- DL manuals

- Haier

- Dryer

- HD80-26A

- Service Manual

Haier HD80-26A Service Manual

HD80-26A

Heat Pump Dryer

Model No.:

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians.Any attempt to service

or repair the product or products dealt with in this service information by anyone else could result in serious injury or death.

Haier Group

year (full name of the company who issues the service information).

All rights reserved.Unauthorized copying and distribution is a violation of law.

SERVICE MANUAL

TL1409S005V1.1

HD80-26A-F

HD80-26A-DF

Summary of HD80-26A

Page 1

Hd80-26a heat pump dryer model no.: warning this service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a pro...

Page 2: Table Of Contents

- 2 - service manual model no: 26a series issue rev. Table of contents document control ......................................................................................................... 1 chapter 1. General information ............................................................................

Page 3: 1-2. General Guidelines

Service manual model no: 26a series issue rev. 1-2. General guidelines 1-3. Caution and warning symbols 1-4. Function indication symbols when servicing,observe the original lead dress.If a short circuit is found, replace all parts which are overheated or damaged by the short circuit.After servicing ...

Page 4: 2-1. Features And Theory

- 4 - service manual model no: 26a series issue rev. Chapter 2. Product feature 2-1. Features and theory energy class a+++ delay time adjustable led display heat pump tumble dryer 1 airflow circuit 2 compressor 3 fan 4 drain pump 5 condenser 6 accessorial condenser 7 motor fan 8 refrigerant circuit ...

Page 5: 2-2.

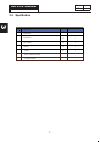

- 5 - service manual model no: 26a series issue rev. 2-2. Specification front loaded dryer hd80-26a-f 1. Product identification description of appliance dryer type of appliance (fs = standing, bi = built-in) fs supplier own brand haier supplier bar code ean (tbc) commercial brand / model haier 2. Ke...

Page 6

- 6 - service manual model no: 26a series issue rev. 3. Basics data unit dimensions (h x w x d) cm 84.5x 59.5 x65 net weight kg 50.5 voltage/frequency v/hz 220~240v/50hz input power(max) w 800w control m = electromechanical, e=electronic,f=fuzzy e drum s = stainless steel / z = zinc coated s door: a...

Page 7: 2-2.

- 7 - service manual model no: 26a series issue rev. 2-2. Specification 6. Function n° 1 function selection dry level mode timer start/pause button power button n° 1 n° 1 n° 1 n° 1.

Page 8

- 8 - service manual model no: 26a series issue rev. Chapter 3. Important safety instructions 3-1 before switching the device on for the first time 1.Ensure that the device is installed and electrically grounded by a qualified service person in accordance to local codes to prevent shock hazard and a...

Page 9: Chapter 4.

- 9- service manual model no: 26a series issue rev. Chapter 4. Operation instructions 4-1 control panel 4.1.1 power button press this button to turn the tumble dryer on and off. 4.1.2 start/pause button press this button to start stop the tumble dryer. Press this button during the running of the tum...

Page 10: Service Manual

- 10 - service manual model no: 26a series issue rev. 4.1.3 programme turn the knob to choose the desired drying program.There are 16 progrmme options. Extra dry wool shoe sport microfiber baby garment towel mix duvet ready to store ready to iron synthetic extra dry cotton ready to iron ready to sto...

Page 11: 4.1.4 Display Screen

Service manual model no: 26a series issue rev. 4.1.4 display screen 6 - 11 - timer mode dry level selection function eco emo 2 7 4 3 5 1 8 10 11 12 9 6.Process indicator: 1 2 3 filters must be cleaned regularly. See lint filter cleaning or condenser filter cleaning section of the manual. Child-lock ...

Page 12: 4.1.5 Function Button

-12 - service manual model no: 26a series issue rev. 4.1.5 function button 7/8 function and selection button there are 4 functions you can choose note: not all the funcions can be selected for different program. Delay function for delay start, turn the knob to theright to set time (in 1 intervals up...

Page 13: Service Manual

-13 - 13 service manual model no: 26a series issue rev. 4-2 using the tumble dryer 4.2.1 connect the tumble dryer to the power supply (220v to 240v~/50hz). 4.2.2 loading the tumble dyer 4.2.3 switch on the power supply 4.2.6 turning off the tumble dryer,empty tank and clean filter. 4.2.5 drying 4.2....

Page 14: Chapter 5.

-14 - service manual model no: 26a series issue rev. Chapter 5. Part identification control panel drawer hold the drawer,the tank can be pulled outwards front panel outer frame of sight window venting door the cooling air is sucked through slots.Do not block the slots. Handle pull the handle , the d...

Page 15

-15 - service manual model no: 26a series issue rev. Wheel support the drum base part box of container drum refrigerant(134a) filter pump condenser capacitor belt fortified panel motor foot evaporator compressor fan.

Page 16

-16 - service manual model no: 26a series issue rev. Cover of air channel process fan wheel wheel lamp cover unscrew 2 screws from the cover, it can be opened,the light can be replaced. Hook of basket humidity sensor filter fan belt pulley motor belt pulley belt seal felt.

Page 17: Chapter 6.

-17 - service manual model no: 26 series issue rev. Chapter 6. Disassembly guide 6-1 control panel push 1) unscrew 2 screws on the back of the top plate. 2) pull the top plate backward and upward as shown. Pull out the tank. 1) unscrew 2 screws on the top of the control panel. 2) unscrew 2 screws ne...

Page 18

-18 - service manual model no: 26a series issue rev. 6-2 bearing and process fan 1) unscrew all the screws around the belt cover and the back cover. 1) remove the blet; 2)unscrew the 2 screw near the bearing; 3) unscrew the screw near the pulley. 1)unscrew 2 screws around the pulley; 1)unscrew 2 the...

Page 19: 6-3 Motor

-19 - service manual model no: 26a series issue rev. 6-3 motor unscrew 4 screws on the holder for bearing. The bearing can be disassembled. Bearing 1) disassemble the top cover; 2) disassemble the front panel; 3) unscrew 5 screw fastening the front girder. 1) unscrew all the screw on the top back an...

Page 20

-20 - service manual model no:26a series issue rev. 1)disconnect the wire of motor ; 2)disassemble the spring drum belt. 3)unscrew 2 screws fastening the motor. 1)unscrew the nut fastening the motor belt pulley and remove the pulley. 2)disassemble the wire of capacitor; 3)unscrew 2 screws fastening ...

Page 21: 6-4 Pump

-21 - service manual model no: 26a series issue rev. 1) unscrew 2 screws on the support of pump. 2) seperate the pipe and pump; 3) disconnect the wire of pump. The pump assembly can be taken out. 1) remove cooling grid ; 2) remove service door. 6-4 pump 6-5 front air channel.

Page 22

-22 - service manual model no: 26a series issue rev. Unscrew all the screw on the front panel and disassemble it. Turn the four spanners anticlockwise and you can take the filter assembly out. Unscrew 2 screws on the hinge, disassemble the door..

Page 23: 6-6 Belt

-23 - service manual model no: 26a series issue rev. Unscrew 3 screws on the front air channel. The front air channel can be disassembled. The belt can be disassembled. 6-6 belt.

Page 24: Service Manual

Unscrew 7 screws on the pcb -24 - service manual model no: 26a series issue rev. Box. 1. Romove the knob. 2. Remove the guide beam. 6-7 pcb remove the power board. 1. 2.Disconnect the lead between the pcb and the touching broad. 3.The pcb assembly can be disassembled. 1.Unscrew 5 screws on the pcb c...

Page 25: 6-8 Base Assembly

-25 - service manual model no: 26a series issue rev. Instruction: 1) all the tubes can be welded together to be a heat pump system; 2) every part in the base assembly can be applied as spareparts; 3) the refrigerant charged is r134a. 4) the system air pressure should be less than 15pa before chargin...

Page 26

-26 - service manual model no: 26a series issue rev. Seal bar.

Page 27: Chapter 7.

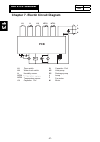

-27 - service manual model no: 26a series issue rev. Chapter 7. Electic circuit diagram k1 door switch hp heat pump k2 water level switch dp drainage pump h humidity sensor l lamp f fan motor ntc2 m motor ntc3 temperature sensor k1 h k2 ntc2 ntc3 hp dp l f n l g pcb m c2 c1 c2 capacitor 17uf capacit...

Page 28: Chapter 8.

-28 - service manual model no: 26a series issue rev. Chapter 8. Circuit interface diagram pump n l empty power motor heat pump fan lamp motor communication moisture content sensor ntc2 touching pcb contact water level sensor ntc3 door switch empty.

Page 29: Chapter 9.

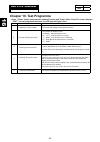

-29 - service manual model no: 26a series issue rev. Chapter 9. Fault detection y 9-1 the dryer does not start the power supply plug peels off; the local circuit is out of power; t he door is not closed tightly; the power button is off the start/pause button has not been pressed the water tank is fu...

Page 30: 9-2

-30 - service manual model no: 26a series issue rev. Y 9-2 the drying result is not good and the drying time is too long. The drying program setting is not correct; the filter screen near the window has not been cleaned the evaporator is blocked the amount of the loaded laundry exceeds the rated loa...

Page 31: 9-3

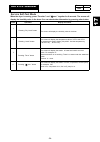

-31 - service manual model no: 26a series issue rev. 9-3 code:f2 n check if the tank is full with water check if there are some lints aroud the floater ; error message:the drain pump is failed. Y empty the tank and restart the dryer. Y clear the lints; n check if the floater switch is failed ; y rep...

Page 32: Service Manual

-32 - service manual model no: 26a series issue rev. 9-6 code:f4 error rmessage:temperature of the laundry in the drum does not change. Check if the refrigerant let out. Y charge the refrigerant again n check if the compressor is failed ; y replace a new base assembly error message:the ntc3(near the...

Page 33: Service Manual

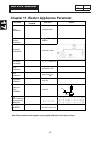

-33 - service manual model no: 26a series issue rev. Chapter 10. Order operation display and action 1 press “power” button and press two buttons(function and temp.) within 10 sec.The screen displays “test”, the test programme will start, the led lamp will light in turn. 2 pressing “function” button ...

Page 34: Service Self-Test Mode

-34 - service manual model no: 26a series issue rev. Order operation display and action 1 pressing “timer” button the screen will display the temperature value of ntc2 and ntc3. For example the screen display “26 d028”. And the temperature of ntc2 is 26 , ntc3 is 28 . 2 pressing “mode” button the sc...

Page 35: Chapter 11.

- 35- service manual model no: 26a series issue rev. Chapter 11. Electric appliances parameter part name motor 0184000013 reference number in sbom parameter remark compressor capacitor 0034200008 ac 450v 50/60hz compressor 0184000016b 220-240v / 50hz door switch 0024000290 16 4 a ,250v ac, pump 0024...

Page 36: Sincere Forever

Printed in china sincere forever group haier industrial park, no.1, haier road 266101, qingdao, china http://www.Haier.Com.