- DL manuals

- Holman

- Oven

- 210HX series

- Installation And Operation Instructions Manual

Holman 210HX series Installation And Operation Instructions Manual

Summary of 210HX series

Page 1

® ® ® ® ® miniveyor multi-purpose oven model 210hx, 214hx series installation and operation instructions 2m-hg0104 rev. J 1/18/2012 214hx 20hx-v67 & v68 24hxa-v68 all models.

Page 2

2 2 these symbols are intended to alert the user to the presence of important operating and maintenance instructions in the manual accompanying the appliance. Retain this manual for future reference notice using any part other than genuine star factory supplied parts relieves the manufacturer of all...

Page 3

Specifications 210hx-120v - 60hz rating/connection: 1,700 watts nema plug: 5-15p, cul 5-20p electrical supply: separate service per oven - 14.2 amp, 120 vac, 60 hz approximate weight (210hx oven with legs): installed - 61.5 lbs (28 kg), shipping - 39.5 lbs (18 kg) dimensions: width: 46 11/16" (118.6...

Page 4

4 general installation data this equipment is designed and sold for commercial use only by personnel trained and experienced in its operation and is not sold for consumer use in and around the home nor for use directly by the general public in food service locations. Before using your new equipment,...

Page 5

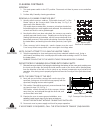

Assembly and installation continued install unit in its operating position allow sufficient space for operating personnel. Install the crumb, load and unload trays as shown, making sure the ends are at least 6" from any vertical combustible surfaces. Have an electrician connect input power to the un...

Page 6

6 stacking ovens when stacking two holman miniveyor ovens a stacking spacer with an external air duct must be used to prevent overheating of the control box of the top oven. 1. Place bottom unit in position where the oven will be located. 2. Place stacking spacer on top of the bottom oven with inter...

Page 7

7 daily operation baking in these units is a combination of heat and belt speed. Some foods may require more top heat or visa versa; other foods may require low top and bottom heat and slow belt speeds. Every product should, therefore, be tested using the separate top & bottom controls and the varia...

Page 8

8 cleaning preventive maintenance for your holman oven consists of the following recommended cleaning procedures. To keep your oven in its top operating condition, these steps should be performed on a daily, weekly or as indicated. Turn unit off, disconnect unit from power supply or turn power off a...

Page 9

Cleaning continued monthly 1. Turn main power switch to the off position. Disconnect unit from its power source and allow to cool. 2. Perform daily & weekly cleaning procedures. Removal & cleaning conveyor belt 3. Heavily soiled conveyor surfaces, 214 models locate all 3 of the master links on the c...

Page 10

0 maintenance procedures a. Replacing heater tubes 1) disconnect power source. 2) remove both the left and right side panels, by removing the truss head screws. Pull the top of each panel out slightly and lift up. 3) remove each heater tube wires which are requiring replacement from its terminal blo...

Page 11

Maintenance procedures continued 10) slide motor until the drive chain has about 1/4” slack when lightly pushed at the center of its top open run. See chain tensioning illustration. 11) tighten screws to secure motor. 12) rewire leads same as removed in step 6. 13) at this time you may plug unit in ...

Page 12

2 troubleshooting guide a. Unit will not heat, conveyor belt will not move. 1) be sure the main circuit breaker is switched to the on position and there is power to the outlet. 2) check to see if the oven is plugged in and all controls are turned to the on position. 3) be sure the hi-limit reset but...

Page 13

Wiring diagrams all wiring diagrams on the following pages are those of current and obsolete design models, and may not represent current production. To determine which diagram goes with your unit, reference the nameplate located on the cord side of the unit, and use the table below. Call the star s...

Page 14

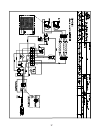

4 ® model: 210hx, 120v, 50/60hz, 4-tube, wired series 214hx, 120v, 60hz, 4-tube, wired series this drawing contains information confidential to star mfg. Int'l. Inc. No reproduction or disclosure of its contents is permitted. 020022 rev b 9/22/2009 gnd heat adjust heat adjust conveyor motor high lim...

Page 15

Red red yel org blu blu yel blk yel blk wht pur blk wht blk red blk red blk blk blk blu red wht wht blk ® models: 210hx, 120v, 60hz, 4-tube, wired series, canada 210hx(p)/214hx, 208,220,240v, 50/60hz, 3.2 kw, 4-tube, wired series 214hx, 220v, 50/60hz, 3.6 kw, 4-tube, wired series 214hx, 208v, 60hz, ...

Page 16

6 blk red high limit switch red red red ground top heat bottom heat blu yel heat adjust org org yel wht pur blk blk blk blk blk blu wht wht blk ® model: 210hx, 120v, 60hz, 4-tube, wired parallel 214hx, 240v, 50hz, 4-tube, wired parallel 214hxr, 240v, 50hz, 4.5kw, 4-tube, wired parallel 214hx, 208/24...

Page 17

7.

Page 18

8 org blu wht org yel blu blu red blk org blk blk blk blk wht brn red red red blk yel ® model: 214hx, 208/240v, 60hz, 4.5kw, 6-tube, wired parallel this drawing contains information confidential to star mfg. Int'l. Inc. No reproduction or disclosure of its contents is permitted. 020175 rev - 9/11/20...

Page 19

Pilot light non-cord supplied units l1 l2 gnd high-limit switch as shown above for cord supplied units black white ground l2 l1 top heat fan bottom heat red red red orn wht blk blk wht yel blk blk brn blk blk blk blk blk blk red red org blu wht org pur org yel pur yel wht wht wht wht org pur org yel...

Page 20

20 ® model: 210hx/214hx, 208/240v, 50hz, 4-tube, wired parallel this drawing contains information confidential to star mfg. Int'l. Inc. No reproduction or disclosure of its contents is permitted. 820039 rev - 2/07/2001 top heat bottom heat m main power or cordset m conveyor motor power on / off bott...

Page 21

2m-4497-2 6/1312 the foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty. For assistance should you need any assistance regarding the operation or maintenance of any star equipment; write, phone, fax or email our service department. ...

Page 22

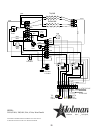

1 2 4 3 5 6 7 8 11 12 11 10 9 7 13 14 15 16 17 18 19 20 22 21 24 25 26 27 33 28 29 30 32 34 35 36 38 37 11 12 11 10 39 40 41 42 43 phase temp nameplate 23 31 44 model: miniveyor 210hx, 214hx sk2150 rev . B 9/14/09 ®.

Page 23

1 ga-401287 1 top cover 2 hm-400891 2 heat shutter 3 2p-150001 1 drive chain, 12 in. 4 2p-z8779 1 sprocket, 25p-1 1t 5/16 id, drive 2p-200646 1 sprocket, 25b20 x 5/16, drive 210hxrc-v01 5 2p-200653 1 sprocket, 25b20 x 3/8, driven 2p-1 15362 1 sprocket, 25b1 1 x 3/8, driven 210hxrc-v01 6 2u-z13803 1 ...

Page 24

Fig no. Part no. Description quantity per 1 gb-401288 1 top cover 2 hm-400899 2 heat shutter 3 2p-150001 1 drive chain, 12 in. 4 2p-z8779 1 drive sprocket (1 1 tooth) .313 id 2p-200646 1 drive sprocket (20 tooth) 214hxrc, hxetb, hxr 2p-200653 1 drive sprocket (20 tooth) 214hxrrcm, 214hxrcm 2p-z8779 ...

Page 25

210hx & 214hx series element chart rev . J 5/23/2013 element chart fig. No part no qty desc unit v oltage unit amp draw 210hx 13 ga-199100 nla 4 heater tube (430w , 3.58a) 120v (metal) 14.3 gh-197848 4 heater tube (7.86Ω, 425w , 3.54a) 120v (quartz) 14.2 2n-209197 4 heater tube (700w , 3.36a) 208v (...

Page 28

Star international holdings inc. Company star - holman - lang - wells - bloomfield - toastmaster 10 sunnen drive, st. Louis, mo 63143 u.S.A. (314) 678-6303 www.Star-mfg.Com.