Summary of ReedJet AUS 100cc-TaG

Page 1

Man-033 reedjet aus 100cc – tag 01/11/04 installation manual.

Page 2

Man-072 1 general description of engine this engine of the "tag" series (touch and go) has been expressly designed and developed to power karts for hobby racing on closed tracks, destined for this specific purpose. When designing this new line of engines, the technical solutions already adopted for ...

Page 3

Man-072 2 engine features – operational limits engine features: cycle: original cubic capacity: original bore: max. Theoretical bore: stroke: lubrification : induction: carburettor: cooling: ignition: electric starter: clutch: otto / 2 stroke 100 cm³ 48.20 mm 48.53 mm 54.05 mm max mixture 5% reed va...

Page 4

Man-072 3 accessories exhaust group coperchio frizione inlet silencer + filter tillotson carburettor sparkplug kit clutch cover + h.T. Coil push buttons bracket wiring harness battery support kit.

Page 5

Man-072 4 engine identification number the engine serial number is marked on the front right part of the clutch side crankcase (see fig.) the number normally includes 1 letter, followed by 2 digits numbers, “au” and 2 other digits numbers (there can be exceptions in some special cases). Other number...

Page 6

Man-072 5 2- preparation and installation of the engine on the chassis note: in case the engine is supplied already assembled on the chassis, it is at care of the assembler to follow these instructions. The final customer, in this case, can skip this section and can start reading from section 4. Whe...

Page 7

Man-072 6 2.2- exhaust manifold installation note: the engine is supplied with an exhaust card board cover to protect the internal parts. The exhaust gasket and stud bolts are already mounted. Remove the nuts and the exhaust card board cover . Make sure that the exhaust gasket is in seat and install...

Page 8

Man-072 7 2.3- installation carburettor install the gas cable clamp on the support (see fig. 5) 12 point wrench 10mm remove the 2 3.5mm screws on the carb. Pump (in correspondence of the throttle lever). (see fig. 6) screwdriver 4.8 mm / torx t20 install the support bracket and the two screws. Screw...

Page 9

Man-072 8 final step - after the complete installation of the engine on the chassis. Connect the fuel feed hose to the inlet fitting on the carburettor cap. (see fig. 10) 2.4- preparation and installaton of the engine-mount note: all the dimensions in millimeters drill 4 holes (diam. 8.25÷8.5mm) in ...

Page 10

Man-072 9 2.5 install the engine on the chassis position the engine on the 2 outside main rails and fix the motor-mount with the two clamps. (see fig.11) suggestion: never torque completely the clamps until the chain is installed and properly aligned. Check the alignment of the engine sprocket and t...

Page 11

Man-072 10 2.6 install the clutch cover with h.T. Coil allen wrench 5 mm removed the 3 screws tcei m6x30 from the crankcase (see fig. 15) and install the clutch cover with the h.T. Coil. (see fig.16) tighten the 3 screw at 8÷10 nm attention: always make sure that the ground cable always connects the...

Page 12

Man-072 11 2.7- electrical connections (refer to the attached electrical scheme) note: for a correct installation follow the under shown instructions. Insert battery fixing stripe in the dedicated slots. (see fig. 17) place the battery support clamps on the chassis tube, fix them through the specifi...

Page 13

Man-072 12 place the starter button in the proper housing and fix it through the provided nut. (see fig.21) fix and place the button with the faston oriented as in the figure: pass the cable with the buttons terminals in the bracket, connect the 2 fastons to the starter button and tighten the stop r...

Page 14

Man-072 13 fix the kit cables through a strap according to the chassis and the need. (see fig.26) connect the superseal 4 ways male faston connector to the female connector of the stop cable. (see fig.27) connect the male faston of the stop cable to the female faston connector of the ingnition. (see...

Page 15

Man-072 14 2.8 assembly of the intake silencer make sure that the intake silencer is positioned with the holes upside and that they are not obstructed. Tighten the clamp on the inlet silencer support on the carburettor and fix the inlet silencer with the dedicated clamp on the chassis tube. (see fig...

Page 16

Man-072 15 3.1- mixture oil and fuel use unleaded premium gasoline 95 ron, mixed with oil at 5% (20:1). Use oils containing castor’s oil that guarantees an optimized lubrication at high temperature. As on the other hand, castor oils create gummy residues that give origin to carbon deposits causing i...

Page 17

Man-072 16 3.2- carburettor setting 1 t.O. * rich lean 1 ¼ t.O. ¾ t.O. 1 ½ t.O. * t.O. = turns open generally the correct settng of the carburettor screws is the following : l (close the screw completely and then open): 2 and 05' t.O. H (close the screw completely and then open): 50' t.O. According ...

Page 18

Man-072 17 3.3-starting and stopping the engine the engine start is achieved by pushing the black rubber button on the bracket. If the engine does not start, stop and try again. If the engine does not start within 5 seconds (check that gasoline flows to the carburettor), stop the procedure and try a...

Page 19

Man-072 18 3.7- exhaust gas temperature probe the exhaust muffler is not provided with a temperature probe lodgment. If necessary, it is possible to install the probe support and as indicated in the figure. Whenever you wish to employ the probe, please proceed as shown in the figure below. 3.8-centr...

Page 20

Man-072 19 3.9-instructions for the disassembly / assembly of the clutch group warning : the following operations can be made by a skilled mechanic, with the proper tools shown in the text ; otherwise, it is necessaty to apply to an authorized service center. Refer to the following drawing during th...

Page 21

Man-072 20 before assembling the clutch, wash with the diluent : the shaft cone, the starter wheel and the clutch drum. Clutch assembly 1.Asseble the starter wheel on the clutch hub by matching the 3 holes and the dragging pin 2.(3 screws tcei m6) warning: it is necessary to always install the Ø 7 m...

Page 22

Man-072 21 never let the battery tension drop under 8v as under this limit the battery can not be used and it will have to be replaced. Never put the battery in contact with solvents, oils, plastifiers or rags containing such elements as the battery external case could be damaged. Never press and/or...

Page 23

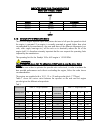

Man-072 22 indicative spark plug comparison table based on thermal degree hot bosch ngk champion wo8cs br9eg n54r wo7cs br10eg n52r wo6cs br11eg cold 3.12- choice of the sprockets ratio the life of an engine depends upon many factors but most of all upon the speed at which the engine is operated. If...

Page 24

Man-072 24 3.13-replacement of the starter brushes operations pictures disassemble the starter motor - loose the screw m6x30 on the additional starter support (see fig.1). (5mm allen wrench t type) - remove the additional starter support 3 screws m6x25 (see fig.2). (5mm allen wrench t type) - remove...

Page 25

Man-072 25 opening the starter motor - unscrew the m4 screw fixing the input cable (see fig.6) (screwdriver) - unscrew the 3 m5 “c” screws (see fig.7) (screwdriver) fig.1 fig.6 fig.7.

Page 26

Man-072 26 - remove the drum from the starter motor keeping the rotor in its seat (be sure to hold the rotor on its toothed side to prevent the brushes from falling out from their seat (see fig . 8) - extract the rotor from the starter motor head (see fig. 9) attention: when extracting the rotor, th...

Page 27

Man-072 27 - remove the silicon from brushes with a screwdriver (see fig. 11) - remove springs - remove the brush making pressure on the tin plate terminal externally (see fig. 13) - install new brush terminal (see fig.14). - place the little rubber cap on the terminal. - reinstall the plate and fix...

Page 28

Man-072 28 replacement of the brush “b” - loose the screw m3 “g” (see fig.16) - extract the brush - fix the new brush with screw m6 (screwdriver) closing the starter - insert the new brush spring "a" into its seat. - install the brush. - keep the brush in place by pressing towards the outer and clam...

Page 29

Man-072 29 5 - check that the o-ring "h" is installed on the starter head. - insert the starter drum on the head being careful to prevent the rotor from rotating and to prevent the brushes from falling out of their seat (see fig. 20). - torque the 3 screws m5 (see fig.21). (screwdriver) - check that...

Page 30

Man-072 30 3.14-schedule maintenance following some simple maintenance standards will allow the engine to perform more reliably and have a longer life. Schedule components actions and comments before each use flexible spring check status muffler check status and fixing (springs) engine sprocket chec...

Page 31

Man-072 31 3.15-troubleshooting here below there are some of the most common problems, the possible causes and the recommended solutions to solve them. Problems probable causes solutions starter will not crank when pushing the start button bad connections on starter cables check connections and tigh...

Page 32

Man-072 35 3.19-engine and accessories preservation when the engine is not operating for a long period, it must be preserved in the most suitable way: disconnect the battery and recharge it regularly (see sect. 12) disassemble the carburettor and clean it seal the inlet and the exhaust with adhesive...

Page 33

Ma n -072 36 1 - s tar t & stop bu tton 2 - ba ttery 3 - ig nitio n a dapter 4 - s tar ter 5 - h. T. C oil 6 - ig nitio n 3. 21 – w iring di ag ra m.