- DL manuals

- IBM

- Server

- pSeries 670

- Installation Manual

IBM pSeries 670 Installation Manual

Summary of pSeries 670

Page 1

Pseries 670 installation guide sa38-0613-04 e rserver.

Page 3

Pseries 670 installation guide sa38-0613-04 erserver.

Page 4

Fifth edition (december 2003) before using this information and the product it supports, read the information in “safety notices” on page vii, appendix b, “environmental notices,” on page 101, and appendix c, “notices,” on page 107. A reader’s comment form is provided at the back of this publication...

Page 5: Contents

Contents safety notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii rack safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii laser safety information . . ...

Page 6

Stopping the diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 verifying that the latest firmware is installed . . . . . . . . . . . . . . . . . . . . . . 25 verifying partition standby operation . . . . . . . . . . . . . . . . . . . . . . . . . 26 verifying that the latest ...

Page 7

Non-raised floor environments . . . . . . . . . . . . . . . . . . . . . . . . . 123 appendix e. Attaching multiple pseries 670s to one hardware management console . . . . . 125 installing the 8-port async adapter . . . . . . . . . . . . . . . . . . . . . . . . . . 125 connect the serial cables from ...

Page 8

Vi eserver pseries 670 installation guide.

Page 9: Safety

Safety notices attention: when moving or relocating certain configurations of the system, the bulk power regulators (bpr’s) must be removed from the top of the rack (front and rear) to ensure product stability. Specifically, removal of the top two bpr’s in the front and rear is required in systems t...

Page 10

Danger an electrical outlet that is not correctly wired could place hazardous voltage on metal parts of the system or the devices that attach to the system. It is the responsibility of the customer to ensure that the outlet is correctly wired and grounded to prevent an electrical shock. Use one hand...

Page 11

Laser safety information caution: this product may contain a cd-rom, dvd-rom, or laser module on a pci card, which are class 1 laser products. C30 laser compliance all lasers are certified in the u.S. To conform to the requirements of dhhs 21 cfr subchapter j for class 1 laser products. Outside the ...

Page 12

X eserver pseries 670 installation guide.

Page 13: Data

Data integrity and verification ibm computer systems contain mechanisms designed to reduce the possibility of undetected data corruption or loss. This risk, however, cannot be eliminated. Users who experience unplanned outages, system failures, power fluctuations or outages, or component failures mu...

Page 14

Xii eserver pseries 670 installation guide.

Page 15: About

About this book this book provides information about how to set up and cable the server, install and remove options, and verify server operation. Iso 9000 iso 9000 registered quality systems were used in the development and manufacturing of this product. Highlighting the following highlighting conve...

Page 16

Related publications the following publications provide related information: v the system unit safety information, order number sa23-2652, contains translations of safety information used throughout this book. V the ibm hardware management console for pseries installation and operations guide, order...

Page 17: Chapter

Chapter 1. Reference materials note: this document may contain references to the aix operating system. If you are using another operating system, consult the appropriate documentation for that operating system. This document may describe hardware features and functions. While the hardware supports t...

Page 18

Hardware installation guide hardware management console installation and operations guide aix installation in a partitioned environment application documentation application documentation aix documentation library aix documentation library hardware user's guide aix installation in a partitioned envi...

Page 19

Documentation overview this section provides descriptions and target audience information for the eserver pseries and aix 5l documentation libraries. Some of the documentation may only be available in softcopy form. Based on the documentation content, the books are divided into the following categor...

Page 20

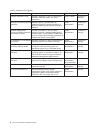

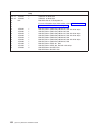

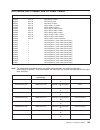

Table 2. Installing and configuring documentation title description audience type hardware installation guide provides information on how to install system hardware, cable the system, and verify operations. System installer printed and softcopy planning for partitioned-system operations describes pl...

Page 21

Table 3. Using the system documentation title description audience type hardware management console for pseries installation and operations guide provides information on how to install, configure, and use a hardware management console (hmc). Logical partition (lpar) tasks, such as configuring and ma...

Page 22

6 eserver pseries 670 installation guide.

Page 23: Chapter

Chapter 2. Installing the pseries 670 use the procedures in this chapter to set up your pseries 670. Installing the pseries 670 can take approximately eight hours. Minimum system configuration the minimum system configuration consists of the redundant bulk power subsystem, one processor subsystem, a...

Page 24

Multiple system configurations the system configuration may vary. Other configurations include multiple hmcs attached to one pseries 670 and multiple pseries 670s servers attached to one hmc. For more information, refer to appendix e, “attaching multiple pseries 670s to one hardware management conso...

Page 25

Step 2. Check the inventory to verify that you have all the items shipped with the pseries 670, use the packing lists for each ship group. The contents of the pseries 670 tool kit are as follows: quantity description 5 pad cleaning brush 2 door key 1 mcm torque wrench 1 l3 support tray 1 magnifier l...

Page 26

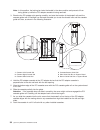

Step 3. Position and level the rack if the customer plans to secure the rack to the floor, see appendix d, “securing the rack,” on page 109. To adjust the leveling feet on the rack, do the following: 1. Ensure the rack is positioned according to the customer plan. 2. Loosen the jam nut on each level...

Page 27

Step 4. Affix the mcm/l3/passthrough plug map to the right frame extender with the front cover open, locate the right frame extender (located on the opposite side of the unit emergency power off (uepo) switch. The 50-mm (approximately 2 inch) wide label should be installed vertically, along this ext...

Page 28

Caution: energy hazard, remove all jewelry before servicing. Step 6. Check the cables and connect i/o devices cables may loosen during shipping. Check for loose cables before completing the installation. For cabling illustrations, see appendix g, “subsystem positioning and cabling,” on page 139. For...

Page 29

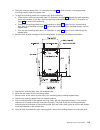

To incorporate the ibf into the room epo, a cable connection must be made to connect to the back of the system uepo panel. The following diagrams illustrate how this connection is made. O i switch in the active position front view rear view j02 j01 j00 room epo cable uepo switch a side bpc b side bp...

Page 30

__ 2. Have the customer locate and turn off the branch circuit breaker and attach tag s229-0237, which reads “do not operate.” note: all measurements are made with the receptacle faceplate in the normally installed position. __ 3. Some receptacles are enclosed in metal housings. On receptacles of th...

Page 31

Step 9. Connect and route the power cords to the pseries 670 before you connect the power cords, loosen or remove the cable retainers and filler plate located along the side and bottom of the frame. The following lists each of the brackets and recommended range of cable sizes for each: part number d...

Page 32

5. Route the front power cord underneath the frame and through the front floor tile hole. For more information about floor cutouts, refer to the site and hardware planning information, order number sa38-0508. 6. If you removed a lower panel, go to 7. If you removed a tool box, do the following: a. R...

Page 33

Step 10. Verify the hardware management console (hmc) installation verify that the hmc is installed. If the hmc has not been installed, go to the ibm hardware management console for pseries installation and operations guide and follow the procedures for installing the hmc. When you have completed in...

Page 34

The part numbers for the serial cables for the pseries 670 are the following: part number and description position 11p3955 6-m cable 9 position to 9 position 44p0206 15-m cable 9 position to 9 position 31l7197 15-m cable 9 position to 25 position step 11. Turn on the ibf breaker (if present) turn on...

Page 35

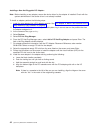

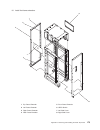

Step 13. Install the doors this step describes how to install the front and rear doors on the pseries 670. For more information about the doors, see “prerequisites to installing the pseries 670” on page 8. Note: the upper pin is longer than the bottom pin. The door is made of aluminum for weight rea...

Page 36

1 1 1 1 2 2 2 3 4 2 1 hinge pin (typical front and rear door) 3 front door 2 rack hinge (typical front and rear door) 4 rear door step 14. Go to verifying the hardware operation go to chapter 3, “verifying the hardware operation,” on page 23. After you have completed the procedures in the verifying ...

Page 37

Using the hmc to manage a full system partition on a managed system, the installer must complete the following: __ 1. Verify the system operation by completing the procedures in chapter 3, “verifying the hardware operation,” on page 23. __ 2. Verify that the latest firmware and adapter/drive microco...

Page 38

22 eserver pseries 670 installation guide.

Page 39: Chapter

Chapter 3. Verifying the hardware operation use the system verification procedure discussed in this chapter to check the system for correct hardware operation. Considerations before running this procedure read the following before using this procedure: v the aix operating system must be installed on...

Page 40

Note: if you are unable to load the diagnostics to the point when the diagnostic operating instructions display, go to “loading the standalone diagnostics from cd-rom.” 12. Monitor the system operator panel value as it boots to the diagnostic screen. This part of the procedure does take time to comp...

Page 41

9. Press enter, to ensure that this option is highlighted. 10. Select 7 to commit. 11. Press enter to start the diagnostics. To check one particular resource, select that resource on the diagnostic selection menu. The checkout program ends with either of the following results: v testing complete scr...

Page 42

Verifying partition standby operation use the following instructions to verify that the system can be booted to partition standby mode. 1. At the hmc, select server, then partition. 2. In the navigation area, select server management. 3. In the contents area, select the managed system and right clic...

Page 43

Configuring the network to configure the network, the following tasks must be performed: v configure inventory scout v collect vital product data (vpd) v configure service agent for more information about performing these tasks, refer to the ibm hardware management console for pseries installation a...

Page 44

28 eserver pseries 670 installation guide.

Page 45: Chapter

Chapter 4. Capacity upgrade on demand features this chapter is intended for system administrators to use as a reference if the system has any capacity upgrade on demand features. Read this chapter for more information about those features, including how to activate or deactivate them. Capacity upgra...

Page 46

For further information about activating and deactivating on/off capacity on demand on your system, refer to “activation process for cuod features” on page 32, or refer to the ibm hardware management console for pseries installation and operations guide that was delivered with your hardware manageme...

Page 47

Cuod activation features will not be fulfilled until you submit the vpd through the electronic service agent or manually to http://www.Ibm.Com/servers/eserver/pseries/cuod/index.Html. When you enter a cuod activation code, standby processors or memory will immediately become activated for use. If yo...

Page 48

Activation process for cuod features the process begins when you determine a potential need for more processing capability in the future and want to have the hardware installed on the server now. If cuod features are ordered for your server, they are included in the server when it is delivered. To a...

Page 49: Chapter

Chapter 5. Installing options this chapter describes how to install and remove pci adapters and pci adapter cassettes. Pci adapters note: linux does not support hot-plugging any hot-pluggable pci adapters or devices. A system with linux installed on one or more partitions must be shut down and power...

Page 50

Removing a pci adapter cassette attention: perform this procedure only when you are instructed to by the removal and replacement procedures in “removing a non-hot-pluggable pci adapter” on page 39 or “hot-pluggable pci adapter” on page 40. Note: an adapter or a blank filler must be installed into th...

Page 51

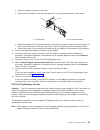

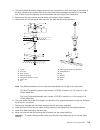

To remove a pci adapter cassette, do the following: 1. Determine which pci adapter cassette you are removing. 2. Disconnect any cables that are connected to the pci adapter. 3. Press the handle release lever, then push the handle to the down position. See the following illustration. 1 locking bar 2 ...

Page 52

1 locking bar 2 pci adapter tailstock tab 3 adapter cassette pull tab 5. Position your index finger under the handle and push up the adapter tailstock tab. Grasp the adapter cassette pull tab with the other hand. Pull the pci adapter cassette from the adapter slot by pulling on the adapter cassette ...

Page 53

Replacing a pci adapter cassette attention: perform this procedure only when you are instructed to from “removing a non-hot-pluggable pci adapter” on page 39 or “hot-pluggable pci adapter” on page 40. Before you replace the pci adapter cassette, check the following: v before installing a pci adapter...

Page 54

Note: in this position, the locking bar locks the handle in the down position and prevents it from being pulled up while the pci adapter cassette is being removed. 3. Examine the pci adapter slot opening carefully, and note the location of the dovetail rails and the cassette guide rails. A flashligh...

Page 55

9. Visually check to ensure that the cassette is parallel with the cassettes to the left or right. If the cassette is not parallel with the neighboring cassettes, the cassette dovetail rails might not be correctly engaged. If the cassette is not correctly aligned, you might need to pull it out so yo...

Page 56

Hot-pluggable pci adapter before performing the following procedure, read “safety notices” on page vii. Attention: the linux operating system does not support these hot-plug procedures. Also, linux does not support hot-plugging any hot-pluggable pci adapters. Systems with linux installed on one or m...

Page 57

11. Answer yes to keep definition. Press enter. 12. The are you sure screen displays. Press enter to verify the information. Successful unconfiguration is indicated by the ok message displayed next to the command field at the top of the screen. 13. Press f3 to return to the pci hot-plug manager menu...

Page 58

Installing a new hot-pluggable pci adapter: note: before installing a new adapter, ensure the device driver for the adapter is installed. Check with the system administrator if the device driver is not already installed. To install an adapter, perform the following steps: 1. Install the new adapter ...

Page 59

E. Slide the cassette partially into the guide. F. Ensure that the dovetail on the top track aligns with its mating component(s) on both sides. 1 i/o subsystem 2 pci adapter cassette g. When the cassette is fully inserted, prepare to activate the handle by lowering the locking bar. Lift the handle a...

Page 60

Accessing hot-plug management functions: note: removing or installing a hot-pluggable pci adapter requires the system administrator to take the pci adapter offline prior to performing the operation. Before taking an adapter offline, the devices attached to the adapter must be taken offline as well. ...

Page 61

Identify a pci hot-plug slot allows the user to identify a pci slot. The selected pci slot will go into the identify state. Unconfigure a device allows the user to put an existing pci adapter into the defined state if the device is no longer in use. This step must be completed successfully before st...

Page 62

Pci adapter or blank filler removal from a snap-assembly-type cassette caution: metal edges might be sharp. C38 use this procedure when you are preparing to install or replace an adapter or an adapter blank filler in the system unit or an i/o drawer. Note: an adapter or an adapter blank filler must ...

Page 63

2. Using two fingers, remove the bushing-lock pin from the bushing. The bushing-lock pin can be removed by pulling it out of the bushing with your fingernails. 1 bushing 2 bushing-lock pin 1 bushing-lock pin chapter 5. Cabling information 47.

Page 64

3. Remove the bushing. The bushing can be removed by pulling it out of the pci adapter cassette assembly with your fingernails. 1 bushing 4. Turn over the pci adapter cassette assembly so that the top is facing away from you. 1 top of adapter 2 handle 48 eserver pseries 670 installation guide.

Page 65

5. Remove the bezel, as follows: a. Locate the plastic latch fingers in the top part of the cassette. 1 top of cassette 2 bezel 3 plastic latch fingers b. Using one hand, pinch the plastic latch fingers, and with your other hand, carefully lift the top part of the bezel extension out until the tabs ...

Page 66

C. While holding the bezel extension out, push the plastic cover latch out of the bezel hook, as shown in the following illustration. This action allows the bezel to be removed. 1 bezel extension 2 plastic cover latch in bezel hook d. On the opposite side of the cassette (cover side), push the cover...

Page 67

E. While holding the bezel extension out, carefully slide the bezel off. You might have to work from both sides to loosen the bezel assembly from the cassette assembly. When the bezel is free, slide it completely off the cassette assembly, and set it aside. 1 bezel extension 2 bezel 1 bezel chapter ...

Page 68

6. Turn over the cassette so that the cover is facing up, as shown in the following illustration. Remove the cover from the cassette as follows: a. Slide the cover until it releases from the cassette assembly. Attention: the cover might be tight and difficult to slide. If you grasp the left end (han...

Page 69

7. Remove the metal emc shield from the top of the tailstock. 1 metal emc shield 8. Remove the blank filler or adapter that is installed in the cassette linkage assembly. Note: if there is a blank filler in the cassette linkage assembly, as shipped from the manufacturer, there are two adapter arms. ...

Page 70

Short adapter or blank filler removal: to remove a short adapter or blank filler, do the following: 1. Slide the long and short adapter arms away from the adapter or blank filler by doing the following: a. Each adapter arm has a release tab that allows the arm to be moved away from the adapter or bl...

Page 71

Illustration. 2 1 3 4 5 3 1 short pci adapter card 2 short adapter arm 3 middle-spacer arm 4 long adapter arm 5 long pci adapter card chapter 5. Cabling information 55.

Page 72

2. Remove the adapter or blank filler from the cassette linkage assembly by rotating the bottom of the tailstock out, as shown in the following illustration. Store the adapter or blank filler in a safe place. 1 cassette linkage assembly 2 bottom of tailstock 3 handle 3. The removal procedure for the...

Page 73

Long adapter removal: to remove a long adapter, do the following: 1. Each adapter arm has a release tab that allows the arm to be moved away from the adapter in the cassette assembly. Use your fingernail to lift the tab, to allow the arm to be moved away from the adapter. Lift the release tab on the...

Page 74

Replacing an adapter in a pci adapter cassette caution: metal edges might be sharp. C38 this procedure is performed when preparing to install a new adapter or a blank filler in the processor subsystem or an i/o drawer. Familiarize yourself with the entire procedure before performing the following st...

Page 75

Note: if you are installing an adapter that is in the following list, use the additional brackets listed to help when you seat the adapter during installation. There are unique brackets (1) for each adapter type (2): 1 2 feature code description bracket part number 2751 s/390 escon channel pci adapt...

Page 76

2. To determine if you are installing a long adapter or a short adapter, use the following steps. If you know the length of your adapter, skip the following steps and proceed to step 3 on page 62. A. Remove the adapter from its protective packaging and, if present, remove the plastic extension handl...

Page 77

C. The cassette linkage assembly is marked to show long or short adapters similar to the adapter shown in the following illustration. Check the right end of the adapter to determine if it is long enough to fall into the long area of the cassette linkage assembly. Ensure that the corner on the left e...

Page 78

3. Remove the adapter or blank filler and ensure that the handle is in the up position. If you need to move the handle, ensure that the locking bar is pulled into the unlocked position, and then rotate the adapter handle until the handle is in the up position (the cassette linkage assembly will exte...

Page 79

1. Place the adapter or blank filler into the cassette so that the upper-left corner of the adapter engages the adjustable top adapter-retaining clip as shown in the following illustration. 4 3 1 2 1 cassette linkage assembly 2 bottom of tailstock 3 retaining clip 4 handle chapter 5. Cabling informa...

Page 80

2. Rotate the adapter so that the adapter engages the slot in the bottom adapter-retaining clip and the top corner of the adapter is seated into the adjustable top adapter-retaining clip. Note: if the adapter is not a full-height adapter, you must slide the adjustable top adapter-retaining clip down...

Page 81

3. Slide the short adapter-retaining arm toward the adapter or blank filler on the cassette linkage rail. If the short-adapter retaining arm has been removed from the cassette linkage rail, install the short-adapter retaining arm and then slide the arm until it contacts the adapter or blank filler a...

Page 82

4. Ensure that the adjustable top retaining clip catches the corner of the adapter as shown in the following illustration: 1 1 short adapter top retaining clip 5. Use the lower short adapter arm clip to engage and hold the bottom of the adapter. Note: it might be necessary to apply pressure to engag...

Page 83

6. To hold the top of the adapter, slide down the adjustable top adapter-retaining clip on the retaining arm. Ensure that the bottom edge of the adapter is held by the lower part of the adapter retaining arm. 1 adjustable top adapter-retaining clip chapter 5. Cabling information 67.

Page 84

7. Press the lock on the handle, and rotate the adapter handle until it is in the down position (adapter or blank filler moves up into the cassette assembly). 2 1 1 handle release lever 2 lock ensure that the right end of the cassette linkage rail moves up into the cassette linkage assembly as shown...

Page 85

8. Position the adapter and cassette assembly with the handle on the left (in the down position) and the top facing away from you. 2 1 1 top of cassette 2 handle chapter 5. Cabling information 69.

Page 86

9. Install the cover on the cassette assembly, as follows: a. Place the cassette cover on the cassette assembly as shown in the following illustration. Slide the cover toward the handle until the hole in the cover aligns with the hole in the cassette assembly. 2 1 1 handle 2 holes aligned 70 eserver...

Page 87

10. Install the bezel assembly using the following procedure: a. Carefully slide the bezel onto the cassette assembly. 1 1 bezel b. Align and insert the cover arm latch in the hooked notch in the bezel. 1 2 1 pci adapter pull tab 2 hooked notch in the bezel for the cover arm latch chapter 5. Cabling...

Page 88

C. Align the top of the bezel assembly into the grooves on the top of the cassette assembly. Push the bezel onto the cassette linkage assembly until the tab on the top of the bezel is seated in the recess of the cassette assembly. 1 2 3 4 1 recess 3 tab 2 groove 4 bezel assembly d. Insert the two ta...

Page 89

11. Check for the following: a. Ensure that the extension arm engages the pins on the cassette. You should be able to see the three pins in the holes in the arm. The bezel tab should be seated as shown in the following illustration. 1 1 1 1 pin b. Ensure that the cover arm latch is completely presse...

Page 90

C. Turn the cassette assembly over so the cover is facing up. Check the cover latch to ensure that it is holding the bezel to the cover as shown. 1 1 cover latch 12. Ensure the holes are aligned, and insert the bushing-lock pin into the bushing as shown. 1 bushing 2 bushing-lock pin 74 eserver pseri...

Page 91

The following illustration shows the location of the bushing in the cassette. 1 1 location of the installed bushing and bushing-lock pin 13. Insert the bushing-lock pin into the hole in the bushing, and push it in until it seats as shown in the following illustration. 1 1 bushing-lock pin chapter 5....

Page 92

14. Depress the handle release lever to ensure the locking bar on the handle is pulled into the unlocked position. Raise the handle on the cassette linkage assembly until it locks into the up position (the blank filler or adapter moves downward). 1 handle release lever 2 locking bar 15. To install t...

Page 93

A. Ensure that the metal emc shield slides up inside the top of the cassette. 1 metal emc shield b. The metal emc shield has clips that slide over the top of the tailstock. Ensure that these clips are holding the metal emc shield to the tailstock. 1 1 top of tailstock chapter 5. Cabling information ...

Page 94

16. Depress the handle release lever on the handle, and rotate the adapter handle until the handle is in the down position (adapter or blank filler moves up into the cassette assembly). 1 1 handle 17. Using the system documentation, determine if the adapter you are installing is hot-swappable. If th...

Page 95

Long adapter installation to install a long adapter, use the following procedure. 1. If installed, remove both long and short adapter retaining arms. See step 1a on page 54 to remove the arms. 2. Install the middle-spacer arm, see the following illustration. Note: some long adapters are shipped with...

Page 96

3. Place the adapter into the cassette so that the upper-left corner of the adapter engages the top adjustable adapter-retaining clip as shown in the following illustration: 5 4 2 3 1 1 top adapter-retaining clip 3 adapter 2 cassette linkage assembly 4 bottom of tailstock 5 handle 80 eserver pseries...

Page 97

4. Rotate the adapter so that the adapter engages the slot in the bottom retaining clip and the top corner of the adapter is seated into the top adjustable adapter-retaining clip. Note: if the adapter is not a full-height adapter, slide the top adjustable adapter-retaining clip downward until the lo...

Page 98

5. Install the long adapter-retaining arm onto the cassette linkage rail, as shown in the following illustration, and slide the arm toward the adapter. 1 2 3 1 cassette linkage assembly 3 top adapter retaining clip 2 adapter retaining arm 82 eserver pseries 670 installation guide.

Page 99

6. Ensure that the top adjustable adapter-retaining clip catches the corner of the adapter as shown in the following illustration. 1 top adjustable-retaining clip 7. Ensure that the bottom edge of the adapter is held by the groove in the lower part of the adapter-retaining arm. 1 2 1 top adjustable-...

Page 100

8. To hold the top of the adapter, slide down the top adjustable adapter-retaining clip on the retaining arm. 1 1 long adapter retaining arm 9. If you installed a middle-spacer arm, ensure that the adapter-retaining clip is seated around the top edge of the adapter. 10. Depress the handle release le...

Page 101

Ensure the right end of the cassette linkage rail moves up into the cassette linkage assembly as shown: 1 1 right end of cassette linkage 11. Position the adapter and cassette assembly with the handle on the left (in the down position) and the top facing away from you. 1 2 1 handle 2 top of cassette...

Page 102

12. Install the cover on the cassette assembly by placing the cassette cover on the cassette assembly as shown. Slide the cover toward the handle until the hole in the cover aligns with the hole in the cassette assembly. 2 1 1 handle 2 hole aligned in the cover 86 eserver pseries 670 installation gu...

Page 103

13. Install the bezel assembly using the following procedure: a. Carefully slide the bezel onto the cassette assembly. 1 1 bezel b. Align and insert the cover arm latch in the hooked notch in the bezel. 1 2 1 pci adapter pull tab 2 hooked notch in the bezel chapter 5. Cabling information 87.

Page 104

C. Align the top of the bezel assembly into the grooves on the top of the cassette assembly, and push the bezel onto the cassette linkage assembly until the tab on the top of the bezel is seated in the recess of the cassette assembly. 1 2 3 4 1 recess 3 tab 2 grooves 4 bezel d. Insert the two tabs o...

Page 105

14. Check for the following: a. Ensure that the extension arm engages the three pins on the cassette. You can see the pins in the holes in the arm. The bezel tab is seated as shown in the following illustration. 1 1 1 1 pins b. Ensure that the cover arm latch is completely pressed into the hooked no...

Page 106

C. Turn the cassette assembly over so that the cover is facing up. Check the cover latch to ensure that it is holding the bezel to the cover as shown. 1 1 cover latch 15. Position the adapter with the cover side facing up. Ensure that the holes are aligned, and insert the bushing as shown. 1 bushing...

Page 107

1 1 bushing 2 bushing-lock pin 16. Insert the bushing-lock pin into the hole in the bushing. Push on the pin until it seats. 1 1 location of the installed bushing and bushing-lock pin chapter 5. Cabling information 91.

Page 108

17. Depress the handle release lever to ensure the locking bar on the handle is pulled into the unlocked position. Raise the handle on the cassette linkage until it locks into the up position (the blank filler or adapter moves downward). 1 handle 2 locking bar 18. To install the metal emc shield on ...

Page 109

A. Ensure that the shield slides up inside the top of the cassette. 1 metal emc shield 2 adapter bracket chapter 5. Cabling information 93.

Page 110

B. The metal emc shield has clips that slide over the top of the tailstock. Ensure that these clips are holding the emc shield to the tailstock. 1 1 top of tailstock 19. Press the lock on the handle and rotate the adapter handle until the handle is in the down position (adapter or blank filler moves...

Page 111

Visible. If the adapter is not hot-swappable, the blue color is visible. 1 2 1 orange indicates hot-swappable 2 blue indicates not hot-swappable 21. The adapter is ready to be installed into a system or an i/o drawer. For more information, refer to your system documentation. Chapter 5. Cabling infor...

Page 112

96 eserver pseries 670 installation guide.

Page 113: Appendix

Appendix a. Communications statements the following statement applies to this product. The statement for other products intended for use with this product appears in their accompanying documentation. Federal communications commission (fcc) statement note: this equipment has been tested and found to ...

Page 114

Interface with this equipment using safe extra low voltages only. In order to maintain the separate (independent) approval of the manufacturer’s adapters, it is essential that other optional cards, not supplied by the manufacturer, do not use main voltages or any other excessive voltages. Seek advic...

Page 115

Geräte dürfen an orten, für die sie nicht ausreichend entstört sind, nur mit besonderer genehmigung des bundesministers für post und telekommunikation oder des bundesamtes für post und telekommunikation betrieben werden. Die genehmigung wird erteilt, wenn keine elektromagnetischen störungen zu erwar...

Page 116

100 eserver pseries 670 installation guide.

Page 117: Appendix

Appendix b. Environmental notices product recycling and disposal this unit contains materials such as circuit boards, cables, electromagnetic compatibility gaskets and connectors which may contain lead and copper/beryllium alloys that require special handling and disposal at end of life. Before this...

Page 118

Dette produkt kan indeholde et f orseglet batteri, der indeholder bly, nikkel-kadmium, nikkel-metal-hydrid, litium eller litium-ion. Der er flere oplysninger om batter iet i bruger- eller servicevejledningen. Batteriet må ikke kasseres sammen med det almindelige aff ald. Batteriet skal kasseres i he...

Page 119

Questo prodotto potrebbe contenere una batteria al piombo, al nichel-cadmio, all ’idruro di nichel, al litio o agli ioni di litio. Consultare il manuale utente o il manuale di assistenza per informazioni specifiche sulla batteria. La batteria deve essere appropriatamente riciclata o smaltita. Il ser...

Page 120

Produkten kan innehålla ett förseglat batteri av någon av typerna blyackumulator , nickel-kadmium, nickel-metallhydrid, litium eller litiumjon. Detaljerad batteriinformation finns i användar - eller servicehandboken. Batteriet måste lämnas till återvinning eller kastas på ett miljösäkert sätt. Det k...

Page 121

In the united states, ibm has established a collection process for reuse, recycling, or proper disposal of used ibm sealed lead acid, nickel cadmium, nickel metal hydride, and other battery packs from ibm equipment. For information on proper disposal of these batteries, please contact ibm at 1-800-4...

Page 122

Acoustical noise emissions the equivalent continuous a-weighted sound pressure level at workstations (emission sound pressure level at the 1-meter bystander positions) does not exceed 70 db(a). Der geräuschpegel der einheit ist kleiner oder gleich 70 db(a). Declared acoustical noise emissions acoust...

Page 123: Appendix

Appendix c. Notices this information was developed for products and services offered in the u.S.A. The manufacturer may not offer the products, services, or features discussed in this document in other countries. Consult the manufacturer’s representative for information on the products and services ...

Page 124

108 eserver pseries 670 installation guide.

Page 125: Appendix

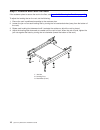

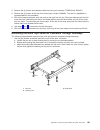

Appendix d. Securing the rack this appendix contains information about installing the rack for the pseries 670. This procedure is optional and should be performed if the customer has ordered the appropriate hardware kits to bolt the system to the floor. For further information, refer to part number ...

Page 126

Installing the frame kit the following tables show the parts required for each of the tie-down kits (a non-raised floor, short-raised floor, and a long-raised floor). Rack tie-down kits 11p4759 frame tie-down kit (non-raised floor) (rpq 8a1183) item part number qty description item 3 in illustration...

Page 127

11p4757 frame tie-down kit (short-raised floor) (rpq 8a1185) item part number qty description illustration on page 119. 44p0673 4 turnbuckle assembly (short) item 3 in illustration 112. 11p3527 2 shipping bar (lower) item 5 in illustration 112. 11p3529 4 hinge plate item 8 in illustration 112. 11p35...

Page 128

Mounting internal rack components to mount the internal rack components, do the following: attention: this procedure is performed by the service representative. 1. Using four m-8 (20 mm) screws (item 1 in illustration 112), install the top shipping bar (item 2 in illustration 112) at eia unit locati...

Page 129

Determine your next step use the following to determine your next step: v if the rack is being attached to a concrete (non-raised) floor, proceed to “attach the rack to a concrete (non-raised) floor.” v if the rack is being attached to a raised floor, proceed to “attaching the rack to a short-raised...

Page 130

1. Be sure the rack is in the correct location. 1 plate lock-down (mounting plates) 4 bushing 2 spacer 5 washer 3 washer 6 bolt 114 eserver pseries 670 installation guide.

Page 131

2. Place the mounting plates (item 1 in illustration on page 114), front and rear, in the approximate mounting position under the system rack. 3. To align the mounting plates to the system rack, do the following: a. Place the four rack-mounting bolts (item 6 in illustration on page 114) through the ...

Page 132

Attention: it is the service representative’s responsibility to complete the following steps. 1. Reposition the system rack over the mounting plates. 2. Place the four rack-mounting bolts through the plate assemblies, with the d-washer positioned so that the straight side of the washer is facing inw...

Page 133

3. Install the four eyebolts that match the dimensions given in the following illustrations. 654.8 mm (4x) 49.3 mm eyebolt (2x) 450 mm ref 1220 mm ref 1019 mm (2x) 170 mm ref (2x) 75 mm ref 64.6 mm 100.5 mm 610 mm (24 inch) floor tile layout (2x) opening for cables 48 in ref 4. Install the eyebolts ...

Page 134

To install the frame, do the following: attention: it is the service representative’s responsibility to complete the following steps. 1. Before starting the installation, check all cable openings in the floor panel and location of the rubber bushing holes so that they match the dimensions given in t...

Page 135

3. The floor eyebolts should be already secured to the concrete floor. Verify the height of the center of the floor eyebolt to the concrete floor or the steel beam/channel adapter mounted to the concrete floor. Ensure that the turnbuckles can accommodate the total height of the raised floor. 4. Remo...

Page 136

11. Turn the leveling foot of the plate assembly down until it contacts the bushing, and level the rack by tightening the lock nuts on the four leveling feet. 12. Lock the leveling feet by tightening the lock nut. 13. Insert the threaded rod into the inner hole of the leveler and the rubber bushing....

Page 137

Installing frame ground straps attention: it is recommended that all pseries 670 systems that are installed in 7040 model w42 racks, be grounded. However, two frame-ground straps are required on a rack for a switched clustered environment (for example, when in a scalable parallel (sp) switch-2 conne...

Page 138

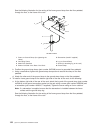

See the following illustration for the routing of the frame ground strap from the floor pedestal, through the floor, to the frame of the rack. 1 2 3 4 5 6 7 8 left rear of rack 1 screw on ground clamp (for tightening the clamp) 5 starwasher (install if supplied) 2 grounding clamp 6 lug on ground str...

Page 139

1 2 3 4 5 6 7 8 right rear of rack 1 screw on ground clamp (for tightening the clamp) 5 starwasher (install if supplied) 2 grounding clamp 6 lug on ground strap 3 metal floor pedestal 7 screw (for attaching lug to the rack) 4 bottom right side of the rear of the rack 8 ground strap b. Position the g...

Page 140

124 eserver pseries 670 installation guide.

Page 141: Appendix

Appendix e. Attaching multiple pseries 670s to one hardware management console this appendix details how to attach multiple pseries 670 servers to one hmc. The hmc might have an 8-port async adapter or a 128-port async adapter installed to allow multiple servers to connect. Procedures for configurin...

Page 142

Connect the serial cables from the pseries 670 to the 8-port async adapters up to two optional 8-port async adapters can be installed. The d-shell connector on the back of the adapter attaches to the 8-port expansion cable. The cable is approximately 3 feet long, and on the other end, has a slim box...

Page 143

128-port async adapter line connectors the 128-port async adapter contains two 15-pin d-shell connectors. The connector that is closest to the edge connector that plugs into the hmc is line 1. The rans are cabled in a daisy chain and are terminated using a line terminator. The following illustration...

Page 144

Setting a ran node number the aix asynchronous communications guide provides information about configuring and running diagnostics on the 128-port async adapter and associated rans. To access the aix asynchronous communications guide, see the aix online documentation. Documentation for the aix opera...

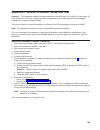

Page 145

A. Question: how many boards would you like to install? Answer: enter the total number of 8-port and/or 128 -port async adapters that are installed in the hmc pc. B. Question: board #1. What type of board is this? (’l’ for list) answer: use board type 16 (ibm 128-port async pci) c. Question: how man...

Page 146

Connect the serial cables from the pseries 670 to the 128-port async adapters up to two optional 128-port async adapters can be installed. The d-shell connectors on the back of the adapter attach to rans. Serial cables can be connected from any of the ports on a ran to the hmc1 ports on the managed ...

Page 147

Verify that installation is complete by using the hmc interface the hmc provides a predefined user id called hscroot. The hscroot password is abc123. This hscroot user id is a member of the system administrator rolehscroot. When the console is powered on for the first time, use this user id to log i...

Page 148

132 eserver pseries 670 installation guide.

Page 149: Appendix

Appendix f. System records use this appendix to keep a record of your server configuration. Record the identification numbers the basic server consists of the redundant bulk power subsystem, one processor subsystem, a media subsystem, and one i/o subsystem in the same rack, as well as access to one ...

Page 150

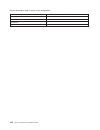

Use the following to keep a record of your components. Component serial number pseries 670 i/o drawer 1 i/o drawer 2 i/o drawer 3 134 eserver pseries 670 installation guide.

Page 151

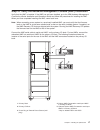

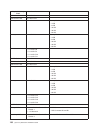

Record system - processor, memory, and i/o configuration the following illustration shows the location codes for the rack. These codes are used to identify the major functional units in the pseries 670. Rear front u1.35-p1-x2 unused u1.35-p2-x2 unused u1.35-p1-x4 u1.35-p2-x4 u1.17 u1.17 u1.9 u1.9 u1...

Page 152

Physical memory card location available other information mcm 0 installed u1.18-p1-c1 mcm 0 vpd card u1.18-p1-h2.3 memory u1.18-p1-m2 memory book v 4 gb v 8 gb v 16 gb v 32 gb v 64 gb memory u1.18-p1-m3 memory book v 4 gb v 8 gb v 16 gb v 32 gb v 64 gb l3 modules v u1.18-p1-c6 v u1.18-p1-c7 v u1.18-...

Page 153

Verify that all hardware is present to verify that all hardware is present, do the following at the command line: v run lsslot -cpci to verify the adapters are plugged into the physical slot they are plugged in. Make note of the adapter types and positions the adapters are plugged in. V run lsdev -c...

Page 154

138 eserver pseries 670 installation guide.

Page 155: Appendix

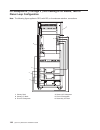

Appendix g. Subsystem positioning and cabling this section describes subsystem positioning and cabling for the pseries 670. Operator panel cable and diskette drive cable to the media subsystem (rear view) 1 primary i/o book 3 diskette drive data cable 2 cable connecting the operator panel to the med...

Page 156

I/o subsystem positions, fully populated rack (rear view without ibf) c1 primary rack 2 second i/o subsystem position 1 first i/o subsystem position 3 third i/o subsystem position 140 eserver pseries 670 installation guide.

Page 157

I/o subsystem positions, fully populated rack (rear view with ibfs) c1 rack 2 second i/o subsystem c2 i/o book (book 0) 3 third i/o subsystem 1 first i/o subsystem 4b two ibfs (primary rack), position 4 appendix g. Subsystem positioning and cabling 141.

Page 158

Rio and rio-2 cabling rules always connect either a one i/o planar loop or a two i/o planar loop to the first six rio ports of the cec in the following order: 1. Primary i/o book slot 0: rio 1 a0 & a1, rio 2 b0 & b1 2. Secondary i/o book slot 2: rio 3 c0 & c1 note: use required pairs of rio ports wi...

Page 159

I/o subsystem (one side of subsystem 1 with ibf) rio cabling to i/o books, two i/o planar loop configuration note: the following figure applies to cecs with rio, or thumbscrew retention, connections. A0 a1 0 1 3 4 1 2 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed) 2 p...

Page 160

I/o subsystems (1 through 3 ) rio cabling to i/o books, two i/o planar loop configuration note: the following figure applies to cecs with rio, or thumbscrew retention, connections. A0 c0 a1 c1 b0 0 0 0 0 0 0 1 1 4 3 5 6 1 1 1 1 b1 1 2 1 primary rack 4 second i/o subsystem 2 primary i/o book 5 first ...

Page 161

I/o subsystems (1 through 3 ) rio-2 cabling to i/o books, two i/o planar loop configuration note: the following figure applies to cecs with rio-2, or bayonette retention, connections. A0 c0 a1 c1 b0 0 0 0 0 0 0 1 1 4 3 5 6 1 1 1 1 b1 1 2 1 primary rack 4 second i/o subsystem 2 primary i/o book 5 fir...

Page 162

I/o subsystem (one side of subsystem 1 with ibf) rio-2 cabling to i/o books, two i/o planar loop configuration note: the following figure applies to cecs with rio-2, or bayonette retention, connections. A0 a1 0 1 3 4 1 2 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed) ...

Page 163

I/o subsystem (one side of subsystem 1 with ibf) rio-2 cabling to i/o books, one i/o planar loop configuration note: the following figure applies to cecs with rio-2, or bayonette retention, connections. 1 primary rack 3 first i/o subsystem (minimum i/o, single i/o board installed) 2 primary i/o book...

Page 164

I/o subsystems (1 through 2) rio-2 cabling to i/o books, one i/o planar loop configuration note: the following figure applies to cecs with rio-2, or bayonette retention, connections. 1 primary rack 4 first i/o subsystem 2 primary i/o book 5 secondary i/o book 3 second i/o subsystem note: the maximum...

Page 165

Power and scsi cables to the media subsystem 1 2 3 5 4 7 6 1 rack 5* scsi cable for media subsystem rear drives 2 primary i/o book 6 scsi cable for media subsystem front drives 3 power cable for media subsystem front drives 7* power cable for media subsystem rear drives 4 rear of media subsystem not...

Page 166

Hardware management console for pseries (hmc) to the primary i/o book to connect your hmc to the pseries 670, connect the serial cable into serial port 1 located on the back of the hmc. Connect the other end of the serial cable into the hmc1 connector located on the primary i/o book in the managed s...

Page 167: Appendix

Appendix h. Cabling information this appendix provides information about the location and label colors of the pseries 670 cables. Power cabling 1 front rear 3 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 35 2 6 10 8 9 7 15 5 16 4 index part number units per assy description 1 n/a bulk power distr...

Page 168

Index part number units per assy description 15 to 17 11p4303 1 i/ob9-p00 to media p02 16 to 18 11p4303 1 i/ob9-p01 to media p00 19, 20, 21, 22 n/a b35-bpdx-p0x to i/o subsystem #x for more information about these cables, refer to “rio cables, rio-2 cables, and i/o power cables” on page 153 23 11p44...

Page 169

Rio cables, rio-2 cables, and i/o power cables fru part number units per assy description 11p2355 up to 3 rio cable 0.5-meter 11p0272 up to 6 rio cable 2-meter 44h9137 up to 6 rio cable 15-meter 00p5238 up to 6 rio-2 cable 1.75-meter 00p5239 up to 6 rio-2 cable 2.5-meter 21p5477 up to 6 rio to rio-2...

Page 170

From to (a=primary) description label color a35p-bpd1b-p04 a01b-dca1-p00 bpd1b to i/o subsystem #3 green a35b-bpd1a-p05 a01b-dca2-p01 bpd1a to i/o subsystem #3 green w/stripes a35p-bpd1b-p05 a01b-dca2-p00 bpd1b to i/o subsystem #3 green 154 eserver pseries 670 installation guide.

Page 171: Appendix

Appendix i. Service processor setup and test attention: this procedure applies to modems attached to the serial ports (s1 and s2) on the primary i/o book (location u1.18-p1-h2). It does not affect the operation of the modem attached to the hardware management console for pseries (hmc). The call-out ...

Page 172

Testing the service processor setup this section contains sample testing procedures to help ensure your service processor setup is working. These tests include communicating with the server operating system. Before you start, ensure that the necessary serial port(s) is configured. If you need assist...

Page 173

Serial port configuration to configure the serial port on an aix system, do the following from an aix console: 1. Log in as root user. 2. To determine if you have any serial ports already configured, type: lsdev -cc tty if no serial ports are configured, none are listed. If you want to configure ser...

Page 174

158 eserver pseries 670 installation guide.

Page 175: Appendix

Appendix j. Removing and installing the rack top frame the following scenarios exist for performing this procedure: v removing and installing the rack top frame for clearance through doorways v installing the rack top frame that was shipped unattached from the rest of the frame note: if the clearanc...

Page 176

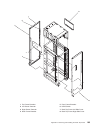

Removing the covers this procedure describes how to remove and replace the side covers of the pseries 670. 1 2 3 4 5 6 7 9 10 11 12 13 14 15 1 part number 44p0127 rear cover 9 part number 11p3535 hinge part number 2665525 screw 2 part number 44p0107 rear cover 10 part number 11p1096 front latch part...

Page 177

2. Remove the (2) screws and washers inside the frame (part numbers 77g0599 and 1625437). 3. Remove the (3) screws at the top of the frame (part number 54g2882). The use of a stepladder is recommended for this procedure. 4. With all the screws removed, rock the cover to the right from the top. There...

Page 178

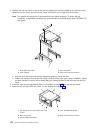

2. Disconnect cables from the bpds. 3. Remove the front and rear bprs, bpds, bpcs, and the fan assemblies. Attention: make note of location identification of the bprs and bpes for later reinstallation. If these components are not reinstalled in their original location, the pseries 670 will not power...

Page 179

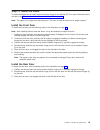

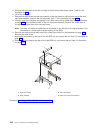

1 8 7 2 3 4 5 1 top frame extender 5 front frame extender 2 left frame extender 6 uepo switch 3 right frame extender 7 rack top frame left side cover 4 rear frame extender 8 rack top frame right side cover appendix j. Removing and installing the rack top frame 163.

Page 180

6. Attention: two people are required to remove the bpes. Remove the bpes (item 1 in the illustration on page 164). 1 bulk power enclosure 2 hex-head screw locations a. Remove the five hex-head screws from the front bpe. B. Remove the five hex-head screws from the rear bpe. C. Install two shipping b...

Page 181

A. Remove the eight screws around the perimeter of the top panels at the front and rear of the rack top-frame assembly. Remove the two top panels (item 1 in the preceding illustration). B. Carefully note the orientation and position of the foam and metal air baffle (item 4 in the preceding illustrat...

Page 182

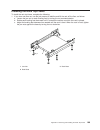

Preparing for rack top-frame installation for pseries 670 (reduced height option) rpq8a1173 to prepare the rack top frame for installation, do the following: 1. Unpack the frame. 2. Unpack the rack top frame. 3. Use the jack screws to stablize and lift the rack off the floor. A. Loosen the jam nut o...

Page 183

D. Remove the bpf (item 5 in the illustration on page 166) as follows: note: a grille covers the fan on the front of the fan assembly. 1) locate the bpf to be replaced. 2) remove the fan cover plate (item 6 in the illustration on page 166). 3) loosen the upper and lower fasteners, using the torque t...

Page 184

A. Remove the two screws at the left and right of the top frame side covers (items 7 and 8 in the illustration on 163). B. Lift off the covers. C. Remove the eight screws around the perimeter of the top panels at the front and rear of the rack top-frame assembly. Remove the two top panels (item 1 in...

Page 185

Installing the rack top frame to install the rack top frame, complete the following: 1. If you have not done so, use the jack screws to stabilize and lift the rack off the floor, as follows: a. Loosen the jam nut on each leveling foot by turning the nut counterclockwise. B. Rotate each leveling foot...

Page 186

2. Position the rack top frame on top of the rack by orienting the two front labels on the rack top frame assembly and the frame. As you face the frame, this label is on the right front of the frame. Note: two people are required to lift and position the top frame assembly. To assist with the instal...

Page 187

5. Insert and align the foam and metal air baffle (item 4 in the illustration on page 170) to the left side of the rack top frame, securing it in place with a screw. 6. Install the rack top-frame cross brace (item 5 in the illustration on page 170). 7. Install the front and rear bpes (item 1 in the ...

Page 188

12. Install any front and rear bulk power fillers. 13. For the reduced height option, remove the front and rear upper shipping bars (item 1 in the following illustration). 1 1 shipping bars 14. Install left and right top-frame side covers (items 7 and 8 in the following illustration). 15. Attach all...

Page 189

16. Install the frame extenders. 1 8 7 2 3 4 5 1 top frame extender 5 front frame extender 2 left frame extender 6 uepo switch 3 right frame extender 7 left side cover 4 rear frame extender 8 right side cover appendix j. Removing and installing the rack top frame 173.

Page 190

17. Install the uepo switch, as follows: a. Install the top and bottom screws. Screws should be bottomed against the end of the slot prior to tightening. B. Plug in the cables. Replacing covers refer to page “removing the covers” on page 160 while performing this task. 1. Examine the bottom of the f...

Page 191: Index

Index numerics 128-port adapter cables connecting 130 8-port adapter cables connecting 126 a about this book xiii accessing information xiii acoustical noise emissions 106 activating process processor on demand 32 activation features processor on demand 29 adapter 128-port 126 8-port 126 adapter and...

Page 192

H hardware operation verifying 23 verification considerations 23 hmc 7 128-port adapter cables connection 130 8-port adapter cables connection 126 cabling 150 configurations 8 installation 17 hmc software, verifying 26 i i/o cpu 135 ibf 140 identification numbers recording 133 information, accessing...

Page 193

Pci adapters (continued) short adapter removal 54 power cords installation 15 routing 15 system connection 15 power source 13 preface xiii prerequisites installation 8 processor cuod overview 29 processor on demand activating process 32 activation features 29 capacity planning 30 dynamic processor s...

Page 194

T tasks, final installation 26 testing the setup call-in 156 call-out 156 top frame removal 161 removing 159 replacement 169 replacing 159 trademarks xiv trial capacity on demand processor features 30 u uepo 12, 18 v verifying hardware operation 23 verifying firmware 25 verifying partition 26 verify...

Page 195: Readers’

Readers’ comments — we’d like to hear from you pseries 670 installation guide publication no. Sa38-0613-04 overall, how satisfied are you with the information in this book? Very satisfied satisfied neutral dissatisfied very dissatisfied overall satisfaction h h h h h how satisfied are you that the i...

Page 196: Business

Readers’ comments — we’d like to hear from you sa38-0613-04 sa38-0613-04 cut or fold along line cut or fold along line fold and tape please do not staple fold and tape fold and tape please do not staple fold and tape no postage necessary if mailed in the united states business reply mail first-class...

Page 198

Part number: 80p3838 printed in usa december 2003 sa38-0613-04 (1p) p/n: 80p3838.