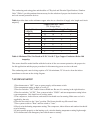

Haier HR18D2VAR Installating And Operation Manual - Table Of Content

1

TABLE OF CONTENT

1.Introduction ---------------------------------------------------------------------------------------

2.Nomenclature for Model Number -------------------------------------------------------------

3.Specification -------------------------------------------------------------------------------------

4.Unit Inspection -----------------------------------------------------------------------------------

5.Equipment Protection From Environment -----------------------------------------------------

6.Installation ----------------------------------------------------------------------------------------

6.1. General ---------------------------------------------------------------------------------------

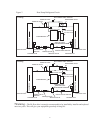

6.2.Unit clearances ------------------------------------------------------------------------------

6.3.Refrigerant piping ---------------------------------------------------------------------------

6.4.Electrical wiring -----------------------------------------------------------------------------

7.System Startup -----------------------------------------------------------------------------------

8.Operation ----------------------------------------------------------------------------------------

9.Miscellaneous -----------------------------------------------------------------------------------

9.1.Replacement parts --------------------------------------------------------------------------

9.2.Troubleshooting guide ---------------------------------------------------------------------

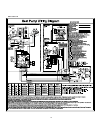

9.3.Wiring diagram -----------------------------------------------------------------------------

1.INTRODUCTION

This manual contains the installation and operating instructions for your new Heat Pump.

Improper installation can result in unsatisfactory operation or dangerous conditions. Carefully

read this manual and any instructions packaged with separate equipment required to make up

the system prior to installation. Give this manual to the owner and explain its provisions. The

owner should retain this manual for future reference.

2.NOMENCLATURE FOR MODEL NUMBER

H Brand symbol - H: Haier

R System type - C: Air conditioner; R: Heat pump.

24 Nominal capacity in (000) Btu/h

D SEER designation. D=13, E=14

2 Design series. 2 - 2nd Generation

V Electric: V=208/230-1-60; C=208/230-3-60, D=460-3-60, Y=575-3-60

A Body style

R Reserved

Example: HR24D2VAR

1

1

2

5

5

5

5

6

6

11

12

13

13

13

13

13