Bladecenter h type 8852, 7989, and 1886 problem determination and service guide.

Bladecenter h type 8852, 7989, and 1886 problem determination and service guide.

Note: before using this information and the product it supports, read: the general information in appendix b, “notices,” on page 63; the ibm warranty information document; and the ibm safety information and ibm systems and environmental notices and user guide documents on the ibm documentation cd. S...

Contents safety . . . . . . . . . . . . . . . V guidelines for trained service technicians . . . . Vi inspecting for unsafe conditions . . . . . . Vi guidelines for servicing electrical equipment . . Vi safety statements . . . . . . . . . . . . Vii chapter 1. Introduction . . . . . . . . 1 related d...

Russia electromagnetic interference (emi) class a statement . . . . . . . . . . . . . 69 people's republic of china class a electronic emission statement . . . . . . . . . . . 69 taiwan class a compliance statement . . . . 69 index . . . . . . . . . . . . . . . 71 iv bladecenter h type 8852, 7989, a...

Safety before installing this product, read the safety information. Antes de instalar este produto, leia as informações de segurança. Pred instalací tohoto produktu si prectete prírucku bezpecnostních instrukcí. Læs sikkerhedsforskrifterne, før du installerer dette produkt. Lees voordat u dit produc...

Guidelines for trained service technicians this section contains information for trained service technicians. Inspecting for unsafe conditions use the information in this section to help you identify potential unsafe conditions in an ibm product that you are working on. Each ibm product, as it was d...

V do not touch the reflective surface of a dental mirror to a live electrical circuit. The surface is conductive and can cause personal injury or equipment damage if it touches a live electrical circuit. V some rubber floor mats contain small conductive fibers to decrease electrostatic discharge. Do...

Danger electrical current from power, telephone, and communication cables is hazardous. To avoid a shock hazard: v do not connect or disconnect any cables or perform installation, maintenance, or reconfiguration of this product during an electrical storm. V connect all power cords to a properly wire...

Statement 2: caution: when replacing the lithium battery, use only ibm part number 33f8354 or an equivalent type battery recommended by the manufacturer. If your system has a module containing a lithium battery, replace it only with the same module type made by the same manufacturer. The battery con...

Statement 4: ≥ 18 kg (39.7 lb) ≥ 32 kg (70.5 lb) ≥ 55 kg (121.2 lb) caution: use safe practices when lifting. Statement 5: caution: the power control button on the device and the power switch on the power supply do not turn off the electrical current supplied to the device. The device also might hav...

Statement 8: caution: never remove the cover on a power supply or any part that has the following label attached. Hazardous voltage, current, and energy levels are present inside any component that has this label attached. There are no serviceable parts inside these components. If you suspect a prob...

Statement 20: caution: to avoid personal injury, before lifting the unit, remove all the blades to reduce the weight. (4x) (2x) 164 kg (360 lbs) 44 kg (96 lbs) (14x) statement 21: caution: hazardous energy is present when the blade is connected to the power source. Always replace the blade cover bef...

Chapter 1. Introduction this problem determination and service guide contains information to help you solve problems that might occur in your ibm ® bladecenter ® type 8852, 7989, and 1886 unit. It describes the diagnostic tools that come with the bladecenter unit, error codes and suggested actions, ...

V bladecenter advanced management module messages guide this document contains a complete list of all non-device specific events and recommended actions, sorted by event id. Device specific event information is in the documentation for the device. V safety information this document contains translat...

Notices and statements in this document the caution and danger statements that appear in this document are also in the multilingual safety information document, which is on the ibm documentation cd. Each statement is numbered for reference to the corresponding statement in the safety information doc...

Features and specifications the following table provides a summary of the features and specifications of the bladecenter unit. Depending on the model, some features might not be available, or some specifications might not apply. Media tray (on front): v optical drive (optional) v two usb v2.0 ports ...

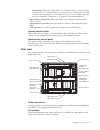

Controls, leds, and connectors this section identifies the components, controls, and leds on the front and rear of the bladecenter unit. Note: the illustrations in this document might differ from your hardware. Front view this section identifies the components, controls, and leds on the front of the...

V ac power led: when this green led is lit, ac input to the power module is present and within specifications. During typical operation, both the ac power and dc power leds are lit. V power module error led: when this amber led is lit, a power module has failed and is not operating within specificat...

– system-error: when this amber led is lit, it indicates that a system error has occurred, such as a failed module or a system error in a blade server. An led on one of the components or on a blade server is also lit to further isolate the error. (see chapter 2, “diagnostics,” on page 11 for more in...

Management modules see the documentation that comes with each management module for a description of the leds and connectors on the module. Blower modules when the amber led on a blower module is lit, an error has been detected in the blower or ac power to the blower is not present. The system-error...

Supplying power to the bladecenter unit to supply power to the bladecenter unit, connect one end of each power cord to a power connector on the rear of the bladecenter unit and the other end of each power cord to a 220-volt pdu that is connected to an appropriate electrical outlet. The bladecenter u...

10 bladecenter h type 8852, 7989, and 1886: problem determination and service guide.

Chapter 2. Diagnostics this chapter describes the diagnostic tools that are available to help you solve problems that might occur in the bladecenter unit. If you cannot locate and correct the problem using the information in this chapter, see appendix a, “getting help and technical assistance,” on p...

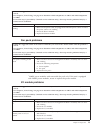

Troubleshooting tables use the troubleshooting tables to find solutions to problems that have identifiable symptoms. If one or more leds on the bladecenter unit or the components is lit, see “light path diagnostic leds” on page 17. If you cannot find the problem in these tables, see “solving undeter...

V follow the suggested actions in the order in which they are listed in the action column until the problem is solved. V see chapter 3, “parts listing,” on page 23 to determine which components are crus and which components are frus. V if an action step is preceded by “(trained service technician on...

Keyboard, mouse, or pointing-device problems note: these symptoms apply only to the devices that are connected to the management module; they do not apply to the remote console. V follow the suggested actions in the order in which they are listed in the action column until the problem is solved. V s...

V follow the suggested actions in the order in which they are listed in the action column until the problem is solved. V see chapter 3, “parts listing,” on page 23 to determine which components are crus and which components are frus. V if an action step is preceded by “(trained service technician on...

Monitor or video problems note: these symptoms apply only to the monitor that is connected to the management module; they do not apply to the remote console. Some ibm monitors have their own self-tests. If you suspect a problem with your monitor, see the documentation that comes with the monitor for...

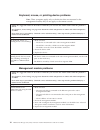

Light path diagnostic leds light path diagnostic leds are a system of leds on the bladecenter unit and the bladecenter components that can be used to identify system errors. If the front or rear system-error led of the bladecenter unit is lit, one or more error leds on the bladecenter components als...

Module leds use the following table to find solutions to problems that are identified by leds on the modules installed in bladecenter unit. Note: to find descriptions and actions for leds on i/o modules or blade servers, see the documentation that comes with the device. V follow the suggested action...

Event log messages messages that are generated while the management module is monitoring the bladecenter unit or by the bist program during startup are displayed in the management module event log. Each message includes a severity level (error [e], warning [w], or information [i]), a source (such as...

Solving undetermined problems if the diagnostic aids did not diagnose the failure or if the bladecenter unit is inoperative, use the information in this section. Note: when you are diagnosing a problem in the bladecenter unit, you must determine if the problem is in the bladecenter unit, one of the ...

Calling ibm for service see appendix a, “getting help and technical assistance,” on page 61 for information about calling ibm for service. When you call for service, have as much of the following information available as possible: v machine type and model v microprocessor or hard disk upgrades v fai...

22 bladecenter h type 8852, 7989, and 1886: problem determination and service guide.

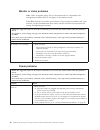

Chapter 3. Parts listing the illustrations and tables in this section identify the replaceable components that are available for the bladecenter h type 8852, 7989, and 1886 unit. Replaceable components are of three types: v tier 1 customer replaceable unit (cru): replacement of tier 1 crus is your r...

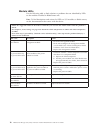

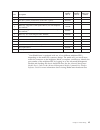

Front view index description cru part number (tier 1) cru part number (tier 2) fru part number 1 chassis shell, without shuttle (all models) 31r3308 2 bezels, top and bottom (all models) 31r3300 3 power module, 2900w, without fan pack 39y7364 4 power module, 2980w high efficiency, with fan pack 39y7...

Index description cru part number (tier 1) cru part number (tier 2) fru part number 7 ultrabay slim cd-rw/dvd-rom combo drive 42c0969 7 dvd drive, sata, multi-burner (model 4sx) (option) 44w3254 7 ultraslim enhanced sata multi-burner 44w3256 8 media tray (supports 9.5 mm optical drives, use with mid...

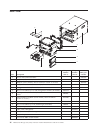

Rear view 1 2 3 4 5 6 7 8 index description cru part number (tier 1) cru part number (tier 2) fru part number 1 chassis shell (without shuttle) 31r3308 2 midplane (older models, chassis hardware version v6 or earlier) 1 25r5780 2 midplane (newer models, chassis hardware version v8 or later) 1 44x230...

Index description cru part number (tier 1) cru part number (tier 2) fru part number filler, i/o module bays 7-10, single high (option) 31r3303 filler, optical drive (option) kit, miscellaneous (all models) 31r3306 kit, rack (all models) 39m3256 label, system service 44x2289 module, infiniband pass-t...

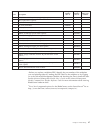

Power cords fru part number description used in these countries 26r0001 cable, iec 320 c20 worldwide 26r0003 cable, nema l6-30p canada, japan, mexico, united states of america 26r0009 cable, 30a 1-phase korea 39m5436 cable, iec 309 32a/iec 320 c20 worldwide except: australia, canada, japan, korea, m...

Chapter 4. Removing and replacing bladecenter components replaceable components are of three types: v tier 1 customer replaceable unit (cru): replacement of tier 1 crus is your responsibility. If ibm installs a tier 1 cru at your request, you will be charged for the installation. V tier 2 customer r...

V blue on a component indicates touch points, where you can grip the component to remove it from or install it in the bladecenter unit, open or close a latch, and so on. V for a list of supported options for the bladecenter unit, see http://www.Ibm.Com/servers/eserver/serverproven/compat/us/. System...

Removing and replacing tier 1 crus replacement of tier 1 crus is your responsibility. If ibm installs a tier 1 cru at your request, you will be charged for the installation. The illustrations in this document might differ from your hardware. Removing a bezel when working with some devices, such as t...

Installing a bezel to install either the top or bottom bezel, complete the following steps. Release buttons release buttons 1. Align the blue tabs on the ends of the bezel with the corresponding holes in the front of the bladecenter unit. 2. Firmly press the bezel into the bladecenter unit until the...

Removing and replacing the media tray and optical drive or optical drive filler your bladecenter is equipped with one of two different media tray frus, depending on the midplane connector design. Before you replace a media tray fru, identify the part number of the media tray you are replacing either...

5. Press the optical drive retainer tab and slide the optical drive or optical drive filler out of the media tray. 6. Remove the retainer clip from the side of the optical drive or optical drive filler. 7. If you are instructed to return the media tray, optical drive, or optical drive filler, follow...

Removing and replacing a power module your bladecenter might be equipped with 2900w power modules that have a removable fan pack (part number 39y7408), or it might be equipped with 2980w high-efficiency power modules with integrated fan pack (part number 39y7415). The 2900w and 2980w high-efficiency...

Removing a power module attention: v to help ensure proper cooling and system reliability, make sure that you replace a removed power module or filler with a power module or filler within 1 minute. V if you are removing a functioning power module, make sure that power leds on the remaining power mod...

Note: these instructions assume that the bladecenter unit is connected to power. 1. Read the safety information that begins on page v and “installation guidelines” on page 29. 2. Remove the top or bottom bezel as needed to access the power module to be removed (see “removing a bezel” on page 31). 3....

Note: the 2980w high-efficiency power module comes with an integrated fan pack. 2. Make sure that the handle on the power module is in the open position. 3. Orient the new power module to the selected power-module bay: v for the upper power-module bays, the rear connector on the power module must be...

Removing and replacing a fan pack the procedures in this section apply only to bladecenter units equipped with 2900w power modules that have a removable fan pack (part number 39y7408). If your bladecenter is equipped with 2980w high-efficiency power modules with integrated fan pack (part number 39y7...

Installing a fan pack to install a fan pack on a 2900w power module, complete the following steps. Handle release tabs 1. Make sure that the handle is rotated down so that it is parallel with the bottom of the module, with the power module rear connector facing up. 2. Slide the fan pack into positio...

Removing a blade server attention: v to maintain proper system cooling, do not operate the bladecenter unit without a blade server, expansion unit, or blade server filler installed in each blade bay. V note the bay number. Reinstalling a blade server into a different bay from the one from which it w...

Installing a blade server statement 21: caution: hazardous energy is present when the blade is connected to the power source. Always replace the blade cover before installing the blade. Attention: v reinstalling a blade server into a different bay from the one from which it was removed could have un...

6. Make sure that the blade server is receiving power. See the documentation that comes with the blade server for more instructions. 7. (optional) write identifying information on one of the labels that come with the blade server; then, place the label on the bladecenter unit top bezel, just above t...

Removing an i/o module to remove an i/o module or module filler, complete the following steps. I/o module module filler i/o module single module filler double module filler release handles (open) release handle (open) note: these instructions assume that the bladecenter unit is connected to power. 1...

Installing an i/o module the bladecenter unit has 10 hot-swap i/o module bays that are compatible with three types of i/o modules (see “rear view” on page 7 for the location of the i/o module bays). See the installation and user’s guide for a description of the types of modules that can be used in e...

Removing a management module to remove a management module or filler, complete the following steps. Notes: 1. These instructions assume that the bladecenter unit is connected to power. 2. If you are replacing the only management module in the bladecenter unit and the management module is functioning...

Installing a management module to install a management module, complete the following steps. Management module release handle (open) module filler note: these instructions assume that the bladecenter unit is connected to power. 1. Make sure that the release handle on the module is in the open positi...

Removing and replacing a blower module your bladecenter might be equipped with standard blower modules (part number 44e5083), or it might be equipped with high-efficiency blower modules (part number 68y8205). The standard and high-efficiency blower modules are not interchangeable and should not be m...

Installing a blower module to install a blower module, complete the following steps. Handle (open) release button note: these instructions assume that the bladecenter unit is connected to power. 1. Make sure that the handle on the blower module is in the open position. 2. Orient the blower module to...

Removing and replacing frus frus must be installed only by trained service technicians. The illustrations in this document might differ from your hardware. Removing the shuttle to remove the shuttle, complete the following steps. Shuttle captive thumb screws release latch release handle (open) shipp...

7. Remove the upper and lower shipping brackets from the rear of the bladecenter unit and the rack, if they are installed (see the rack installation instructions for more information). 8. Remove the top and bottom bezels (see “removing a bezel” on page 31). 9. Disengage the following components from...

Installing the shuttle to install the shuttle, complete the following steps. Shuttle captive thumb screws release latch release handle (open) shipping screws 1. If you are installing a new shuttle, install the midplane from the removed shuttle (see “installing the midplane” on page 57). 2. Make sure...

9. Push the following components fully into the front of the bladecenter unit to re-engage the midplane using the procedure indicated: v blade servers: push each blade server into the bay; then, push the two release handles to the closed position (see “installing a blade server” on page 42). V power...

Removing the rear led/serial connector assembly to remove the rear led/serial connector assembly, complete the following steps. 1. Read the safety information that begins on page v and “installation guidelines” on page 29. 2. Shut down the operating systems and turn off any blade servers in the blad...

Installing the rear led/serial connector assembly to install the rear led/serial connector assembly, complete the following steps. 1. Insert the assembly into the opening in the shuttle bottom; then, carefully slide it forward until the serial port is seated firmly in the opening on the back panel o...

2. If your bladecenter h chassis hardware is version v8 or later, install midplane fru 44x2302. There is no bladecenter h chassis hardware version v7. Attention: the different midplane frus are not interchangeable. A failed midplane fru should only be replaced with a midplane having the same fru par...

Attention: note the position of the midplane between the locating tabs on each end of the lower ac cable bracket. The replacement midplane must be positioned correctly between the tabs to avoid damaging the midplane. 10. Pull the bottom of the midplane away from the shuttle; then, lift the midplane ...

8. Install the shuttle into the bladecenter unit (see “installing the shuttle” on page 52). 9. Reconnect the power to the bladecenter unit (see “supplying power to the bladecenter unit” on page 9). 10. Restart any blade servers that were shut down in the bladecenter unit. See the documentation that ...

Chapter 5. Configuration information and guidelines this chapter provides information about updating the firmware, configuring the bladecenter unit and its components, and networking guidelines. Updating the firmware the firmware for the management module and other bladecenter components is periodic...

Configuring blade servers to achieve communication redundancy on a blade server, you must configure the ethernet controllers on the blade servers for failover. When failover occurs on a blade server, the secondary ethernet controller takes over network communications, using the i/o module that is as...

Appendix a. Getting help and technical assistance if you need help, service, or technical assistance or just want more information about ibm products, you will find a wide variety of sources available from ibm to assist you. This section contains information about where to go for additional informat...

Getting help and information from the world wide web on the world wide web, the ibm web site has up-to-date information about ibm systems, optional devices, services, and support. The address for ibm system x ® and xseries ® information is http://www.Ibm.Com/systems/x/. The address for ibm bladecent...

Appendix b. Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently availab...

Law trademarks in other countries. A current list of ibm trademarks is available on the web at “copyright and trademark information” at http://www.Ibm.Com/ legal/copytrade.Shtml. Adobe and postscript are either registered trademarks or trademarks of adobe systems incorporated in the united states an...

Ibm makes no representations or warranties with respect to non-ibm products. Support (if any) for the non-ibm products is provided by the third party, not ibm. Some software might differ from its retail version (if available) and might not include user manuals or all program functionality. Particula...

Information development ibm corporation 205/a015 3039 e. Cornwallis road p.O. Box 12195 research triangle park, north carolina 27709-2195 u.S.A. In the request, be sure to include the publication part number and title. When you send information to ibm, you grant ibm a nonexclusive right to use or di...

Relating to electromagnetic compatibility. Ibm cannot accept responsibility for any failure to satisfy the protection requirements resulting from a nonrecommended modification of the product, including the fitting of non-ibm option cards. Attention: this is an en 55022 class a product. In a domestic...

Verantwortlich für die einhaltung der emv vorschriften ist der hersteller: international business machines corp. New orchard road armonk, new york 10504 914-499-1900 der verantwortliche ansprechpartner des herstellers in der eu ist: ibm deutschland technical regulations, department m456 ibm-allee 1,...

Russia electromagnetic interference (emi) class a statement people's republic of china class a electronic emission statement taiwan class a compliance statement appendix b. Notices 69.

70 bladecenter h type 8852, 7989, and 1886: problem determination and service guide.

Index a accessible documentation 65 activity led optical drive 7 airflow 4 assistance, getting 61 b bezels installing 32 removing 31 blade server installing 42 problems 12 removing 41 bladecenter unit configuring 59 blower module error led 18 installing 49 problems 12 removing 48 bridge module probl...

Optical drive (continued) eject button 7 problems 15 removing and replacing 33 optical drive filler removing and replacing 33 over-temp led 6 p particulate contamination 65 parts listing 23 replaceable components 23 parts listing 23 pointing device problems 14 power problems 16 power module error le...

Part number: 81y1107 printed in usa (1p) p/n: 81y1107.