- DL manuals

- IBM

- Storage

- Storwize V7000

- Troubleshooting And Maintenance Manual

IBM Storwize V7000 Troubleshooting And Maintenance Manual

Summary of Storwize V7000

Page 1

Ibm storwize v7000 troubleshooting, recovery, and maintenance guide version 6.1.0 gc27-2291-00

Page 3

Ibm storwize v7000 troubleshooting, recovery, and maintenance guide version 6.1.0 gc27-2291-00

Page 4

Note before using this information and the product it supports, read the general information in “notices” on page 115, the information in the “safety and environmental notices” on page ix, as well as the information in the ibm environmental notices and user guide on the documentation cd. This editio...

Page 5

Contents figures . . . . . . . . . . . . . . . V tables . . . . . . . . . . . . . . . Vii safety and environmental notices . . . Ix sound pressure . . . . . . . . . . . . . Ix about this guide . . . . . . . . . . . Xi who should use this guide . . . . . . . . . Xi emphasis . . . . . . . . . . . . . ...

Page 6

Procedure: collecting information for support . . . 49 san problem determination. . . . . . . . . 50 fibre channel link failures . . . . . . . . . 50 servicing storage systems. . . . . . . . . . 51 chapter 6. Recovery procedures. . . . 53 recover cluster procedure . . . . . . . . . 53 when to run th...

Page 7

Figures 1. 12 drives . . . . . . . . . . . . . . 2 2. 24 drives . . . . . . . . . . . . . . 2 3. Led indicators on a single 3.5" drive . . . . 2 4. Led indicators on a single 2.5" drive . . . . 3 5. 12 drives and two end caps . . . . . . . 4 6. Left enclosure end cap . . . . . . . . . 4 7. Rear view...

Page 8

Vi storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 9

Tables 1. Ibm documentation and related websites xii 2. Drive leds . . . . . . . . . . . . . 3 3. Led descriptions . . . . . . . . . . . 4 4. Power supply unit leds in the rear of the control enclosure . . . . . . . . . . . 6 5. Power supply unit leds in the rear of the expansion enclosure . . . . ....

Page 10

Viii storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 11

Safety and environmental notices review the multilingual safety notices for the ibm ® storwize ® v7000 system before you install and use the product. Suitability for telecommunication environment: this product is not intended to connect directly or indirectly by any means whatsoever to interfaces of...

Page 12

X storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 13

About this guide this guide describes how to service, maintain, and troubleshoot the ibm storwize v7000. The chapters that follow introduce you to the hardware components and to the tools that assist you in troubleshooting and servicing the storwize v7000, such as the management gui, and the service...

Page 14

Storwize v7000 library unless otherwise noted, the publications in the storwize v7000 library are available in adobe portable document format (pdf) from the following website: support for storwize v7000 website at www.Ibm.Com/storage/support/storwize/v7000 ibm documentation and related websites tabl...

Page 15

– publication form number: gc27-2291-00 – page, table, or illustration numbers that you are commenting on – a detailed description of any information that should be changed about this guide xiii.

Page 16

Xiv storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 17

Chapter 1. Storwize v7000 hardware components a storwize v7000 system consists of one or more machine type 2076 rack-mounted enclosures. There are four model types. The main differences among the model types are the following items: v the number of drives that an enclosure can hold. Drives are locat...

Page 18

The drives are located in the front of the enclosure. The 12 drives are mounted in four columns with three rows. The 24 drives are mounted vertically in one row. Note: the drive slots cannot be empty. A drive assembly or blank carrier must be in each slot. Figure 1 shows 12 drives, and figure 2 show...

Page 19

1 fault led 2 activity led table 2 shows the status descriptions for the two leds. Table 2. Drive leds name description color activity indicates if the drive is ready or active. V if the led is on, the drive is ready to be used. V if the led is off, the drive is not ready. V if the led is flashing, ...

Page 20

No controls, indicators, or connectors. Table 3. Led descriptions name description color symbol power 1 the power led is the upper led. When the green led is lit, it indicates that the main power is available to the enclosure green . Fault 2 the fault led is the middle led. When the amber led is lit...

Page 21

Two canisters are located in the middle of each enclosure. The power supply units are located on the left and right of the canisters. The left slot is power supply 1 ( 1 ), and the right slot is power supply 2 ( 2 ). Power supply 1 is top side up, and power supply 2 is inverted. The upper slot is ca...

Page 22

Table 4 identifies the leds in the rear of the control enclosure. Table 4. Power supply unit leds in the rear of the control enclosure name color symbol ac power failure amber power supply ok green fan failure amber dc power failure amber battery failure amber + - battery state green + - see “proced...

Page 23

There is a power switch on each of the power supply units. The switch must be on for the power supply unit to be operational. If the power switches are turned off, the power supply units stop providing power to the system. Figure 10 shows the locations of the leds 1 in the rear of the power supply u...

Page 24

Each node canister has four fibre channel ports located on the left side of the canister as shown in figure 11. The ports are in two rows of two ports. The ports are numbered 1 - 4 from left to right and top to bottom. Note: the reference to the left and right locations applies to canister 1, which ...

Page 25

Table 6. Fibre channel port led locations on canister 1 associated port led location led status port 3 3 first led between ports 1 and 3 1 speed port 1 1 second led between ports 1 and 3 2 speed port 3 3 third led between ports 1 and 3 3 link port 1 1 fourth led between ports 1 and 3 4 link port 4 4...

Page 26

The usb ports have no indicators. Ethernet ports and indicators two ethernet ports are located side by side on the node canister. The ethernet ports are numbered 1 on the left and 2 on the right as shown in figure 14 on page 11. Port 1 must be connected; the use of port 2 is optional. Two leds are a...

Page 27

Table 8 provides a description of the two leds. Table 8. Ethernet port leds name description color link speed (led on right of upper canister) the led is on when there is a link connection; otherwise, the led is off. Green activity (led on left of upper canister) the led is flashing when there is ac...

Page 28

Sas ports must be connected to storwize v7000 enclosures only. See “problem: sas cabling not valid” on page 39 for help in attaching the sas cables. Four leds are located with each port. Each led describes the status of one data channel within the port. The data channel number is shown with the led....

Page 29

Note: the reference to the left and right locations applies to canister 1, which is the upper canister. The port locations are inverted for canister 2, which is the lower canister. Table 10. Node canister leds name description color symbol cluster status indicates the status of the node. V the on st...

Page 30

The wwpns are derived from the worldwide node name (wwnn) that is allocated to the storwize v7000 node in which the ports are installed. The wwnn for each node is stored within the enclosure. When you replace a node canister, the wwpns of the ports does not change. The wwnn is in the form 5005076802...

Page 31

Four leds are located with each port. Each led describes the status of one data channel within the port. The data channel is shown with the led. Table 11. Sas port leds on the expansion canister led state description off no link is connected. Flashing the link is connected and has activity. On the l...

Page 32

Table 12. Expansion canister leds (continued) name description color symbol fault indicates if a fault is present and identifies the canister. V if the led is on, a fault exists. V if the led is off, no fault exists. V if the led is flashing, the canister is being identified. This status might or mi...

Page 33

Chapter 2. Best practices for troubleshooting troubleshooting is made easier by taking advantage of certain configuration options and ensuring that you have recorded vital information that is required to access your system. Record access information it is important that anyone who has responsibility...

Page 34

Its internal disk and the data is lost. If both node canisters in a control enclosure are removed in quick succession, you will have to run recovery actions, which might include restoring your volume data from a backup. Set up event notifications configure your system to send notifications when a ne...

Page 35

Manage your spare and failed drives your raid arrays that are created from drives in the storwize v7000 system consist of drives that are active members and drives that are spares. The spare drives are used automatically if a member drive fails. If you have sufficient spare drives, you do not have t...

Page 36

Subscribe to support notifications by visiting the storwize v7000 support page on the ibm website. By subscribing, you are informed of new and updated support site information, such as publications, hints and tips, technical notes, product flashes (alerts), and downloads. Know your ibm warranty and ...

Page 37

Chapter 3. Understanding the storwize v7000 battery operation for the control enclosure storwize v7000 node canisters cache volume data and hold state information in volatile memory. If the power fails, the cache and state data is written to a local solid-state drive (ssd) that is held within the ca...

Page 38

A battery is considered failed for the following conditions: v when the system can communicate with it and it reports an error. V when the system is unable to communicate with the battery. Failed communication exists because the power supply, which contains the battery, has been removed or because t...

Page 39

V a battery has provided protection for at least 20 brown outs, which lasted up to 10 seconds each. V a battery must restart a maintenance discharge because the previous maintenance cycle was disrupted by an ac power outage. If a system suffers repeated ac power failures without a sufficient time in...

Page 40

24 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 41

Chapter 4. Storwize v7000 user interfaces for servicing your system storwize v7000 provides a number of user interfaces to troubleshoot, recover, or maintain your system. The interfaces provide various sets of facilities to resolve any situation that you encounter. Use the initialization tool to do ...

Page 42

Accessing the management gui this procedure describes how to access the management gui. You can use the management gui to manage your system as soon as you have created a cluster. 1. Start a supported web browser and point the browser to the management ip address of your system. The management ip ad...

Page 43

V collect logs to create and download a package of files to send to support personnel. V remove the cluster data from a node. V recover a cluster if it fails. V install a software package from the support site or rescue the software from another node. V upgrade software on nodes manually versus perf...

Page 44

Nearly all of the flexibility that is offered by the cli is available through the management gui. However, the cli does not provide the fix procedures that are available in the management gui. Therefore, use the fix procedures in the management gui to resolve the problems. Use the cli when you requi...

Page 45

When a usb key is plugged into a node, the node software searches for a text file named satask.Txt in the root directory. If the software finds the file, it attempts to run a command that is specified in the file. When the command completes, a file called satask_result.Html is written to the root di...

Page 46

Reset service ip address and superuser password command use this command to obtain service assistant access to a node even if the current state of the node is unknown. The physical access to the node is required and is used to authenticate the action. Syntax satask chserviceip -serviceip ipv4 -gw ip...

Page 47

Syntax satask resetpassword parameters none. Description this command resets the service assistant password to the default value passw0rd . If the node is active in a cluster, the cluster superuser password is reset; otherwise, the superuser password is reset on the node. If the node becomes active ...

Page 48

Description this command copies the file from the usb key to the upgrade directory on the node. This command calls the satask installsoftware command. Create cluster command use this command to create a cluster. Syntax satask mkcluster -clusterip ipv4 -gw ipv4 -mask ipv4 -name cluster_name satask mk...

Page 49

Description this command writes the output from each node to the usb key. This command calls the sainfo lsservicenodes command, the sainfo lsservicestatus command, and the sainfo lsservicerecommendation command. Chapter 4. Storwize v7000 user interfaces for servicing your system 33 4 4 4 4 4.

Page 50

34 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 51

Chapter 5. Resolving a problem this topic describes the procedures that you follow to resolve fault conditions that exist on your system. This topic assumes that you have a basic understanding of the storwize v7000 system concepts. The following procedures are often used to find and resolve problems...

Page 52

The fix procedure also checks that another existing problem does not result in a fix procedure that causes volume data to be lost. For example, if a power supply unit in a node enclosure must be replaced, the fix procedure checks and warns you if the integrated battery in the other power supply unit...

Page 53

V if you are not logging in as superuser , contact your system administrator who can verify your user name and reset your account password. V if the user name that you are using is authenticated through a remote authentication server, verify that the server is available. If the authentication server...

Page 54

V if you know the service address of any node canister in the system, follow a similar procedure to the one described previously. Rather than using cluster address /service to start the service assistant, use the service address that you know. V use a usb key to find the service address of a node. F...

Page 55

V after the node has been used in a cluster, the node canister has saved information that can identify whether the canister has been moved to a different enclosure or a different slot in the same enclosure from where it was previously used. Moving a node canister might compromise its access to stora...

Page 56

You have the following choices: v validate that the volume copies are identical. V validate that the volume copies are identical, mark, and repair any differences that are found. If you want to resolve any differences, you have the following options: v consider that one volume is correct and make th...

Page 57

Note: use the manage device options from the management gui to change the id of an enclosure. Use this option to set a unique id on all your enclosures. V within an enclosure, a canister is identified by its slot location. Slot 1 is the upper canister. Slot 2 is the lower canister. A canister is uni...

Page 58

The home page shows a table of node errors that exist on the node and a table of node details for the current node. The node errors are shown in priority order. The node details are divided into several sections. Each section has a tab. Examine the data that is reported in each tab for the informati...

Page 59

Table 14. Power-supply unit leds power supply ok ac failure fan failure dc failure status action on on on on communication failure between the power supply unit and the enclosure chassis replace the power supply unit. If failure is still present, replace the enclosure chassis. Off off off off no ac ...

Page 60

Table 15. Cluster status and fault leds cluster status led fault led status action off off code is not active. V follow procedures for reviewing power leds. V if the power leds show green, reseat the node canister. See “procedure: reseating a node canister” on page 48. If the led status does not cha...

Page 61

The status, speed, and mac address are returned for each port. Information is returned that identifies whether the node is the configuration node and if any node errors were reported. V examine the two leds of the ethernet ports. The activity led flashes when there is activity on the connection. The...

Page 62

4. If the recommended action does not provide sufficient information to determine the service action, review the node error descriptions and service actions. Go to “error code range” on page 76. See the node error descriptions if you cannot access the management gui or if the management gui is not r...

Page 63

In these situations, you must manually create an satask.Txt file on a usb key to initialize your cluster. Use the usb key that was supplied with your system or any usb key that is formatted with a fat32, an ext2, or an ext3 file system on its first partition. 1. Open a file editor that can create as...

Page 64

5. Click create cluster . Attention: without a usb key to service the system, it is not possible to reset the superuser password or to change the service ip addresses in the event of a fault that prevents access to the management interface. It is essential that you take steps to record this informat...

Page 65

2. Verify that you have selected the correct node canister and verify why you are reseating it. Go to “procedure: identifying which enclosure or canister to service” on page 40. If you reseat a node that is active, it cannot store its state data and cannot restart without other service actions. If t...

Page 66

San problem determination the procedures that are provided here help you solve problems on the storwize v7000 system and its connection to the storage area network (san). San failures might cause storwize v7000 drives to be inaccessible to host systems. Failures can be caused by san configuration ch...

Page 67

Servicing storage systems storage systems that are supported for attachment to the storwize v7000 system are designed with redundant components and access paths to enable concurrent maintenance. Hosts have continuous access to their data during component failure and replacement. The following guidel...

Page 68

52 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 69

Chapter 6. Recovery procedures this topic describes the recovery procedures that you follow to recover a cluster and to back up and restore a cluster configuration. Recover cluster procedure the recover cluster procedure recovers the entire cluster if cluster data has been lost from all nodes. The p...

Page 70

V node identifiers in the format: enclosure_serial >- canister slot id > number), for example, 01234a6-2 v quorum drive identifiers in the format: enclosure_serial >: drive slot id >[ number>] (7 characters, colon, 1 or 2 numbers, open square bracket, 22 characters, close square bracket), for exampl...

Page 71

To remove cluster information from a node canister with an error 550 or 578, follow this procedure using the service assistant: 1. Point your browser to the service ip address of one of the node canisters. If you do not know the ip address or if it has not been configured, you must assign an ip addr...

Page 72

Attention: if the time stamp is not less than 10 minutes before the cluster failure, call ibm support. If you do not meet all the conditions that were discussed previously, call ibm support. Verify the date and time of the last backup date. The time stamp must be less than 24 hours before the cluste...

Page 73

V no independent operations that change the cluster configuration can be running while the backup command is running. V no object name can begin with an underscore character (_). Note: v the default object names for controllers, i/o groups, and managed disks (mdisks) do not restore correctly if the ...

Page 74

– all other objects with default names are renamed during the restore process. The new names appear in the format name _r. Where name is the name of the object in your cluster. The backup feature of the svcconfig cli command is designed to back up information about your cluster configuration, such a...

Page 75

Scp -p 22 admin@ your_cluster :/tmp/svc.Config.Backup.* / offclusterstorage / where your_cluster is the name of your cluster and offclusterstorage is the location where you want to store the backup files. You must copy these files to a location outside of your cluster because the /tmp directory on t...

Page 76

To restore your cluster configuration data, follow these steps: 1. The node must be available as a candidate node before you can run this recovery procedure. You must remove error code 550 or 578 to put the node in candidate status. 2. Use the usb key to initialize the system. 3. From the management...

Page 77

12. Issue the following cli command to restore the cluster configuration: svcconfig restore -execute note: issuing this cli command on a single node cluster adds the other nodes to the cluster. This cli command creates a log file in the /tmp directory of the configuration node. The name of the log f...

Page 78

62 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 79

Chapter 7. Event reporting events that are detected are saved in an event log. As soon as an entry is made in this event log, the condition is analyzed. If any service activity is required, a notification is sent. Event reporting process the following methods are used to notify you and the ibm suppo...

Page 80

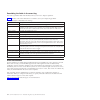

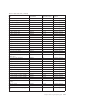

Describing the fields in the event log the event log includes fields with information that you can use to diagnose problems. Table 16 describes some of the fields that are available to assist you in diagnosing problems. Table 16. Description of data fields for the event log data field description ev...

Page 81

Table 17. Notification types notification type description error an error notification is sent to indicate a problem that must be corrected as soon as possible. This notification indicates a serious problem with the storwize v7000. For example, the event that is being reported could indicate a loss ...

Page 82

Configuration events are generated when configuration parameters are set. Configuration events are recorded in a separate log. Configuration events are not notified through email, snmp, or syslog. Informational event codes the informational event codes provide information on the status of an operati...

Page 83

Table 18. Informational event codes (continued) event code notification type description 981026 i drive fpga download started 981101 i sas discovery occurred; no configuration changes are required. 981102 i sas discovery occurred; configuration changes are required. 981103 i sas discovery occurred; ...

Page 84

Table 18. Informational event codes (continued) event code notification type description 986032 i a thin-provisioned volume copy validation is started. 986033 i a thin-provisioned volume copy validation is successful. 986201 i a medium error has been repaired for the mirrored copy. 986203 w a mirror...

Page 85

Table 19. Event ids and codes (continued) event id notification type condition error code 009052 e the following causes are possible: v the node is missing v the node is no longer a functional member of the cluster v one or more nodes are not available v the node has probably had a hardware or softw...

Page 86

Table 19. Event ids and codes (continued) event id notification type condition error code 010022 w there are too many managed disks presented to the cluster. 1200 010023 w there are too many luns presented to a node. 1200 010024 w there are too many drives presented to a node. 1200 010025 w a disk i...

Page 87

Table 19. Event ids and codes (continued) event id notification type condition error code 010062 e a drive exceeded the warning temperature threshold. 1217 010063 w drive medium error. 1321 010066 w controller indicates that it does not support descriptor sense for luns that are greater than 2 tbs. ...

Page 88

Table 19. Event ids and codes (continued) event id notification type condition error code 045004 e the power supply unit is not installed. 1128 045005 w the power supply unit has indicated an input power failure. 1138 045006 e the power supply unit has indicated a dc failure. 1126 045007 e the power...

Page 89

Table 19. Event ids and codes (continued) event id notification type condition error code 045046 w an enclosure is connected to more than one i/o group. 1005 045047 w a managed enclosure is connected to the wrong i/o group. 1005 045048 w an enclosure is connected to more than one chain. 1005 045049 ...

Page 90

Table 19. Event ids and codes (continued) event id notification type condition error code 060002 w the thin-provisioned volume copy is offline because the metadata is corrupt. 1862 060003 w the thin-provisioned volume copy is offline because the repair has failed. 1860 062001 w unable to mirror medi...

Page 91

Table 19. Event ids and codes (continued) event id notification type condition error code 079500 w the limit on the number of cluster secure shell (ssh) sessions has been reached. 2500 079501 i unable to access the network time protocol (ntp) network time server. 2700 081001 e an ethernet port failu...

Page 92

Cluster recovery codes you must perform software problem analysis before you can perform further cluster operations to avoid the possibility of corrupting your cluster configuration. Error code range this topic shows the number range for each message classification. Table 20 lists the number range f...

Page 93

502 no enclosure identity exists and a status from the partner node could not be obtained. Explanation: the enclosure has been replaced and communication with the other node canister (partner node) in the enclosure is not possible. The partner node could be missing, powered off or unable to boot, or...

Page 94

506 no enclosure identity and no node state on partner explanation: the enclosure vital product data indicates that the enclosure chassis has been replaced. There is no cluster state information on the other node canister in the enclosure (the partner canister), so both node canisters from the origi...

Page 95

510 the detected memory size does not match the expected memory size. Explanation: the amount of memory detected in the node canister is less than the expected memory. The error code date shows the detected memory, in mb, followed by the expected memory, in mb. User response: follow troubleshooting ...

Page 96

Diagnostics the system provides to diagnose problems on sas cables and expansion enclosures. 4. If a quorum disk on an external storage system is shown as missing, find the storage control and confirm that the lun is available, check the fibre channel connections between the storage controller and t...

Page 97

The node error does not persist across restarts of the node software and operating system. User response: follow troubleshooting procedures to reload the software: 1. Get a support package (snap), including dumps, from the node using the management gui or the service assistant. 2. If more than one n...

Page 98

5. Attempt to determine what caused the nodes to shut down. Possible cause-frus or other: v none 671 the available battery charge is not enough to allow the node canister to start. Two batteries are charging. Explanation: the battery charge within the enclosure is not sufficient for the node to safe...

Page 99

Possible cause-frus or other: v none 801 memory reduced. Explanation: memory is reduced but sufficient memory exists to run i/o operations. User response: follow troubleshooting procedures to fix the hardware. 803 one or more fibre-channel ports are not operational. Explanation: one or more fibre-ch...

Page 100

84 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 101

Chapter 8. Removing and replacing parts you can remove and replace field-replaceable units (frus) from the control enclosure or the expansion enclosure. Attention: if your system is powered on and performing i/o operations, go to the management gui and follow the fix procedures. Performing the repla...

Page 102

1. Read the safety information to which “preparing to remove and replace parts” on page 85 refers. 2. Confirm that you know which canister to replace. Go to “procedure: identifying which enclosure or canister to service” on page 40. 3. Record which data cables are plugged into the specific ports of ...

Page 103

9. Insert the new canister into the slot with the handle pointing towards the center of the slot. Insert the unit in the same orientation as the one that you removed. 10. Push the canister back into the slot until the handle starts to move. 11. Finish inserting the canister by closing the handle unt...

Page 104

5. Squeeze them together to release the handle. 6. Pull out the handle to its full extension. 7. Grasp canister and pull it out. 8. Insert the new canister into the slot with the handle pointing towards the center of the slot. Insert the unit in the same orientation as the one that you removed. 9. P...

Page 105

Even though many of these procedures are hot-swappable, these procedures are intended to be used only when your system is not up and running and performing i/o operations. Unless your system is offline, go to the management gui and follow the fix procedures. Be careful when you are replacing the har...

Page 106

Replacing a power supply unit for a control enclosure you can replace either of the two 764 watt hot-swap redundant power supplies in the control enclosure. These redundant power supplies operate in parallel, one continuing to power the canister if the other fails. Danger when working on or around t...

Page 107

Be careful when you are replacing the hardware components that are located in the back of the system that you do not inadvertently disturb or remove any cables that you are not instructed to remove. Attention: in some instances, it might not be advisable to remove a power supply unit when a system i...

Page 108

6. Insert the replacement power supply unit into the enclosure with the handle pointing towards the center of the enclosure. Insert the unit in the same orientation as the one that you removed. 7. Push the power supply unit back into the enclosure until the handle starts to move. 8. Finish inserting...

Page 109

Replacing a power supply unit for an expansion enclosure you can replace either of the two 580 watt hot-swap redundant power supplies in the expansion enclosure. These redundant power supplies operate in parallel, one continuing to power the canister if the other fails. Danger when working on or aro...

Page 110

Be careful when you are replacing the hardware components that are located in the back of the system that you do not inadvertently disturb or remove any cables that you are not instructed to remove. Ensure that you are aware of the procedures for handling static-sensitive devices before you replace ...

Page 111

6. Insert the replacement power supply unit into the enclosure with the handle pointing towards the center of the enclosure. Insert the unit in the same orientation as the one that you removed. 7. Push the power supply unit back into the enclosure until the handle starts to move. 8. Finish inserting...

Page 112

Replacing a battery in a power supply unit this topic describes how to replace the battery in the control enclosure power-supply unit. Danger when working on or around the system, observe the following precautions: electrical voltage and current from power, telephone, and communication cables are ha...

Page 113

Be careful when you are replacing the hardware components that are located in the back of the system that you do not inadvertently disturb or remove any cables that you are not instructed to remove. Each power supply unit in a control enclosure contains an integrated battery that is used during temp...

Page 114

B. Lift the handle on the battery 2 c. Lift the battery out of the power supply unit 3 . 4. Install the replacement battery. Caution: the replacement battery has protective end caps that must be removed prior to use. A. Remove the battery from the packaging. B. Remove the end caps. C. Attach the end...

Page 115

2. Pull the lever next to the black plastic loop towards you as shown in figure 30 on page 100. Svc00686 figure 29. Unlocking the cable retention bracket chapter 8. Removing and replacing parts 99.

Page 116

3. Continue to pull the lever towards you as you slide the cable retention bracket away from the end of the cable. Replacing a 3.5" drive assembly or blank carrier this topic describes how to replace a 3.5" drive assembly or blank carrier. Attention: if your drive is configured for use, go to the ma...

Page 117

3. Open the handle to the full extension. 4. Pull out the drive. 5. Push the new drive back into the slot until the handle starts to move. 6. Finish inserting the drive by closing the handle until the locking catch clicks into place. Svc00612 figure 31. Unlocking the 3.5" drive svc00613 figure 32. R...

Page 118

Replacing a 2.5" drive assembly or blank carrier this topic describes how to remove a 2.5" drive assembly or blank carrier. Attention: if your drive is configured for use, go to the management gui and follow the fix procedures. Performing the replacement actions without the assistance of the fix pro...

Page 119

4. Pull out the drive. 5. Push the new drive back into the slot until the handle starts to move. 6. Finish inserting the drive by closing the handle until the locking catch clicks into place. Replacing an enclosure end cap this topic describes how to replace an enclosure end cap. To replace the encl...

Page 120

3. Plug the replacement cable into the specific port. 4. Ensure that the sas cable is fully inserted. A click is heard when the cable is successfully inserted. Replacing a control enclosure chassis this topic describes how to replace a control enclosure chassis. Note: ensure that you know the type o...

Page 121

Danger when working on or around the system, observe the following precautions: electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid a shock hazard: v connect power to this unit only with the ibm provided power cord. Do not use the ibm provided power...

Page 122

V if you are replacing the enclosure because neither node canister can start, retrieve this information after you have completed the replacement. A. Start the service assistant on one of the canisters. B. Go to the node location data on the home page. C. Record the machine type and model, the serial...

Page 123

22. Attach the power cords and the cable retention brackets to the power supply units. 23. Write the old enclosure machine type and model (mtm) and serial number on the repair identification (rid) tag that is supplied. Attach the tag to the left flange at the back of the enclosure. 24. Turn on the p...

Page 124

Danger when working on or around the system, observe the following precautions: electrical voltage and current from power, telephone, and communication cables are hazardous. To avoid a shock hazard: v connect power to this unit only with the ibm provided power cord. Do not use the ibm provided power...

Page 125

To replace a control enclosure, perform the following steps: 1. Shut down the i/o activity to the enclosure, which includes host access, flashcopy, metro mirror and global mirror access. 2. Turn off the power to the enclosure using the switches on the power supply units. 3. Record which data cables ...

Page 126

4. Working from the front of the rack cabinet, remove the clamping screw from the rail assembly on both sides of the rack cabinet. 5. From one side of the rack cabinet, grip the rail and slide the rail pieces together to shorten the rail. 6. Remove the rail location pins 2 . 7. From the other side t...

Page 127

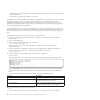

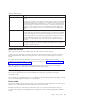

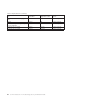

Table 21. Replaceable units (continued) part part number applicable models fru or customer replaced expansion canister 85y5850 212, 224 customer replaced 764 w power supply unit 85y5847 112, 124 customer replaced 580 w power supply unit 85y5846 212, 224 customer replaced battery backup unit 85y5898 ...

Page 128

Table 21. Replaceable units (continued) part part number applicable models fru or customer replaced longwave small form-factor pluggable (sfp) 85y5957 112, 124 customer replaced rail kit 85y5852 all customer replaced left enclosure cap including rid tag but no black mtm label 85y5901 all customer re...

Page 129

Appendix. Accessibility accessibility features help a user who has a physical disability, such as restricted mobility or limited vision, to use software products successfully. Features these are the major accessibility features in the management gui: v you can use screen-reader software and a digita...

Page 130

114 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 131

Notices this information was developed for products and services offered in the u.S.A. Ibm may not offer the products, services, or features discussed in this document in other countries. Consult your local ibm representative for information on the products and services currently available in your a...

Page 132

Licensees of this program who wish to have information about it for the purpose of enabling: (i) the exchange of information between independently created programs and other programs (including this one) and (ii) the mutual use of the information which has been exchanged, should contact: ibm corpora...

Page 133

Trademarks ibm, the ibm logo, and ibm.Com are trademarks or registered trademarks of international business machines corp., registered in many jurisdictions worldwide. Other product and service names might be trademarks of ibm or other companies. A current list of ibm trademarks is available on the ...

Page 134

Avis de conformité à la réglementation d'industrie canada cet appareil numérique de la classe a est conforme à la norme nmb-003 du canada. New zealand compliance statement ensure that you are familiar with the new zealand compliance statement. This is a class a product. In a domestic environment thi...

Page 135

En 55022 klasse a geräte müssen mit folgendem warnhinweis versehen werden: “warnung: dieses ist eine einrichtung der klasse a. Diese einrichtung kann im wohnbereich funk-störungen verursachen; in diesem fall kann vom betreiber verlangt werden, angemessene maßnahmen zu ergreifen und dafür aufzukommen...

Page 136

Taiwan class a compliance statement european contact information this topic contains the product service contact information for europe. European community contact: ibm technical regulations pascalstr. 100, stuttgart, germany 70569 tele: 0049 (0)711 785 1176 fax: 0049 (0)711 785 1283 email: mailto:t...

Page 137

Index numerics 2.5" drive assembly replacing 102 3.5" drive assembly replacing 100 a about this document sending comments xii accessibility keyboard 113 repeat rate of up and down buttons 113 shortcut keys 113 accessing canisters ethernet cable 48 cluster cli 28 management gui 26 service assistant 2...

Page 138

Enclosure end cap replacing 103 end cap indicators 3 environmental notices ix error expansion enclosure 39 node canister 38 not detected 39 sas cabling 39 error codes 68 understanding 65 error events 63 error id 68 errors logs describing the fields 64 error events 63 managing 63 understanding 63 vie...

Page 139

Passwords best practices 17 people's republic of china, electronic emission statement 119 ports ethernet 10 port names, worldwide 13 port numbers, fibre channel 13 sas 11, 14 post (power-on self-test) 65 power management best practices 17 power supply replacing 90, 93 power supply unit control enclo...

Page 140

W warranty agreement best practices 20 when to use cluster cli 28 management gui interface 25 service assistant 26 worldwide port names (wwpns) description 13 124 storwize v7000 version 6.1.0: troubleshooting, recovery, and maintenance guide.

Page 142

Printed in usa gc27-2291-00