- DL manuals

- Jackson

- Dishwasher

- CONSERVER XL HH

- Installation, Operation And Service Manual

Jackson CONSERVER XL HH Installation, Operation And Service Manual - Preventative

07610-003-92-84-Q

22

The manufacturer highly recommends that any maintenance and repairs not specifically

discussed in this manual be performed only by QUALIFIED SERVICE PERSONNEL.

Performing maintenance on your dishmachine may void your warranty, lead to larger

problems, or even cause harm to the operator. So if you have a question or concern, do

not hesitate to contact a QUALIFIED SERVICE AGENCY.

By following the operating and cleaning instructions in this manual, you should get the most

efficient results from your machine. As a reminder, here are some steps to take to ensure

that you are using the dishmachine the way it was designed to work:

1. Ensure that the water temperatures match those listed on the machine data plate.

There can be a variety of reasons why your water temperature could be too low.

2. Ensure that all strainers are clean and secruely in place before operating the machine.

When cleaning out strainers, do NOT beat them on waste cans. Wipe out strainers

with a rag and rinse under a faucet if necessary. Use a toothpick to dislodge any

stubborn debris.

3. Ensure that all wash/rinse arms are secure in the machine before operating.

4. Ensure that the drain stopper is in position before operating.

5. Remove as much soil from ware as possible before loading into racks.

6. Do not overfill racks.

7. Ensure that glasses are placed upside-down in the rack.

8. Ensure that all chemicals being injected into machine have been verified as being at

the correct concentrations.

9. Clean out the machine at the end of every workday per the Shutdown and Cleaning

section of this manual.

10. Follow all safety procedures, whether listed in this manual or put forth by local, state,

or national codes/regulations.

PREVENTATIVE

MAINTENANCE

i

PREVENTATIVE MAINTENANCE

MAINTENANCE

Summary of CONSERVER XL HH

Page 1

Conser ver installation, operation, and service manual conserver ® xl-e/xl-e-lth/xl hh manual • 07610-003-92-84-q conserver ® xl-e, xl-e-lth, & xl hh dishmachines ®.

Page 2

Manufacturer's warranty one year limited parts and labor warranty all new jackson dishwashers are warranted to the original purchaser to be free from defects in material or workmanship, under normal use and operation, for a period of (1) one year from date of purchase, but in no event to exceed (18)...

Page 3: Revision History

I revision letter revision date made by applicable ecns details a 1-6-14 mhh 8241 release to production. B 8-18-14 kap 8305 removed pg 17, updated part on page 20. C 8-29-14 kap n/a updated part on pg. 27. D 10-14-14 kap n/a added 208 volt schematic on page 32. Updated available electrical character...

Page 4: Conserver

Ii the manufacturer provides technical support for all of the dishmachines detailed in this manual. We strongly recommend that you refer to this manual before making a call to our technical support staff. Please have this manual open when you call so that our staff can refer you, if necessary, to th...

Page 5: Guides

Iii guides symbols ......................................................................................................................................1 abbreviations & acronyms ..........................................................................................................1 specificatio...

Page 6: Table of Contents

Iv table of contents maintenance preventative maintenance ........................................................................................................ 22 troubleshooting common problems .........................................................................................................

Page 7: Guides

07610-003-92-84-q 1 guides guides symbols ! Caution ! Warning notice - risk of injury to personnel. - risk of damage to equipment. - risk of electrical shock. - lockout electrical power. - reference data plate. - important note. I - caustic chemicals. Abbreviations & acronyms ansi - american nationa...

Page 8: Specifications

07610-003-92-84-q 2 e1 main electrical connection (1 1/8” hole) (located on back of control box) w main inlet water connection (3/4" npt) d drain connection (2” npt) det detergent bulkhead access (7/8” hole) san sanitizer inlet ra rinse-aid inlet 1 (24.63 mm) 13 1/4 (337.18 mm) 29 1/2 (750.28mm) 78 ...

Page 9: Specifications

07610-003-92-84-q 3 e1 main electrical connection (1 1/8” hole) (located on back of control box) w main inlet water connection (3/4" npt) d drain connection (2” npt) det detergent bulkhead access (7/8” hole) san sanitizer inlet ra rinse-aid inlet 1 (24.63 mm) 13 1/4 (337.18 mm) 29 1/2 (750.28mm) 78 ...

Page 10: Specifications

07610-003-92-84-q 4 conserver xl-e hh 13 in [328 mm] 5 3 4 in [146 mm] 79 1 2 in [2019 mm] doors open 29 1 2 in [748 mm] 76 in [1928 mm] w det san ra 67 3 4 in [1721 mm] 2 1 2 in [63 mm] 9 3 4 in [248 mm] 29 1 4 in [743 mm] e1 6 3 4 in [174 mm] 24 1 2 in [620 mm] 33 1 2 in [853 mm] 31 in [787 mm] 13...

Page 11: Specifications

07610-003-92-84-q 5 please remove the front dress panel from the dishmachine if mounting dishmachine for a corner installation and attaching side tables. Corner installation will trap panel making it difficult to remove. Specifications table dimensions notice 20 1/2” (52.1 cm) opening 25 1/4” (64.1 ...

Page 12: Specifications

07610-003-92-84-q 6 model designation: xl-e xl-e-lth xl hh operating capacity: racks per hour 39 39 39 dishes per hour 975 975 975 glasses per hour 1404 1404 1404 tank capacity (gallons): wash tank 1.02 (40.2 gph) 1.02 (40.2 gph) 1.61 (62.8 gph) electrical loads (as applicable): wash motor hp 1 1 1 ...

Page 13: Specifications

07610-003-92-84-q 7 all electrical ratings provided in this manual are for reference only. Always refer to the machine data plate to get exact electrical information for this machine. All electrical work performed on machines should be done in accordance with applicable local, state, territorial, an...

Page 14: Installation

07610-003-92-84-q 8 instructions installation before installing the unit, check the packaging and machine for damage. If the packaging is damaged, the machine might also be damaged. If there is damage to both the packaging and machine, do not throw away the packaging. The dishmachine has been inspec...

Page 15: Water Supply

07610-003-92-84-q 9 water supply connection: water hardness of 3 gpg or lower pressure regulator shock absorber connecting the drain line if water hardness tests at 3 gpg or lower, install the water supply line to the dishmachine’s incoming water connection point using copper pipe (or order the flex...

Page 16: Electrical Power

07610-003-92-84-q 10 electrical and grounding connections must comply with the applicable portions of the national electrical code ansi/nfpa 70 (latest edition) and/or other electrical codes. Disconnect electrical power supplies and place a tag at the disconnect switch to indicate that you are worki...

Page 17: Voltage Check

07610-003-92-84-q 11 1. Ensure the power switch is in the off position and apply power to the dishmachine. 2. Check the incoming power at the terminal block and ensure it corresponds to the voltage listed on the data plate. If not, contact a qualified service agency to examine the problem. Caution! ...

Page 18: Installation

07610-003-92-84-q 12 instructions installation priming chemical feeder pumps 5. Rinse-aid is dispensed as required into the final rinse. The amount of rinse-aid might need to be adjusted depending on water hardness and results. 6. Sanitizer is dispensed into the final rinse. The amount of sanitizer ...

Page 19: Cam Timer

07610-003-92-84-q 13 the cam timer is a 1-minute, 30-second, 8-cam timer that controls the operation of the dishmachine. The following is a description of the setpoints for each cam and the function of each switch. Function: when the machine is in operation mode the notch is in the home position. Th...

Page 20: Cam Timer

07610-003-92-84-q 14 function: the fill solenoid cam works off the normally-closed contacts of cam 5. The switch is held open by the cam until it drops into the notch of the cam. This energizes the fill solenoid, which starts filling the machine with water. After a 10-second delay, the cam reverses ...

Page 21: Installation

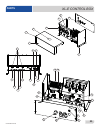

07610-003-92-84-q 15 false panel weldment 05700-002-51-66 false panel kit 05700-003-12-93 rack rail removed and repositioned for a corner operation insert this side first bottom of side panel xl-e/xl-e-lth false panel instructions installation false panel positioned in unit. The false panel will mou...

Page 22: Installation

07610-003-92-84-q 16 rack rail removed and repositioned for a corner operation. Xl hh false panel instructions installation false panel weldment 05700-002-52-54 false panel kit 05700-002-52-89 false panel positioned in unit. The false panel will mount inside of the dishmachine. 1. Remove the rack as...

Page 23: Preparation

07610-003-92-84-q 17 operating range before operating the unit, verify the following: 1. The sump strainer and pan strainer are in place and clean. 2. The drain stopper is installed. 3. The wash/rinse arms are installed and secure. To place the unit in standby, flip the "off/on/fill" switch to the o...

Page 24: First Rack

07610-003-92-84-q 18 the first rack of ware that you place into the unit can have the effect of quickly reducing the temperature of the wash tank. This is because you are introducing cold materials into the dishmachine and the unit has to circulate water to activate the heating cycle. You might have...

Page 25: Shutdown &

07610-003-92-84-q 19 shutdown & cleaning 1. Turn machine off by flipping the “off/on/fill” switch to the “off” position. 2. Open the door. 3. Remove the drain stopper and allow tub to drain. 4. Remove the sump strainer and pan strainer. 5. Use a hand-scraper to scrape foodsoil into a trash basket. 6...

Page 26: Operation

07610-003-92-84-q 20 operating instructions operation 8. Verify the nozzles and arms are free from obstruction. If clogged, remove end- caps, clean nozzles with a brush, and flush with fresh water. 9. Replace end-caps and ensure they have been tightened. 10. Spray or wipe out interior of machine. 11...

Page 27: Operation

07610-003-92-84-q 21 1. Follow filling the wash tub section. 2. Add deliming solution per chemical supplier’s instructions. 3. Close the door. 4. Flip the normal/delime switch on the back of the control box to delime. 5. Run machine the period of time recommended by chemical supplier. 6. Wait five m...

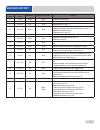

Page 28: Preventative

07610-003-92-84-q 22 the manufacturer highly recommends that any maintenance and repairs not specifically discussed in this manual be performed only by qualified service personnel. Performing maintenance on your dishmachine may void your warranty, lead to larger problems, or even cause harm to the o...

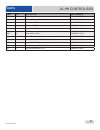

Page 29: Troubleshooting

07610-003-92-84-q 23 problem possible cause remedy dishmachine will not run, no voltage at wash relay terminals l1 and t1. 1. Service disconnect switch off or faulty. 2. Branch circuit breaker tripped/fuse blown. 3. Loose or broken connection to dishmachine. 1. Turn disconnect on. 2. Reset or replac...

Page 30: Troubleshooting

07610-003-92-84-q 24 problem possible cause remedy dishmachine fills slowly and/ or the rinse is weak. 1. Clogged or obstructed rinse arms. 2. Low incoming water pressure. 3. Y-strainer is clogged. 1. Remove and clean the rinse arms. 2. Adjust the water pressure regulator to ensure that there is 15 ...

Page 31: Parts

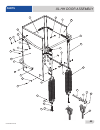

07610-003-92-84-q 25 1 11 19 28 18 10 9 8 7 4 3 2 4 5 9 9 15 16 17 27 25 26 22 24 12 13 14 20 21 23 29 xl-e control box parts 19a.

Page 32: Parts

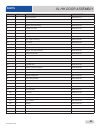

07610-003-92-84-q 26 item qty description part number 1 1 control box top 05700-003-81-49 2 1 decal, warning–disconnect power 09905-004-08-16 3 1 upper decal, xl-e 09905-004-00-07 4 2 chemical feeder pump assembly, 36 rpm (208 v units) chemical feeder pump assembly, 36 rpm (115 v units) 05700-003-78...

Page 33: Parts

07610-003-92-84-q 27 xl-e-lth control box parts d item qty description part number xl-e-lth control box complete assembly 05700-004-49-01 1 1 box, control assembly 05700-004-49-02 2 1 bracket, terminal block 05700-004-51-59 3 2 bracket, pressure switch 05700-004-08-99 4 1 bracket, timer mounting 057...

Page 34: Parts

07610-003-92-84-q 28 item qty description part number 8 1 contactor, 30 a 05945-004-43-74 9 9a 1 1 thermostat, elan electric (dual) probe, thermistor 4” 06685-004-17-27 06685-004-17-26 10 1 terminal board 05940-021-94-85 11 1 terminal block, 3-pole 05940-011-48-27 12 1 contactor, 30 a 05945-002-74-2...

Page 35: Parts

07610-003-92-84-q 29 detail a pump installation detail a (2 plc's) (4 plc's) (3 plc's) (3 plc's) (2 plc's) (2 plc's) (6 plc's) (6 plc's) (4 plc's) (2 plc's) (2 plc's) (2 plc's) (4 plc's) (3 plc's) (2 plc's) (4 plc's) 39 19 16 15 4 18 13 1 30 26 2 24 34 32 3 5 6 23 38 20 27 14 14 33 28 13 35 13 37 10...

Page 36: Parts

07610-003-92-84-q 30 item qty description part number high hood control box complete assembly 05700-004-25-41 1 1 control box weldment 05700-003-81-49 2 3 light, red 05945-504-07-18 3 1 light, green 05945-504-08-18 4 1 switch, carling 05930-301-21-18 5 1 counter, 115 v 05990-111-35-38 1 counter, 208...

Page 37: Parts

07610-003-92-84-q 31 item qty description part number 30 1 upper decal 09905-004-30-01 31 2 bracket, pressure switch 05700-004-08-99 32 1 decal, wash/rinse 09905-002-82-46 33 6 p-clamp 1/4" id 05975-002-61-42 34 1 temperature gauge 06685-111-68-49 35 35a 1 8 timer microswitch, timer 05945-004-11-78 ...

Page 38: Parts

07610-003-92-84-q 32 parts section technical manual (07610-003-92-84) 25 pagecreated:01/30/2012 revised:n/a chemical feeder pump components motor, 14 rpm 115v rinse aid feeder pump 04320-111-35-13 motor, 14 rpm 240v rinse aid feeder pump 04320-111-47-46 motor, 36 rpm 115v detergent/sanitizer feeder ...

Page 39: Parts

07610-003-92-84-q 33 item qty description part number 1 1 rear housing 04320-111-37-09 2 1 motor, 14 rpm 115 v rinse-aid feeder pump 04320-111-35-13 motor, 14 rpm 208/230 v, rinse-aid feeder pump 04320-111-47-46 1 motor, 36 rpm 115 v, detergent/sanitizer feeder pump 04320-111-35-14 motor, 36 rpm 208...

Page 40: Parts

07610-003-92-84-q 34 before ordering plumbing assembly or plumbing parts, see the note on the next page. 1 2 7 8 4 6 3 17 5 xl-e hood assembly parts complete inlet plumbing assembly 05700-004-34-44 14 13 12 11 10 9 15 16 18 notice.

Page 41: Parts

07610-003-92-84-q 35 1 1 control box assembly, 115 v control box assembly, 208 v 05700-004-01-65 05700-004-16-66 2 1 hood, weldment 05700-004-08-68 3 10 locknut, 1/4-20 with nylon insert 05310-374-01-00 4 2 hood support 05700-002-78-99 5 6 bolt, 1/4-20 x 1/2” 05305-274-02-00 6 12 washer, ss 1/4” 053...

Page 42: Parts

07610-003-92-84-q 36 xl-e-lth hood assembly parts complete inlet plumbing assembly 05700-004-49-05 1 2 3 4 6 5 6 7 8 9 10 12 13 14 15 17 16 18 19 20 21 22 22 11.

Page 43: Parts

07610-003-92-84-q 37 xl-e-lth hood assembly parts 1 1 control box assembly, xl-e-lth 05700-004-49-01 2 1 hood, weldment 05700-004-08-68 3 1 gasket, air-gap 05330-002-14-48 4 1 air-gap 05700-004-34-42 5 1 nipple, 3/4" x 2" brass 04730-207-46-00 6 2 elbow, 3/4", 90-degree brass 04730-206-13-00 7 1 nip...

Page 44: Parts

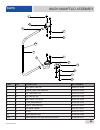

07610-003-92-84-q 38 8 1 2 12 11 10 7 4 6 15 16 17 9 3 5 xl hh hood assembly parts complete inlet plumbing assembly 05700-004-34-44 14 13 18 before ordering plumbing assembly or plumbing parts, see the note on the next page. Notice.

Page 45: Parts

07610-003-92-84-q 39 item qty description part number xl hh hood assembly parts 1 1 control box assembly, 115 v control box assembly, 208 v 05700-004-25-41 05700-004-30-24 2 1 hood, weldment 05700-004-24-96 3 10 locknut, 1/4-20 with nylon insert 05310-374-01-00 4 2 hood support 05700-004-13-45 5 6 b...

Page 46: Parts

07610-003-92-84-q 40 1 2 24, 18 10, 11, 12 13 9 15, 16 7 8 5 22 4 14 3 6 23, 18 17, 18 19, 11, 12 20 21, 25 3a 3b 3c 3d 3e 3f xl-e/xl-e-lth door assembly parts.

Page 47: Parts

07610-003-92-84-q 41 item qty description part number 1 1 arm, cantilever 05700-031-50-67 2 2 spring pin, 1/4” dia. X 1 1/8” 05315-407-06-00 3 2 yoke assembly 05700-000-75-77 3a 1 cotter pin 05315-207-01-00 3b 1 yoke 05700-000-75-78 3c 1 clevis pin 05315-700-01-00 3d 2 nylon washer 05311-369-03-00 3...

Page 48: Parts

07610-003-92-84-q 42 26 2 1 8 17 24 25 8 23 9 20 22 21 9 7 3 6 5 9 7 16 12 7 19 18 11 10 13 4 8 14 27 27c 27e 27d 27a 27b 15 xl hh door assembly parts.

Page 49: Parts

07610-003-92-84-q 43 item qty description part number 1 1 door, front outer 05700-004-14-21 2 1 door, left outer 05700-004-14-19 3 1 door, right outer 05700-004-14-17 4 2 bracket, door connecting 05700-004-14-23 5 1 handle, door front 05700-004-14-30 6 2 plug, cantilever 05340-011-35-00 7 22 washer,...

Page 50: Parts

07610-003-92-84-q 44 3 1 2 4 5 6 item qty description part number 1 1 bearing assembly 05700-021-35-97 2 1 o-ring, 117-s70 silicon 05330-002-60-69 3 2 wash arm end-cap 05700-011-35-92 4 1 wash arm 05700-003-57-70 wash arm assembly 05700-003-59-35 wash arm assembly parts 1 2 3 4.

Page 51: Parts

07610-003-92-84-q 45 item qty description part number 1 2 bolt, 3/8-16 x 3/8" ss 05306-011-36-95 2 1 casting, upper wash manifold 05700-031-34-82 3 4 3/8" lockwasher, ss 05311-276-01-00 4 4 3/8" hex nut, ss 05310-276-01-00 5 2 bolt, 3/8-16 x 1 1/4" ss 05305-276-10-00 6 1 lower wash manifold 05700-00...

Page 52: Parts

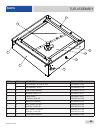

07610-003-92-84-q 46 item qty description part number 1 1 tub assembly, xl-e/xl-e-lth 05700-003-78-39 1 tub assembly, xl hh 05700-004-27-28 2 1 rack guide assembly 05700-031-36-76 3 1 bulkhead fitting, 1/2” 04730-011-45-21 4 1 1 clamp, nylon lock nut, 10-24 ss 04730-011-39-01 05310-373-01-00 5 1 was...

Page 53: Parts

07610-003-92-84-q 47 item qty description part number 1 1 pump and motor assembly 06105-004-24-80 2 1 pump drain hose 05700-004-08-52 3 2 clamp, 7/16” to 25/32” 04730-011-36-05 4 1 clamp, 5 5/8” to 6” 04730-011-34-90 5 1 sump weldment 05700-003-78-41 6 1 sump gasket 05330-003-78-31 7 9 lock nut, 1/4...

Page 54: Parts

07610-003-92-84-q 48 drain, seat 05700-021-34-38 gasket, spillway 05700-111-34-52 lock nut, ¼-20 s/s 05310-374-01-00 connection, drain link 05700-002-38-10 drain link 05700-003-78-49 spillway weldment 05700-003-52-13 spillway assembly parts 05700-004-37-18.

Page 55: Parts

07610-003-92-84-q 49 complete pump and motor assembly 06105-004-24-80 pump dishcharge hose (not shown) 05700-003-78-50 hose clamp, 1 5/16" to 2 1/4" s/s (not shown) 04730-719-18-00 (2 required) case cap screw 05305-356-04-00 shim kit 05700-002-82-58 case o-ring 05330-002-81-83 seal plate 05700-002-8...

Page 56: Parts

07610-003-92-84-q 50 xl-e-lth booster tank assembly parts 16.

Page 57: Parts

07610-003-92-84-q 51 item qty description part number complete booster tank assembly 05700-004-52-09 1 1 booster tank 05700-004-52-23 2 1 plate, booster tank base 05700-004-48-90 3 4 bracket, booster mount 05700-004-48-83 4 1 bracket, booster tank 05700-004-52-08 5 2 plumbing, booster inlet/outlet 0...

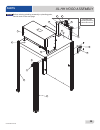

Page 58: Parts

07610-003-92-84-q 52 frame assembly parts item qty description part number 1 1 frame weldment 05700-003-78-38 2 1 splash shield 05700-004-01-54 3 1 strainer 05700-004-09-08 4 1 strainer stop 05700-004-18-33 5 1 accumulator 05700-004-08-39 6 4 adjustable foot 05340-108-01-03 7 1 1 screw, 1/4-20 x 1 1...

Page 59: Parts

07610-003-92-84-q 53 ball stopper 05700-121-35-54 blue chemical tubing (120") 05700-011-37-17 red chemical tubing (120") 05700-011-37-15 white chemical tubing (120") 05700-011-37-13 chemical tubing stiffener 05700-002-66-49 bulk head fitting 04730-011-45-21 flanged bullet foot (optional) 05340-002-3...

Page 60: Schematics

07610-003-92-84-q 54 schematics xl-e/xl hh 115 v, 60 hz, 1-phase.

Page 61: Schematics

07610-003-92-84-q 55 schematics xl-e/xl hh 208 v, 60 hz, 1-phase.

Page 62: Schematics

07610-003-92-84-q 56 schematics xl-e-lth 208/230 v, 60 hz, 1/3 phase.

Page 64

58 jackson wws, inc. • 6209 n. Us hwy 25e • gray, ky 40734 usa 1.888.800.5672 • www.Jacksonwws.Com conserver ® xl-e/xl-e-lth/xl hh manual • 07610-003-92-84-q.