- DL manuals

- Haier

- Refrigerator

- DW-86L288

- Service Manual

Haier DW-86L288 Service Manual

Summary of DW-86L288

Page 1

Service e manua al ultra‐l dw-86l2 dw-86l ow tem 288•dw-86 l486•dw-86 dw-86w mperatur l338•dw-8 6l628•dw-8 w1006•dw- haier m re refrig 86l388•dw- 86l728•dw -86w420 edical & l gerator -86l388a w-86l828 laboratory file no y product : hmrsm ts co., ltd ‐001‐01 ..

Page 2

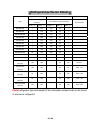

2 / 88 effective models this service manual is effective for following models model name product code voltage(v) frequency(hz) plug-type dw-86l288 be06s8e1t 220 50 all dw-86l338 be0fu3e1t 220 50 all dw-86l388 be06rce1t 220 50 all dw-86l388a be0fv3e1t 220 50 all dw-86l486 be06rje1t 220 50 all dw-86l4...

Page 3: Content

3 / 88 content ●● designation ........................................................................................................................................... 5 ●● introduction to product features ...............................................................................................

Page 4

4 / 88 5.Requirements of battery control ..................................................................................................... 41 6. Meanings of fault codes ................................................................................................................ 41 7 precautio...

Page 5: 【Designation】

5 / 88 【designation】 regulations for type naming: note: rated volume can be the gross volume or effective volume; the manufacturer can decide it by him according to the actual situation. The effective volume value must be marked on the nameplate whether effective volume or gross volume is marked in ...

Page 6

6 / 88 【introduction to product features】 1.1 temperature inside the ultralow temperature cabinet: ‐10~‐86℃, adjustable,temperature set arrange ‐40~‐86℃; 1.2 balanced pressure design inside and outside the cabinet, the door is easily opened and closed; 1.3 temperature inside the cabinet, high and lo...

Page 7: 【Product Appearance】

7 / 88 【product appearance】 dw‐86l388/486/628/728/828.

Page 8

8 / 88 dw‐86l288 dw‐86l338/388a.

Page 9

9 / 88 dw‐86l490 dw‐86w100

Page 10

10 / 88 dw‐86w420

Page 11: Dimensions

11 / 88 【 dimensions 】 dw-86w100

Page 12: Dw-86L490

12 / 88 dw-86l490

Page 13: Other Modles

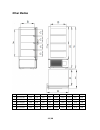

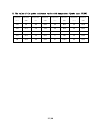

13 / 88 other modles sn model a b c d e f g h i 1 dw-86l388 1310 550 296 620 1960 1980 620 915 870 2 dw-86l486 1310 630 296 590 1960 1980 590 945 900 3 dw-86l628 1310 630 296 760 1960 1980 760 1035 900 4 dw-86l728 1310 630 296 870 1960 1980 870 1145 900 5 dw-86l828 1310 710 296 870 1960 1980 870 114...

Page 14: 【Parts Layout】

14 / 88 【parts layout】 1. Display structure 2. Box structure locked network run regulator back system high temp alarm low temp alarm sensor failure low battery condenser dirty high ambient temperature buzzer cancel shelf: replace the shelf around 45 ° shelf strips inner door: pu foam structure the i...

Page 15

Main s cover senso stainle shelvin bo deco senser: the f of the main r in the box ess steel ng fixed clam ox beams orated bar fixed mp 15 / 88 inner colo material: steel shee or: cream yel electro‐galva et inner door h replace dism handle the c rotation of th cabinet mou llow anized handle: mantled ...

Page 16

T c c the ca the ca p door h name numb s test hole co2 backup s cabin guard p bin right guar abin left guar power code inge (under) eplate and ber senser hole system plate rd rd serial 16 / 88 powe batte r swtich ry swtich.

Page 17

Ma 3. Electr ain control boa low tem pressuriz the high buck ac transform batte conden ronic stru ard mperature zed ac contac h temperature contactor mer ery nser ucture ctor e elec 17 / 88 ctrical control box remote alarm wiring w r232/4 port m wiring board relay 485 serial module battery switch sw...

Page 18

18 / 88 high temperature compressor low temperature compressor condensation fan induced draft fan standby pressure increase pressure decrease mother board.

Page 19

19 / 88 network connection display panel connection temperature regulation screw master sensor condenser sensor heat exchanger sensor computer panel test key: under the condition of power on, press down the test key and see if all relay lamps are lighting in continuous cycle, otherwise, check if the...

Page 20

20 / 88 4. System architecture compressor: look from the back the left: high temperature stage the right: low temperature stage high-stage gas-liquid separator high‐temperature filter low‐temperature filter anti‐dew tube high temperature condenser condenser fan oil separator low temperature pressure...

Page 21: 【Cooling Unit Parts】

21 / 88 【cooling unit parts】 part decripetion parameter models high temperature stage low temperature stage compressor dw‐86l628/728/828 escop/danfoss gs26clx power 220‐240v/50hz start capacitance 117u5381(100uf) run capacitance 117‐7135(20uf) compressor dw‐86l628/728/828 danfoss gs26clx power 208‐2...

Page 22: 【Refrigeration Circuits】

22 / 88 【refrigeration circuits】 diagram of refrigerating system dry filter dry filter capillary tube capillary tube condenser evaporator heat exchanger gas-liquid separator high temperature compressor low temperature compressor pressure control valve oil separator.

Page 23: 【 Circuit Diagram】

23 / 88 【 circuit diagram】 mother board display panel 10 8 9 11 22 22 7 2 1 2 1 1 2 1 2 2 1 1 2 2 1 1 2 c e b c e b a k 2 1 1 2 1 2 k a 2 1 2 1 1 2 1 2 6 5 1 2 1 2 2 1 2 1 1 2 2 1 1 2 2 1 1 2 1 2 2 1 2 1 2 1 2 1 2 1 2 1 2 1 1 2 1 2 1 2 a k k a 1 2 1 2 1 2 1 2 1 2 1 2 2 1 1 2 1 2 1 2 1 2 1 2 1 2 1 2 ...

Page 24

24 / 88 heat prober heat prober power panel booster high te mper ature co mpress or low t e m perat ure c o m presso r blower f an pressure switch heating wire boostin g rela y reducti on rel ay suction fan display board rechargeable battery.

Page 25

25 / 88 【connections on main pcb】 connector connect to usage cn1 wiring board power supply cn3 compressor realy control compressor cn4 battery battery power cn5 main sensor main sensor cn6 two fans and heater control fans and heater cn7 condenser sensor condenser sensor cn8 heat exchanger sensor hea...

Page 26

26 / 88 【specifications of sensor】 1. The value of the probe resistance varies with temperature (probe type: ntc) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) ‐40 63.3 ‐19 17.8 2 5.8 23 2.1 ‐39 59.4 ‐18 16.8 3 5.5 24 ...

Page 27

27 / 88 2. The value of the probe resistance varies with temperature (probe type: pt100) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) temperature (℃) resistance (kΩ) ‐130 48 ‐80 68.3 ‐30 88.2 20 107.8 ‐120 52.1 ‐70 72.3 ‐20 92.2 30 111.7 ‐110 56.2 ‐...

Page 28

28 / 88 【detailed technical data of the product】 type effective volume(l) rated voltage input power(w) overall dimensions (depth*width*height) (mm) inner dimensions (depth*width*height) (mm) compre ssor inner door dw‐86 l288/28 6 288/286l 220v50hz 930w 1641*915*870 971*620*550 sc21cl 3 dw‐86 l388/38...

Page 29: 【Product Nameplate】

29 / 88 【product nameplate】 for example: dw‐86l338.

Page 30

30 / 88 【transportation and installation】 1. Transportation of the product and removal of package 1.1 transportation: the product is heavy, so fork or hydraulic jack will be used during transportation, to avoid damaging the personnel and product. 1.2 removal of package: packing method of the product...

Page 31

31 / 88 figure 1: connecting pieces of the wooden base figure 2 fastening pieces of low temperature cabinet 2. The product enters the placement room 2.1 it is difficult to enter the door: if the product can’t enter the room height required by the client and its access is unavailable without the bott...

Page 32

32 / 88 remove two screws of front cap of cabinet remove the front cap of cabinet ③open the outside door to 180 degree ④after the product enters the room; install the front cap of cabinet as original. Notes: the installation must be in position, otherwise the safety or performance problem will be ca...

Page 33

33 / 88 ⑥height of the working position of the equipment: less than 2000m ⑦operating humidity: less than80%rh. If the maximum operating temperature is 32℃,the humidity shall be less than 57%rh. ⑧input voltage: within 220±10%. Notes: because the ultralow equipment is sensitive to the ambient temperat...

Page 34

34 / 88 underground.( burial depth is 25cm at least). Notes: the earth wire shall not be connected to the gas pipe, telephone line or lighting line. 3.3 method of application after completion of installation for the ultralow temperature cabinet firstly used, or after the ultralow temperature cabinet...

Page 35

35 / 88 【specifications of lcd panel】 1. Unlock for adjusting the setting values, firstly they must be unlocked. Press “△”or”▽”, temperature setting values will flash, press “△”or”▽”, and input the number 06, then hold “function selection” for 5 seconds, “lock” lamp goes out, to enter unlock status....

Page 36

36 / 88 3. High temperature alarm when set “high temperature alarm”, if temperature set display area flashes, it indicates the temperature setting value, at this time press shifting and adjusting key to adjust the alarm setting value. If no operation is done within 10 seconds after adjustment, then ...

Page 37

37 / 88 【indicating of working status of display panel】 1. The refrigerator will enter starting status after it is switched on, and all parameters on the display screen will be saved as those before the last power interruption. The displayer will display the actual temperature, setting temperature a...

Page 38

38 / 88 【indication of alarm status】 “high temperature” indicating lamp: if the lamp lights, indicating the alarm display when the temperature inside the refrigerator is higher than the setting value. “low temperature” indicating lamp: if the lamp lights, indicating the alarm display when the temper...

Page 39

39 / 88 ambient temperature, when the ambient temperature exceeds 38℃ (excluding 38℃), “too high ambient temperature” indicating lamp in the alarm display area will light and send alarm, accompanied with buzzer alarm. Light flashing alarm can’t be cancelled, until the fault is removed. While the buz...

Page 40

40 / 88 【setting of special functions】 1. Setting of password value when the low temperature refrigerator is firstly used, unlock password is 06. After unlocking, press “function selection” and “buzzer cancel” for 5 seconds simultaneously, 06 will be displayed on the display, then press “▲” and “▼”t...

Page 41

41 / 88 two fans will be turned off. 5. Requirements of battery control there is a battery power switch on the equipment, which will be turned on before normal start. The equipment will enter normal operating status only it is connected to ac power satisfying the equipment requirement. When ac power...

Page 42

42 / 88 display fault on the display screen is e5. Alternate display time: the actual temperature display is 6 seconds and fault code display is 2 seconds (since nov. 2009). 7. Precautions 7.1 after initial installation or moving equipment, clockwise rotation of the horizontal leg horizontal feet su...

Page 43: 【Fa

The main ①pe minu initia ② w ③wh the m ④wh the m fault cod rception co utes), the c l on electric when the se hen the ma main sensor hen conden main sensor des ondenser te ondenser is city within t ensor failure ain sensor f r fault code nsation sen r fault code 【fa mperature s dirty "ind two hours,...

Page 44

⑤w temp ⑥wh actua after temp hen the ri perature an hen heat ex al temperat the buzze perature lev ng temper d the main xchanger se ture and the er canceled vel press sta rature sens sensor faul ensor failure e heat exch 5 seconds art, the low 44 / 88 sor failure, t code "e0" e, sensor fa hange "e3"...

Page 45

45 / 88 ⑦when heat exchanger sensor senses the temperature ≥ 90 ℃ , alarm display e4 remarks: (model ‐25 ° c and ‐50 ℃ heat exchanger sensor so no e3, e4, fault) (model: independent backup system no e0, e1, e3, e4 fault) alternately display time: the actual temperature display 6 seconds, the fault c...

Page 46

46 / 88 【product use and maintenance】 1. Principle of work: the design of overlaying‐type freezing medium system is used for freezing mediums with different boiling points; this system needs two independent cooling systems. It is shown as above, each system can work synchronously; first level system...

Page 47

47 / 88 hours prior to use (or powered up again before use) inspection machine. Qualified to confirm the testing machine the use of the cryogenic cabinet 1) must stand for the freezer for at least 24 hours to energize. 2) empty containers not put items power on in stages so that the freezer before c...

Page 48

48 / 88 decreases to 1.35mpa, contact connects, low temperature cabinet starts up; when pressure exceeds 2.1mpa again, contact disconnects again, and it circulates in order. Note: when pressure switch is being welded, put a wet towel on it to keep temperature below 100℃. The parameters of pressure s...

Page 49

49 / 88 the systems. For the machine that its system has already been opened, the pipe welding shall be finished at once. As the machines have strict requirement for system moisture content, so, when a machines pipe is opened, the opening of pipe shall be sealed with tape at once to prevent air from...

Page 50

50 / 88 4. Fan parameters product model parameter sl‐490c2w special no. / / fan application evaporation fan condensation fan manufacturer ebm ebm fan model / / rated voltage 230v 230v input power 10w 10w fan type induced draft type induced draft type dimension fan blade diameter 200 fan blade diamet...

Page 51

51 / 88 【gas collection and charge】 1. Diagram of refrigerating machine 2. Compressor parameters product model dw‐86l386/288/388, dw‐86w420 compressor model sc21cl voltage range(v) 208~230 refrigerating output(w) 3/4 hp rated frequency(hz) 50 input power(w) 800w current(a) 3 rated voltage(v) 220 coo...

Page 52

52 / 88 3. The characteristics of the refrigerant 1) refrigerant mixed working quality, some flammable, explosive refrigerant perfusion spaces should be ventilated, once the leak, not in the vicinity of the ignition or sparking. Refrigeration system problems, feedback issues point by the local after...

Page 53

53 / 88 open, and let go of the refrigerant in the system. 2) in the system, the opening 20 minutes, the open pipe with a pressure gauge welding is completed 【note】 1) this model is a two refrigeration, sub‐high temperature and low temperature level, two separate sets of system maintenance, do not a...

Page 54

High sea can figu 4) l gau hou this the pre as t 【note】 1) u to 1 h pressur ling mach n not seal ure 4 ow press uge valve, ur or mor s period re time to m ssure stat the pressu using 4 lit 12 hours e the tim hine refrig the mout ure for ta pressure e to chec equires th more than te for mor ure does ...

Page 55

55 / 88 picture 2 picture 3 picture 4 u unit: pa 3pa.

Page 56

56 / 88 perfusion refrigerant high temperature level perfusion, the machine should be in a stopped state before perfusion r134a refrigerant and then perfusion r404a refrigerant. Perfusion was performed in accordance with the attached table! 【note】 1) to ensure the refrigerant once reperfusion in pla...

Page 57

57 / 88 refrigerant necessary, using the above export perfusion, the above infusion refrigerant cylinders upright perfusion, the perfusion gas. 4) in order to ensure the accuracy of refrigerant perfusion, perfusion of all refrigerant necessary electronic weighing scales perfusion. 5) evacuation and ...

Page 58

58 / 88 picture 6 5. Infusion flow of freezing medium ①the schematic diagram of each freezing medium cylinder ②infusion flow of freezing medium when infusing high temperature level freezing medium, machine shall be under the status of stop, firstly, infuse r134afreezing medium, then infuse r404afree...

Page 59

59 / 88 medium, at the time of infusion, you must turn on cylinder valve a little to avoid wasting freezing medium and affecting maintenance progress. When infusing low temperature level freezing medium, machine shall also be under the status of stop, firstly, infuse hra freezing medium, then infuse...

Page 60

60 / 88 【refrigerant perfusion details】 type high-temperature stage low-temperature stage the refrigerant (type / amount) 1 the refrigerant (type / amount) 2 improved date r134a(g) r404a(g) r508b(g) r290(g) r23(g) dw-86w100 / 510 140 20 / dw-86w420 / 540 160 20 / dw-86l288/286 / 540 210 20 / dw-86l3...

Page 61: 【Troubleshooting】

61 / 88 【troubleshooting】 fault analysis maintenance measures 1.High temperature level compressor fails to start 1. User’s fuse burns out change the fuse 2. Machine storehouse wiring connector plugs s are damaged change the connector plugs 3. Bas wire contact check contact and make in good condition...

Page 62

62 / 88 fault analysis maintenance measures 6.Freezing cabinet noise is high 1. Uneven placement change the location of the freezing cabinet. 2. When compressor is running, there is resonance between pipeline and cabinet. Clear up pipeline,or add a shock pad under compressor baseboard to avoid reson...

Page 63

63 / 88 fault analysis maintenance measures 8. Displayed temperature is different from actually tested temperature 1. The user's test instrument is not accurate change the test instrument 2. Temperature probe of sensor is not accurate under locked state,press down "temperature" button until temperat...

Page 64

64 / 88 1.E0 alarm ring temperature sensor input voltage ≥ 4.9v, the sensor open; ≤ 0.1v, the short‐circuit 1.Check the ambient temperature sensor terminal plug bad or falling; sensor for damage 2 check the display board sensor connector terminals are loose or poor contact; whether the display panel...

Page 65

65 / 88 【how to deal with high temperature alarm】 high-temperature stage fan is normal low-temperature stage fan is normal refrigerator temperature ≥ high temperature alarm set temperature (high temperature alarm set temperature ≥ run set temperature +5 ° c) check the power is normal check the fan a...

Page 66

66 / 88 【how to deal with low temperature alarm】 low-temperature stage fan is normal measuring the actual temperature of the refrigerator low-temperature stage compressor is normal after 15 minutes flashing alarm, sound alarm low temperature alarm lights flashing refrigerator temperature ≥ high temp...

Page 67

【points needing to pay attention】 1. Points needing attention during normal use-proper use ●when the refrigerator is firstly used or the storage box hasn’t been used for a long time, the alarm “low battery” will appear, because the charged battery has been completely discharged. But it doesn’t mean ...

Page 68

68 / 88 inner door of the refrigerator body. If it is too thick, freezing effect of the storage box will be influenced, to increase the power consumption. Therefore, when the frost layer reaches 5mm thick, it shall be removed with the shovel attached at intervals. ●prior to defrosting, please take o...

Page 69

69 / 88 2. Points needing attention during normal use-safety requirement please apply the special power (ac220v‐/50hz) marked on the equipment nameplate. If the voltage applied is less than 198v or higher than 242v, the automatic stabilizer exceeding 4000w shall be provided. If the power wire needs ...

Page 70

70 / 88 explosion or fire. The corrosive articles such as acid and alkali shall not be stored in the equipment; otherwise its inner components or electric parts will be damaged. The metal object such as iron nail or iron wire shall not be inserted into any port or clearance of this equipment, or any...

Page 71

71 / 88 equipment damage will be caused due to equipment turnover. Close the box door with your hand holding the handle, to avoid the fingers being clamped. Don’t put the glass bottle or canned goods into the box, since personal injury will be caused due to their frost cracking. Don’t touch the good...

Page 72

72 / 88 later, so as not to damage the compressor or system. The power plug must be pulled out during maintenance. Don’t roll or damage the power wire. Disposal of the discarded equipment must be carried out by the relative personnel. The box door shall be dismantled, to avoid the accidents such as ...

Page 73

73 / 88 3. Points needing attention during normal use-disposal of special circumstances if the equipment has any fault, please check the following faulty points before maintenance: the equipment can’t be started ●check the power is normally connected or the mains switch is switched on or not? ●is th...

Page 74

74 / 88 hence the equipment temperature shall be reduced by steps, to avoid too much temperature reduction within a short time. 【warning】 in order to prevent electric shock or personal injury, the equipment shall be disconnected from the power prior to any repair or maintenance. Ensure that the chem...

Page 75

75 / 88 【other maintenance and repair】 1. Clean storage box storage box shall be cleaned once a month. Regular cleaning can make storage box keep clean appearance. Use a dry cloth to wipe off dirt on box shell, inner chamber, and all attached bodies. If storage box is very dirty, dip a clean cloth i...

Page 76

76 / 88 4. Defrost inner wall generally, frost occurs on the upper part of refrigerator body and inner door. Frost may cause gap between refrigerator body and door sealing strip, which may cause bad refrigerating effect. Defrost on inner door with a defrosting shovel, which is provided together with...

Page 77

77 / 88 storage may be affected. It is suggested that the battery shall be replaced as soon as possible. If you need to replace battery, please contact haier after‐sale service personnel. Warning: to avoid electric shock or personal injury, before equipment maintenance or repair, the power must be c...

Page 78: 【Faq】

78 / 88 【faq】 1. Common faults analysis and maintenance measures ①question: displayed temperature is not the same as actual test temperature: answer: as the displayed temperature is the temperature at one point in refrigerator, while a user is testing the temperature of another point in refrigerator...

Page 79

79 / 88 ⑤question: why is it displaying e0 and other signs? Answer: main sensor failure: e2,condenser sensor failure:e1, ambient temperature sensor failure:e0, check if above wiring is normal or not, if is not normal, please contact after‐sale service personnel for maintenance or replacement. ⑥quest...

Page 80

80 / 88 6, it shall be over 7.5v),so model machine computer panel can recharge battery; if battery electric quantity is lower than 10.5(for old products with mode of 6, when it is lower than 7.5v), a machine starts to recharge the battery, it takes about 5 days to finish recharging battery; if the m...

Page 81: Dw-86L628

【used spare parts photo gallery】 dw-86l628 sn part code spares name qty picture whether wearing parts 1 0070701061 filter dryer 1 2 0070700606 pressure control switch for 2nd stage 1 3 0070701865 suction accumulator 1 4 0270200538 outer gasket for outer door 1 y 5 0270200322b inner gasket for outer ...

Page 82

7 0070101872 duplex all‐round caster 1 8 0074091318 display board 1 y 9 0074091225 condenser temperature sensor 1 10 0074090884 ambient sensor 1 y 11 0070204295 cover for access port 1 12 0070204827 inner door handle 1 y 13 / defrost shovel 1.

Page 83

14 0270800385 outer gasket for inner door (interior door assembly) 1 y 16 0270800385 inner gasket for inner door (interior door assembly) 1 y 17 0070401235 battery power switch 1 y 18 0070106373 inner door hinge 1 y 19 0070107087 outer door hinge 2 y 20 0070107112 outer door handle 1 21 0074091430a ...

Page 84

22 00707 23 00740 24 02707 25 / 26 00740 27 00740 28 00740 29 00740 700552 091183 700027 / 090871 a 090857 090857 (2 091167 oil sep cabinet tem control pt1 air cooled c door switch system c ac contactor fan for lo (220v/ fan for hi 20v/60hz) 17 compressor( (danf arator mperature sensor 100 condenser...

Page 85

30 00240 31 00708 32 00740 000070 815591 090752 power re compressor( catch assem mecha circuit b elay for 220v/60hz) bly for latch anism breaker 1 1 1 y y.

Page 86: 【Testing Date】

【testing date】 cooling rate sn model power supply ambient temp cooling time(from ambient temp to ‐80℃)min 1 dw‐86l288 220‐240v/50hz 25℃±3 ≤360 2 dw‐86l388 220‐240v/50hz ≤420 3 dw‐86l486 220‐240v/50hz 208‐230v /60hz 115v60hz ≤420 4 dw‐86l628 220‐240v/50hz 208‐230v /60hz 115v60hz ≤450 5 dw‐86l728 220‐...

Page 87

Temperature of the cooling system parts temperature of the parts sn model power supply ambient temp cooling system temperature h‐in h‐out l‐in e‐in e‐out 1 dw‐86l288 220‐240v/50hz 25℃±3 ≤‐32℃ ≤ ‐32℃ ≤ ‐32℃ ≤ ‐86℃ ≤ ‐85℃ 2 dw‐86l388 220‐240v/50hz 3 dw‐86l486 220‐240v/50hz 208‐230v /60hz 115v60hz 4 dw...

Page 88: Qingdao China

Inspired living haier medical & laboratory products co., ltd. Room 403d, brand building, haier industrial park, no.1 haier road qingdao china website: www.Haiermedical.Com.