- DL manuals

- IBM

- Server

- pSeries 670

- Installation Manual

IBM pSeries 670 Installation Manual

Summary of pSeries 670

Page 1

Pseries 670 installation guide sa38-0613-02 e rserver.

Page 3

Pseries 670 installation guide sa38-0613-02 erserver.

Page 4

Third edition (may 2003) before using this information and the product it supports, read the information in “safety notices” on page vii, appendix b, “environmental notices”, on page 37, and appendix c, “notices”, on page 39. A reader’s comment form is provided at the back of this publication. If th...

Page 5: Contents

Contents safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii laser safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ix laser compliance . . . . . . ....

Page 6

Stopping the diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 verifying that the latest firmware and adapter and drive microcode are installed . . . . . . . . . 23 verifying partition standby operation . . . . . . . . . . . . . . . . . . . . . . . . . 24 verifying that the l...

Page 7

Installing the 128-port async adapter . . . . . . . . . . . . . . . . . . . . . . . . . 57 128-port async adapter line connectors . . . . . . . . . . . . . . . . . . . . . . . 57 setting a ran node number . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 configuring the 128-port async adapter...

Page 8

Vi eserver pseries 670 installation guide.

Page 9: Safety Notices

Safety notices attention: when moving or relocating certain configurations of the system, the bulk power regulators (bprs) must be removed from the top of the rack (front and rear) to ensure product stability. Specifically, removal of the bprs in the front and rear is required in systems that have f...

Page 10

Caution: this unit has more than one power supply cord. Follow procedures for removal of power from the system when directed. C28 caution: energy hazard, remove power before servicing. C22 caution: energy hazard, remove all jewelry before servicing. C29 viii eserver pseries 670 installation guide.

Page 11

Laser safety information caution: this product may contain a cd-rom, dvd-rom, or laser module on a pci card, which are class 1 laser products. C30 laser compliance all lasers are certified in the u.S. To conform to the requirements of dhhs 21 cfr subchapter j for class 1 laser products. Outside the ...

Page 12

X eserver pseries 670 installation guide.

Page 13

Data integrity and verification ibm computer systems contain mechanisms designed to reduce the possibility of undetected data corruption or loss. This risk, however, cannot be eliminated. Users who experience unplanned outages, system failures, power fluctuations or outages, or component failures mu...

Page 14

Xii eserver pseries 670 installation guide.

Page 15: About This Book

About this book this book provides information about how to set up and cable the server, install and remove options, and verify server operation. Iso 9000 iso 9000 registered quality systems were used in the development and manufacturing of this product. Highlighting the following highlighting conve...

Page 16

V the rs/6000 and eserver diagnostic information for multiple bus systems, order number sa38-0509, contains diagnostic information, service request numbers (srns), and failing function codes (ffcs). V the rs/6000 and eserver adapters, devices and cable information for multiple bus systems, order num...

Page 17

Chapter 1. Reference materials note: this document may contain references to the aix operating system. If you are using another operating system, consult the appropriate documentation for that operating system. This document may describe hardware features and functions. While the hardware supports t...

Page 18

Hardware installation guide hardware management console installation and operations guide aix installation in a partitioned environment application documentation application documentation aix documentation library aix documentation library hardware user's guide aix installation in a partitioned envi...

Page 19

Documentation overview this section provides descriptions and target audience information for the eserver pseries and aix 5l documentation libraries. Some of the documentation may only be available in printed form or in softcopy form. Based on the documentation content, the books are divided into th...

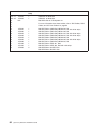

Page 20

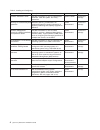

Table 2. Installing and configuring documentation title description audience type hardware installation guide provides information on how to install system hardware, cable the system, and verify operations. System installer printed and softcopy planning for partitioned-system operations describes pl...

Page 21

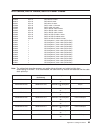

Table 3. Using the system documentation title description audience type hardware management console for pseries installation and operations guide provides information on how to install, configure, and use a hardware management console (hmc). Logical partition (lpar) tasks, such as configuring and ma...

Page 22

6 eserver pseries 670 installation guide.

Page 23: Chapter 2. Installing The

Chapter 2. Installing the eserver pseries 670 use the procedures in this chapter to set up your pseries 670. Installing the pseries 670 can take approximately eight hours. Minimum system configuration the minimum system configuration consists of the redundant bulk power subsystem, one processor subs...

Page 24

V planning procedures outlined in site and hardware planning information, order number sa38-0508, are complete. Before you begin to ensure that all of the installation steps are complete, the installer should use the following installation checklist during the installation process: v “complete the i...

Page 25

Rack inventory the following is a list of rack inventory items: v front and rear door for the rack v two power cords v optional display and keyboard chapter 2. Installing the pseries 670 9.

Page 26

Step 3. Position and level the rack if the customer plans to secure the rack to the floor, see appendix d, “securing the rack”, on page 41. To adjust the leveling feet on the rack, do the following: 1. Ensure the rack is positioned according to the customer plan. 2. Loosen the jam nut on each leveli...

Page 27

Step 4. Affix the mcm/l3/passthrough plug map to the right frame extender with the front cover open, locate the right frame extender (located on the opposite side of the unit emergency power off (uepo) switch. The 50-mm (approximately 2 inch) wide label should be installed vertically, along this ext...

Page 28

Step 6. Check the cables and connect i/o devices cables may loosen during shipping. Check for loose cables before completing the installation. For cabling illustrations, see appendix g, “subsystem positioning and cabling”, on page 69. For further details on the cable descriptions and labels, see app...

Page 29

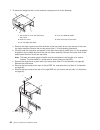

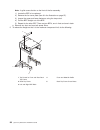

To incorporate the ibf into the room epo, a cable connection must be made to connect to the back of the system uepo panel. The following diagrams illustrate how this connection is made. The preceding figure illustrates the back of the machine uepo panel with the room epo cable plugging into the mach...

Page 30

__ 2. Have the customer locate and turn off the branch circuit breaker and attach tag s229-0237, which reads “do not operate.” note: all measurements are made with the receptacle faceplate in the normally installed position. __ 3. Some receptacles are enclosed in metal housings. On receptacles of th...

Page 31

Step 9. Connect and route the power cords to the pseries 670 before you connect the power cords, loosen or remove the cable retainers and filler plate located along the side and bottom of the frame. The following lists each of the brackets and recommended range of cable sizes for each: part number d...

Page 32

To route the rear power cord, do the following: 1. Connect the plug to the bulk power assembly (bpa), and ensure that the dots are aligned on the plug and receptacle. 2. Secure the power cord in the channel with the brackets from top to bottom. 3. Remove the lower panel of the frame, and route the c...

Page 33

The part numbers for the serial cables for the pseries 670 are the following: part number and description position 11p3955 6-m cable 9 position to 9 position 11p3956 15-m cable 9 position to 9 position 31l7196 15-m cable 9 position to 25 position step 11. What is the next step? The next step in the ...

Page 34

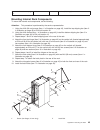

Install the rear door to install the rear door, do the following (refer to the illustration on page 18): 1. Position the door so that both the top and the bottom hinge pins (1) partially engage the hinges. 2. Simultaneously slide the top and bottom hinge pins on the rear door into the top and bottom...

Page 35

Chapter 3. Verifying the hardware operation use the system verification procedure discussed in this chapter to check the system for correct hardware operation. Considerations before running this procedure read the following before using this procedure: v the aix operating system must be installed on...

Page 36

The next section discusses each of these power-on modes. Note: you must power off your managed system to switch between using the full system partition and using either logical or affinity partitions. You must also power off the system between using logical parititions and affinity partitions. Parti...

Page 37

System profile the system profile option powers on the system according to a predefined set of profiles. Note: the profiles are activated in the order in which they are shown in the system profile. Power-on autostart this option powers on the managed system to partition standby mode and then activat...

Page 38

Loading the online diagnostics in service mode note: online diagnostics are not available when the system is running linux. To run the online diagnostics in service mode from the boot hard disk, do the following: 1. From the hmc, click server. 2. From the hmc, click partition management. For more in...

Page 39

Note: if you are unable to load standalone diagnostics, call your support center for assistance. Running system verification before you run system verification, the diagnostics must have been loaded. For information about how to load diagnostics, see chapter 3, “verifying the hardware operation”, on...

Page 40

From the web site, follow the instructions for checking your system’s firmware level and for downloading the latest level of code. Adapter and drive microcode packages are also available from this web site. V current object repository (core): if you have access to core, do the following to access th...

Page 41

Configuring the network to configure the network, the following tasks must be performed: v configuring inventory scout v collecting vital product data (vpd) v configuring service agent for more information about performing these tasks, refer to the ibm hardware management console for pseries install...

Page 42

26 eserver pseries 670 installation guide.

Page 43

Chapter 4. Completing the installation this chapter contains information about how to ensure that the installation is complete and you are ready to turn the system over to the system administrator. Complete the steps described in this chapter after you verify the hardware operation as described in c...

Page 44

Leave this document with your customer because customers may need this guide to perform various tasks, leave this guide with them for their reference. 28 eserver pseries 670 installation guide.

Page 45

Chapter 5. Capacity upgrade on demand features this chapter is intended for system administrators to use as a reference if the system has any capacity upgrade on demand features. Read this chapter for more information about those features, including how to activate or deactivate them. Capacity upgra...

Page 46

For further information about activating and deactivating on/off capacity on demand on your system, refer to “activation process for cuod features” on page 31, or refer to the ibm hardware management console for pseries installation and operations guide, order number sa38-0590, that was delivered wi...

Page 47

Cuod activation features will not be fulfilled until you submit the vpd through the electronic service agent or manually tohttp://www.Ibm.Com/servers/eserver/pseries/cuod/index.Html. When you enter a cuod activation code, standby processors or memory will immediately become activated for use. If you...

Page 48

V web-based vpd entry. For details on how to submit the vpd either through the electronic service agent or using the web, view the planning guide for capacity upgrade on demand located at http://www.Ibm.Com/servers/eserver/pseries/cuod/index.Html . 5. After the activation code is received (from eith...

Page 49

Appendix a. Communications statements the following statement applies to this product. The statement for other products intended for use with this product appears in their accompanying documentation. Federal communications commission (fcc) statement note: this equipment has been tested and found to ...

Page 50

Interface with this equipment using safe extra low voltages only. In order to maintain the separate (independent) approval of the manufacturer’s adapters, it is essential that other optional cards, not supplied by the manufacturer, do not use main voltages or any other excessive voltages. Seek advic...

Page 51

Dieses gerät erfüllt die bedingungen der en 55022 klasse a. Für diese von geräten gilt folgende bestimmung nach dem emvg: geräte dürfen an orten, für die sie nicht ausreichend entstört sind, nur mit besonderer genehmigung des bundesministers für post und telekommunikation oder des bundesamtes für po...

Page 52

36 eserver pseries 670 installation guide.

Page 53

Appendix b. Environmental notices product recycling and disposal this unit contains materials such as circuit boards, cables, electromagnetic compatibility gaskets and connectors which may contain lead and copper/beryllium alloys that require special handling and disposal at end of life. Before this...

Page 54

Acoustical noise emissions the equivalent continuous a-weighted sound pressure level at workstations (emission sound pressure level at the 1-meter bystander positions) does not exceed 70 db(a). Der geräuschpegel der einheit ist kleiner oder gleich 70 db(a). Declared acoustical noise emissions acoust...

Page 55: Appendix C. Notices

Appendix c. Notices this information was developed for products and services offered in the u.S.A. The manufacturer may not offer the products, services, or features discussed in this document in other countries. Consult the manufacturer’s representative for information on the products and services ...

Page 56

40 eserver pseries 670 installation guide.

Page 57

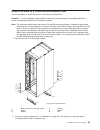

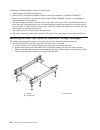

Appendix d. Securing the rack this appendix contains information about installing the rack for the pseries 670. This procedure is optional and should be performed if the customer has ordered the appropriate hardware kits to bolt the system to the floor. For further information, refer to part number ...

Page 58

Item 2 in illustration on page 45. 05n6345 4 spacer item 4 in illustration on page 45. 05n6344 4 bushing item 5 in illustration on page 45. 21l4309 4 washer item 3 in illustration on page 45. 0130985 4 washer item 6 in illustration on page 45. 05n6346 4 bolt 11p4757 frame tie-down kit (short-raised ...

Page 59

Item 10 in illustration on page 43. 1622307 8 washer (m-8, hinge) mounting internal rack components to mount the internal rack components, do the following: attention: this procedure is performed by the service representative. 1. Using four m-8 (20 mm) screws (item 1 in illustration on page 43), ins...

Page 60

2 shipping bar (upper) 8 latch plate 3 shipping bar (lower) 9 screw (hex, 25mm, long, hinge) 5 hinge plate 10 washer (m 8, hinge) 6 eq support determine your next step use the following to determine your next step: v if the rack is being attached to a concrete (non-raised) floor, proceed to “attach ...

Page 61

Attach the rack to a concrete (non-raised) floor use this procedure to attach the rack to a concrete (non-raised) floor. Attention: it is the customer’s responsibility to ensure the following steps are completed before the service representative performs the tie-down procedure. Note: the customer sh...

Page 62

3. To align the mounting plates to the system rack, do the following: a. Place the four rack-mounting bolts (item 6 in illustration on page 45) through the plate assembly holes at the bottom of the rack. Install the bushings and washers (item 4 and 5 in illustration on page 45) to ensure bolt positi...

Page 63

3. Place the isolator bushing (item 4 in illustration on page 45) inside the leveling foot, with a washer between the isolator bushing and the floor plate. 4. Turn the rack-mounting bolts three or four rotations into the tapped holes. 5. Turn the leveling foot of the plate assembly down until it con...

Page 64

Attaching the rack to a short-raised or long-raised floor attention: it is the customer’s responsibility to ensure the following steps are completed before the service representative performs the tie-down procedure. Note: to accommodate a floor with a depth of more than 16 inches, a steel beam or a ...

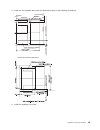

Page 65

3. Install the four eyebolts that match the dimensions given in the following illustrations. 654.8 mm (4x) 49.3 mm eyebolt (2x) 450 mm ref 1220 mm ref 1019 mm (2x) 170 mm ref (2x) 75 mm ref 64.6 mm 100.5 mm 610 mm (24 inch) floor tile layout (2x) opening for cables 48 in ref 4. Install the eyebolts ...

Page 66

To install the frame, do the following: attention: it is the service representative’s responsibility to complete the following steps. 1. Before starting the installation, check all cable openings in the floor panel and location of the rubber bushing holes so that they match the dimensions given in t...

Page 67

3. The floor eyebolts should be already secured to the concrete floor. Verify the height of the center of the floor eyebolt to the concrete floor or the steel beam/channel adapter mounted to the concrete floor. Ensure that the turnbuckles can accommodate the total height of the raised floor. 4. Remo...

Page 68

11. Turn the leveling foot of the plate assembly down until it contacts the bushing, and level the rack by tightening the lock nuts on the four leveling feet. 12. Lock the leveling feet by tightening the lock nut. 13. Insert the threaded rod into the inner hole of the leveler and the rubber bushing....

Page 69

Installing the frame-ground straps install a frame-ground strap on all pseries 670 systems if the following conditions are met: v a frame-ground strap is provided for installation. And v the customer provides a ground to which the frame-ground strap will attach. Attention: it is recommended that all...

Page 70

1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 front of rack rear of rack 1 screw on ground clamp (for tightening the clamp) 5 lockwasher (install if supplied) 2 grounding clamp 6 ground-strap lug 3 metal floor pedestal 7 screw (for attaching lug to rack) 4 rear bottom-left side of rack 8 ground strap note: see the ...

Page 71: Management Console

Appendix e. Attaching multiple pseries 670s to one hardware management console this appendix details how to attach multiple pseries 670 servers to one hmc. The hmc might have an 8-port async adapter or a 128-port async adapter installed to allow multiple servers to connect. Procedures for configurin...

Page 72

Note: the second hmc system serial port is reserved for use by the modem. 56 eserver pseries 670 installation guide.

Page 73

Installing the 128-port async adapter the 128-port async adapter is an option for the hmc. It must be configured by the service representative when the hmc is installed. The 128-port async adapter software is included in the hmc base software installation package. This adapter provides the control f...

Page 74

Setting a ran node number the aix asynchronous communications guide provides information about configuring and running diagnostics on the 128-port async adapter and associated rans. To access the aix asynchronous communications guide, see the aix online documentation. Documentation for the aix opera...

Page 75

A. Question: how many boards would you like to install? Answer: enter the total number of 8-port and/or 128 -port async adapters that are installed in the hmc pc. B. Question: board #1. What type of board is this? (’l’ for list) answer: use board type 16 (ibm 128-port async pci) c. Question: how man...

Page 76

Connect the serial cables from the pseries 670 to the 128-port async adapters up to two optional 128-port async adapters can be installed. The d-shell connectors on the back of the adapter attach to rans. Serial cables can be connected from any of the ports on a ran to the hmc1 ports on the managed ...

Page 77

Verify that installation is complete by using the hmc interface the hmc provides a predefined user id called hscroot. The hscroot password is abc123. This hscroot user id is a member of the system administrator rolehscroot. When the console is powered on for the first time, use this user id to log i...

Page 78

62 eserver pseries 670 installation guide.

Page 79

Appendix f. System records use this appendix to keep a record of your server configuration. Record the identification numbers the basic server consists of the redundant bulk power subsystem, one processor subsystem, a media subsystem, and one i/o subsystem in the same rack, as well as access to one ...

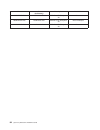

Page 80

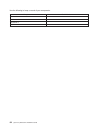

Use the following to keep a record of your components. Component serial number pseries 670 i/o drawer 1 i/o drawer 2 i/o drawer 3 64 eserver pseries 670 installation guide.

Page 81

Record system - processor, memory, and i/o configuration the following illustration shows the location codes for the rack. These codes are used to identify the major functional units in the pseries 670. Rear front u1.35-p1-x2 unused u1.35-p2-x2 unused u1.35-p1-x4 u1.35-p2-x4 u1.17 u1.17 u1.9 u1.9 u1...

Page 82

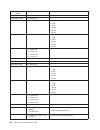

Physical memory card location available other information mcm 0 installed u1.18-p1-c1 mcm 0 vpd card u1.18-p1-h2.3 memory u1.18-p1-m2 memory book v 4 gb v 8 gb v 16 gb v 32 gb v 64 gb memory u1.18-p1-m3 memory book v 4 gb v 8 gb v 16 gb v 32 gb v 64 gb l3 modules v u1.18-p1-c6 v u1.18-p1-c7 v u1.18-...

Page 83

Verify that all hardware is present to verify that all hardware is present, do the following at the command line: v run lsslot -cpci to verify the adapters are plugged into the physical slot they are plugged in. Make note of the adapter types and positions the adapters are plugged in. V run lsdev -c...

Page 84

68 eserver pseries 670 installation guide.

Page 85

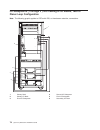

Appendix g. Subsystem positioning and cabling this appendix describes subsystem positioning and cabling for the pseries 670. Operator panel cable and diskette drive cable to the media subsystem (rear view) 1 primary i/o book 3 diskette drive data cable 2 cable connecting the operator panel to the me...

Page 86

I/o subsystem positions, fully populated rack (rear view without ibf) c1 3 2 1 c1 primary rack 2 second i/o subsystem position 1 first i/o subsystem position 3 third i/o subsystem position 70 eserver pseries 670 installation guide.

Page 87

I/o subsystem positions, fully populated rack (rear view with ibfs) c1 c2 3 2 1 4b c1 rack 2 second i/o subsystem c2 i/o book (book 0) 3 third i/o subsystem 1 first i/o subsystem 4b two ibfs (primary rack), position 4 appendix g. Subsystem positioning and cabling 71.

Page 88

Rio and rio-g cabling rules always connect either a one i/o planar loop or a two i/o planar loop to the first six rio ports of the cec in the following order: 1. Primary i/o book 0: rio 1 a0 & a1, rio 2 b0 & b1 2. Secondary i/o book 2: rio 3 c0 & c1 note: use required pairs of rio ports without omit...

Page 89

I/o subsystem (one side of subsystem 1 with ibf) rio cabling to i/o books, two i/o planar loop configuration note: the following graphic applies to cecs with rio, or thumbscrew retention, connections. A0 a1 0 1 3 4 1 2 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed) 2 ...

Page 90

I/o subsystems (1 through 3 ) rio cabling to i/o books, two i/o planar loop configuration note: the following graphic applies to cecs with rio, or thumbscrew retention, connections. A0 c0 a1 c1 b0 0 0 0 0 0 0 1 1 4 3 5 6 1 1 1 1 b1 1 2 1 primary rack 4 second i/o subsystem 2 primary i/o book 5 first...

Page 91

I/o subsystem (one side of subsystem 1 with ibf) rio-g cabling to i/o books, two i/o planar loop configuration note: the following graphic applies to cecs with rio-g, or bayonette retention, connections. A0 a1 0 1 3 4 1 2 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed)...

Page 92

I/o subsystem (one side of subsystem 1 with ibf) rio-g cabling to i/o books, one i/o planar loop configuration note: the following graphic applies to cecs with rio-g, or bayonette retention, connections. 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed) 2 primary i/o boo...

Page 93

I/o subsystems (1 through 2) rio-g cabling to i/o books, one i/o planar loop configuration note: the following graphic applies to cecs with rio-g, or bayonette retention, connections. 1 primary rack 4 first i/o subsystem 2 primary i/o book 5 secondary i/o book 3 second i/o subsystem note: the maximu...

Page 94

Power and scsi cables to the media subsystem 1 2 3 5 4 7 6 1 rack 5* scsi cable for media subsystem rear drives 2 primary i/o book 6 scsi cable for media subsystem front drives 3 power cable for media subsystem front drives 7* power cable for media subsystem rear drives 4 rear of media subsystem not...

Page 95

Hardware management console for pseries (hmc) to the primary i/o book to connect your hmc to the pseries 670, connect the serial cable into serial port 1 located on the back of the hmc. Connect the other end of the serial cable into the hmc1 connector located on the primary i/o book in the managed s...

Page 96

80 eserver pseries 670 installation guide.

Page 97

Appendix h. Cabling information this appendix provides information about the location and label colors of the pseries 670 cables. Power cabling 1 front rear 3 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 35 2 6 10 8 9 7 15 5 16 4 index part number units per assy description 1 n/a bulk power distr...

Page 98

Index part number units per assy description 15 to 17 11p4303 1 i/ob9-p00 to media p02 16 to 18 11p4303 1 i/ob9-p01 to media p00 19, 20, 21, 22 n/a b35-bpdx-p0x to i/o subsystem #x for more information about these cables, refer to “rio cables, rio-g cables, and i/o power cables” on page 83 23 11p446...

Page 99

Rio cables, rio-g cables, and i/o power cables fru part number units per assy description 11p2355 up to 3 rio cable 0.5-meter 11p0272 up to 6 rio cable 2-meter 44h9137 up to 6 rio cable 15-meter 00p5238 up to 6 rio-g cable 1.75-meter 00p5239 up to 6 rio-g cable 2.5-meter 21p5477 up to 6 rio to rio-g...

Page 100

From to (a=primary) description label color a35p-bpd1b-p04 a01b-dca1-p00 bpd1b to i/o subsystem #3 green a35b-bpd1a-p05 a01b-dca2-p01 bpd1a to i/o subsystem #3 green w/stripes a35p-bpd1b-p05 a01b-dca2-p00 bpd1b to i/o subsystem #3 green 84 eserver pseries 670 installation guide.

Page 101

Appendix i. Service processor setup and test attention: this procedure applies to modems attached to the serial ports (s1 and s2) on the primary i/o book (location u1.18-p1-h2). It does not affect the operation of the modem attached to the hardware management console for pseries (hmc). The call-out ...

Page 102

Testing the service processor setup this section contains sample testing procedures to help ensure your service processor setup is working. These tests include communicating with the server operating system. Before you start, ensure that the necessary serial port(s) is configured. If you need assist...

Page 103

6. Select rs232. 7. Select baud rate 9600 or higher. 8. Select login enable and set the flow control to rts. 9. Commit the selections and set up any other needed serial ports. 10. Exit smit. Appendix i. Service processor setup and test 87.

Page 104

88 eserver pseries 670 installation guide.

Page 105

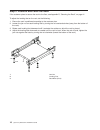

Appendix j. Removing and installing the rack top frame the following scenarios exist for performing this procedure: v removing and installing the rack top frame for clearance through doorways v installing the rack top frame that was shipped unattached from the rest of the frame note: if the clearanc...

Page 106

Required tools the following tools are necessary to remove or install the rack top frame: v ladder v stepladder tool description ratchet 3/8 inches square drive ratchet accessories 3/8 inches drive, 6 inches extension x2 (8-inch reach required) drive socket 3/8 inches (10mm) drive ratchet 1/4 inches...

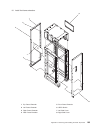

Page 107

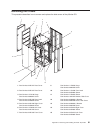

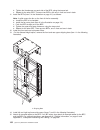

Removing the covers this procedure describes how to remove and replace the side covers of the pseries 670. 1 2 3 4 5 6 7 9 10 11 12 13 14 15 1 part number 44p0127 rear cover 9 part number 11p3535 hinge part number 2665525 screw 2 part number 44p0107 rear cover 10 part number 11p1096 front latch part...

Page 108

Complete the following steps to remove the side covers: 1. Always remove the right side cover first. 2. Remove the (2) screws and washers inside the frame (part numbers 77g0599 and 1625437). 3. Remove the (3) screws at the top of the frame (part number 54g2882). The use of a stepladder is recommende...

Page 109

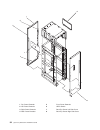

2. Disconnect cables from the bpds. 3. Remove the front and rear bprs, bpds, bpcs, and the fan assemblies. Attention: make note of location identification of the bprs and bpes for later reinstallation. If these components are not reinstalled in their original location, the pseries 670 will not power...

Page 110

1 8 7 2 3 4 5 1 top frame extender 5 front frame extender 2 left frame extender 6 uepo switch 3 right frame extender 7 rack top frame left side cover 4 rear frame extender 8 rack top frame right side cover 94 eserver pseries 670 installation guide.

Page 111

6. Attention: two people are required to remove the bpes. Remove the bpes (item 1 in the illustration on page 95). 1 bulk power enclosure 2 hex-head screw locations a. Remove the five hex-head screws from the front bpe. B. Remove the five hex-head screws from the rear bpe. C. Install two shipping br...

Page 112

7. To reduce the weight so that it is the maximum two-person limit, do the following: 1 top panels for front and rear rack top frame 4 foam and metal air baffle 2 rack top frame 5 rack top-frame cross brace 3 left and right bpe rails a. Remove the eight screws around the perimeter of the top panels ...

Page 113

1 rack top frame 3 top frame bolts 2 rack chassis 4 rack top-frame cross brace 8. Remove the 16 m8 x 20mm bolts (part number 1624804) 9. Lift the rack top frame off the locating pins and remove it. Note: two people are required to lift and position the rack top-frame assembly. Preparing for rack top...

Page 114

Note: a grille covers the fan on the front of the fan assembly. 1) locate the bpf to be replaced. 2) remove the fan cover plate (item 6 in the illustration on page 97). 3) loosen the upper and lower fasteners, using the torque tool. 4) pull the bpf straight out of the bpe. 5) repeat for the other bp...

Page 115

A. Remove the two screws at the left and right of the top frame side covers (items 7 and 8 in the illustration on 94). B. Lift off the covers. C. Remove the eight screws around the perimeter of the top panels at the front and rear of the rack top-frame assembly. Remove the two top panels (item 1 in ...

Page 116

1 2 3 1 jam nut 3 rack base 2 rack base 2. Position the rack top frame on top of the rack by orienting the two front labels on the rack top frame assembly and the frame. As you face the frame, this label is on the right front of the frame. Note: two people are required to lift and position the top f...

Page 117

A. Align the rack top frame with the four alignment guides on top of the rack. B. Fasten the rack top frame to the rack, using 16 m8 x 20mm bolts (part number 1624803). Tighten the bolts securely to ensure solid contact along the mating surfaces of the rack and the rack top frame. 3. Install the fro...

Page 118

B. Tighten the thumbscrew on each side of the bpd, using the torque tool. C. Repeat for the other bpd. There are two bpds, with one in front and one in back. 11. Install the bpfs (item 5 in the illustration on page 101) as follows: note: a grille covers the fan on the front of the fan assembly. A. L...

Page 119

16. Install the frame extenders. 1 8 7 2 3 4 5 1 top frame extender 5 front frame extender 2 left frame extender 6 uepo switch 3 right frame extender 7 left side cover 4 rear frame extender 8 right side cover appendix j. Removing and installing the rack top frame 103.

Page 120

17. Install the uepo switch, as follows: a. Install the top and bottom screws. Screws should be bottomed against the end of the slot prior to tightening. B. Plug in the cables. Replacing covers refer to page “removing the covers” on page 91 while performing this task. 1. Examine the bottom of the fr...

Page 121: Index

Index numerics 128-port adapter cables connecting 60 8-port adapter cables connecting 55 a about this book xiii accessing information xiii acoustical noise emissions 38 activating process processor on demand 31 activation features processor on demand 29 adapter 128-port 57 8-port 55 aix operating sy...

Page 122

Hmc (continued) 128-port adapter cables connection 60 8-port adapter cables connection 55 cabling 79 configurations 7 installation 16 i i/o cpu 65 ibf 70 identification numbers recording 63 information, accessing xiii installation 128-port async adapter 57 completing 17 doors 17 frame raised floor 5...

Page 123

R rack bolting 41 covers removing 91 replacing 104 installation 41 raised floor 50 inventory 9 leveling 10 securing 41 setup 41 top frame removal 89 removing 89 replacement 89 replacing 89 raised floor rack installation 50 records device 24, 65 system 24 updating 24 recycling 37 related publications...

Page 124

108 eserver pseries 670 installation guide.

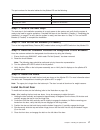

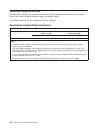

Page 125

Readers’ comments — we’d like to hear from you pseries 670 installation guide publication no. Sa38-0613-02 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall satisfaction h h h h h how satisfied are you that the i...

Page 126: Business Reply Mail

Readers’ comments — we’d like to hear from you sa38-0613-02 sa38-0613-02 cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape no postage necessary if mailed in the united states business reply mail first-class...

Page 128

Part number: 00p5809 printed in u.S.A. May 2003 sa38-0613-02 (1p) p/n: 00p5809.