- DL manuals

- Jacobsen

- Lawn Mower

- LF 550

- Safety, operation and maintenance manual

Jacobsen LF 550 Safety, operation and maintenance manual - Notice

OPERATION 5

31

5.10 TOWING / TRAILERING _____________________________________________________

If the mower experiences problems and must be shut down

and removed from the area, it should be loaded onto a trailer

for transport. If a trailer is not available, the unit can be

towed slowly short distances.

Use care when loading and unloading mower. Fasten

mower to trailer to prevent mower from rolling or shifting

during transport.

Before towing, open tow valve. The tow valve permits

moving the mower without starting the engine and prevents

possible damage to hydraulic components.

The tow valve

(A)

is located on the hydraulic drive pump

beneath the operators seat. Remove cover from floor in front

of operator’s seat. To open valve, use a wrench or insert a

pin or small screw driver into the small hole in the valve

stem. Turn the valve counterclockwise one full turn.

Rotate brake release lever

(B)

counter clockwise. Brake

release lever is located under access panel, near right front

axle mount. Turn steering wheel for right hand turn

(clockwise) until resistance is felt.

Before towing make sure cutting units are raised. If they

cannot be raised, remove them from the mower.

Close tow valve

(A)

completely, rotate brake release lever

(B)

clockwise, and replace cover after towing.

Figure 5F

Figure 5G

NOTICE

Do not exceed 2 MPH (3.2 KPH) while towing. Long

distance towing is not recommended

.

A

LF006

Brake released

for towing.

Brake engaged

(Normal operation)

B

Summary of LF 550

Page 1

When performance matters. ™ lightweight fairway mower with rops 67978 – lf 550 ™ , kubota v1505-e3b, 5 gang 2wd 67979 – lf 550 ™ , kubota v1505-e3b, 5 gang 4wd 67981 – lf 570 ™ , kubota v1505-e3b, 5 gang 2wd 67982 – lf 570 ™ , kubota v1505-e3b, 5 gang 4wd 67980 – lf 550 ™ turbo, kubota v1505-t-e3b, ...

Page 2

2 this manual contains safety and operating instructions for your new jacobsen mower. This manual should be stored with the equipment for reference during operation. Before you operate your mower, you and each operator you employ should read the manual carefully in its entirety. By following the saf...

Page 3

Contents 3 contents contents safety 1.1how to operate safely . . . . . . . . . . . . . . . . . . . . 4 1.2 important safety notes . . . . . . . . . . . . . . . . . 7 specifications 2.1 product identification . . . . . . . . . . . . . . . . . . 8 2.2 v1505-e3b engine . . . . . . . . . . . . . . . . ....

Page 4: Warning

1 safety 4 1 safety 1.1 how to operate safely safe operation a read the operator’s manual and other training material. If the operator or technician can not read this manual, the owner is responsible to describe this material to the operators and technicians. Manuals in additional languages may be a...

Page 5

Safety 1 5 d keep your legs, arms and body inside the operator compartment while the mower is in operation. Keep your hands and feet away from the cutting units. E do not use on the slopes greater than the safe slope limit for the equipment. F to guard against over turning or loss of control: – oper...

Page 6

1 safety 6 e refuel the mower before you start the engine. When the engine is in operation or while the engine is hot, never remove the fuel cap or add fuel to the mower. F refuel outdoors only and do not smoke when you add fuel. Extinguish all types of ignition. G the fuel nozzle must touch the rim...

Page 7: Warning

Safety 1 7 1.2 important safety notes ________________________________________________ this safety alert symbol is used to alert you to potential hazards. Danger - indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning - indicates a potenti...

Page 8

2 specifications 8 2 specifications 2.1 product identification _________________________________________________ 67978.............................. Lf 550, 2wd with rops, uses 5 in. (12.7 cm) diameter reel 67979.............................. Lf 550, 4wd with rops, uses 5 in. (12.7 cm) diameter reel...

Page 9

Specifications 2 9 2.4 mower__________________________________________________________________ tires: front ................................26.5 x 14 - 12: (4 ply) rear (s/n 1651~2499) ....18 x 9.5 - 8: (4 ply) rear (s/n 2500 and up) ..20 x 10-8 (4 ply) pressure...........................10-12 psi (...

Page 10

2 specifications 10 2.8 declaration of conformity ____________________________________________ declaration of conformity ▪ ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ ▪ prohlÁŠenÍ o shodĚ ▪ overensstemmelseserklÆring ▪ conformiteitsverklaring ▪ vastavusdeklaratsioon ▪ vaatimustenmukaisuusvakuutus ▪ declaration de co...

Page 11

Specifications 2 11 guaranteed sound power level ▪ Гарантирано ниво на звукова мощност ▪ garantovaný akustický výkon ▪ garanteret lydstyrkeniveau ▪ gegarandeerd geluidsniveau ▪ garanteeritud helivõimsuse tase ▪ taattu äänitehotaso ▪ niveau de puissance sonore garanti ▪ garantierter schalldruckpegel ...

Page 12

2 specifications 12 signature of the person empowered to draw up the declaration on behalf of the manufacturer, holds the technical documentation and is authorised to compile the technical file, and who is established in the community. Подпис на човека, упълномощен да състави декларацията от името н...

Page 13

Specifications 2 13 2.9 vibration level_________________________________________________________ the mower was tested for hand and arm vibration levels. The operator was in the normal position to drive the vehicle, with two hands on the steering mechanism. The engine was in operation and the cutting...

Page 14: Caution

2 specifications 14 2.10 accessories ___________________________________________________________ refer to the parts catalog and contact your area jacobsen dealer for a complete listing of accessories and attachments. Mower orange touch-up paint (12 oz. Spray).............. 554598 canopy / sunshade ....

Page 15

Decals 3 15 3 decals 3.1 decals _________________________________________________________________ familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181865 4181864 • read operator's manual. Do not allow untrain...

Page 16

3 decals 16 familiarize yourself with the following decals. They are critical to the safe operation of the machine. Replace damaged decals immediately. 4181861 4182520 i mportant do not use starting assist fluids use of starting assist fluids in the air intake system may be potentially explosive or ...

Page 17: 105

Decals 3 17 3008521 3008682 3008683 tow valve vehicle can normal operation be towed (closed) (open) 105 db l wa traction pedal reverse forward turn reel valve knob to adjust backlap reel speed. Sound power level.

Page 18: Warning

4 controls 18 4 controls 4.1 icons ___________________________________________________________________ warning never attempt to drive the mower unless you have read the safety and operation manual and know how to operate all controls correctly. Familiarize yourself with the icons shown above and wha...

Page 19

Controls 4 19 ! 4131663 a e b f j c g d h k l m n p r w s t u v r a lcd display unit (ldu) b mow switch c parking brake switch d cruise control switch e ignition switch f horn switch g light switch h joystick j fuel cap k air cleaner indicator l backlap switch m steering tilt lever n traction pedal ...

Page 20: Notice

4 controls 20 4.2 armrest controls _____________________________________________________ a. Lcd display unit (ldu) used to display and set operating conditions. See section 4.4. B. Mow switch enables and disables the reels, and switches lift system between manual mode and mow mode. Pull up on the kn...

Page 21: Caution

Controls 4 21 4.3 controls _______________________________________________________________ j. Fuel cap fill fuel tank with fresh, clean, #2 low or ultra low sulfur diesel fuel, minimum cetane rating of 45. Section 5.11. K. Air cleaner indicator indicates condition of air cleaner on engine. Clean or ...

Page 22: Caution

4 controls 22 r. 12 volt accessory outlet located inside armrest storage compartment. Allows operation of approved 12 volt accessories and attachments. To prevent excessive battery drain, only use 12 volt outlet with engine running. Caution the 12 volt accessory outlet circuit is protected by a 10 a...

Page 23: Caution

Controls 4 23 4.4 lcd display unit (ldu) ___________________________________________________ the ldu displays current functional values for the operation of the mower, has indicator lights, and sounds audible warning alerts. The ldu operates in one of two modes, operator mode (default) and maintenan...

Page 24

4 controls 24 4.4.2 alarm codes _____________________ in addition to the lights on the ldu, there are eight screen displays that are used to alert the operator or mechanic of a problem the needs to be corrected. Figure 4c low oil pressure screen is shown, alarm sounds, reels stop and raise to full u...

Page 25: Caution

Operation 5 25 5 operation 5.1 daily inspection ________________________________________________________ 1. Perform a visual inspection of the entire unit. Look for signs of wear, loose hardware, and missing or damaged components. Check for fuel or oil leaks to ensure connections are tight and hoses...

Page 26: Warning

5 operation 26 5.3 operating procedures_________________________________________________ 1. Under no circumstances should the engine be started without the operator seated on the mower. 2. Do not operate mower or attachments with loose, damaged, or missing components. Whenever possible mow when gras...

Page 27: Notice

Operation 5 27 5.4 starting________________________________________________________________ 1. Sit in operator’s seat, make sure the mow switch (b) is off (down) and the parking brake switch (c) is engaged. Remove feet from pedals. Always use the seat belt when operating mowers equipped with a rops....

Page 28: Warning

5 operation 28 5.6 to drive / transport____________________________________________________ read and follow all safety notes contained in this manual when driving or transporting mower. When operating in reverse look behind you to ensure you have a clear path. Important: if this mower is driven on p...

Page 29: Warning

Operation 5 29 5.8 mowing speed __________________________________________________________ cutting quality is better at speeds well below the transport speed of the mower. An initial mow speed of 7 mph (11 kph) is set at the factory and should be satisfactory for most cutting conditions. Local turf ...

Page 30

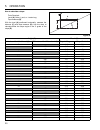

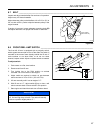

5 operation 30 how to calculate a slope: tools required: level (a) , either 1 yard, or 1 meter long. Tape measure (b) . With the level (a) positioned horizontally, measure the distance (c) with tape measure (b) . Use the chart to calculate either the slope angle or the % grade of the slope (d) . Fig...

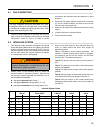

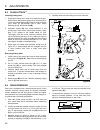

Page 31: Notice

Operation 5 31 5.10 towing / trailering _____________________________________________________ if the mower experiences problems and must be shut down and removed from the area, it should be loaded onto a trailer for transport. If a trailer is not available, the unit can be towed slowly short distanc...

Page 32: Notice

5 operation 32 5.11 daily maintenance _____________________________________________________ important: for more detailed maintenance information, adjustments, and maintenance/lubrication charts, see the parts& maintenance manual. 1. Park the mower on a flat and level surface. Fully lower the cutting...

Page 33: Warning

Maintenance & lubrication charts 6 33 6 maintenance & lubrication charts 6.1 general ________________________________________________________________ 1. Always clean grease fittings before and after lubrication. 2. Lubricate with grease that meets or exceeds nlgi grade 2 lb specifications. Apply gre...

Page 34

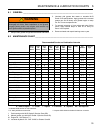

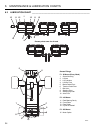

6 maintenance & lubrication charts 34 6.3 lubrication chart _____________________________________________________ 2 3 3 5 6 7 7 8 8 9 10 12 12 11 13 11 13 14 14 14 4 15 1 9 grease fittings f1 - 50 hours (every week) 1 swivel housing 2 lift arm 3 lift cylinders 4 lift arm pivot 5 brake pedal pivot 6 ...

Page 35: Warning

Maintenance 7 35 7 maintenance 7.1 general ________________________________________________________________ 1. Adjustment and maintenance should always be performed by a qualified technician. If proper adjustments cannot be made, contact an authorized jacobsen dealer. 2. Inspect the equipment on a r...

Page 36: Warning

7 maintenance 36 7.4 air filter_______________________________________________________________ check the service indicator daily. If red band appears in the window (b) replace the element. Do not remove the element for inspection or cleaning. Unnecessary removal of the filter increases the risk of i...

Page 37: Caution

Maintenance 7 37 7.7 battery ________________________________________________________________ make absolutely certain the ignition switch is off and the key has been removed before servicing the battery. Tighten cables securely to battery terminals and apply a light coat of silicone dielectric greas...

Page 38: Warning

7 maintenance 38 7.10 muffler and exhaust __________________________________________________ to protect from carbon monoxide poisoning, inspect the complete exhaust system regularly, and always replace a defective muffler. If you notice a change in the color or sound of the exhaust, stop the engine ...

Page 39: Notice

Maintenance 7 39 7.13 hydraulic filters ______________________________________________________ the hydraulic system is protected by two 10 micron filters, a charge filter (b) and return line filter (a) . Flow though the filters is monitored during operation. When pressure drop across the filters is ...

Page 40: Warning

7 maintenance 40 7.15 radiator _______________________________________________________________ check coolant level daily. Radiator should be full and recovery bottle should be up to the cold mark. Drain and refill annually. Remove the radiator cap, open the engine block drain, and the radiator drain...

Page 41: Warning

Maintenance 7 41 7.18 wheel mounting procedure ____________________________________________ 1. Remove dirt, grease, and oil from stud thread. Do not lubricate threads. 2. Position wheel on hub and inspect to insure full contact between mounting surface of wheel and hub or brake drum. 3. Finger tight...

Page 42: Warning

7 maintenance 42 7.20 reel backlapping ______________________________________________________ check the reel and bedknife to determine if backlapping or grinding will restore the cutting edge. If wear or damage is beyond the point where the cutting edges can be corrected by the lapping process, they...

Page 43: Caution

Maintenance 7 43 7.21 storage ________________________________________________________________ general 1. Wash the mower thoroughly and lubricate. Repair and paint damaged or exposed metal. 2. Inspect the mower, tighten all hardware, and replace worn or damaged components. 3. Drain and refill radiat...

Page 44: Warning

8 adjustments 44 8 adjustments 8.1 general ________________________________________________________________ 1. Adjustments and maintenance should always be performed by a qualified technician. If proper adjustment cannot be made, contact an authorized jacobsen dealer. 2. Replace, do not adjust, worn...

Page 45: Caution

Adjustments 8 45 8.3 bedknife adjustment ___________________________________________________ read section 8.2 before making the adjustment. Start adjustment at leading end of reel, followed by the trailing end. The leading end of the reel blade is that end which passes over the bedknife first during...

Page 46

8 adjustments 46 8.5 flash attach ™ _________________________________________________________ installing cutting units 1. Place each cutting unit in front of its respective lift arm. Raise lift arm and position cutting unit so that yoke (t) is in line with swivel housing (s) . Carefully lower arm on...

Page 47: Notice

Adjustments 8 47 8.7 belt ____________________________________________________________________ inspect and adjust new belt after first ten hours of operation. Adjust every 100 hours thereafter. Adjust alternator pulley so belt deflects 1/4 to 5/16 in. (0.6 to 0.8 cm) with a 20 lb. Push at midpoint b...

Page 48

8 adjustments 48 8.9 steering toe-in _________________________________________________________ 1. Turn wheels to straight ahead position. 2. Loosen jam nuts (j) on both sides of tie rod (m) . 3. Turn tie rod (m) to provide proper toe-in. Toe-in must not exceed +1/16 in. (0.15 cm) (k) . Retighten jam...

Page 49

Adjustments 8 49 8.11 armrest pivot __________________________________________________________ 1. Tighten or loosen pivot plunger (w) as required so plunger button stops the armrest at both ends of armrest pivot slots, and plunger body does not contact armrest pivot. Do not use plunger to increase p...

Page 50: Notice

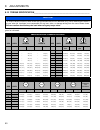

8 adjustments 50 8.12 torque specification___________________________________________________ jacobsen uses grade 5 plated bolts as standard, unless otherwise noted. For tightening plated bolts, use the value given for lubricated. Notice all torque values included in these charts are approximate and...

Page 51

Troubleshooting 9 51 9 troubleshooting 9.1 general ________________________________________________________________ the troubleshooting chart below lists basic problems that may occur during start-up and operation. For more detailed information regarding the hydraulic and electrical systems contact ...

Page 52

10 quality of cut 52 10 quality of cut 10.1 quality of cut troubleshooting _______________________________________ it is recommended that a “test cut” be performed to evaluate the mower’s performance before beginning repairs. An area should be available where “test cuts” can be made. This area shoul...

Page 53

Quality of cut 10 53 10.3 marcelling _____________________________________________________________ note: arrow indicates direction of travel. Marcelling, like washboarding, is a cyclical pattern of varying cutting heights, resulting in a wave-like cut appearance. In most cases, the wave tip-to-tip d...

Page 54

10 quality of cut 54 10.4 step cutting ___________________________________________________________ note: arrow indicates direction of travel. Step cutting occurs when grass is cut taller on one side of a reel than the other or one cutting unit to another. This is usually caused by mechanical wear or...

Page 55

Quality of cut 10 55 10.5 scalping _______________________________________________________________ note: arrow indicates direction of travel. Scalping is a condition in which areas of grass are cut noticeably shorter than the surrounding areas, resulting in a light green or even brown patch. This is...

Page 56

10 quality of cut 56 10.6 stragglers ____________________________________________________________ note: arrow indicates direction of travel. Stragglers are scattered blades of uncut or poorly cut grass. Probable cause remedy bedknife improperly adjusted. Adjust reel-to-bedknife setting. Dull reel or...

Page 57

Quality of cut 10 57 10.7 streaks ________________________________________________________________ note: arrow indicates direction of travel. A streak is a line of uncut grass. This is usually caused by a nicked or bent bedknife. Probable cause remedy damaged bedknife. Replace bedknife. Damaged or u...

Page 58

10 quality of cut 58 10.8 windrowing ____________________________________________________________ note: arrow indicates direction of travel. Windrowing is the deposit of clippings concentrated at one end of cutting unit(s) or between two cutting units, forming a line in the direction of travel. Prob...

Page 59

Quality of cut 10 59 10.9 rifling or tramlining ___________________________________________________ 10.10mismatched cutting units ______________________________________________ note: arrow indicates direction of travel. Rifling or tramlining is a pattern of varying cutting heights, resulting in a wa...

Page 60

Europe & rest of the world except north & south america ransomes jacobsen limited west road, ransomes europark, ipswich, ip3 9tt english company registration no. 1070731 www.Ransomesjacobsen.Com north & south america jacobsen, a textron company 11108 quality drive, charlotte, nc 28273, usa www.Jacob...