- DL manuals

- IBM

- Server

- 87302RU

- Hardware Maintenance Manual

IBM 87302RU Hardware Maintenance Manual

Summary of 87302RU

Page 1

Bladecenter t type 8720 and 8730 hardware maintenance manual and troubleshooting guide.

Page 3

Bladecenter t type 8720 and 8730 hardware maintenance manual and troubleshooting guide.

Page 4

Note before using this information and the product it supports, be sure to read appendix c, “notices,” on page 157. Sixth edition (august 2006) © copyright international business machines corporation 2004. All rights reserved. Us government users restricted rights – use, duplication or disclosure re...

Page 5: About

About this manual this manual contains diagnostic information, a symptom-to-fru index, service information, error codes, error messages, and configuration information for the bladecenter ® type 8720 and 8730. Important safety information be sure to read all caution and danger statements in this book...

Page 6

Lea atentamente todas las declaraciones de precaución y peligro ante de llevar a cabo cualquier operación. Online support you can download the most current diagnostic, h8 flash, and device driver files from http://www.Ibm.Com/pc/support on the world wide web. Support telephone numbers view support t...

Page 7: Contents

Contents about this manual . . . . . . . . . . . . . . . . . . . . . . . Iii important safety information . . . . . . . . . . . . . . . . . . . . Iii online support . . . . . . . . . . . . . . . . . . . . . . . . . Iv support telephone numbers . . . . . . . . . . . . . . . . . . . . Iv chapter 1. Ge...

Page 8

Removing the media tray . . . . . . . . . . . . . . . . . . . . 50 installing the media tray . . . . . . . . . . . . . . . . . . . . 50 removing and installing management modules . . . . . . . . . . . . . 51 removing a management module . . . . . . . . . . . . . . . . . 52 installing a management mo...

Page 9

Getting help and information from the world wide web . . . . . . . . . 111 software service and support . . . . . . . . . . . . . . . . . . . 112 hardware service and support . . . . . . . . . . . . . . . . . . . 112 appendix b. Related service information . . . . . . . . . . . . . . 113 safety info...

Page 10

Viii bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 11: Chapter

Chapter 1. General information the ibm ® bladecenter ® t types 8720 and 8730 units are rack-mounted, high-density, high-performance blade server systems developed for telecommunications network applications and other applications requiring physical robustness. The bladecenter t unit uses blade serve...

Page 12

Record information about your bladecenter t unit in the following table. You will need this information when you register your bladecenter t unit with ibm. Product name ibm eserver bladecenter t machine type (8720 or 8730) _________________________________________ model number ______________________...

Page 13

User label cmm 1 cmm 2 important: do not place the label on the blade server itself or in any way block the ventilation holes on the blade server. Related publications this hardware maintenance and troubleshooting guide is provided in portable document format (pdf). It contains information to help y...

Page 14

Notices and statements used in this book the caution and danger statements that appear in this book are also in the multilingual safety information book, which is on the ibm bladecenter t documentation cd. Each statement is numbered for reference to the corresponding statement in the safety informat...

Page 15

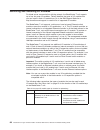

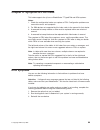

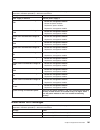

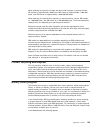

Features and specifications for the bladecenter t type 8720 unit the following table provides a summary of the features and specifications of the bladecenter t type 8720 unit. Table 1. Bladecenter t type 8720 features and specifications media tray (on front): v dvd/cd-rw drive: slim ide v two univer...

Page 16

Notes: 1. For details about the bladecenter t unit port specifications, see “bladecenter t unit power, controls, and indicators” on page 19. 2. For information about which types of i/o modules can be installed in which i/o-module bays, see “i/o modules” on page 19. 3. The operating system in the bla...

Page 17

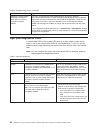

Features and specifications for the bladecenter t type 8730 unit the following table provides a summary of the features and specifications of the bladecenter t type 8730 unit. Table 2. Bladecenter t type 8730 features and specifications media tray (on front): v dvd/cd-rw drive: slim ide v two univer...

Page 18

Notes: 1. For details about the bladecenter t unit port specifications, see “bladecenter t unit power, controls, and indicators” on page 19. 2. For information about which types of i/o modules can be installed in which i/o-module bays, see “i/o modules” on page 19. 3. The operating system in the bla...

Page 19

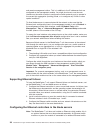

Major components of the bladecenter t types 8720 and 8730 unit the following illustration shows the locations of major components in your bladecenter t unit. Kvm module i/o module power module esd a c i n d c o u t a c 1 3 0 0 w a c i n ! D c o u t blade server filler blade media tray management mod...

Page 20

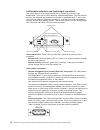

System service cards these cards contain system service instructions and a writable area for your use. The cards are located in a slot just above the management-module bays. To access the service cards, slide out the cards as shown in the following illustration. Cmm 1 cm m 2 esd system service card ...

Page 21

V error: when this amber led is lit, it indicates that an error has been detected somewhere on the management module. When this led is lit, the system error led (critical, major, or minor) on each of the bladecenter t system-status panels is also lit. Management module ip reset button: do not press ...

Page 22

System status leds: the leds on this part of the panel provide status information for the bladecenter t unit. V power: when continuously lit, this green led indicates the presence of power in the bladecenter t unit. The led turns off when the power source is interrupted. Attention: if the power led ...

Page 23

Power modules ac in led dc out led dc in led error led ac power module dc power module dc out led error led power module leds: each power module has three leds to indicate the status of the power module. V ac (or dc) in: when continuously lit, this green led indicates that the input power source is ...

Page 24

Table 3. Power module leds (continued) dc in or ac in dc out ! (error) (amber) description and action off off off or on* there is an input power problem. Possible causes: v there is no power to the power module. Actions: make sure that: 1. The power is correctly connected to the unit. 2. The power i...

Page 25

Rear view this section identifies the components and indicators on the rear of the bladecenter t unit. I/o module 2 i/o module 1 i/o module 4 esd connector i/o module 3 lan module kvm module blower module 2 blower module 4 blower module 1 blower module 3 top d top d btm e btm e 2 4 1 3 crt mjr mnr 2...

Page 26

Kvm (keyboard, video, mouse) module indicators and input/output connectors the kvm module is a hot-swap module that is installed on the rear of the bladecenter t unit and is held in place by captive thumbscrews. This module contains two ps/2 connectors for the keyboard and mouse, a system-status pan...

Page 27

Connectors: the kvm module has the following i/o connectors: v keyboard connector: the bladecenter t kvm module contains one ps/2-style keyboard connector. Use this connector to connect a ps/2 keyboard to the bladecenter t unit. 6 4 2 1 3 5 v mouse connector: the bladecenter t kvm module contains on...

Page 28

Lan-module indicators and input/output connectors the lan module is a hot-swap module that is installed on the rear of the bladecenter t unit and is held in place by captive thumbscrews. The lan module provides the electrical and mechanical interface to the bladecenter t unit for the two local area ...

Page 29

Note: the service processor, management module, or systems-management function must monitor the alarm reset inputs to maintain the fault condition that you set for the unit. The alarm reset inputs can be voltages in excess of standard logic levels, so you must electrically or optically isolate them ...

Page 30

2. Reinstall the four blowers into the rear of the bladecenter t unit if you have not done so already. See “removing and installing blower modules” on page 54 for detailed instructions. Note: the blowers will not start until the power modules are installed. 3. When the power connections are in place...

Page 31

Notes: 1. Within 2 minutes after power has been connected to the bladecenter t unit, the management module applies power to the i/o modules. 2. If a power failure occurs, the bladecenter t unit restarts automatically when power is restored. 3. The blade-server power button turns on or turns off the ...

Page 32

Breakers to the off position or removing the fuses as applicable. Make sure that both circuits are disconnected or turned off. If you have a bladecenter t type 8730 (ac-power) unit, disconnect all power cords on the bladecenter t unit from the ac power distribution unit (pdu). Note: after you discon...

Page 33: Chapter

Chapter 2. Configuring the bladecenter t unit the bladecenter t unit automatically detects the modules and blade servers that are installed and stores the vital product data (vpd). When the bladecenter t unit is started, the management module automatically configures the remote management port on th...

Page 34

For best results when using the web browser, set the monitor to 256 colors. Use only the video resolutions and refresh rates given in the following table. These are the only video resolution and refresh rate combinations that are supported for all system configurations. Resolution refresh rate 640 x...

Page 35

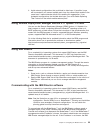

Setting up the remote connection to configure and manage the bladecenter t unit and blade servers, you must first set up the remote connection through an ethernet port on the lan module. The lan module is on the rear of the bladecenter t unit at the top-right side. Lan module kvm module top d top d ...

Page 36

Complete the following steps to connect the ethernet cable to the management module. 1. Connect one end of a category 5 or higher ethernet cable to an ethernet connector on the lan module. Connect the other end of an ethernet cable to the network. 2. Check the ethernet leds to make sure that the net...

Page 37

Starting the management and configuration program complete the following steps to start the management and configuration program: 1. Open a web browser. In the address or url field, type the ip address or host name that is defined for the management-module remote connection (see “setting up the mana...

Page 38

Setting management and configuration program options from the management and configuration program main menu, you can select settings that you want to view or change. The navigation pane (on the left side of the management module window) contains navigational links that you use to manage the bladece...

Page 39

Module automatically when needed). Otherwise, configure the dhcp setting as you prefer. You must configure the static ip address only if dhcp is disabled. – ip address - the ip address for the management module. The ip address must contain four integers from 0 through 255, separated by periods, with...

Page 40

And remote management station. This is in addition to the ip addresses that are configured on the management module. You might also have to use the user interface on the switch module to configure the switch external ports to operate in the correct link aggregation (trunking) mode, or to configure a...

Page 41

Must be installed in the bladecenter t unit in i/o-module bay 1 or 2, or both, before the integrated ethernet controllers on each blade server system board can be used. The ethernet controllers are integrated on each blade server system board. The ethernet controllers provide 1-gbps full-duplex capa...

Page 42

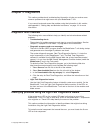

A typical, preferred bladecenter t network topology is shown in the following illustration. See the ibm eserver bladecenter t planning and installation guide for more information and other topologies and guidelines. Mac 1a 1b 2a 2b 3a 3b 4a 4b 5a 5b 6a 6b 7a 7b 8a 8b 1 2 3 4 5 6 7 8 mac 1a 1b 2a 2b ...

Page 43

3. Avoid network configurations that could lead to data loops, if possible. Loops will be created if you connect multiple ports from the same switch module to the same layer 2 network device without first enabling link aggregation. If you implement configurations that include data loops, you must en...

Page 44

Director software can automatically discover the bladecenter t unit (out-of-band, using the ethernet port on the management module) and create a managed object for the unit. For the ibm director software to discover the bladecenter t unit, your network must initially provide connectivity from the ib...

Page 45: Chapter

Chapter 3. Diagnostics this section provides basic troubleshooting information to help you resolve some common problems that might occur with your bladecenter t unit. If you cannot locate and correct the problem using the information in this section, see appendix a, “getting help and technical assis...

Page 46

For example: a system error has occurred, and you have noted that the bladecenter t system-error led is lit on the system led panel. You then locate the module or blade server that also has an error led lit (see “bladecenter t unit power, controls, and indicators” on page 19 for the location of erro...

Page 47: Chapter

Chapter 4. Setting up the bladecenter t hardware this chapter provides instructions for setting up the bladecenter t unit and installing and removing modules, options, and blade servers. Setting up the bladecenter t unit statement 20: caution: to avoid personal injury, before lifting the unit, remov...

Page 48

Before you begin to install options in the bladecenter t unit, read the following information: v read the safety information beginning on page 113 and the guidelines in “handling static-sensitive devices” on page 40. This information will help you work safely with your bladecenter t unit and options...

Page 49

(see the documentation that comes with your blade server for information about turning on the blade server). Make sure that you shut down the blade-server operating system before turning off a blade server, to avoid damaging the hard disk drives. Notes: 1. Within two minutes after power has been con...

Page 50

Handling static-sensitive devices attention: static electricity can damage electronic devices and your system. To avoid damage, keep static-sensitive devices in their static-protective packages until you are ready to install them. Use an esd wrist strap and the esd connectors on the bladecenter t un...

Page 51

V limit your movement. Movement can cause static electricity to build up around you. V handle the device carefully, holding it by its edges or its frame. V do not touch solder joints, pins, or exposed printed circuitry. V do not leave the device where others can handle and damage it. V while the dev...

Page 52

Preinstallation steps before you begin, read the documentation that comes with your module or option. Statement 8: caution: never remove the cover on a power supply or any part that has the following label attached. Hazardous voltage, current, and energy levels are present inside any component that ...

Page 53

Removing and installing the bezel assembly the bladecenter t unit comes with a bezel assembly containing a removable and replaceable air filter. There are software features in the management-module that detect a clogged filter and generate system alerts based on the severity of the airflow reduction...

Page 54

Installing the bezel assembly complete the following steps if you are installing the bezel assembly at the front of the bladecenter t unit: 1. Ensure that the bezel lock is open; then, insert the bottom bezel hooks into the bezel slots at the bottom of the bladecenter t unit. 2. Push in the bottom a...

Page 55

1. Remove the bezel from the front of the bladecenter t unit (see “removing the bezel assembly” on page 43 for instructions). 2. Place the bezel front-side down on a work surface. 3. Remove the air-filter retainer by pulling the retainer upwards and off the ball-stud fasteners on the bezel. 4. Remov...

Page 56

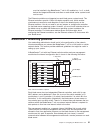

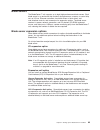

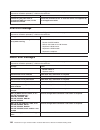

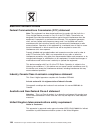

Removing and installing power modules the bladecenter t unit is separated into two power domains. To support devices in power domain b, a power-supply module option (consisting of two power modules) must be installed. The following table summarizes the modules that are powered by each power domain. ...

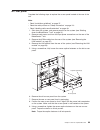

Page 57

Power module 1 power module 2 cmm 1 cm m 2 power module 3 esd power module 4 release handle filler module release button removing a power module complete the following steps to remove a power module or filler panel from the front of the bladecenter t unit. The procedure is the same for both ac-power...

Page 58

2. Grip the power-module handle with one hand and slowly pull the power module out of the bay. Use your other hand to support the bottom of the power module as you pull the power module out from the bay. Attention: do not carry the power module by only the power-module handle. You must support the w...

Page 59

Removing and installing the media tray the media tray is a hot-swap unit that is installed in the front of the bladecenter t unit and contains the system-status panel, two usb connectors, and the cd-rom drive. See “media tray” on page 11 for information about the system-status panel controls and ind...

Page 60

Removing the media tray complete the following steps to remove the media tray in the front of the bladecenter t unit: 1. Open the two release levers as shown in the illustration. The media tray moves out of the bay approximately 0.6 cm (0.25 inch). 2. Make sure that the release latches are in the op...

Page 61

Removing and installing management modules the bladecenter t unit comes with one hot-swap management module in management-module bay 1. You can add a second management module in management-module bay 2. Note: only one management module is active; the second management module, if present, provides re...

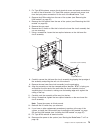

Page 62

Cm m 1 cm m 2 esd release latch management module removing a management module notes: 1. If you are removing the only management module in the bladecenter t unit, to avoid unexpected termination of sessions, stop all management-module local and remote sessions before proceeding. 2. If you are removi...

Page 63

Installing a management module complete the following steps to install a management module in the bladecenter t unit: 1. If you are installing a second management module, see the ibm bladecenter t management module user’s guide for information about management-module redundancy. 2. If you are replac...

Page 64

Removing and installing blower modules the bladecenter t unit comes with four hot-swap blowers for cooling redundancy. The blowers are installed at the rear of the system. The blower speeds vary depending on the ambient air temperature at the front of the bladecenter t unit. If a blower fails, the r...

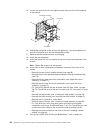

Page 65

2 4 1 3 release latch (open) error led power led removing a blower module use the following instructions to remove a blower at the rear of the bladecenter t unit. 1. Press the release lever at the end of the release latch and pull the latch to the open position. The blower module moves slightly out ...

Page 66

Removing and installing the kvm (keyboard, video, mouse) module the kvm module is a hot-swap unit that is installed in the rear of the bladecenter t unit and is held in place by captive thumbscrews. The kvm module provides the electrical and mechanical interface to the bladecenter t unit for a local...

Page 67

Removing the kvm module complete the following steps to remove the kvm module at the rear of the bladecenter t unit. 1. Remove the keyboard, mouse, and video cables if any are connected. 2. Fully loosen each thumbscrew counterclockwise. 3. Hold the kvm module by both thumbscrews. 4. Carefully pull t...

Page 68

Removing and installing the lan module the lan module is a hot-swap unit that is installed in the rear of the bladecenter t unit and is held in place by captive thumbscrews. The lan module provides the electrical and mechanical interface to the bladecenter t system for the two local area network (et...

Page 69

Removing the lan module complete the following steps to remove a lan module from the rear of the bladecenter t unit: 1. Fully loosen each thumbscrew counter clockwise. 2. Grasp the lan module by both thumbscrews. 3. Carefully pull the lan module outward from the lan module bay until you feel it rele...

Page 70

Removing and installing i/o modules for blade server communication with the network, the bladecenter t unit supports up to four hot-swap i/o modules. Table 5 identifies the types of i/o modules that you can install in each i/o-module bay. Go to the ibm support web site at http://www.Ibm.Com/support/...

Page 71

Table 5. Hot-swap i/o module types by location for redundancy (continued) bays i/o-module function permissible i/o module 3 and 4 network connections 3 and 4 (for all i/o expansion options on blade servers in the bladecenter t unit) one of the following combinations. V two ethernet switch modules v ...

Page 72

Release latch (open) release latch (open) ethernet switch module fibre channel switch module filler module filler module removing an i/o module use the following instructions to remove an i/o module or filler module from the rear of the bladecenter t unit. 1. Press the release lever at the end of th...

Page 73

Blade servers the bladecenter t unit supports up to eight high-performance blade servers. Each blade server is an enclosure that contains microprocessors, memory, a control chip set, an i/o bus, ethernet controllers, hard disk drives or flash drives, and user-interface controls, and connectors for e...

Page 74

Removing and installing a blade server or filler module use the instructions in this section to remove or install a blade server at the front of the bladecenter t unit. Important: reinstalling a blade server into a different bay than the one from which it was removed could have unintended consequenc...

Page 75

Installing a blade server complete the following steps to install a blade server or filler blade in the bladecenter t unit. Statement 21: caution: hazardous energy is present when the blade is connected to the power source. Always replace the blade cover before installing the blade. 1. Install any o...

Page 76

10. If you have other modules to install at the front of the unit, do so now. Otherwise reinstall the bezel assembly on the front of the bladecenter t unit. Note: reinstall the bezel assembly on the bladecenter t unit after you have finished installing the blades. However, if you installed an option...

Page 77: Chapter

Chapter 5. Service replaceable units this chapter describes the removal of server components. Important: the field replaceable unit (fru) procedures are intended for trained servicers who are familiar with ibm xseries products. See the parts listing in chapter 7, “parts listing, bladecenter t type 8...

Page 78

Dc terminal cover with fasteners complete the following steps to replace the dc terminal cover on the type 8720 unit. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Shut down...

Page 79

Ac rear panel complete the following steps to replace the ac rear panel located at the rear of the unit. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Shut down the system, ...

Page 80

10. If you have no other replacement procedures to perform at the rear of the system, re-install the lan module (see “installing the lan module” on page 59) and the kvm module (see “removing and installing the kvm (keyboard, video, mouse) module” on page 56). 11. Plug each power cord into the input ...

Page 81

9. Position the new dc rear panel so that it aligns with the dc power terminals on the system. Make sure that the dc rear panel is well seated on the system. 10. Using a screwdriver, tighten the three captive fasteners on the new dc rear panel. Note: torque the screws to 8 inch-pounds. 11. If you ha...

Page 82

Upper flex circuit assembly captive fasteners 7. Carefully remove the old upper flex circuit assembly by placing your fingers under the lower edge of the assembly and pulling the unit out of the chassis. 8. Remove the new upper flex circuit assembly from the packaging. 9. Align the assembly so that ...

Page 83

2. For type 8720 systems, remove the dc terminal covers and power connections to each of the dc terminals. For type 8730 systems, remove each power cord from the input power connections on the rear of the bladecenter t unit. 3. Remove the kvm module from the rear of the system (see “removing the kvm...

Page 84

17. Start up the system (see “starting the bladecenter t unit” on page 19). 74 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 85

Docking board/blower housing assembly - (dc type 8720 and ac type 8730) complete the following steps to replace the docking board/blower housing assembly. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensit...

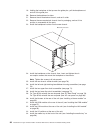

Page 86

Docking board/blower housing assembly (dc shown) 12. Grab the housing by the housing frame above and below the power inlet receptacles, and carefully pull the housing out from the system chassis. 13. Remove the new docking board/blower housing assembly from its packaging. 14. Align the new assembly ...

Page 87

Rear chassis stiffener bracket complete the following steps to replace the rear chassis stiffner bracket. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Shut down the system ...

Page 88

Up chassis stiffener bracket captive fastener (4) up 10. Pull the old rear chassis stiffner bracket off the chassis. 11. Remove the new rear chassis stiffner bracket from its packaging. 12. Align the stiffner bracket with the ″up″ arrow pointing upwards. 13. Position the bracket on the chassis, and ...

Page 89

Backplane complete the following steps to replace the backplane in your bladecenter t unit note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Shut down the system, and remove pow...

Page 90

15. Loosen and remove the six non-captive screws that mount the old backplane to the chassis. Backplane insulator backplane screw (6) 16. Holding the backplane at the top near the guide pins, pull the backplane out and off of the guide pins. Set the old backplane aside. 17. Remove the new backplane ...

Page 91

Backplane insulator complete the following steps to replace the backplane insulator. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Perform steps 1 on page 79 through 15 on p...

Page 92

V reinstall the lan module (see “installing the lan module” on page 59). V reinstall the kvm module (see “installing the kvm module” on page 57). V reinstall the i/o switches or switch fillers. V reinstall the two blowers (see “installing a blower module” on page 55). V for type 8720 (dc) units, con...

Page 93

Spring 7. Use tape to hold the air dampers above and below the empty air damper slot in the open position. This will provide more room to install the air damper and reduce the chance of breaking additional air dampers. 8. Turn the air damper on an angle 1 and insert the end with the pins into the ai...

Page 94

Slight angle toward the rear of the system 11. Hold the air damper angled slightly towards the back of the server; then, pull the air damper towards the center of the chassis until the pins on the air damper snap into the slots located on the back side of the air damper slot. Rock the air damper up ...

Page 95

Mechanical chassis complete the following steps to replace the mechanical chassis of the bladecenter t system. Note: v read “installation guidelines” on page 37. V read the safety notices at ″safety information ″ on page 113. V read “handling static-sensitive devices” on page 40. 1. Shut down the sy...

Page 96

19. Holding the backplane at the top near the guide pins, pull the backplane out and off of the guide pins. 20. Remove the backplane insulator. 21. Remove the old mechanical chassis, and set it aside. 22. Remove the new mechanical chassis from its packaging, and set it into position to reassemble al...

Page 97

35. Install the management module(s) at the front of the unit (see “installing a management module” on page 53). 36. Install the blade servers at the front of the unit (see “removing and installing a blade server or filler module” on page 64). 37. For type 8720 (dc) units, connect the power cables t...

Page 98

88 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 99: Chapter

Chapter 6. Symptom-to-fru index this index supports the eserver bladecenter t type 8720 and 8730 systems. Notes: 1. Check the configuration before you replace a fru. Configuration problems can cause false errors and symptoms. 2. For ibm devices not supported by this index, refer to the manual for th...

Page 100

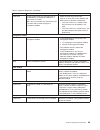

Table 6. Troubleshooting charts device suggested action blade server problem blade servers turn off for no apparent reason. All blade bays must have a blade server, expansion unit, or filler blade in them. Blade bays that do not have these items installed or have them installed improperly disturb ai...

Page 101

Table 6. Troubleshooting charts (continued) device suggested action “media not found” error message and other file system error occur on a blade server running linux or dos. Attempting to access the mounted cd-rom drive (media tray) after it has been switched to another blade server results in i/o e...

Page 102

Table 6. Troubleshooting charts (continued) device suggested action remote control does not work with default suse linux version 8.0 display settings. The remote console requires a display setting of 1024x768@60hz in the blade server operating system. The default resolution in suse is 1024x768, but ...

Page 103

Table 6. Troubleshooting charts (continued) device suggested action cd-rom drive is not recognized after being switched back to blade server running on windows 2000 advanced server with sp3 applied. When the cd-rom drive is owned by blade server x, is switched to another blade server, then is switch...

Page 104

Table 6. Troubleshooting charts (continued) device suggested action ethernet disconnect notice will not appear when running windows 2000. If an ethernet cable is accidentally removed from the back of the bladecenter t unit, the small red x (disconnect notice) that normally would appear to indicate t...

Page 105

Table 6. Troubleshooting charts (continued) device suggested action pressing f1 brings up browser help instead of performing bladecenter t management functions. Connecting to the bladecenter t management module through the web interface does not provide proper coverage for the f1 key. In particular,...

Page 106

Table 6. Troubleshooting charts (continued) device suggested action the monitor displays video for blade server 8 during management module restart. The monitor attached to the bladecenter t management module normally shows the video output from the blade server that is the current owner of the keybo...

Page 107

Table 6. Troubleshooting charts (continued) device suggested action mouse is not detected during suse installation. The installation of the suse linux operating system does not detect the mouse. You will need to select the mouse manually. Download the latest operating system installation instruction...

Page 108

Table 6. Troubleshooting charts (continued) device suggested action updating the switch-module configuration through the switch does not save the management-module nvram. If you log in to the ethernet switch module directly (through the ethernet switch-module web interface or telnet interface instea...

Page 109

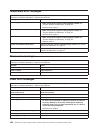

Table 7. Light path diagnostics (continued) lit led cause action critical error a critical system error has occurred, such as nonredundancy on the power modules or a system error in a blade. Note: you can configure the critical error led to be either red or amber through the management module. V che...

Page 110

Temperature error messages note: see chapter 7, “parts listing, bladecenter t type 8720 and 8730,” on page 107 to determine which components should be replaced by a field service technician. Message action power supply x temperature fault 1. Make sure that the system is being properly cooled; see “s...

Page 111

Note: see chapter 7, “parts listing, bladecenter t type 8720 and 8730,” on page 107 to determine which components should be replaced by a field service technician. Message action power supply x removed reinstall power supply x. System over recommended voltage for +12v 1. Reseat the management module...

Page 112

Note: see chapter 7, “parts listing, bladecenter t type 8720 and 8730,” on page 107 to determine which components should be replaced by a field service technician. Message action received an [xxx] alert from an unsupported ismp type xxxx, via the interconnect network ensure that all blade servers in...

Page 113

Note: see chapter 7, “parts listing, bladecenter t type 8720 and 8730,” on page 107 to determine which components should be replaced by a field service technician. Message action lan: ethernet [x] interface now longer active information only. Take action as required. Management-module error messages...

Page 114

Bus error messages note: see chapter 7, “parts listing, bladecenter t type 8720 and 8730,” on page 107 to determine which components should be replaced by a field service technician. Message action failure reading i2c device. Check devices on bus 1. 1. Reset the management module. 2. Reseat the mana...

Page 115

3. Damaged data in bios code can cause undetermined problems. Check the leds on all the power supplies. If the leds indicate the power modules are working correctly and reseating the bladecenter t components does not correct the problem, remove or disconnect the bladecenter t components one at a tim...

Page 116

V operating system software — type and version level note: to eliminate confusion, identical systems are considered identical only if they: 1. Are the exact machine type and models 2. Have the same bios level 3. Have the same adapters/attachments in the same locations 4. Have the same address jumper...

Page 117: Chapter

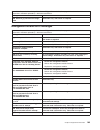

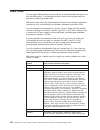

Chapter 7. Parts listing, bladecenter t type 8720 and 8730 this parts listing supports the eserver bladecenter t type 8720 and 8730. To check for an updated parts listing on the web, complete the following steps: 1. Go to http://www.Ibm.Com/support/ 2. Under search technical support, type 8720 or 87...

Page 118

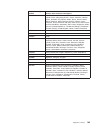

Index system ( eserver bladecenter t type 8720 and 8730) fru no. Cru/fru 2-post rack mount kit (8720 model 1rx) 90p3802 fru 2-post rack mount kit (model 2rx) 39m4299 fru 4-post rack mount kit (8720 model 1rx) 90p3803 fru 4-post rack mount kit (model 2rx) 39r8313 fru 73.4 gb hard disk drive (option) ...

Page 119

Index system ( eserver bladecenter t type 8720 and 8730) fru no. Cru/fru 1 switch filler (model 2rx) 39m3261 cru 2 blower module (model 1rx) 32r0914 cru 2 blower module (model 2rx) 39m4285 cru 3 docking board/blower housing assembly - dc (8720 model 1rx) 90p3790 fru 3 docking board/blower housing as...

Page 120

110 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 121: Appendix

Appendix a. Getting help and technical assistance if you need help, service, or technical assistance or just want more information about ibm products, you will find a wide variety of sources available from ibm to assist you. This appendix contains information about where to go for additional informa...

Page 122

Can create a customized support page. The support page has many sources of information and ways for you to solve problems, including: v diagnosing problems, using the ibm online assistant v downloading the latest device drivers and updates for your products v viewing frequently asked questions (faq)...

Page 123: Appendix

Appendix b. Related service information note: the service procedures are designed to help you isolate problems. They are written with the assumption that you have model-specific training on all computers, or that you are familiar with the computers, functions, terminology, and service information pr...

Page 124

Electrical safety caution: electrical current from power, telephone, and communication cables can be hazardous. To avoid personal injury or equipment damage, disconnect the attached power cords, telecommunication systems, networks, and modems before you open the server covers, unless instructed othe...

Page 125

V do not use worn or broken tools and testers. V never assume that power has been disconnected from a circuit. First, check that it has been powered-off. V always look carefully for possible hazards in your work area. Examples of these hazards are moist floors, nongrounded power extension cables, po...

Page 126

3. Check the power cord for: a. A third-wire ground connector in good condition. Use a meter to measure third-wire ground continuity for 0.1 ohm or less between the external ground pin and frame ground. B. The power cord should be the appropriate type as specified in the parts listings. C. Insulatio...

Page 127

Grounding requirements electrical grounding of the computer is required for operator safety and correct system function. Proper grounding of the electrical outlet can be verified by a certified electrician. Safety notices (multi-lingual translations) the caution and danger safety notices in this sec...

Page 128

Statement 1 danger electrical current from power, telephone and communication cables is hazardous. To avoid a shock hazard: v do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm. V connect all power cords to a pr...

Page 129

Statement 2 caution: when replacing the lithium battery, use only ibm part number 33f8354 or an equivalent type battery recommended by the manufacturer. If your system has a module containing a lithium battery, replace it only with the same module type made by the same manufacturer. The battery cont...

Page 130

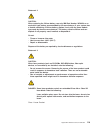

Statement 4 ≥ 18 kg (37 lbs) ≥ 32 kg (70.5 lbs) ≥ 55 kg (121.2 lbs) caution: use safe practices when lifting. Statement 5 caution: the power control button on the device and the power switch on the power supply do not turn off the electrical current supplied to the device. The device also might have...

Page 131

Statement 20 caution: to avoid personal injury, before lifting the unit, remove all the blades to reduce the weight. Statement 21 caution: hazardous energy is present when the blade is connected to the power source. Always replace the blade cover before installing the blade. Importante: todas as ins...

Page 132

Instrução 1 perigo a corrente elétrica proveniente de cabos de alimentação, de telefone e de comunicações é perigosa. Para evitar risco de choque: v não conecte ou desconecte cabos e não realize instalação, manutenção ou reconfiguração deste produto durante uma tempestade com raios. V conecte todos ...

Page 133

Instrução 2 cuidado: ao substituir a bateria de lítio, utilize apenas uma bateria ibm, número de peça 33f8354 ou uma bateria de tipo equivalente, recomendada pelo fabricante. Se o seu sistema possui um móídulo com uma bateria de lítio, substitua-o apenas pelo mesmo tipo de mídulo, do mesmo fabricant...

Page 134

Instrução 4 ≥ 18 kg (37 lbs) ≥ 32 kg (70.5 lbs) ≥ 55 kg (121.2 lbs) cuidado: ao levantar a máquina, faça-o com segurança. Instrução 5 cuidado: os botões liga/desliga localizados no dispositivo e na fonte de alimentação não desligam a corrente elétrica fornecida ao dispositivo. O dispositivo também p...

Page 135

Instrução 20 cuidado: para prevenir acidentes, antes de erguer a unidade, remova todas as láminas para reduzir o peso. Instrução 21 cuidado: a energia é uma ameaça quando a låmina estiver conectada à fonte de alimentação. Sempre substitua a cobertura da låmina antes de efetuar a instalação. Appendix...

Page 136

126 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 137

Laser klass 1. Appendix b. Related service information 127.

Page 138

128 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 139

Appendix b. Related service information 129.

Page 140

130 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 141

Appendix b. Related service information 131.

Page 142

Luokan 1 laserlaite 132 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 143

Important: toutes les consignes attention et danger indiquées dans la bibliothèque ibm documentation sont précédées d’un numéro. Ce dernier permet de mettre en correspondance la consigne en anglais avec ses versions traduites dans la présente section. Par exemple, si une consigne de type attention e...

Page 144

Notice n° 1 danger le courant électrique passant dans les câbles de communication, ou les cordons téléphoniques et d’alimentation peut être dangereux. Pour éviter tout risque de choc électrique: v ne manipulez aucun câble et n’effectuez aucune opération d’installation, d’entretien ou de reconfigurat...

Page 145

Notice n° 2 attention: remplacez la pile au lithium usagée par une pile de référence identique exclusivement - voir la référence ibm - ou par une pile équivalente recommandée par le fabricant. Si votre système est doté d’un module contenant une pile au lithium, vous devez le remplacer uniquement par...

Page 146

≥ 18 kg (37 lbs) ≥ 32 kg (70.5 lbs) ≥ 55 kg (121.2 lbs) attention: faites-vous aider pour soulever ce produit. Notice n° 5 attention: le bouton de mise sous tension/hors tension de l’unité et l’interrupteur d’alimentation du bloc d’alimentation ne coupent pas l’arrivée de courant électrique à l’inté...

Page 147

Attention: pour éviter tout risque de blessure, retirez tous les serveurs lame de l’unité avant de la soulever. Notice n° 21 attention: un courant électrique dangereux est présent lorsque le serveur lame est connecté á une source d’alimentation. Remettez toujours en place le carter du serveur lame a...

Page 148

Hinweis 1 vorsicht elektrische spannungen von netz-, telefon- und datenübertragungsleitungen sind gefährlich. Aus sicherheitsgründen: v bei gewitter an diesem gerät keine kabel anschließen oder lösen. Ferner keine installations-, wartungs- oder rekonfigurationsarbeiten durchführen. V gerät nur an ei...

Page 149

Hinweis 2 achtung: eine verbrauchte batterie nur durch eine batterie mit der ibm teilenummer 33f8354 oder durch eine vom hersteller empfohlene batterie ersetzen. Wenn ihr system ein modul mit einer lithium-batterie enthält, ersetzen sie es immer mit dem selben modultyp vom selben hersteller. Die bat...

Page 150

Hinweis 4 ≥ 18 kg ≥ 32 kg ≥ 55 kg achtung: beim anheben der maschine die vorgeschriebenen sicherheitsbestimmungen beachten. Hinweis 5 achtung: mit dem betriebsspannungsschalter an der vorderseite des servers und dem betriebsspannungsschalter am netzteil wird die stromversorgung für den server nicht ...

Page 151

Hinweis 20 achtung: um verletzungen zu vermeiden, entfernen sie vor dem anheben der einheit zur verringerung des gewichts alle blades. Hinweis 21 achtung: wenn das blade an eine stromquelle angeschlossen ist, besteht die gefahr eines stromschlags. Bringen sie die abdeckung der blades immer an, bevor...

Page 152

Avviso 1 pericolo la corrente elettrica circolante nei cavi di alimentazione, del telefono e di segnale è pericolosa. Per evitare il pericolo di scosse elettriche: v non collegare o scollegare i cavi, non effettuare l’installazione, la manutenzione o la riconfigurazione di questo prodotto durante i ...

Page 153

Avviso 2 attenzione: quando si sostituisce la batteria al litio, utilizzare solo una batteria ibm con numero parte 33f8354 o batterie dello stesso tipo o di tipo equivalente consigliate dal produttore. Se il sistema di cui si dispone è provvisto di un modulo contenente una batteria al litio, sostitu...

Page 154

Avviso 4 ≥ 18 kg ≥ 32 kg ≥ 55 kg attenzione: durante il sollevamento della macchina seguire delle norme di sicurezza. Avviso 5 attenzione: il pulsante del controllo dell’alimentazione situato sull’unità e l’interruttore di alimentazione posto sull’alimentatore non disattiva la corrente elettrica for...

Page 155

Avviso 20 attenzione: per evitare incidenti, prima di sollevare l’unità, rimuovere tutte le lame in modo da ridurre il peso. Avviso 21 attenzione: quando la lama è collegata alla sorgente elettrica è presente una tensione pericolosa. Sostituire sempre il coperchio della lama prima di installarla. Ap...

Page 156

146 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 157

Appendix b. Related service information 147.

Page 158

148 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 159

Appendix b. Related service information 149.

Page 160

150 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 161

Importante: todas las declaraciones de precauciín de esta ibm documentation empiezan con un número. Dicho número se emplea para establecer una referencia cruzada de una declaraciín de precauciín o peligro en inglés con las versiones traducidas que de dichas declaraciones pueden encontrarse en esta s...

Page 162

Declaración 1 peligro la corriente eléctrica de los cables telefínicos, de alimentaciín y de comunicaciones es perjudicial. Para evitar una descarga eléctrica: v no conecte ni desconecte ningún cable ni realice las operaciones de instalación, mantenimiento o reconfiguración de este producto durante ...

Page 163

Declaración 2 precauciÓn: cuando desee sustituir la batería de litio, utilice únicamente el número de pieza 33f8354 de ibm o cualquier tipo de batería equivalente que recomiende el fabricante. Si el sistema tiene un mídulo que contiene una batería de litio, sustitúyalo únicamente por el mismo tipo d...

Page 164

≥ 18 kg ≥ 32 kg ≥ 55 kg precauciÓn: tome medidas de seguridad al levantar el producto. Declaración 5 precauciÓn: el botín de control de alimentaciín del dispositivo y el interruptor de alimentaciín de la fuente de alimentaciín no apagan la corriente eléctrica suministrada al dispositivo. Es posible ...

Page 165

PrecauciÓn: para prevenir ferimentos pessoais, antes de levantar a unidade retire todas as låminas para diminuir o peso. Declaración 21 precauciÓn: existe energia perigosa quando a låmina está ligada à fonte de alimentação. Substitua sempre a cobertura da låmina antes de instalar a mesma. Appendix b...

Page 166

156 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 167: Appendix

Appendix c. Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently availab...

Page 168

Trademarks the following terms are trademarks of international business machines corporation in the united states, other countries, or both: active memory predictive failure analysis active pci serveraid active pci-x serverguide alert on lan serverproven bladecenter techconnect c2t interconnect thin...

Page 169

When referring to processor storage, real and virtual storage, or channel volume, kb stands for approximately 1000 bytes, mb stands for approximately 1 000 000 bytes, and gb stands for approximately 1 000 000 000 bytes. When referring to hard disk drive capacity or communications volume, mb stands f...

Page 170

Electronic emission notices federal communications commission (fcc) statement note: this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interf...

Page 171

European union emc directive conformance statement this product is in conformity with the protection requirements of eu council directive 89/336/eec on the approximation of the laws of the member states relating to electromagnetic compatibility. Ibm cannot accept responsibility for any failure to sa...

Page 172

Power cords for your safety, ibm provides a power cord with a grounded attachment plug to use with this ibm product. To avoid electrical shock, always use the power cord and plug with a properly grounded outlet. Ibm power cords used in the united states and canada are listed by underwriter’s laborat...

Page 173

Ibm power cord part number used in these countries and regions 14f0033 abu dhabi, bahrain, botswana, brunei darussalam, channel islands, china (hong kong s.A.R.), cyprus, dominica, gambia, ghana, grenada, iraq, ireland, jordan, kenya, kuwait, liberia, malawi, malaysia, malta, myanmar (burma), nigeri...

Page 174

164 bladecenter t type 8720 and 8730: hardware maintenance manual and troubleshooting guide.

Page 175: Index

Index a ac power led 13 acoustical noise emissions 5, 7 b bezel installing 45 removing 45 bezel assembly installing 44 removing 43 removing and installing 43 blade filler, installing 65 blade server installing 64, 65 removing 66 bladecenter t unit configuring 23 networking guidelines 31 shutting dow...

Page 176

I i/o module 60 configuring 29 installing 62 removing 62 types 60 installation completing 66 guidelines 37 installing air filter 44 bezel 45 bezel assembly 44 blade filler 65 blade server 65 bladecenter t unit 37 blower module 55 i/o module 62 in a rack 37 kvm module 57 lan module 59 management modu...

Page 177

Modules (continued) management 51 media tray 49 mouse connector 17 n network connecting 25 networking guidelines 31 notes, important 158 notices electronic emission 160 fcc, class a 160 o option problems 97 options installing 37 p planning guide 33 port see connector post (power-on self test) error ...

Page 178

T telco alarms connector 18 temperature 5, 7 trademarks 158 troubleshooting charts 89 u united states electronic emission class a notice 160 united states fcc class a notice 160 usb connectors 12 utility, configuration/setup 26 v video connector 17 w web browsers, supported 23 weight 5, 7 168 bladec...

Page 180

Part number: 25k8107 (1p) p/n: 25k8107.