- DL manuals

- Jacobsen

- Lawn Mower

- HR 5111

- Parts And Maintenance Manual

Jacobsen HR 5111 Parts And Maintenance Manual

RJ 100 012003

WARNHINWEIS: Wenn diese Maschine nicht ordnungsgemäß

verwendet wird, können ernsthafte Verletzungen verursacht

werden. Personen, die diese Maschine verwenden und

warten, müssen in ihrer richtigen Verwendung ausgebildet

sein, auf die Gefahren aufmerksam gemacht worden sein

und die Anleitung ganz gelesen haben, bevor sie versuchen,

die Maschine aufzustellen, zu bedienen, einzustellen oder

zu warten.

WAARSCHUWING: Bij verkeerd gebruik kan deze machine

ernstig lichamelijk letsel veroorzaken. Degenen die de machine

gebruiken en onderhouden moeten worden getraind in het

juiste gebruik ervan, worden gewaarschuwd voor de

gevaren ervan en behoren de volledige handleiding

aandachtig te lezen alvorens de machine bedrijfs-klaar te

maken, te bedienen, af te stellen en/of te onderhouden.

AVERTISSEMENT : Risque de blessures graves en cas

d’utilisation incorrecte de la machine. Les opérateurs et le

personnel d’entretien doivent être formés et conscients des

dangers encourus. Ils doivent lire avec attention le manuel

avant d’essayer de monter, d’utiliser, de régler ou maintenir la

machine.

WARNING: If incorrectly used this machine can cause severe

injury. Those who use and maintain this machine should be

trained in its proper use, warned of its dangers and should

read the entire manual before attempting to set up, operate,

adjust or service the machine.

4103524-ML1 (rev.0)

Parts and Maintenance Manual

Nomenclature Des Pieces De Rechange

& Manuel De Maintenance

Onderhouds - En Onderdelenhandleiding

Wartungsanleitung Und Stückliste

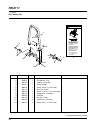

HR 5111 Turf Mower

With ROPS Product Number 69116 - Engine Type: Kubota V2203

Serial Numbers: 5901 and up

Summary of HR 5111

Page 1

Rj 100 012003 warnhinweis: wenn diese maschine nicht ordnungsgemäß verwendet wird, können ernsthafte verletzungen verursacht werden. Personen, die diese maschine verwenden und warten, müssen in ihrer richtigen verwendung ausgebildet sein, auf die gefahren aufmerksam gemacht worden sein und die anlei...

Page 2: To Order Parts

Copyright 2000 textron inc. “all rights reserved, including the right to reproduce this material or portions thereof in any form.” to order parts 1. Write your full name and complete address on the order. 2. Explain where and how to make shipment. 3. Give product number, name and serial number that ...

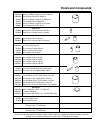

Page 3: Suggested Stocking Guide

Gb-3 suggested stocking guide to keep your equipment fully operational and productive, textron turf care and specialty products suggests you maintain a stock of the more commonly used maintenance items. We have included part numbers for additional support materials and training aids. To order any of...

Page 4: 1 Safety

1 safety gb-4 1 safety 1.1 operating safety ______________________________________________________ 1. Safety is dependent upon the awareness, concern and prudence of those who operate or service the equipment. Never allow minors to operate any equipment. 2. It is your responsibility to read this man...

Page 5: Safety 1

Safety 1 gb-5 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a pote...

Page 6: 2 Specifications

2 specifications gb-6 2 specifications 2.1 product identification _________________________________________________ 69116 .............................. Hr-5111 with rops. Serial number ................ An identification plate, like the one shown, listing the serial number, is attached to the frame ...

Page 7: Specifications 2

Specifications 2 gb-7 2.4 cutting units ___________________________________________________________ type................................. Three fully floating decks width: front deck................. 64 in. (1625 mm) wing decks ............... 42 in. (1067 mm) cutting width: front and both wings 134...

Page 8: 3 Adjustments

3 adjustments gb-8 3 adjustments 3.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized textron turf care and specialty products deale...

Page 9: Adjustments 3

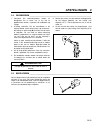

Adjustments 3 gb-9 3.4 parking brake__________________________________________________________ 1. Check linkages, cables and pivot points, to ensure they are operating smoothly. Check brake pads for wear. 2. To set brake force: place brake lever in the disengaged position. Sit in the operator’s seat...

Page 10: 3 Adjustments

3 adjustments gb-10 3.6 cruise control switch _________________________________________________ 1. If the cruise control does not disengage when brake pedal is depressed, loosen hardware (d) and slide switch so roller (e) is centered on bolt (f). 2. Loosen hardware and adjust bolt (f) so head makes ...

Page 11: Adjustments 3

Adjustments 3 gb-11 3.9 hydro neutral _________________________________________________________ if the tractor “creeps” in either direction, the neutral position must be adjusted. The tractor may tend to “creep” if the hydraulic oil is cold. Operate tractor for 15 minutes before determining if adjus...

Page 12: 3 Adjustments

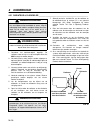

3 adjustments gb-12 3.11 steering toe in _________________________________________________________ “toe in” should be adjusted from x ± 1/16 in (1.5 mm). 1. Turn wheels to straight ahead position. 2. Loosen tie rod jam nuts (u). 3. Adjust tie rod and retighten jam nuts 4. After adjusting “toe in” it...

Page 13: Adjustments 3

Adjustments 3 gb-13 3.14 reverse sensing switch ________________________________________________ 1. Adjust actuating rod (z) so tractor shifts into 2wd at approximately 0.5 m.P.H. In reverse. 2. Loosen nut and turn rod end counterclockwise to decrease speed or clockwise to increase speed. 3. Tighten...

Page 14: 3 Adjustments

3 adjustments gb-14 3.16 cutting height _________________________________________________________ level the front mower before setting the cutting height for the first time. Do not remove the cutting units from the tractor to change cutting height. Cutting height for decks can be adjusted from 1 to ...

Page 15: Adjustments 3

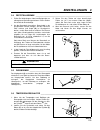

Adjustments 3 gb-15 3.17 servicing front deck___________________________________________________ the front deck can be raised and tilted up to improve access to the cutting unit and blades for service and cleaning. Be sure to disengage all drives, engage parking brake, stop engine and remove ignitio...

Page 16: 3 Adjustments

3 adjustments gb-16 3.19 torque specification___________________________________________________ textron turf care and specialty products uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Caution all torque values included...

Page 17: Maintenance 4

Maintenance 4 gb-17 4 maintenance 4.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized textron turf care and specialty products deal...

Page 18: 4 Maintenance

4 maintenance gb-18 4.3 sharpening blades_____________________________________________________ 1. Place a wooden block between the blade and mower housing to stop the blade from moving. To remove blade, turn screw holding blade counterclockwise . 2. When dressing or sharpening the blade, do not foll...

Page 19: Maintenance 4

Maintenance 4 gb-19 4.4 engine _________________________________________________________________ important: a separate engine manual, prepared by the engine manufacturer, is supplied with this tractor. Read the engine manual carefully until you are familiar with the operation and maintenance of the ...

Page 20: 4 Maintenance

4 maintenance gb-20 4.6 air filter_______________________________________________________________ do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk of injecting dust and other impurities into the engine. Air cleaner servicing is required when ...

Page 21: Maintenance 4

Maintenance 4 gb-21 4.9 battery ________________________________________________________________ make absolutely certain the ignition switch is “off” and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric ...

Page 22: 4 Maintenance

4 maintenance gb-22 4.12 hydraulic hoses _______________________________________________________ 1. Always lower implements to ground, disengage all drives, engage parking brake, stop engine and remove key before inspecting or disconnecting hydraulic lines or hoses. 2. Check visible hoses and tubes ...

Page 23: Maintenance 4

Maintenance 4 gb-23 4.14 hydraulic oil filters ___________________________________________________ the hydraulic system is protected by two 10 micron filters. To replace hydraulic oil filter: 1. Remove the old filter. 2. Fill new filter with oil then install new filter. Hand tighten only. 3. Operate...

Page 24: 4 Maintenance

4 maintenance gb-24 4.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub. 3. Finger tighten all hardw...

Page 25: Maintenance 4

Maintenance 4 gb-25 4.21 radiator and oil cooler _______________________________________________ 1. Check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. 2. Drain and refill annually. Remove the radiator cap, open the engine block drain and the radiato...

Page 26: 4 Maintenance

4 maintenance gb-26 4.22 storage________________________________________________________________ general 1. Wash the tractor thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the tractor, tighten all hardware, replace worn or damaged components. 3. Drain and refill radi...

Page 27: Troubleshooting 5

Troubleshooting 5 gb-27 5 troubleshooting 5.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems conta...

Page 28: Warning

6 maintenance & lubrication charts gb-28 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean the grease fitting before and after lubricating. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. App...

Page 29

Maintenance & lubrication charts 6 gb-29 6.3 maintenance charts ___________________________________________________ a - add or adjust c - clean i - inspect l- lubricate r - replace ar - as required * indicates initial service for new machines. ** or every two years whichever comes first. *** inspect...

Page 30: 7 Notes

7 notes gb-30 7 notes.

Page 32: Table Des Matières

Copyright 2000 textron inc. ‘tous droits réservés. Il est interdit de reproduire tout ou en partie de ce document’ commande des pièces de rechange 1. Inscrivez votre nom et adresse sur le bordereau de commande. 2. Indiquez l’adresse et le mode de transport pour l’expédition. 3. Indiquez le numéro, n...

Page 33: Utilisation Du Manuel

F-3 stockage des pièces de rechange pour garder votre équipement entièrement opérationnel et productif, textron turf care and specialty products vous conseille de tenir un stock des pièces de maintenance les plus courantes. Nous avons inclus les références de documents d'assistance supplémentaires e...

Page 34: 1 Securite

1 securite f-4 1 securite 1.1 consignes de securite relatives au fonctionnement __________________ 1. Les utilisateurs de ces machines doivent être vigilants et consciencieux quand ils s'en servent ou effectuent des services de révision afin que la sécurité soit opti- male. Les mineurs ne doivent ja...

Page 35: Securite 1

Securite 1 f-5 1.2 consignes de securite importantes ____________________________________ ce symbole sert à vous signaler la présence de dangers éventuels. Danger - indique un danger immédiat avec risque de mort ou de blessures graves. Avertissement - indique un danger avec risque eventuel de mort o...

Page 36: 2 Specifications

2 specifications f-6 2 specifications 2.1 identification du produit_______________________________________________ 69116 .............................. Hr-5111 avec protection au retournement. Numéro de série ............ Une plaque signalétique, comme celle illustrée, indique le numéro de série et ...

Page 37: Specifications 2

Specifications 2 f-7 2.4 unites de coupe ________________________________________________________ type................................. Trois plateaux flottants largeur : plateau avant ............ 1 625 mm plateaux latéraux ...... 1 067 mm largeur de coupe : plateaux avant et latéraux ................

Page 38: 3 Reglages

3 reglages f-8 3 reglages 3.1 generalites ____________________________________________________________ 1. Les réglages et services d’entretien doivent toujours être effectués par un technicien agréé. Quand il est impossible d’obtenir les réglages requis, adressez- vous au concessionnaire agréé textr...

Page 39: Reglages 3

Reglages 3 f-9 3.4 frein de stationnement _________________________________________________ 1. Vérifiez les tringleries, câbles et points de pivotement, pour vous assurer qu’ils fonctionnent correctement. Vérifiez l’absence d’usure des patins du frein. 2. Réglage de la force de freinage : desserrez ...

Page 40: 3 Reglages

3 reglages f-10 3.6 interrupteur de commande de croisiere _______________________________ 1. Si la commande de croisière ne se débraye pas quand vous appuyez sur la pédale du frein, desser- rez la pièce (d) et faites glisser l’interrupteur de façon à ce que que le galet (e) soit centré sur le boulon...

Page 41: Reglages 3

Reglages 3 f-11 3.9 point mort hydrostatique ______________________________________________ si le tracteur « broute » dans l’un ou l’autre sens, il faut ajuster la position du point mort. Le tracteur peut avoir tendance à « brouter » si l’huile de transmission est froide. Faites fonctionner le tract...

Page 42: 3 Reglages

3 reglages f-12 schéma 3i 3.11 pincement de la direction _______________________________________________________ le pincement doit être réglé de x + 1,5 mm. 1. Alignez les roues en avant. 2. Desserrez les deux écrous de blocage de la barre d’accouplement (u). 3. Réglez la barre d’accouplement et res...

Page 43: Reglages 3

Reglages 3 f-13 3.14 capteur de marche arriere ____________________________________________ 1. Réglez la bielle de commande (z) de façon à ce que la machine passe en 2 rm dès que sa vitesse de marche arrière atteint 0,8 km/h. 2. Desserrez l’écrou et faites tourner l’embout de tige dans le sens contr...

Page 44: 3 Reglages

3 reglages f-14 3.16 hauteur de coupe ______________________________________________________ avant de régler la hauteur de coupe la première fois, nivelez l’unité de coupe avant. Ne retirez pas les unités de coupe de la machine pour modifier la hauteur de coupe. La hauteur de coupe des plateaux est ...

Page 45: Reglages 3

Reglages 3 f-15 3.17 entretien du plateau avant ____________________________________________ le plateau avant se relève et s’incline pour faciliter sa révision et maintenance de même que de ses lames. Veillez à désembrayer tous les entraînements, serrer le frein de stationnement, arrêter le moteur e...

Page 46: 3 Reglages

3 reglages f-16 3.19 specifications des couples de serrage ________________________________ textron turf care and specialty products recommande l’utilisation, en standard, de boulons métallisés de qualité 5, à moins qu’indiqué différemment. Pour coupler ces boulons, se reporter aux valeurs indiquées...

Page 47: Maintenance 4

Maintenance 4 f-17 4 maintenance 4.1 generalites ____________________________________________________________ 1. Les réglages et services d'entretien doivent toujours être effectués par un technicien agréé. Quand il est impossible d'obtenir les réglages requis, adressez- vous au concessionnaire agré...

Page 48: 4 Maintenance

4 maintenance f-18 4.3 affutage des lames ____________________________________________________ 1. Placez une cale en bois entre la lame et le logement de tondeuse pour empêcher la lame de tourner. Pour déposer la lame, tournez la vis de maintien de l'alarme dans le sens contraire des aiguilles d'une...

Page 49: Maintenance 4

Maintenance 4 f-19 4.4 moteur _________________________________________________________________ important : un manuel du moteur, fourni par le fabricant, accompagne le moteur. Lisez-le attentivement jusqu'à ce que vous vous familiarisez au fonctionnement et à la maintenance du moteur. Suivez attenti...

Page 50: 4 Maintenance

4 maintenance f-20 4.6 filtre a air diesel ______________________________________________________ ne retirez pas l'élément pour le vérifier ou nettoyer. Le retrait inutile du filtre augmente les risques d'infiltration de poussières et de diverses impuretés dans le moteur. L’entretien du filtre à air...

Page 51: Maintenance 4

Maintenance 4 f-21 4.8 circuit carburant _____________________________________________________ reportez-vous au chapitre 6.3 pour ce qui concerne les intervalles spécifiques de maintenance. Avant de remplacer un filtre, nettoyez à fond son boîtier et sa surface environnante. Les saletés ne doivent p...

Page 52: 4 Maintenance

4 maintenance f-22 4.11 charge de la batterie _________________________________________________ 1. Reportez-vous au chapitre 4.9 de même qu'à la notice accompagnant la batterie et le chargeur pour tous renseignements complémentaires. 2. Quand possible, retirez la batterie de la machine avant de proc...

Page 53: Maintenance 4

Maintenance 4 f-23 4.13 huile hydraulique ______________________________________________________ reportez-vous au chapitre 6.3 pour tous renseignements concernant les intervalles de maintenance. Vidangez et remplissez d'huile hydraulique après toute panne de composant important ou si vous apercevez ...

Page 54: 4 Maintenance

4 maintenance f-24 4.16 silencieux et pots d'echappement______________________________________ afin de vous protéger contre l'oxyde de carbone, vérifiez régulièrement le circuit d'échappement et remplacez toujours tout pot défectueux. Si vous détectez un changement de couleur ou de bruit de l'échapp...

Page 55: Maintenance 4

Maintenance 4 f-25 4.19 entretien_______________________________________________________________ nettoyez la machine et ses accessoires dès la fin du travail et veillez à ce que les composants restent propres. Remarque : ne nettoyez pas certaines parties des composants alors qu'ils sont encore chaud...

Page 56: 4 Maintenance

4 maintenance f-26 4.21 radiateur et refroidisseur d'huile ____________________________________ 1. Vérifiez quotidiennement le niveau du refroidisseur. Le radiateur doit être rempli et un flacon de rechange rempli jusqu'au point de repère maxi. 2. Vidangez le radiateur et reremplissez-le annuellemen...

Page 57: Maintenance 4

Maintenance 4 f-27 4.22 entreposage ___________________________________________________________ généralités 1. Nettoyez entièrement la machine et graissez-la. Réparez et peignez ses surfaces métalliques extérieures ou endommagées. 2. Examinez la machine, serrez les composants et remplacez ceux qui s...

Page 58: 5 Depistage Des Defauts

5 depistage des defauts f-28 5 depistage des defauts 5.1 generalites ____________________________________________________________ le tableau suivant de dépistage des défauts indique les problèmes rencontrés couramment lors de la mise en marche et du fonctionnement. Pour tous renseignements concernan...

Page 59: Avertissement

Tableaux de maintenance et de graissage 6 f-29 6 tableaux de maintenance et de graissage 6.1 generalites ____________________________________________________________ 1. Nettoyez toujours les graisseurs avant et après les avoir utilisés. 2. Utilisez toujours de la graisse répondant aux spécifi- catio...

Page 60

6 tableaux de maintenance et de graissage f-30 6.3 tableau de maintenance _______________________________________________ a - ajouter ou régler c - nettoyer i - vérifier l- graisser r - remplacer ar - s'il y a lieu * indique le premier service d'une nouvelle machine. ** ou tous les deux ans, ce qui ...

Page 61: Remarques 7

Remarques 7 f-31 7 remarques.

Page 62: Bestellen Van Onderdelen

Copyright 2000 textron inc. "alle rechten voorbehouden inclusief het recht op reproductie in enigerlei vorm van dit materiaal of gedeelten ervan". Bestellen van onderdelen 1. Vul uw volledige naam en adres op de order in. 2. Maak duidelijk waar en hoe moet worden geleverd. 3. Vermeld het productnumm...

Page 63: Aanbevolen Voorraadvorming

Nl-3 aanbevolen voorraadvorming om uw machine volledig operationeel en productief te houden, adviseert textron turf care and specialty products om een voorraad aan te houden van de wat vaker gebruikte onderdelen. Wij hebben ook stuknummers opgenomen van aanvullend ondersteuningmateriaal en trainings...

Page 64: 1 Veiligheid

1 veiligheid nl-4 1 veiligheid 1.1 operationele veiligheid ________________________________________________ 1. Veiligheid hangt af van de alertheid, zorg en voorzichtig- heid van degenen die de machine bedienen of onder- houden. Minderjarigen mag nooit worden toegestaan om enig deel van de apparatuu...

Page 65: Veiligheid 1

Veiligheid 1 nl-5 1.2 belangrijke veiligheidsoverwegingen _________________________________ dit veiligheidssymbool wordt gebruikt om u te attenderen op potentiële gevaren. Gevaar - duidt op dreigende gevaarlijke situatie die, indien niet vermeden, zal resulteren in dood of ernstig letsel. Waarschuwi...

Page 66: 2 Specificaties

2 specificaties nl-6 2 specificaties 2.1 productidentificatie ___________________________________________________ 69116 .............................. Hr-5111 met rops. Serienummer ................. Er is een identificatieplaatje met het serienummer (zie het getoonde model) aangebracht op het tracto...

Page 67: Specificaties 2

Specificaties 2 nl-7 2.4 maaieenheden __________________________________________________________ type................................. Drie volledig zwevende maaidekken breedte: voorste maaidek ....... 1625 mm zijmaaidekken ........... 1067 mm maaibreedte: voorste en beide zijmaaidekken ........... ...

Page 68: 3 Afstellingen

3 afstellingen nl-8 3 afstellingen 3.1 algemeen ______________________________________________________________ 1. Afstellingen en onderhoud behoren altijd te worden verricht door een bevoegd monteur. Als de gewenste afstelling niet kan worden uitgevoerd, neem dan con- tact op met een erkende textron...

Page 69: Afstellingen 3

Afstellingen 3 nl-9 3.4 parkeerrem ____________________________________________________________ 1. Controleer alle verbindingstukken, kabels en draaipunten om er zeker van te zijn dat ze probleemloos werken. Inspecteer de remblokken op slijtage. 2. Instelling remkracht: zet de remhefboom in de uitge...

Page 70: 3 Afstellingen

3 afstellingen nl-10 3.6 kruissnelheidsregelschakelaar ______________________________________ 1. Als de kruissnelheidsregeling niet wordt uitgeschakeld wanneer de rempedaal wordt ingedrukt, zet de bevestiging (d) dan los en verschuif de schakelaar zodat rol (e) zich gecentreerd op bout (f) bevindt. ...

Page 71: Afstellingen 3

Afstellingen 3 nl-11 3.9 hydro neutraal ________________________________________________________ als de tractor voor- of achteruitkruipt moet de 'neutrale' stand worden bijgesteld. De tractor heeft de neiging om te 'kruipen' als de transmissieolie koud is. Bedien de tractor daarom 15 minuten alvoren...

Page 72: 3 Afstellingen

3 afstellingen nl-12 3.11 toespoor stuurinrichting _____________________________________________ het toespoor moet worden bijgesteld van x + 1,5 mm. 1. Draai de wielen in de recht-vooruit stand. 2. Los de twee tegenmoeren van de trekstang (u). 3. Stel de trekstang bij en draai de tegenmoeren weer va...

Page 73: Afstellingen 3

Afstellingen 3 nl-13 3.14 sensorische omkeerschakelaar _______________________________________ 1. Stel de bedieningsstang (z) zodanig bij dat de tractor naar tweewielaandrijving overschakelt bij een snelheid van 0,8 km/uur achteruit. 2. Los de moer en draai het stangeind linksom om de snelheid te ve...

Page 74: 3 Afstellingen

3 afstellingen nl-14 3.16 maaihoogte ____________________________________________________________ nivelleer de voorste maaier alvorens de maaihoogte voor het eerst in te stellen. Verwijder de maaieenheden niet van de tractor om de maaihoogte te veranderen. De maaihoogte van de dekken kan worden vers...

Page 75: Afstellingen 3

Afstellingen 3 nl-15 3.17 servicen van het voorste maaidek _____________________________________ het voorste maaidek kan worden geheven en gekanteld om de toegang tot de maaieenheid en de messen te vergemakkelijken ten behoeve van onderhoud en schoonmaken. Zorg ervoor om alle aandrijvingen uit te sc...

Page 76: 3 Afstellingen

3 afstellingen nl-16 3.19 draaikoppelspecificatie _______________________________________________ textron turf care and specialty products gebruikt kwaliteit 5 gegalvaniseerde bouten als standaard, tenzij anderszins vermeld. Bij het aandraaien van dergelijke bouten moet de waarde worden gebruikt die...

Page 77: Onderhoud 4

Onderhoud 4 nl-17 4 onderhoud 4.1 algemeen_______________________________________________________________ 1. Afstelling en onderhoud behoren altijd te worden verricht door een bevoegd monteur. Als de gewenste afstelling niet kan worden uitgevoerd, neem dan contact op met een erkende textron turf car...

Page 78: 4 Onderhoud

4 onderhoud nl-18 4.3 aanscherpen van de messen ___________________________________________ 1. Plaats een houten blok tussen het mes en het maaierhuis om draaiing van het mes te voorkomen. Voor verwijdering van het mes dient de schroef die het vastzet linksom te worden gedraaid . 2. Tijdens het afbr...

Page 79: Onderhoud 4

Onderhoud 4 nl-19 4.4 motor __________________________________________________________________ belangrijk: bij deze tractor wordt een aparte motorhandleiding meegeleverd die is samengesteld door de motorfabrikant. Deze handleiding dient aandachtig te worden doorgelezen totdat u voldoende vertrouwd b...

Page 80: 4 Onderhoud

4 onderhoud nl-20 4.6 luchtfilter ____________________________________________________________ verwijder het element niet voor inspectie of reiniging. Onnodige verwijdering van het filter verhoogt het risico op het toevoeren van stof en andere verontreinigingen naar de motor. Service van het luchtfi...

Page 81: Onderhoud 4

Onderhoud 4 nl-21 4.8 brandstofsysteem ____________________________________________________ zie sectie 6.3 voor specifieke perioden tussen onderhoudsbeurten. Vóór terugplaatsing van het filter moet het filterhuis worden schoongemaakt, evenals het gedeelte rond het filter. Voorkomen moet worden dat v...

Page 82: 4 Onderhoud

4 onderhoud nl-22 4.11 acculading ____________________________________________________________ 1. Zie sectie 4.9. Lees de accu- en acculaderhandleiding voor specifieke instructies. 2. Waar mogelijk dient de accu vóór het opladen uit de tractor te worden gehaald. Als de accu niet is afgedicht, contro...

Page 83: Onderhoud 4

Onderhoud 4 nl-23 4.13 hydrauliekolie _________________________________________________________ zie sectie 6.3 for specifieke perioden tussen onderhoudsbeurten. Na het falen van een belangrijk onderdeel dient de hydrauliekolie te worden afgetapt en ververst. Het laatste geldt ook als u de aanwezighe...

Page 84: 4 Onderhoud

4 onderhoud nl-24 4.16 geluiddemper en uitlaat _______________________________________________ ter beveiliging tegen koolmonoxidevergiftiging moet het volledige uitlaatsysteem regelmatig worden geïnspecteerd. Een defecte uitlaat moet altijd worden vervangen. Als u een verandering waarneemt in de kle...

Page 85: Onderhoud 4

Onderhoud 4 nl-25 4.19 verzorging en schoonmaken ___________________________________________ was de tractor en aanzetstukken na ieder gebruik. Houd de uitrusting goed schoon. N.B. Geen enkel deel van de machine mag worden gewassen zolang het nog warm is. Gebruik geen hogedrukspuit of stoom, maar uit...

Page 86: 4 Onderhoud

4 onderhoud nl-26 4.21 radiateur & oliekoeler ________________________________________________ 1. Controleer het koelvloeistofpeil dagelijks. De radiateur moet vol zijn en in de overloopfles dient het max-streepje te worden bereikt. 2. Het koelsysteem moet jaarlijks worden afgetapt en opnieuw gevuld...

Page 87: Onderhoud 4

Onderhoud 4 nl-27 4.22 stalling ________________________________________________________________ algemeen 1. De tractor dient eerst grondig te worden gewassen en gesmeerd. Repareer en lak beschadigd of blootgesteld metaal. 2. Inspecteer de tractor, draai alle bevestigingen vast en vervang versleten ...

Page 88: 5 Foutopsporing

5 foutopsporing nl-28 5 foutopsporing 5.1 algemeen ______________________________________________________________ onderstaande foutopsporingstabel vermeldt basisproblemen die zich kunnen voordoen tijdens start-up en werking. Voor meer gedetailleerde informatie betreffende de hydraulische en elektris...

Page 89: Waarschuwing

Onderhouds- en smeerschema’s 6 nl-29 6 onderhouds- en smeerschema’s 6.1 algemeen_______________________________________________________________ 1. Maak de vetsmeerpunten voor en na het smeren altijd schoon. 2. Smeer met vet dat voldoet aan de nlgi kwaliteit 2 lb specificaties of deze overtreft. Gebr...

Page 90

6 onderhouds- en smeerschema’s nl-30 6.3 onderhoudsschema’s __________________________________________________ a = toevoegen of bijstellen c = reinigen i = inspecteren l = smeren r = vervangen ar = als vereist * geeft eerste service voor nieuwe machines aan. ** of iedere 2 jaar indien eerder bereikt...

Page 91: Notities 7

Notities 7 nl-31 7 notities.

Page 92: Bestellen Von Ersatzteilen

Copyright 2000 textron inc. "alle rechte vorbehalten, einschließlich des rechts, dieses material oder teile davon auf irgendeine weise zu reproduzieren." bestellen von ersatzteilen 1. Schreiben sie ihren vor- und zunahmen sowie ihre vollständige adresse auf die bestellung. 2. Erklären sie, wann und ...

Page 93: Empfohlener Lagerbestand

D-3 empfohlener lagerbestand damit ihre ausrüstung voll einsatzfähig und produktiv bleibt, empfiehlt textron turf care and speciality products, daß sie einen lagerbestand der häufiger verwendeten wartungsteile erhalten. Wir haben die teilnummern für zusätzliches unterstützungsmaterial und ausbildung...

Page 94: 1 Sicherheit

1 sicherheit d-4 1 sicherheit 1.1 betriebssicherheit ____________________________________________________ 1. Die sicherheit ist vom bewußtsein, von der aufmerk- samkeit und umsicht der personen abhängig, die die ausrüstung bedienen oder warten. Niemals zulassen, daß minderjährige diese ausrüstung be...

Page 95: Sicherheit 1

Sicherheit 1 d-5 1.2 wichtige hinweise zur sicherheit _______________________________________ dieses warnsymbol wird verwendet, um sie auf potentielle gefahren aufmerksam zu machen. Gefahr - weist auf eine sofortige gefahrensituation hin, die einen todesfall oder eine ernsthafte verletzung zur folge...

Page 96: 2 Technische Daten

2 technische daten d-6 2 technische daten 2.1 produktidentifizierung ________________________________________________ 69116 .............................. Hr-5111 mit rops. Seriennummer ................ Am chassis des traktors rechts neben dem fahrersitz befindet sich am traktorrahmen, neben dem zen...

Page 97: Technische Daten 2

Technische daten 2 d-7 2.4 schneideeinheiten ______________________________________________________ typ............................................. Drei vollständig schwimmend gelagerte schneideeinheiten breite: vordere schneideeinheiten .............. 1625 mm seitliche schneideeinheiten .............

Page 98: 3 Einstellungen

3 einstellungen d-8 3 einstellungen 3.1 allgemeine informationen _____________________________________________ 1. Die einstellungen und wartungsarbeiten müssen immer von einem qualifizierten techniker durch- geführt werden. Wenn es nicht möglich ist, die rich- tige einstellung vorzunehmen, wenden si...

Page 99: Einstellungen 3

Einstellungen 3 d-9 3.4 feststellbremse ______________________________________________________ 1. Prüfen sie verbindungen, kabel und drehpunkte, um reibungslosen betrieb zu garantieren. Prüfen sie den verschleiß der bremsbeläge. 2. Um die bremskraft einzustellen: bremshebel in der ausgerückten posit...

Page 100: 3 Einstellungen

3 einstellungen d-10 3.7 kraftstoff-elektromagnet____________________________________________ 1. Positionieren sie das pleuel (h) so, dass das kraftstoff-elektromagnet in seiner position sperrt, wenn der zündschlüssel auf die position start gedreht wurde und in die position ein zurückgekehrt ist. Ha...

Page 101: Einstellungen 3

Einstellungen 3 d-11 3.9 hydroneutralstellung ________________________________________________ falls der traktor in eine richtung „kriecht“, muss die „neutralstellung“ nachgestellt werden. Der traktor neigt bei kaltem getriebeöl zu diesem verhalten. Lassen sie den traktor 15 minuten laufen, bevor si...

Page 102: 3 Einstellungen

3 einstellungen d-12 3.11 vorspur _____________________________________________________________________________ die vorspur sollte von x + 1,5 mm eingestellt werden. 1. Räder in gerade fahrposition bringen. 2. Die zwei gegenmuttern (u) der spurstange lockern. 3. Spurstange einstellen und gegenmutter...

Page 103: Einstellungen 3

Einstellungen 3 d-13 3.14 schalter zur erkennung des rÜckwÄrtsgangs ________________________ 1. Schaltstange (z) so einstellen, dass der traktor im rückwärtsfahren bei ungefähr 0,8 km/h auf zweiradantrieb umschaltet. 2. Dazu die mutter abschrauben und das stangenende entgegen dem uhrzeigersinn drehe...

Page 104: 3 Einstellungen

3 einstellungen d-14 3.16 schnitthÖhe ___________________________________________________________ bevor die schnitthöhe zum ersten mal eingestellt wird, ist die höhe der vorderen schneideeinheit einzustellen. Zum verändern der schnitthöhe die schneidvorrichtungen nicht vom traktor abnehmen. Die schn...

Page 105: Einstellungen 3

Einstellungen 3 d-15 3.17 wartung der vorderen schneideeinheit ________________________________ die vordere schneideeinheit kann angehoben und gekippt werden, um bei wartungs- und reinigungsarbeiten besser zugang zu der schneidvorrichtung und den messern zu erlangen. Prüfen sie vor arbeiten an der s...

Page 106: 3 Einstellungen

3 einstellungen d-16 3.19 drehmomentdaten _____________________________________________________ textron turf care and specialty products verwendet standardmäßig plattierte schrauben der festigkeitsklasse 5, wenn nicht anders angegeben. Beim anziehen plattierter schrauben ist der wert für geschmiert ...

Page 107: Wartung 4

Wartung 4 d-17 4 wartung 4.1 allgemeine informationen _____________________________________________ 1. Die einstellung und wartungsarbeiten müssen immer von einem qualifizierten techniker durchgeführt werden. Wenn keine ordnungsgemäßen einstellungen vorgenommen werden können, wenden sie sich bitte a...

Page 108: 4 Wartung

4 wartung d-18 4.3 schleifen der messer _________________________________________________ 1. Zwischen messer und mähergehäuse einen holzblock positionieren, damit sich das messer nicht bewegt. Zum entfernen des messers die halteschraube des messers im uhrzeigersinn drehen . 2. Beim glätten oder schl...

Page 109: Wartung 4

Wartung 4 d-19 4.4 motor __________________________________________________________________ wichtig: eine separate anleitung für den motor wird vom motorhersteller mit diesem traktor geliefert. Diese anleitung für den motor genau durchlesen, bis sie mit dem betrieb und der wartung des motors vertrau...

Page 110: 4 Wartung

4 wartung d-20 4.6 luftfilter______________________________________________________________ das element zur prüfung oder reinigung nicht entfernen. Ein unnötiges entfernen des filters erhöht das risiko des eindringens von staub und anderen fremdkörpern in den motor. Der luftfilter muss gewartet werd...

Page 111: Wartung 4

Wartung 4 d-21 4.8 kraftstoffsystem _____________________________________________________ die spezifischen wartungsabstände sind in abschnitt 6.3 enthalten. Vor dem auswechseln eines filters das filtergehäuse und den bereich um das filter herum gründlich reinigen. Es darf kein schmutz in das kraftst...

Page 112: 4 Wartung

4 wartung d-22 4.11 aufladen der batterie _________________________________________________ 1. Den abschnitt 4.9 einsehen. Spezifische anweisungen befinden sich in der anleitung für batterie und ladegerät, die gelesen werden muß. 2. Wenn immer möglich, die batterie vor dem aufladen vom traktor entfe...

Page 113: Wartung 4

Wartung 4 d-23 4.13 hydraulikÖl ____________________________________________________________ die spezifischen wartungsabstände sind in abschnitt 6.3 angegeben. Nach dem ausfall einer hauptkomponente, oder wenn das vorhandensein von wasser oder schaum im Öl, oder ein ranziger geruch festgestellt wird...

Page 114: 4 Wartung

4 wartung d-24 4.16 gerÄuschdÄmpfer und auspuff ________________________________________ um eine vergiftung durch kohlenmonoxid zu verhindern, das komplette auspuffsystem regelmäßig prüfen und einen fehlerhaften geräuschdämpfer immer auswechseln. Wenn festgestellt wird, daß sich die farbe oder der t...

Page 115: Wartung 4

Wartung 4 d-25 4.19 pflege und reinigung __________________________________________________ den traktor und die vorrichtungen nach jedem gebrauch abwaschen. Die ausrüstung sauber halten. Hinweis: keinen teil der ausrüstung abwaschen, wenn sie heiß ist. Keine hochdruckspritzvorrichtung oder dampf ver...

Page 116: 4 Wartung

4 wartung d-26 4.21 kÜhler & ÖlkÜhler _____________________________________________________ 1. Den kühlmittelstand täglich prüfen. Der kühler muß voll sein und die auffangflasche muß bis zur markierung 'max.' voll sein. 2. Jährlich ablassen und wieder auffüllen. Den kühler- deckel entfernen, den mot...

Page 117: Wartung 4

Wartung 4 d-27 4.22 lagerung_______________________________________________________________ allgemeine informationen 1. Den traktor gründlich waschen und schmieren. Beschädigtes und freigelegtes metall reparieren und lackieren. 2. Den traktor überprüfen, alle schrauben anziehen, verschlissene oder b...

Page 118: 5 Fehlersuche

5 fehlersuche d-28 5 fehlersuche 5.1 allgemeine informationen _____________________________________________ die folgende fehlersuchtabelle listet die grundsätzlichen probleme auf, die beim anlassen und betrieb entstehen können. Ausführlichere informationen über das hydraulik- und elektrische system ...

Page 119: Achtung

Wartung und schmierung 6 d-29 6 wartung und schmierung 6.1 allgemeine informationen _____________________________________________ 1. Die schmierstellen immer vor und nach dem schmieren reinigen. 2. Zum schmieren eine nlgi-schmiere verwenden, die der lb-spezifikation von klasse 2 gerecht wird oder si...

Page 120

6 wartung und schmierung d-30 6.3 wartungsplan _________________________________________________________ a - hinzufügen oder nachstellen c - reinigen i - inspizieren l- schmieren r - austauschen ar - nach bedarf * zeigt den ersten kundendienst für neue maschinen an. ** oder alle zwei jahre (früheste...

Page 121: Anmerkungen 7

Anmerkungen 7 d-31 7 anmerkungen.

Page 123: Parts Catalog 8

Parts catalog 8 8 parts catalog 8.1 table of contents______________________________________________________ 1.1 ......... Decals ................................................................ 32 2.1 ......... Hood ................................................................... 34 3.1 ............

Page 124: Hr-5111

32 hr-5111 4wd use jacobsen hydraulic fluid see manual for specifcations push to latch wing arms. Pull to release this radiator contains anti-freeze protected to -26 f (-32 c) mix equal parts of clean water and a premium quality ethylene glycol based anti-freeze to maintain the boil over, rust and c...

Page 125: Hr-5111

33 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 364907 1 decal, tow valve 2 3002541 1 decal, instruction 3 363994 1 decal, service 4 340623 1 decal, spanish 5 3001435 1 decal, battery danger 6 366608 2 decal, wing transport lock cable 7 3002517 1 deca...

Page 126: Hr-5111

34 hr-5111 2.1 hood serial no. 69116-5901 and up 1 2 3 4 5 6 / 7 17 8 9 10 11 12 13 14 15 16 18 40 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 4 22 26 35 27 part of item 2.

Page 127: Hr-5111

35 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 117117 1 hood assembly 1 555873 1 • hood, lower 2 555874 1 • hood, upper 3 366563 1 • • bracket, screen 4 463720 26 • • rivet, 1/8 5 395362 1 • • screen 6 2720955 1 • • right side roller bracket 7 2720956 ...

Page 128: Hr-5111

36 hr-5111 3.1 floorboard platform serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 10 18 4 4 5 5 6 6 10 11 11 12 12 12 11 13 13 13 14 11 12 13 18 11 12 13.

Page 129: Hr-5111

37 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 117132 1 floorboard 2 366403 5 plug, floorboard 3 404072 4 screw, 5/16-18 x 1” turss head 4 452006 8 flat washer, 5/16 5 446136 8 lockwasher, 5/16 heavy 6 443106 8 nut, 5/16-18 hex 7 402636 4 screw, 5/16...

Page 130: Hr-5111

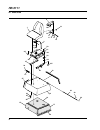

38 hr-5111 4.1 seat pan serial no. 69116-5901 and up 1 2 3 4 5 6 / 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 8 37 20

Page 131: Hr-5111

39 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 66172 1 seat 2 554390 1 • switch, seat reference sw3, see 67.1 3 163583 1 • seat wire harness 4 434011 2 • screw, 1/4-20 x 5/8” socket head 5 446130 2 • lockwasher, 1/4 heavy 66156 1 arm rest kit 6 55473...

Page 132: Hr-5111

40 hr-5111 5.1 steering console support serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 7 7 8 8 8 9 10 17 23 23 24 25 28 29.

Page 133: Hr-5111

41 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720268 1 support, steering console 2 2720191 2 • bushing 3 ref 1 steering console assembly see 9.1 4 401223 1 screw, 3/4-10 x 4-1/2” hex head 5 446178 1 lockwasher, 3/4 heavy 6 443130 1 nut, 3/4-10 hex ...

Page 134: Hr-5111

42 x x y w y z z w hr-5111 6.1 control panel serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 39 39 39 39 part of 19 part of 8 part of 11 part of 34 42.

Page 135: Hr-5111

43 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 5002593 1 control panel includes decals 2 338601 1 circuit breaker, 10amp reference cb1, see 67.1 3 338601 1 circuit breaker, 10amp reference cb2, see 67.1 4 338601 1 circuit breaker, 10amp reference cb3...

Page 136: Hr-5111

44 > change from previous revision hr-5111 7.1 lift valve serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 1001802 1 lift valve see 54.1 2 366150 1 weather strip 3 132473 1 right wing lift lever 4 132472 1 center lift lever 5 132471 1 left wing lift lever 6 366522 3...

Page 137: Hr-5111

45 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720168 1 lever, throttle control 2 326731 1 knob, throttle 3 162478 1 ball joint 4 339023 1 cable, throttle 5 443104 2 nut, 1/4-28 hex 6 366132 1 plate, throttle 7 360885 2 disc, friction 8 315966 1 spr...

Page 138: Hr-5111

46 hr-5111 9.1 steering console serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 part of console wire harness 21 22 23.

Page 139: Hr-5111

47 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 5002131 1 steering console 2 2720191 2 • bushing 3 1004867 1 valve, steering see 55.1 4 5000431 1 • nut, steering column 5 557829 1 steering wheel 6 557830 1 steering wheel cap 7 453009 4 flat washer, 5/...

Page 140: Hr-5111

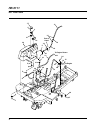

48 hr-5111 10.1 traction pedal linkage serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 part of floorboard part of right front lift arm support part of floorboard 2 12 14 17 18 19 21 22 24 31 32 33 34.

Page 141: Hr-5111

49 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720169 1 traction pedal 2 2720202 2 • bushing 3 366573 1 pad, traction pedal non slip 4 366129 1 bracket, traction pedal mounting 5 400188 2 screw,5/16-18 x 1” hex head 6 452006 2 flat washer, 5/16 7 44...

Page 142: Hr-5111

50 hr-5111 11.1 traction linkage serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 37 5 7 7 8 8 8 8 9 12 12 12 12 12 13 15 19 20 21 13 13 31 32 35 36 8.

Page 143: Hr-5111

51 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720173 1 tube, traction return 2 3007095 1 stop, rear pivot 3 3000593 1 spacer, traction control 4 358795 1 screw, 3/8-24 x 5-1/2” special 5 358794 4 washer 6 364970 1 spring, compression 7 443812 4 nut...

Page 144: Hr-5111

52 hr-5111 12.1 brake pedal serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 8 15 18 16 17.

Page 145: Hr-5111

53 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 132470 1 brake pedal 2 2720393 1 pin, pedal 3 345020 1 pad, brake pedal 4 446148 1 lockwasher, 7/16 heavy 5 343256 1 nut, pedal pin 6 350558 1 spring, pedal return 7 441668 1 carriage bolt, 1/4-20 x 1-1/...

Page 146: Hr-5111

54 hr-5111 13.1 parking brake serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 8 9 10 19 19 24 24 25 25 26 27 28.

Page 147: Hr-5111

55 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 163931 1 parking brake lever 2 555855 1 • parking brake handle 3 461455 1 • pin, parking brake 4 460016 1 • cotter pin, 3/32 x 1” 5 366341 5 • spacer 6 401166 3 screw, 5/16-18 x 3-3/4” hex head 7 400194 ...

Page 148: Hr-5111

56 hr-5111 14.1 frame and front axle serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 26 20 21 22 23 24 25 4 4 5 5 6 6 5 5 27 27 24 24 20 20 21 22 19 28 29 30

Page 149: Hr-5111

57 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2246001 1 frame 2 1003327 1 axle, front see 62.1 3 556891 10 • nut, m14-1.5 wheel 4 363386 12 screw, m12-1.75 x 30 mm 5 446154 16 lockwasher, 1/2 heavy 6 453017 8 flat washer, 1/2 7 366292 2 tire, 26 x 1...

Page 150: Hr-5111

58 hr-5111 15.1 front lift arms serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 2 4 6 8 7 13 14 14 7 17 23 24.

Page 151: Hr-5111

59 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720206 1 right front lift arm 2 342033 2 • bushing 3 2720207 1 left front lift arm 4 342033 2 • bushing 5 366037 2 shaft, lift arm pivot 6 346091 4 pin, retaining 7 446136 5 lockwasher, 5/16 heavy 8 400...

Page 152: Hr-5111

60 hr-5111 16.1 wing lift arms right wing shown serial no. 69116-5901 and up 1 / 3 2 / 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 28 29 30 31 32 33 34 35 36 37 38 27 27 27 8 7 9 14 20 28 16 2 / 4.

Page 153: Hr-5111

61 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720295 1 right wing arm 2 2720298 2 • bushing 3 2720294 1 left wing arm (not shown) 4 2720298 2 • bushing 5 2248004 2 shaft, pivot arm 6 453004 4 flat washer, #10 7 446136 3 lockwasher, 5/16 heavy 8 400...

Page 154: Hr-5111

62 hr-5111 17.1 wing deck latch serial no. 69116-5901 and up 1 2 3 4 5 38 7 8 9 10 11 6 13 14 15 16 17 18 / 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 12 3 3 3 4 4 4 5 5 5 38 6 13 21 22 23 36 37.

Page 155: Hr-5111

63 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 446136 2 lockwasher, 5/16 heavy 2 443106 2 nut, 5/16-18 hex 3 453011 12 flat washer, 3/8 4 446142 12 lockwasher, 3/8 heavy 5 443110 12 nut, 3/8-16 hex 6 400272 4 screw, 3/8-16 x 2-1/4” hex head 7 132601 ...

Page 156: Hr-5111

64 hr-5111 18.1 steering axle serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 2 3 3 3 8 8 8 8 8 9 10 11 14 20 35 36 36 38 39 16.

Page 157: Hr-5111

65 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 2720313 1 steering axle 2 2720298 2 • bushing, axle pivot 3 2720314 4 • bushing, mount pivot 4 400444 1 screw, 1/2-20 x 1-3/4” hex head 5 400446 1 screw, 1/2-20 x 2” hex head 6 443820 2 nut, 1/2-20 hex j...

Page 158: Hr-5111

66 hr-5111 19.1 air cleaner serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 13 7 7 7 12 12 13 13 14 14 15 19 20 24 25 26 13 14 32 33 32 31 30 16.

Page 159: Hr-5111

67 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 122907 1 air filter assembly 503628 1 • wing nut and gasket kit 549633 1 • element, air cleaner 2 131059 2 band, air cleaner mounting 3 400266 4 screw, 3/8-16 x 1-1/2” hex head 4 503574 1 rear bumper inc...

Page 160: Hr-5111

68 hr-5111 20.1 radiator and oil cooler serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 9 10 12 12 13 13 17 12 22 27 27 27.

Page 161: Hr-5111

69 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 503608 1 radiator shroud includes decal 2 473144 1 cable tie 3 400182 4 screw, 5/16-18 x 5/8” hex head 4 452006 4 flat washer, 5/16 5 446136 4 lockwasher, 5/16 heavy 6 503609 1 radiator includes decals 7...

Page 162: Hr-5111

70 hr-5111 21.1 engine serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17.

Page 163: Hr-5111

71 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 1000441 1 engine, kubota v2203 for complete listing of engine service parts, see engine parts manual 555773 1 • engine oil filter 557619 1 • cartridge, fuel filter 2811870 1 • upper gasket kit 5000938 1 ...

Page 164: Hr-5111

72 hr-5111 22.1 engine mounts serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 5 5 5 6 6 6 7 7 7 11 23 12 6 6 6 16 17 18 19 20 21 22 22 21.

Page 165: Hr-5111

73 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 132427 1 mount, right rear engine 2 132428 1 mount, left rear engine 3 132426 1 mount, left front engine 4 132425 1 mount, right front engine 5 365979 7 screw, m12-1.25 x 25 mm metric grade 8.8 6 446154 ...

Page 166: Hr-5111

74 > change from previous revision hr-5111 23.1 engine fuel control serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 338289 1 fuel solenoid reference k17, see 67.1 2 400108 2 screw, 1/4-20 x 3/4” hex head 3 453023 2 flat washer, 1/4 4 446130 5 lockwasher, 1/4 heavy ...

Page 167

75 > change from previous revision item part no. Qty. Description serial numbers/notes 1 1001226 1 muffler 2 1001251 1 exhaust pipe 3 553020 1 gasket, exhaust included with engine 4 555606 4 bolt and lockwasher set included with engine 5 1000050 1 muffler bracket 6 400188 4 screw, 5/16-18 x 1” hex h...

Page 168: Hr-5111

76 hr-5111 25.1 fuel tank serial no. 69116-5901 and up to engine return to engine 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 26 27 28 29 30 31 25 part of hood 5 5 5 16 21 21 21 21 21 21 21 29.

Page 169: Hr-5111

77 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 163987 1 fuel cap 2 163986 1 fuel sender reference u8, see 67.1 3 n/s 1 • gasket 4 403910 5 screw, #10-24 x 1/2” truss head 5 361117 4 bushing, fuel 6 366606 2 washer, fuel tank 7 400188 2 screw, 5/16-18...

Page 170: Hr-5111

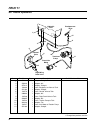

78 hr-5111 26.1 pumps and control valve serial no. 69116-5901 and up 1 2 3 4 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 8 8 14 14 14 8 14 16 16 15 15 16 15 17 17 18 18 19 19 20 21 21 21 21 21 23 24 24 15 35 5 6 14 15 36.

Page 171: Hr-5111

79 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 117083 1 pump, traction see 58.1 2 557447 1 • o-ring 3 338938 1 • pump coupler 4 2720560 1 pump, 4 section gear 2721419 1 • seal kit 5 3001523 1 plate, bulkhead 6 400260 1 screw, 3/8-16 x 7/8” hex head 7...

Page 172: Hr-5111

80 hr-5111 27.1 tank support serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 29 30 1 5 5 5 5 6 6 8 10 9 13 14 28 20 20 28.

Page 173: Hr-5111

81 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 132433 2 support, rear tank 2 132432 1 support, left side tank 3 132431 1 support, right side tank 4 400286 2 screw, 3/8-16 x 2-3/4” 5 446142 12 lockwasher, 3/8 heavy 6 443110 6 nut, 3/8-16 hex 7 400262 ...

Page 174: Hr-5111

82 hr-5111 28.1 hydraulic tank serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 10

Page 175: Hr-5111

83 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 503612 1 hydraulic oil tank includes decals 2 365959 1 strainer, 100 mesh screen 2812075 1 • o-ring 3 69051-04 1 plug, pipe 4 367551 1 switch, hydraulic oil temperature reference sw13, see 67.1 ★ 5 16391...

Page 176: Hr-5111

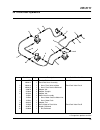

84 hr-5111 29.1 traction hydraulics serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 19 1 2 14 14 14 15 18 17 19.

Page 177: Hr-5111

85 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 132417 2 hose, traction pump to axle motor 2 340269 2 adapter, tee 3 340074 2 adapter, 90° 4 ref 1 traction pump see 26.1 5 ref 1 front axle motor see 26.1 6 132446 1 hose, pump to 4wd valve port b 7 340...

Page 178: Hr-5111

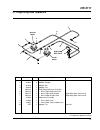

86 > change from previous revision hr-5111 30.1 gear pump hydraulics serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 338946 1 adapter, 90° beaded 339903 1 • o-ring 2 326112 6 clamp, hose 3 366083 1 hose, pump suction 4 339113 1 manifold, pump suction 5 2720893 2 ho...

Page 179: Hr-5111

87 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 340065 3 adapter, 90° 2 364945 3 adapter, diagnostic port 3 363030 3 dust cover 4 339989 1 adapter, straight 5 1003105 1 hose, pump to control valve control valve port p 6 340033 1 adapter, 45° 7 340061 ...

Page 180: Hr-5111

88 > change from previous revision in out lt rt hr-5111 32.1 steering hydraulics serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 339984 1 adapter, straight 2 123223 1 tube, control valve to tube 3 339910 1 o-ring 4 2692222-05 1 hose, tube to steering valve steering...

Page 181: Hr-5111

89 > change from previous revision in out b d f hr-5111 item part no. Qty. Description serial numbers/notes 1 340066 2 adapter, 90° 2 123222 1 tube, control valve to lift valve lift valve port in 3 339984 2 adapter, straight 4 132571 1 hose, lift valve to front cylinders lift valve port d 5 132571 1...

Page 182: Hr-5111

90 > change from previous revision hr-5111 34.1 lift return hydraulics serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 340061 3 adapter, 90° 2 132573 1 hose, cylinder to cylinder 3 340263 1 adapter, tee 4 132570 1 hose, front cylinder to bulkhead 5 340215 2 adapter...

Page 183: Hr-5111

91 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 340055 2 adapter, 90° 2 ref 1 hose, left wheel motor drain see 29.1 3 ref 1 hose, right wheel motor drain see 29.1 4 359186 3 adapter, tee 5 ref 1 hose, right wing deck drain see 41.1 6 ref 1 hose, left ...

Page 184: Hr-5111

92 > change from previous revision hr-5111 36.1 charge hydraulics serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 132540 1 hose, control valve to tee control valve port f 2 340029 2 adapter, 45° 3 340120 1 adapter, tee 4 132864 1 hose, 4wd valve to tee 4wd valve po...

Page 185: Hr-5111

93 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 340070 1 adapter, 90° 2 2692224-07 1 hose, front to left wing deck valve 3 2720559 1 adapter, tee 4 132441 1 hose, left valve to oil cooler 5 340077 2 adapter, 90° 6 1003705 1 hose, oil cooler to return ...

Page 186: Hr-5111

94 > change from previous revision hr-5111 38.1 return hydraulics serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 351124 2 adapter, straight 2 358949 1 adapter, 90° 3 357613 1 adapter, striaght 4 132866 1 hose, backpressure valve to tank 5 351108 1 adapter, straigh...

Page 187: Hr-5111

95 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 ref 1 bracket, bulkhead see 15.1 1003613 1 front deck hose assembly 2 1003614 1 • hose, front valve to motor front deck valve port a 3 1003615 1 • hose, front deck to bulkhead 4 340070 2 adapter, 90° 5 3...

Page 188: Hr-5111

96 > change from previous revision hr-5111 40.1 left wing deck hydraulics serial no. All item part no. Qty. Description serial numbers/notes 1 340070 2 adapter, 90° 2 339989 4 adapter, straight 3 366445 1 adapter, tee 4 362288 1 adapter, 90° 1003134 1 left wing deck hose assembly 5 132575 1 • hose, ...

Page 189: Hr-5111

97 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 340070 2 adapter, 90° 2 339989 4 adapter, straight 3 362288 1 adapter, 90° 4 366445 1 adapter, tee 1003133 1 right wing deck hose assembly 5 1003138 1 • hose, right wing deck drain 6 1003137 1 • hose, ri...

Page 190: Hr-5111

98 return tubes front axle motor hoses front axle reverse hose charge filter hose charge filter tube hr-5111 42.1 hydraulic clamping serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 4 4 5 5 13 14 10 13 14 15 15 16 17 17 18 19 13 13 14 15 24.

Page 191: Hr-5111

99 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 366607 2 spacer, hose 2 359860 2 clamp, 2 hose 3 400204 2 screw, 5/16-18 x 3-1/2” 4 446136 4 lockwasher, 5/16 heavy 5 443106 4 nut, 5/16-18 hex 6 400114 1 screw, 1/4-20 x 1-1/4” hex head 7 364221 1 clamp...

Page 192: Hr-5111

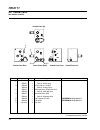

100 k2 k7 k3 k6 k5 k9 k8 1 2 3 4 5 6 bk2 hr-5111 43.1 electrical components serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 13 13 14 21 21 21 27 28 25 25 relay identification part of left wing part of right wing limit...

Page 193: Hr-5111

101 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 132488 1 tail light reference l11, see 67.1 555869 1 • tail light 555870 1 • grommet 555871 1 • harness 2 400336 1 screw, 7/16-14 x 1-1/4” hex head 3 446148 1 lockwasher, 7/16 heavy 4 443114 1 nut, 7/16...

Page 194: Hr-5111

102 hr-5111 44.1 electrical routing serial no. 69116-5901 and up 1 2 3 4 6 10 11 12 13 14 15 16 17 18 19 20 9 5 7 12 14 14 14 14 15 18 engine harness tractor harness.

Page 195: Hr-5111

103 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 366618 1 grommet 2 362263 1 screw, m10-1.25 x 25 mm 3 365980 1 screw, m12-1.25 x 20 mm 4 446154 1 lockwasher, 1/2 heavy 5 446130 1 lockwasher, 1/4 heavy 6 443102 1 nut, 1/4-20 hex 7 453023 1 flat washer...

Page 196: Hr-5111

104 circuit break ers hour meter v olt meter fuel gauge t achometer switches rela ys cab connector p anel lights hor n/t est switch diodes ignition switch t emper ature gauge glo w plug switch hor n ground p a rking br ak e seat switch control v alv e re v erse switch headlights br ak e switch diff ...

Page 197: Hr-5111

105 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 1004542 1 wire harness, console 554492 2 • lockwasher, size 24 554493 2 • panel nut, size 24 555845 10 • light bulb 555846 10 • diode 555847 1 • light strip 2 1004523 1 wire harness, engine 3 1004522 1 ...

Page 198: Hr-5111

106 hr-5111 46.1 deck mounting serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 1 8 21 21 22 23 24 25.

Page 199: Hr-5111

107 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 342675 6 pin, snap ring 2 3000439 2 clevis pin, 1/2 x 3-3/4” 3 3000487 1 clevis pin, 5/8 x 3” 4 346913 1 spacer 5 460050 2 cotter pin, 3/16 x 1-1/4” 6 3006300 1 clevis pin, 5/8 x 3-5/16” 7 362464 12 whe...

Page 200: Hr-5111

108 no step serious injury or death can result from blade contact or from objects being thrown very long distances do not operate machine with discharge chute or guards flipped up or removed. Do not operate machine with bent components or with implement in raised position. Keep yourself and others a...

Page 201: Hr-5111

109 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 503573 1 front deck 2 3002502 3 • decal, blade contact danger 3 3002676 1 • decal, cutting height 4 2000787 1 • decal, no step 5 2721180 2 motor, deck counter-clockwise rotation 6 557523 1 • key 7 39103...

Page 202: Hr-5111

110 serious injury or death can result from blade contact or from objects being thrown very long distances do not operate machine with discharge chute or guards flipped up or removed. Do not operate machine with bent components or with implement in raised position. Keep yourself and others away from...

Page 203: Hr-5111

111 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 5001073 1 left wing deck includes items 3 and 4 2 5001072 1 right wing deck (not shown) 3 3002502 2 • decal, blade contact danger 4 3002676 1 • decal, cutting height 5 2721180 2 motor, ccw rotation deck...

Page 204: Hr-5111

112 hr-5111 49.1 caster wheels serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 2 2 2 3 4 5 6 7 9 8 10 11 11 11 12 12 12 15 15.

Page 205: Hr-5111

113 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 131717 8 yoke, caster wheel spindle 2 453022 20 flat washer, 3/4 3 3003207 10 shaft, caster wheel 4 460056 10 cotter pin, 3/16 x 2” 5 403578 10 screw, #10-24 x 1” hex head 6 446118 10 lockwasher, #10 7 ...

Page 206: Hr-5111

114 > change from previous revision hr-5111 50.1 deck bumper serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 3003427 1 bracket, deck bumper 2 400262 2 screw, 3/8-16 x 1” hex head 3 453011 2 flat washer, 3/8 4 446142 4 lockwasher, 3/8 heavy 5 443110 4 nut, 3/8-16 he...

Page 207: Hr-5111

115 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 5002620 1 spring kit 2 400186 1 screw, 5/16-18 x 7/8” hex head 3 446136 1 lockwasher, 5/16 heavy 4 443106 1 nut, 5/16-18 hex 5 554718 4 nut, push 6 554717 2 shaft, pivot 7 554715 1 knob, spring tension ...

Page 208: Hr-5111

116 > change from previous revision p ld st f cd l sw sd dl 4wd t hr-5111 52.1 control valve part number 1004555 serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 5003150 1 relief valve, 115 psi 555861 1 • seal kit, relief valve 2 556845 1 priority valve, 4.5 gpm 556...

Page 209: Hr-5111

117 > change from previous revision l1 l2 r1 r2 4wd a b c ad bd hr-5111 item part no. Qty. Description serial numbers/notes 1 556897 1 spool valve 5003581 1 • seal kit 2 558038 1 check valve 5003581 1 • seal kit 3 556847 1 solenoid valve, 4wd reverse 5003578 1 • seal kit, solenoid valve 4 556849 1 c...

Page 210: Hr-5111

118 hr-5111 54.1 lift valve part number 1001802 serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 19 20 21 22 23 24 25 26 27 7 14 18.

Page 211: Hr-5111

119 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 558005 1 plug 2 500745 3 plug 3 545914 3 spring ● 4 n/s 3 poppet 5 500736 3 seat 6 5001599 1 plunger 7 5001603 2 plunger 8 558004 3 cap 9 558007 3 retaining ring 10 5001613 1 seat 11 558011 3 spacer 12 ...

Page 212: Hr-5111

120 hr-5111 55.1 steering valve part number 1004867 serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 3 3 3 39 39.

Page 213: Hr-5111

121 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 443108 4 nut, 5/16-24 hex 557738 1 seal kit 2 n/s 1 • seal, o-ring 3 n/s 4 • seal, o-ring 4 n/s 4 • seal, o-ring 5 n/s 1 • seal, commutator 6 n/s 1 • face seal 7 5000431 1 nut, 13/16-20 hex jam 8 n/s 4 ...

Page 214: Hr-5111

122 > change from previous revision hr-5111 56.1 deck valve part number 1002499 serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 5002911 1 relief valve, 3000 psi 5003579 1 • seal kit, relief valve 2 5002912 1 relief valve, 430 psi 5003554 1 • seal kit, relief valve ...

Page 215: Hr-5111

123 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 554579 2 spacer, brake 2 503296 1 stud plate with lining 3 503295 1 rib plate with lining 4 549441 1 v-plate 5 502517 1 cam lever, brake 6 590259 2 locknut, 3/8-24 center 7 546131 2 spring, brake return...

Page 216: Hr-5111

124 hr-5111 58.1 traction pump part number 117083 serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 1 2 12 15 22 24 28 29.

Page 217: Hr-5111

125 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 557445 2 relief valve 2 557444 2 plug 3 557443 1 housing 4 557442 1 rotating kit 5 557441 1 valve plate 6 557440 1 backplate 7 557439 1 seal, cover 8 557438 1 trunnion cover 9 557437 1 cam plate 10 5574...

Page 218: Hr-5111

126 > change from previous revision hr-5111 59.1 deck motor part numbers 2721180 and 2721181 serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 557515 1 spindle ● 2 n/s 1 o-ring ● 3 n/s 2 back up seal ● 4 n/s 2 bushing seal 5 557518 1 shaft, spindle ● 6 557520 1 snap ...

Page 219: Hr-5111

127 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 557423 1 backplate assembly 2 557424 1 camplate insert 3 557425 1 thrust bearing 4 557426 2 thrust race 5 557427 1 housing 6 557428 1 drive shaft 7 557429 1 rotating kit 8 554756 1 key, 1/4 x 1/4 x 31/3...

Page 220: Hr-5111

128 > change from previous revision hr-5111 61.1 rear wheel motor part number 2720540 serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes ● 1 n/s 1 seal exclusion ● 2 n/s 4 seal, 3” i.D. ● 3 n/s 1 back-up ring ● 4 n/s 1 shaft seal 5 5003384 1 shaft and bearing kit 6 5547...

Page 221: Hr-5111

129 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 556844 4 screw, m10 x 35 mm hex head 2 592665 4 dowel, sleeve 3 556901 4 screw, m10 x 45 mm hex head 4 556902 4 nut, m10 hex 5 556846 4 screw, m10 x 110 mm hex head 6 n/s 1 differential assembly see 63....

Page 222: Hr-5111

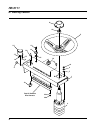

130 hr-5111 63.1 differtial assembly part of 1003327 serial no. 69116-5901 and up 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 3 5 11 19 20 21 22 27.

Page 223: Hr-5111

131 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 556889 1 housing, left side differential 2 556888 1 housing, right side differential 3 556871 1 bevel gear and pinion matched set 4 592548 1 differential 5 556859 2 tapered bearing, cup and cone 6 55687...

Page 224: Hr-5111

132 hr-5111 64.1 drive axle reducer part of 1003327 (left side shown) serial no. 69116-5901 and up 1 / 2 3 / 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 5.

Page 225: Hr-5111

133 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 5002782 1 housing, left side reducer 2 5002783 1 housing, right side reducer not shown 3 556882 1 shaft, left side reducer 4 556881 1 shaft, right side reducer not shown 5 590502 4 bearing, ball 6 55685...

Page 226: Hr-5111

134 > change from previous revision hr-5111 65.1 differential lock assembly part of 1003327 serial no. 69116-5901 and up item part no. Qty. Description serial numbers/notes 1 556885 1 housing, differential lock 2 556870 1 collar, differtial lock 3 556875 1 fork 4 592993 1 screw, m8 x 20 mm hex head ...

Page 227: Hr-5111

135 > change from previous revision hr-5111 item part no. Qty. Description serial numbers/notes 1 556890 2 brake cliper 2 557991 1 • brake pad set 3 557989 1 • caliper seal repair kit 4 557988 4 • screw, caliper bleed 5 557987 4 • cap, bleed screw 6 557990 1 • pad retaining pin and spring kit 66.1 b...

Page 228: Hr-5111

136 m1 b1 b s cb7 cb6 cb4 cb3 cb1 cb2 cb5 30 85 86 87 k4 sw4 k3 k2 bk bk bk bk bk bn rd/bn rd/bn bn ye ye ye wh wh/bn wh/bn pu/ye pu/wh pu/wh gn/wh gn/wh gn/wh gn/wh gn/wh pu/wh pk/bu pk/bu pu/ye rd rd pk/bu pk/bu og/bu wh/rd wh/rd wh/rd rd rd rd rd rd rd rd rd rd bn bn rd/wh bk bk bk bk bk pk pk pk...

Page 229: Hr-5111

137 30 85 86 87 87a pu/wh pu/wh gn/wh gn gn/wh bn/rd bn/rd bn/rd pk/bu pk/bu pk/bu ye ye ye ye pu/wh sw5 sw18 b i x y s a off - none on - b+i+a; x+y start - b+i+s sw1 bk tn/rd og/bu og/bu og/bu tn/rd ye wh wh gy gy tn/rd l11 bk bk bk bk lb lg l10 l12 l13 og og og og og og og og og og og og og og l3 ...

Page 230: Hr-5111

138 hr-5111 item reference illustration part number description serial numbers/notes b1 see 3.1 n/s battery cb1 see 6.1 338601 10 amp circuit breaker (interlock) cb2 see 6.1 338601 10 amp circuit breaker (instruments) cb3 see 6.1 338601 10 amp circuit breaker (cruise, 4wd) cb4 see 6.1 338558 30 amp ...

Page 231: Hr-5111

139 hr-5111 l10 not shown 555845 left turn light l11 see 43.1 555869 tail light l12 optional head light included in kit 69128 l13 optional head light included in kit 69128 m1 see 21.1 556988 starter motor included in engine r1 see 21.1 556996 glow plugs included in engiine sw1 see 9.1 1001958 igniti...

Page 232: Hr-5111

140 3500 psi 3500 psi 1.04 1.04 1.04 0.66 in 3 2.48 in 3 in 3 in 3 in 3 430 psi 3000 psi b t a p d 430 psi 3000 psi b t a p d 430 psi 3000 psi b t a p d .0669 1.04 in 3 .0669 1.04 in 3 .0669 1.04 in 3 .0669 1.04 in 3 .0669 1.04 in 3 .0669 1.04 in 3 .0669 1.04 in 3 2.48 in 3 25 psi switch 25 psi crac...

Page 233: Hr-5111

141 c a ad ab b l2 r2 4wd l1 r1 11.9 in 3 11.9 in 3 250 psi sd st ld p l 4wd dl sw cp f t 1450 psi 6.6 in 3 in out lt rt in out a b c d e f 1500 psi 300 psi 300 psi 300 psi 50 psi 4wd valve control valve differential lock cylinder steering valve steering cylinder lift valve backpressure valve left w...

Page 234: Hr-5111

142 > change from previous revision this tractor may tip over unexpectedly and quicker than an operator is able to jump free. 1. Never operate a tractor without proper roll protection (see manual) 2. Always wear you seat belt when operating this tractor equipped with roll protection. 3. Never hitch ...

Page 235: Fluids And Compounds

Fluids and compounds * refer to the operator’s manual or the parts & maintenance manual for the correct hydraulic oil requirements for your machine. Textron turf care and specialty products offers a high usage parts catalog illustrating commonly used parts through easy to read line drawings. See you...

Page 236: Hr-5111

144 x w w w x w x w w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size o-ring boss dash size w-x o-ring face seal size w-x o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face seal size o-ring face seal size w-x o-ring face seal size o-ring face se...

Page 237: Hr-5111

145 > change from previous revision hr-5111 adapter part number. Dash size adapter type (w) o-ring (x) o-ring (y) o-ring (z) o-ring 339979 6-6 straight adapter 339909 339897 339983 8-6 straight adapter 339910 339897 339984 8-8 straight adapter 339910 339898 339989 10-10 straight adapter 339911 33989...

Page 238: Index

146 index 1000050.......................75 1000588.......................43 1000649.......... 49 , 53 , 55 1000700.......................85 1000843.......................85 1001226.......................75 1001251.......................75 1001298.......................65 1001311........................

Page 239: Index

147 index 3001855 ...................... 71 3002248 ...................... 33 3002502 ............ 109 , 111 3002515 ...................... 33 3002517 ...................... 33 3002518 ...................... 33 3002520 ...................... 33 3002529 ...................... 33 3002541 ................

Page 240: Index

148 index 365965 ........................73 365966 ........................91 365967 ........................93 365974 ........................81 365977 ........................71 365979 ........................73 365980 ..................71 , 73 365981 ........................73 365991 ...............

Page 241: Index

149 index 554752 ....................... 77 554756 ..................... 127 554779 ............... 65 , 128 554780 ............... 65 , 128 554855 ..................... 121 554856 ..................... 121 554857 ..................... 121 555606 ....................... 75 555771 ......................

Page 244

Bob-cat bunton cushman jacobsen ransomes ryan e-z-go equipment from ransomes jacobsen limited is built to exacting standards ensured by iso 9001 registration at all our manufacturing locations. A worldwide dealer network and factory-trained technicians backed by ransomes jacobsen parts xpress provid...