a note: 1. When connecting the pipe and the outdoor, please pay attention...

Page 25

23 8.5 piping installation important ■ please don't let the pipe and the parts in the unit collide each other. When connecting the pipes, close the valves fully. ■ protect the pipe end against the water, impurity into the pipes (welding after being flat, or being sealed with adhesive tape). ■ bend t...

Page 26

24 ■ the refrigerant pipe should be clean. The nitrogen should flow under the pressure of about 0.5mpa and when charging the nitrogen, stop up the end of the pipe by hand to enhance the pressure in the pipe, then loose the hand (meanwhile stop up the other end). Source valve hand 1st side 2nd side ■...

Page 27

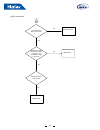

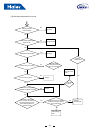

25 8.7 evacuation evacuate at the check valve of liquid stop valve and both sides of the gas stop valve. Operation procedure: after reaching -100.7kpa or less (below -755mmhg), let the vacuum pump running continuously for over 1hour. Leakage test passe d evacuation begins evacuation ends check vacuu...

Page 28

26 8.8 additional refrigerant charging charge the additional refrigerant as liquid state with the gauge. If the additional refrigerant can not be charged totally when the outdoor stops, charge it at the trial mode. If the unit runs for a long period in the state of lack of refrigerant, compressor wi...

Page 29

27 8.9 utilized tool comparison for mrviii r22 and r410a tool purpo8e r22 r410a rea8on knife cut the pipe Ο Ο expander enlarge the pipe Ο Χ for r410a, must enlarge the projecting pipe. Spanner fasten the flare nut Ο Χ standard torque of 1/2, 5/8 pipe is larger. Flare tool flare the pipe Ο Ο pipe ben...

Page 30

28 8.10 trial operation 8.10.1. Before trial running make sure the following works have been finished according to the installation manual. A. Piping work b. Wiring work c. Leakage check d. Evacuate work e. Additional refrigerant charging f. Also check if the indoor works have been finished note: re...

Page 31

29 9. Electric installation warning: in european market: local 3 phase isolator (power switch) must be fitted locally to the unit (legal requirement for eu). For other area, pls. Comply with local regulation requirement. Electric wiring should be executed by the specialized well-trained person. Warn...

Page 32

30 the outdoor and all indoor units are in parallel through 2 non-polar wires. Three wiring methods between wired controller and indoor unit: a. 1 to multi (group control): one wired controller controls 2-16 indoors, as shown in above figure, indoor 1-indoor 2: indoor 2 is wired control master unit,...

Page 33

31 (3) communication wire for wired controller wire length (m) wire spec wire length (m) wire spec 0.3mm 2 × (3-core) shielded wire ≤300 and 1.25mm 2 × (3-core) shielded wire ≤100 and 0.5mm 2 × (3-core) shielded wire ≤300 and 2mm 2 × (3-core) shielded wire ≤200 and 2 × (3-core) shielded wire a. Shie...

Page 34

32 (3) function explanation of switch sw01, sw02. We can know the number of some parameters by using testing device, but must to connect the testing device. Which is not in the control board. The testing device must be bought from manufacturer. Sw01 sw02 display of numeral pipe light with seven segm...

Page 35

33 sw01 sw02 display of numeral pipe light with seven segments 3 0-2 no used 3 error view (previous 3 error code displayed; quit this condition automatically in 2 min; check the last/next error code with up/down button. This error code list cannot be cleared. The earliest error code is blushed off a...

Page 36

34 3-minute delay function if starting up the unit after being powered off, the compressor will run about 3 minutes later against being damaged. Cooling/heating operation indoor units can be controlled individually, but cannot run in cool and heat mode at the same time. If the cool mode and the heat...

Page 37

35 10.1 system marks on the condition that multi mrv ii systems are installed, in order to confirm the relationship between outdoor and indoor, please make marks on outdoor electric control box cover to indicate the connected indoor unit. As the below figure: indoor model: 10.2 trial operation seque...

Page 38

36 10.3.2 outdoor unit confirmation no. Inspection items results 1 if outdoor unit is in good condition, and if the electric box is fixed firmly. 2 if outdoor wiring is correct. If the wires are broken. 3 if the dip switch of outdoor unit is set correctly. If the outdoor address is correct. The mast...

Page 39

37 10.4 state setting of trial operation confirm being electrified indoor and outdoor are electrified respectively and then check as the following table: no. Inspection items results 1 if outdoor pcb is electrified; if the communication indicator flashes. 2 if indoor communication indicator flashes....

Page 40

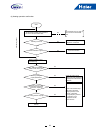

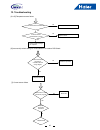

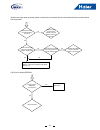

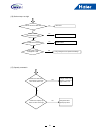

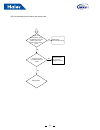

38 (3) cooling operation confirmation start set the mode as cool: press the button for over 5 seconds at off state no no no no no no no once outdoor stops, re-start up the unit 2 and a half minutes later if blowing out cold air if the ventilation is good confirm the running state of the compressor, ...

Page 41

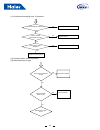

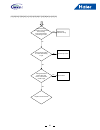

39 (4) heating operation confirmation start no no no no no no no once outdoor stops, re-start up the unit 2 and a half minutes later if the ventilation is good confirm the running state of the compressor, indoor eev if the louver direction make all indoors running simultaneously temp. Difference bet...

Page 42

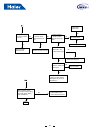

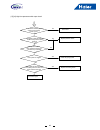

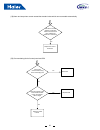

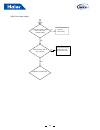

40 if voltage among a, b, c on wired controller is ac 14v if voltage between a and b on indoor terminal block is ac 14v if voltage between l and n on indoor terminal block is ac 220v check indoor power cable if indoor fuse is check the abnormal reason wired controller pcb abnormal wiring between ind...

Page 43

41 if fan motor runs if the other indoors begin to run if voltage among b, c on wired controller is ac 15v if voltage between b and c on indoor terminal block is 15v 1. Indoor pcb abnormal 2. Wiring of indoor pcb is damaged or the port is not inserted well in heating mode, fan motor not run and "pre...

Page 44

42 note 1: temp. Difference between air inlet and air outlet 8tandard a. In cooling mode, after running for at least 30 minutes, it is normal that the temp. Difference between air inlet and air outlet is over 10°c, (at max. Frequency). B. In heating mode, after running for at least 30 minutes, it is...

Page 45

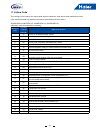

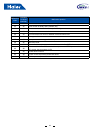

43 11. Failure code the nixie light of the outdoor unit control panel displays malfunction code directly when malfunction occurs. (this malfunction table only applies to the follow models referred in this manual.) au282fhera, au482fiera (g), au48nfiera (g), au60nfiera (g) malfunction code and malfun...

Page 46

44 malfunction code indication on wired controller malfunction position 31 3f power module overload due to constant high current 32 40 over current at steady state (software trip) 33 41 over current at deceleration state (software trip) 34 42 compressor is not connected 35 43 communication loss time...

Page 47

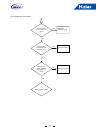

45 12. Troubleshooting [01~05] temperature senor failure if sensor terminal is fixed well reconnect replace sensor if sensor resistor /characteristic is proper check if pcb is faulty, if yes, replace it [6] incorrect dip switch setting for model selection on outdoor pcb check check if the outdoor di...

Page 48

46 [8] dc motor failure check if the wiring of the motor is well replace the motor measure if the pcb vcc-earth voltage is 15v±15%, and 310v-earth voltage is 310v±15% replace pcb replace pcb replace the motor solve the fault no no yes yes yes.

Page 49

47 [9] alarm and stop when the testing indoor numbers are inconsistent with the initial searched locked numbers which can recoverable check if the indoor unit address setting by manual setting the indoor communication address by manual, research indoor unit and lock check if all the indoor units com...

Page 50

48 [11] compressor discharging temp. Td protection if sensor terminal is fixed well reconnect if sensor resistor /characteristic is proper replace sensor if the system is lack of refrigerant charge refrigerant replace connecting board check if the condenser is blocked check if the ipm radiator is di...

Page 51

49 [13][14] high/ low pressure switch open circuit if connection between pressure switch and connecting board is good if the system pressure meets the condition that pressure switch shuts off make pressure switch close, measure if terminal is conductive by multimeter if the system is clogged make pr...

Page 52

50 [15] discharge temperature is too low discharge sensor well connected reconnect of discharge sensor is ok? Reconnect change sensor recharge refrigerant overcharged? Tc1 and tc2 is good? Change change indoor eev is good? (by cut off power and power on again) all indoor fans run normally check fan ...

Page 53

51 [16] suction temp. Too high if sensor terminal is fixed well if sensor resistor /charactenstic is proper if pcb terminal is well if the system is lack of refrigerant or leak reconnect replace sensor replace pcb charge refrigerant and repaired the leakage check if the total indoor units capacity i...

Page 54

52 [18] alarm and stop when current exceed the standard value which can recoverable automatically use the pc-monitor detector and ampere meter to test the current value, whether the difference is within±15% replace the current transducer check if the communication wiring of the module plug well chec...

Page 55

53 [21] compressor over current check if the wiring of compressor is normal replace the compressor wiring measure if the compressor short circuit to ground replace compressor replace compressor measure if the phase resistance of compressor is normal replace inverter module yes yes yes no no no.

Page 56

54 [22] communicating fault of indoor and outdoor units check if the communication wiring pq between indoor and outdoor units is short circuit or short circuit to ground check if the indoor unit address setting by manual replace pcb setting the indoor communication address by manual replace the comm...

Page 57

55 [23][25][26][27][29][30][31][32][33][35][36][37][38][39][40][41][42][43] check the wiring connection of the electrical box according to the wiring diagram, if loosening, flint, etc. Check if the dip switch of outdoor pcb setting is right change the pcb to search state, and confirm if the outdoor ...

Page 58

56 [28] dc bus under voltage check if the outdoor voltage within ±15% of the standard voltage check the power supply check if the ptc wiring connect wrong, if not replace the ptc relay check if the ptc relay is pull in normally replace the inverter board no no yes yes.

Page 59

57 [34] compressor is not connected check if the wiring of compressor connect right and if fall off or burned replace the inverter board reconnect or replace the wiring yes no.

Page 60

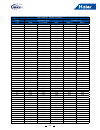

58 appendix sensor characteristic temp. Sensor characteristic no. Sensor type characteristic 1 indoor coil/outdoor suction/oil temp./defrost/ambient temp. Sensor r (25°c)=10kΩ b (25°c/50°c)=3700k 2 wired controller ambient temp./indoor ambient temp. Sensor r (25°c)=23kΩ b (25°c/50°c)=4200k 3 outdoor...

Page 61

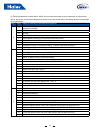

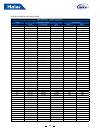

59 7 22.54 21.61 20.68 4.31 4.31 8 21.52 20.65 19.77 4.24 4.24 9 20.56 19.74 18.92 4.16 4.16 10 19.65 18.87 18.10 4.09 4.09 11 18.78 18.05 17.33 4.02 4.02 12 17.96 17.28 16.59 3.95 3.95 13 17.18 16.54 15.90 3.87 3.87 14 16.44 15.83 15.23 3.80 3.80 15 15.73 15.17 14.60 3.73 3.73 16 15.06 14.53 14.00 ...

Page 62

60 57 3.12 2.97 2.83 5.00 5.00 58 3.02 2.87 2.73 5.06 5.06 59 2.91 2.77 2.63 5.13 5.13 60 2.82 2.68 2.54 5.19 5.19 61 2.72 2.59 2.45 5.25 5.25 62 2.63 2.50 2.36 5.31 5.31 63 2.54 2.41 2.28 5.38 5.38 64 2.46 2.33 2.21 5.44 5.44 65 2.38 2.26 2.13 5.50 5.50 66 2.30 2.18 2.06 5.56 5.56 67 2.23 2.11 1.99...

Page 63

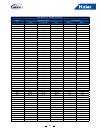

61 (2) r (25°c)=23kΩ b (25°c/50°c)=4200k r25=23kΩ±3% b25/50=4200k±3% temp resistance (kΩ) % (resist. Tol) °c rmax r (t) normal rmin max (+) min (-) -30 538.77 513.12 487.46 5.00 5.00 -29 502.58 478.89 455.21 4.95 4.95 -28 469.29 447.41 425.53 4.89 4.89 -27 438.61 418.38 398.15 4.84 4.84 -26 410.29 3...

Page 64

62 r25=23kΩ±3% b25/50=4200k±3% temp resistance (kΩ) % (resist. Tol) °c rmax r (t) normal rmin max (+) min (-) 18 32.98 32.22 31.45 2.38 2.38 19 31.39 30.67 29.96 2.33 2.33 20 29.87 29.21 28.55 2.27 2.27 21 28.45 27.83 27.21 2.22 2.22 22 27.10 26.52 25.95 2.16 2.16 23 25.82 25.28 24.75 2.11 2.11 24 2...

Page 65

63 r25=23kΩ±3% b25/50=4200k±3% temp resistance (kΩ) % (resist. Tol) °c rmax r (t) normal rmin max (+) min (-) 67 4.15 3.99 3.84 3.84 3.84 68 4.00 3.85 3.70 3.88 3.88 69 3.86 3.71 3.56 3.93 3.93 70 3.72 3.58 3.44 3.97 3.97 71 3.59 3.45 3.31 4.01 4.01 72 3.47 3.33 3.20 4.06 4.06 73 3.35 3.22 3.08 4.10...

Page 66

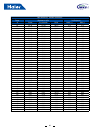

64 (3) r (80°c)=50kΩ b (25°c/80°c)=4450k r80=50kΩ±3% b25/80=4450k±3% temp resistance (kΩ) % (resist.Tol) °c rmax r (t) normal rmin max (+) min (-) 0 1749.01 1921.99 2094.97 9.00 9.00 1 1651.43 1813.27 1975.10 8.93 8.93 2 1560.17 1711.65 1863.13 8.85 8.85 3 1474.74 1616.59 1758.45 8.78 8.78 4 1394.71...

Page 67

65 r80=50kΩ±3% b25/80=4450k±3% temp resistance (kΩ) % (resist.Tol) °c rmax r (t) normal rmin max (+) min (-) 48 168.70 178.33 187.96 5.40 5.40 49 161.74 170.83 179.93 5.33 5.33 50 155.09 163.68 172.28 5.25 5.25 51 148.75 156.87 164.98 5.18 5.18 52 142.70 150.37 158.04 5.10 5.10 53 136.92 144.17 151....

Page 68

66 r80=50kΩ±3% b25/80=4450k±3% temp resistance (kΩ) % (resist.Tol) °c rmax r (t) normal rmin max (+) min (-) 97 26.34 27.48 28.61 4.13 4.13 98 25.45 26.56 27.68 4.20 4.20 99 24.59 25.69 26.78 4.27 4.27 100 23.76 24.84 25.91 4.33 4.33 101 22.97 24.02 25.08 4.40 4.40 102 22.20 23.24 24.28 4.47 4.47 10...

Page 69

Haier commercial air condition web: http://www.Haier.Com haier reserves the right to make change without any notice..