Summary of i2015 CNC

Page 1

I2015 owner’s manual of 1 35.

Page 2

I2015 owner’s manual of 2 35.

Page 3: Table Of

Table of contents iconiccnc i2015 specifications 4 routine maintenance 5 pre-operation warning 6 warning labels 6 machine safety 7 electrical safety 7 environment safety 7 grounding instructions 10 hazardous areas 11 machine components 12 unpacking your iconiccnc machine 13 decibel levels 14 machine...

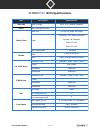

Page 4: Iconic

Iconic cnc i2015 specifications i2015 owner’s manual of 4 35 item description specifications table size width x length 23.75” x 25” (604mm x 635mm) travel max. Carving area (xyz) 20” x 15” x 4” (508mm x 381mm x 102mm) cutting tools shaft size 1/4” and 1/2” (6mm and 12mm) types conical bit: 1/32” rad...

Page 5: Iconic

Iconic cnc i2015 specifications (cont.) routine maintenance the x/y/z rails on the i2015 are specially-designed rails, and are completely maintenance-free; no grease application is ever required. If any of the axis’ produce a high-pitch sound, simply apply some wd-40, and then wipe any excessive oil...

Page 6: Pre-Operation Warning

Pre-operation warning please read this manual thoroughly before operating the machine. Iconic inc. Reserves the right to alter its contents without prior notice. This machine is designed for wood/plastic carving only. Do not tamper and operate this machine for any application other than for which it...

Page 7: Machine Safety

Machine safety 1. For support/warranty purposes, keep a record of your machine’s model & serial number. 2. Ensure the power is off before installing a new cutting tool. 3. To avoid the risk of danger, make sure that the workpiece is properly secured. 4. Please use a collet that match cutting tools (...

Page 8

For your own safety, please read the instruction manual before operating tools: 1. Keep guards in place and in working order. 2. Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on. 3. Keep work area clean. Clu...

Page 9: Safety Guidelines (Cont.)

Safety guidelines (cont.) 15. Disconnect tools before servicing; when changing accessories, such as blades, bits, cutters, and the like. 16. Reduce the risk of unintentional stating. Make sure switch is in off position before plugging in. 17. Use recommended accessories. Consult the owner's manual f...

Page 10: Grounding Instructions

Grounding instructions 1. All grounded, cord-connected tools: in the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a...

Page 11: Hazardous Areas

Hazardous areas i2015 owner’s manual of 11 35.

Page 12: Machine Components

Machine components i2015 owner’s manual of 12 35 no. Description no. Description 1 z-axis stepper motor 9 z- limit switch 2 x-axis stepper motor 10 y- limit switch 3 brushless dc spindle motor 11 y+ limit switch 4 y-axis stepper motor 12 x- limit switch 5 usb port 13 x+ limit switch 6 main power 14 ...

Page 13: Unpacking Your Iconic

Unpacking your iconic cnc machine please unpack your cnc machine with care. It should be removed from the packaging and set on a sturdy surface using the handle on the sides of the machine, which will require two individuals. The i2015 comes fully assembled, and is ready for operation once the owner...

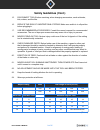

Page 14: Decibel Levels

Decibel levels 1. When machine is under dry run operation, decibel level should be 2. Decibel is measured from the front of the machine, in which the operator‘s distance to the spindle should be approximately 50cm. Measured front, back, right, and left of the machine. Machine structure x, y & z-axis...

Page 15: X, Y, Z Movements

X, y, z movements x+ moves spindle to the right x- moves spindle to the left z+ moves spinde up z- moves spindle down y+ moves spindle backwards y- moves spindle forwards installing cutting tools 1. Press round pin. 2. Lock cutting tool nut manually. 3. Insert tool into the net. 4. Lock down the nut...

Page 16: Standard Tooling

Standard tooling tool box contents 1. Conical bit 2. End mill 3. 60° v-bit 4. 90° v-bit 5. 1/4” collet nut 6. 1/2” collet nut 7. Open-end wrench (11mm x 13mm) 8. Double-ended screw driver 9. Open-end wrench (22mm x 24mm) 10. Brush 11. 3d greyscale image library dvd 12. Usb stick (with ipicture softw...

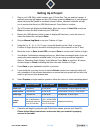

Page 17: Setting Up A Project

Setting up a project 1. Plug in your usb stick, which contains your g-code files. Turn on machine’s power. A welcome message will appear on the lcd screen; press the enter key on your keypad, which will move the spindle to its default home position. Handheld controller will ask you to confirm that t...

Page 18

Using on-board sd card storage to avoid accidental usb disconnection during operation, users may choose to transfer their g-code files from the usb stick to the onboard sd card. 1. Plug in your usb stick, which contains your g-code files. Turn on machine’s power. A welcome message will appear on the...

Page 19: Setting Spindle On/off

Adjusting manual jog speed the default jogging speed (level 2) can be adjusted manually, from 0.6 - 3.6m/min. 1. From the main menu on your handheld controller, select position. 2. Select manual jog mode. 3. Move the cursor the the desired axis, and press enter. 4. The cursor will become a solid blo...

Page 20

Activating safety enclosure sensor when the safety enclosure is chosen (optional accessory), users may activate/ deactivate the safety enclosure sensor. When the sensor is activated, the spindle motor will come to an immediate stop when the enclosure is lifted. To resume machine operation, the enclo...

Page 21: Iconic

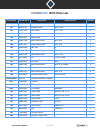

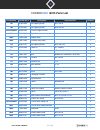

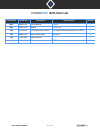

Iconic cnc i2015 parts list i2015 owner’s manual of 21 35 part number internal ref. # description specifications quantity 1 490777-000 led (green) 1 2 490778-000 led (right) 1 4 000303-101 phillips head screw m5*0.8p*6 11 5 280182-000 spring 1 6 251083-615 spindle front cover 1 7 360931-908 pin 1 8 ...

Page 22: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 22 35 part number internal ref. # description specifications quantity 18 000103-102 cap screw m6*1.0p*10 11 19 310459-911 sliding plate for z-axis 1 20 173510-902 plate for z-axis 1 21 310285-923 rail for z-axis (l) 1 22 310270-909 sliding block fo...

Page 23: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 23 35 part number internal ref. # description specifications quantity 45 174194-904 cable tubing bracket 1 46 174005-904 bracket 1 47 174209-000 adjusting bracket 2 48 174182-000 switch plate 1 49 310458-911 x spindle bracket 1 50 490925-000 limit ...

Page 24: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 24 35 part number internal ref. # description specifications quantity 71 001802-102 cap with spring wahser m6*1.0p*20/6.1*12.3 8 72 006001-022 washer 6.3*13*1.0t 10 73 011103-105 pin 5*12 1 74 090272-008 left column 1 75 173190-000 cover for beam 2...

Page 25: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 25 35 part number internal ref. # description specifications quantity 95.2 173010-902 clamp nut sphc 1 95.3 000303-112 phillip head screw m5*0.8p*18 1 95.4 006302-100 spring washer 5.1*9.3 1 95.5 000304-107 phillips head screw m6*1.0p*16 1 99 17405...

Page 26: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 26 35 part number internal ref. # description specifications quantity 125 008005-100 hexagon nut m6*1.0p(10b*5h) 1 126 000002-105 hexagon screw m6*1.0p*25 1 127 021107-100 cord clamp acc-1.5-b 8 129 923978-000 chain for y-axis (18-links) 1 138 2501...

Page 27: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 27 35 part number internal ref. # description specifications quantity 167 001202-602 self tapping screw m3*1.06p*6 4 168 001106-601 self tapping screw m2*0.63p*6l 4 169 complete 923343-000 cover for right column 1 169.1 250860-615 right cover 1 169...

Page 28: Iconic

Iconic cnc i2015 parts list i2015 owner’s manual of 28 35 part number internal ref. # description specifications quantity 192.5 006302-100 spring washer 5.1*9.3 1 192.6 006001-012 washer 5.3*12*1.0t 1 193 491003-000 tool measurement switch r13-24bl-05-br-wh (24awg*2c*120mm) 1 194 000804-104 button h...

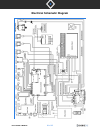

Page 29

Electrical schematic diagram i2015 owner’s manual of 29 35.

Page 30: Exploded Diagrams

Exploded diagrams i2015 owner’s manual of 30 35.

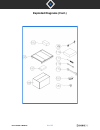

Page 31: Exploded Diagrams (Cont.)

Exploded diagrams (cont.) i2015 owner’s manual of 31 35.

Page 32: Exploded Diagrams (Cont.)

Exploded diagrams (cont.) i2015 owner’s manual of 32 35.

Page 33: Exploded Diagrams (Cont.)

Exploded diagrams (cont.) i2015 owner’s manual of 33 35.

Page 34: Exploded Diagrams (Cont.)

Exploded diagrams (cont.) i2015 owner’s manual of 34 35.

Page 35: Contact Information

Contact information i2015 owner’s manual of 35 35.