- DL manuals

- Jandy

- Recording Equipment

- AquaLink RS series

- Troubleshooting manual

Jandy AquaLink RS series Troubleshooting manual

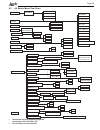

Troubleshooting Data

Troubleshooting Manual

WARNING

FOR YOUR SAFETY - This product must be installed and serviced by a pro fes sion al pool/

spa service technician. The procedures in this manual must be followed ex act ly. Failure to

follow warning notices and instructions may result in property damage, serious injury, or

death.

Pool/Spa Combination Systems

Pool/Spa Only Systems

Dual Equipment Systems

AquaLink

®

RS

All Button and

OneTouch

™

Control Systems

6919E

Summary of AquaLink RS series

Page 1

Troubleshooting data troubleshooting manual warning for your safety - this product must be installed and serviced by a pro fes sion al pool/ spa service technician. The procedures in this manual must be followed ex act ly. Failure to follow warning notices and instructions may result in property dam...

Page 2

Page 2.

Page 3: Table of Contents

Page 3 table of contents section 1. Important safety instructions ........ 4 section 2. Control panel overview ................. 6 2.1 indoor control panel ..........................................6 2.2 controller ...........................................................6 2.3 reset switch ..........

Page 4: Lire La Notice Technique.

Page 4 section 1. Important safety instructions read and follow all instructions lire la notice technique. All electrical work must be performed by a licensed electrician and conform to all national, state, and local codes. When installing and using this electrical equipment, basic safety precaution...

Page 5: Save These Instructions

Page 5 caution a ground-fault circuit-interrupter must be provided if this device is used to control underwater lighting fixtures. The conductors on the load side of the ground-fault circuit-interrupter shall not occupy conduit, boxes, or enclosures containing other conductors unless the additional ...

Page 6

Page 6 section 2. Control panel overview 2.1 indoor control panel the indoor control panel serves as a means of turning equipment on and off, entering programs to run equipment automatically at selected times, and displaying what is going on in the rest of the system. Programs (and other information...

Page 7

Page 7 page up/ onetouch 1 back/ onetouch 2 page down/ onetouch 3 controller 1 controller 2 controller 3 controller 4 w 2 w 1 w 2 w 1 w 2 w 1 w 2 w 1 jumper settings for multiple controllers cancel delay button* reset switch* highlight bar moves high- lighted bar up or down selects highlighted items...

Page 8: Section 3. Controller

Page 8 section 3. Controller 3.1 diagnostics the aqualink system has an internal self-checking process, which can display its current status on the indoor control panel. Use the following steps to get to this "diagnostics" information: 1. All button: use the buttons along the lower left side of the ...

Page 9

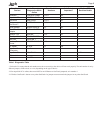

Page 9 table 1. Diagnostics table possible online devices as shown in diagnostics while online possible unit numbers unit order* important? Earliest ppd revision usable all button control panel 1,2,3,4 no* c aqualink pc control panel 4 4 yes** c onetouch onetouch 1,2,3,4 no i wireless onetouch*** on...

Page 10

Page 10 3.2 controller troubleshooting 3.2.1 display is not illuminated check the voltage between the red and green wires at the red terminal bar (terminals 1 and 4). If the voltage is between 8 and 10 vdc, check the polarity. The red wire is positive (+) and the green wire is negative (-). If the v...

Page 11

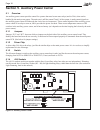

Page 11 s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fil ter pum p au x 1 au x 2 aux 3 aux 4 au x 5 au x 6 au x 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill auto red wire green wire figure 5. Checking voltage at red terminal bar figure...

Page 12

Page 12 3.2.2 control not communicating with power center pcb the following conditions indicate that the control is not communicating with the power center pcb: 1. All button control: all the circuit leds are illuminated and the display is locked on a part number and revision letter. 2. Onetouch con...

Page 13

Page 13 3.3 heater operation the pool and spa heater led and the solar led are two-color leds. Green indicates the heater is enabled but not on. Red indicates the signal to the heater relay is being sent. A heater or solar led will remain green for the following reasons: 1. Thermostat setting has be...

Page 14: Section 4. Power Center

Page 14 section 4. Power center 4.1 overview the power center pcb is the true brain of the system. The micro-controller on the pcb is constantly sending signals through the communication wires to the control panel and polling the system to determine which circuits should be on and which should be of...

Page 15

Page 15 4.2 power center troubleshooting 4.2.1 loss of power check the power center transformer for the proper voltage. 1. Disconnect the transformer from the power center pcb. Check the voltage on the secondary transformer (the two (2) outside yellow wires). The two (2) outside wires provide the 24...

Page 16

Page 16 4.3 main power center pcb 4.3.1 pcb circuit layout 1. Jva relays (k2 - k5) 2. Low voltage heater relay 3. 3.15 amp fuse. Fuse will blow to protect the transformer when there is a short circuit in the jva(s) or the circuit board driver chip is damaged. 4. Cpu board 5. U2 communication chip. T...

Page 17

Page 17 4.3.2 pcb voltages 1. From power center to controller, between terminals one (1) and four (4) of the two (2) red terminal blocks = 8 to 10 vdc. 2. To jva 2444 = 24 to 28 vac*. 3. To relay coils = 24 to 32 vdc*. 4. Transformer primary = 105 to 130 vac. 5. Transformer secondary = 24 to 28 vac....

Page 18

Page 18 section 5. Auxiliary power center 5.1 overview an auxiliary power center provides control for systems that need to run more relays (and/or jvas) than can be handled by the main power center. The main one is still the central "brain" of the system; it sends control signals to the auxiliary po...

Page 19

Page 19 5.2 dip switches all dip switches are located on the left side of the power center bezel. To change a setting, turn off the power and move the approprate switch from left (off) to right (on). S1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fil ter pump au x 1 au...

Page 20

Page 20 table 3. Pool or spa only controls table 4. Dual equipment controls dip switch # off on 1 aux. 1 = any equipment aux. 1 = pool cleaner 2 aux. 2 = any equipment aux. 2 = low speed for a two speed fi lter pump. Filter pump circuit becomes high speed. 3 aux. 3 = any equipment aux. 3 = spa spill...

Page 21

Page 21 5.3 water temperature sensor 5.3.1 troubleshooting when the power center pcb is put in service or time out mode, the thermostat setting will automatically be switched to 104° f for testing. If the heater circuit is activated and the water heater temperature is less than 104° f, the led above...

Page 22

Page 22 s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fil ter pump au x 1 au x 2 au x 3 au x 4 aux 5 au x 6 au x 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill auto to solar sensor to air sensor to water sensor solar sensor part numbers 7...

Page 23

Page 23 5.4 3 hp relay 5.4.1 operation 1. A standard 3 hp relay's coil is supplied with 24 vdc from the power center pcb via one (1) of the driver chips. When 24 vdc is received by the relay's coil wires, it closes the contacts that complete the circuit to turn on the equipment (i.E., power supplied...

Page 24

Page 24 s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fil ter pump aux 1 au x 2 au x 3 au x 4 au x 5 aux 6 au x 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill auto s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time ...

Page 25

Page 25 5.5 two speed relay 5.5.1 operation 1. The two speed relay operates in conjunction with a standard relay to operate a two speed pump/motor. The standard relay is the on/off relay and the two speed relay is the switching relay. Activating the relay coil for the standard relay will complete th...

Page 26

Page 26 s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fil ter pum p au x 1 au x 2 au x 3 au x 4 au x 5 au x 6 au x 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill auto s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service ti...

Page 27

Page 27 5.6 light dimming relay 5.6.1 operation the controller signals the light dimming relay to turn "fully on", "partially dimmed", or "completely off" by sending a specifi c number of pulses in a set period of time to the light dimming relay. The circuitry of the light dimming relay, which requi...

Page 28

Page 28 s1 s2 6 5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 4 3 2 1 4 3 2 1 reset service time out fi lt er p um p aux 1 au x 2 au x 3 aux 4 au x 5 au x 6 au x 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill figure 20. Wiring 120 v light dimming figure 21. Wiring low voltage light di...

Page 29

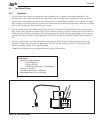

Page 29 section 6. Jandy valve actuator 6.1 operation one leg of a 24 vac transformer secondary supplies voltage to the common terminal of a spdt (single-pole, double- throw) relay. The n.C. (normally closed) terminal of that relay is connected to the red wire of the jva cord, and the n.O. (normally...

Page 30

Page 30 figure 23. Jva internal wiring.

Page 31

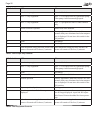

Page 31 section 7. Troubleshooting 7.1 quick check list table 6. Quick check list. Symptom problem possible solution power center override switches operate when in service or time out mode, but the controller is completely dead. No lights on, no display. Mis-wired four (4) conductor wires. Broken fo...

Page 32

Page 32 table 6. Quick check list (continued) symptom problem possible solution system sometimes does not run pro- grammed on and off times. Power outage with dead battery. At the controller, check battery level. With software level rev. F or newer, battery status is located in diagnostics section o...

Page 33

Page 33 remove, align and carefully reinstall the fi rmware chip. Test system, if still not operable, replace power center pcb and fi rmware chip. If fuse blows again: pcb is damaged. If fuse doesn't blow, driver chips are bad. Replace appro- priate compo- nent. Check voltage on red terminal bar bet...

Page 34

Page 34 yes no check controller operation. Are multiple controllers installed? 7.3 all lights lit on controller go to the power center. Switch from auto to ser- vice. Do power center override switches operate? Go to the in house controller. Check reset button on the left side of the controller for d...

Page 35

Page 35 7.4 some controller buttons do not operate yes yes no press button that does not operate. Does the display read locked? Go to the power cen- ter and look at the led above the button. Is the led on? Some buttons on controller do not operate (leds for those buttons don't light). Press reset bu...

Page 36

Page 36 7.5 three amp fuse keeps failing yes no yes no disconnect all jvas and replace fuse. Does fuse fail again? Three amp fuse on the power center pcb keeps failing. Turn off power and remove both relay driver chips. Replace the fuse and turn on power. Does fuse fail again? Check jva cords. Are j...

Page 37

Page 37 7.6 heater doesn't fire heater doesn't fi re. Note: before proceeding, check controller display. If the display reads "shorted" or "open" on water temperature sensor, check the water temperature sensor resistance (see chart on page 10). Yes no go to the power center. Switch from auto to serv...

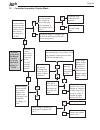

Page 38: Section 8. Flow Charts

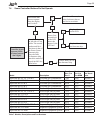

Page 38 section 8. Flow charts 8.1 onetouch menu flow chart menu/help temp calibrate in floor clean solar heat priority † assign jvas dimmers** spa switch** spa link** product info clear memory intake return cleaner solar 1 2 3 ok go back enabled disabled enabled disabled set temp degrees f/c fahren...

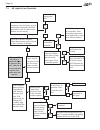

Page 39

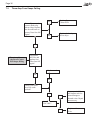

Page 39 8.2 all button menu flow chart t items seen only with optional equipment * items seen only in revision "m" ** not available on export models review program select equipment on all days set temp pool temp spa temp set time set year, day hour & minute lockouts system spa switch spa link device...

Page 40

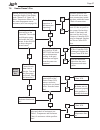

Page 40 8.3 all button cancel flow chart cancel button programs frz protect aux label lockouts dimmers* jva assign cancel some cancel all label removed system spa switch spa link device unlocked no jvas assigned to auxs select aux to remove label from select device to be cancelled press enter to rem...

Page 41: Warning

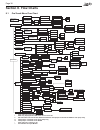

Page 41 section 9. Wiring diagrams 9.1 aqualink rs pool/spa combination and pool/spa only sheet #7192, rev. H 6000 condor drive • moorpark, ca usa 930201 707.776.8200 • fax 707.763.7785 litho in usa © jandy pool products, inc. 0703 important installation instructions: enclosure: rainproof (type 3r, ...

Page 42: Warning

Page 42 9.2 aqualink rs dual equipment auto service time out mode normal operation. Leave the system in this mode unless you are servicing the pool or the system. Power center buttons (above) do not work. Mode in-house controller is locked out. Allows manual operation of equipment using the buttons ...

Page 43

Page 43 9.3 aqualink rs auxiliary power center aux b 1 r elay aux b 4 r elay aux b 2 r elay line on e low v o lt age raceway (do not run high vol tage wire in this comp artment ) line tw o load on e load tw o aux b 3 r elay grounding bar wire nut to 120 va c p ower system powe r aux b 1 jv a aux b 3...

Page 44

Page 44 figure 25. Power center bezel options section 10. Power center bezel reset auto service time out fil ter pump au x 1 aux 2 au x 3 au x 4 au x 5 au x 6 aux 7 rs6 & rs8 only rs8 only heater solar pool mode spa mode spa drain spa fill 6762 reset auto service time out po o l pump au x 1 aux 2 au...

Page 45

Page 45 notes.

Page 46

Page 46 notes.

Page 47

Page 47 notes.

Page 48: Limited Warranty

Limited warranty thank you for purchasing jandy pool and spa products. Jandy pool products, inc. Warrants all parts to be free from manufacturing defects in materials and workmanship for a period of one (1) year from the date of retail purchase, with the following exceptions: • aqualink ® rs units i...