Summary of 423S -

Page 1

Models 419s & 423s.

Page 2: Danger

Important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the followings: read all instructions before using this appliance. Danger – to reduce the risk of electric shock: 1. An appliance should never be left unattended when plugg...

Page 3

1 table of contents section 1. Essential parts name of parts .................................................................................................................................... 2 section 2. Getting ready to sew extension table ...........................................................

Page 4

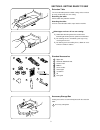

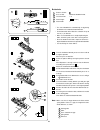

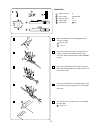

2 section 1. Essential parts name of parts 1 reverse stitch button 2 pattern selector dial 3 stitch width control 4 stitch length control 5 bobbin winder stopper 6 bobbin winder spindle 7 spool pins 8 bobbin winder thread guide 9 thread guide 10 thread take-up lever 11 thread tension dial 12 pressur...

Page 5

3 extension table the extension table provides added sewing surface and can be easily removed for free arm sewing. Detaching the table: pull the table away from the machine. Attaching the table: push the extension table until it snaps into the machine. Advantages and uses of free arm sewing: Å[ avoi...

Page 6

4 connecting the machine to the power supply before connecting the power cord, make sure the voltage and frequency shown on the machine conform to your electrical power. 1. Turn off the power switch. 2. Insert the machine plug into the machine socket. 3. Insert the power supply plug into the outlet ...

Page 7

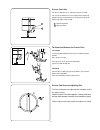

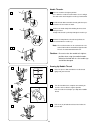

5 to attach and remove the presser foot to remove turn the handwheel toward you to raise the needle to its highest position. Raise the presser foot. Press the lever on the back of the foot holder. The presser foot will drop off. To attach place the presser foot so the pin on the foot lies just under...

Page 8

6 thread and needle chart fabrics thread needle size crepe de chine, voile, fine silk 9/65 lawn, organdy, fine cotton or georgette, fine synthetic 11/75 tricot fine cotton covered polyester linens, cotton, pique, 50 silk 11/75 serge, double knits, 50 to 80 cotton or percale 50 to 60 14/90 synthetic ...

Page 9

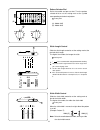

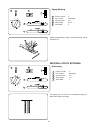

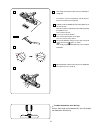

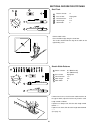

7 removing or inserting the bobbin case open the hook cover. Raise the needle by turning the handwheel toward you. Take out the bobbin case by holding the latch. When inserting the bobbin case, place the horn into the recess of the hook race. Hook cover latch horn 1 2 3 3 2 1 setting spool pins the ...

Page 10

8 threading bobbin case 1 place the bobbin into the bobbin case. Make sure the thread unwinds in the direction of arrow. 2 pull the thread into the bobbin case slot. 3 draw the thread under the tension spring and into the delivery eye. * leave about 10 cm (4") of free thread. Winding the bobbin 1 dr...

Page 11

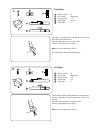

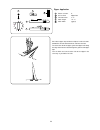

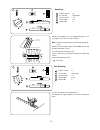

9 threading the machine raise the take–up lever to its highest position by turning the handwheel toward you. Raise the presser foot. Place a spool on the spool pin as shown, with thread coming from back of the spool. 1 draw the thread into thread guide. 2 while holding the thread near spool, draw th...

Page 12

10 drawing up bobbin thread 1 raise the presser foot and hold the needle thread lightly with your left hand. 2 turn the handwheel one complete turn toward you and raise the needle to its highest position. Pull the needle thread to pick up a loop of the bobbin thread. 3 pull 15 cm (6") of both thread...

Page 13

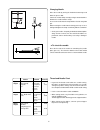

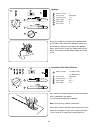

11 balancing needle thread tension 1 2 3 4 5 6 1 correct tension the thread tension is adjusted depending on the sewing materials, layers of fabric and other sewing conditions. * the ideal straight stitch has threads looked between two layers of fabric, as illustrated (magnifies to show detail). * f...

Page 14

12 slide the stitch length control to set the setting mark at the desired stitch length. The higher the number, the longer the stitch setting mark pattern selector dial stitch length control " " is the recommended setting for buttonhole stitching. Adjust the stitch length control in the 0.5–4 range ...

Page 15

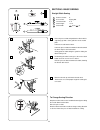

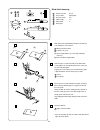

13 reverse stitch button as long as you keep the reverse stitch button depressed, the machine sews backwards. Dropping the feed dog 1 remove the extension table. Raise the presser foot. 2 to drop the feed dog, push the lever to the right . 3 to raise the feed dog, push the lever to the left. * the f...

Page 16

14 pattern selector: a presser foot: zigzag foot thread tension: 2–6 stitch length: 1.5–4 stitch width: (0) or (5) section 3. Basic sewing straight stitch sewing 1 raise the presser foot and position the fabric with its edge lining up with a seam guide line on the needle plate. Lower the needle into...

Page 17

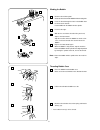

15 seam guides line the numbers on the needle plate indicate the distance between the center needle position and the line. The numbers in front are millimeters. The numbers in back are fractions of an inch. Variable needle position 0 1 2 3 4 5 when the straight stitch (pattern a) is selected, you ca...

Page 18

16 zigzag stitching simple zigzag stitching is widely used for overcasting, sewing on buttons etc. Pattern selector: c presser foot: zigzag foot thread tension: 2–5 stitch length: 0.5–4 stitch width: 5 1 2 3 4 4 1 2 3 section 4. Utility stitching overcasting the zigzag stitch is used on the seam all...

Page 19

17 1 2 3 4 1 2 3 4 tricot stitch pattern selector: d presser foot: zigzag foot thread tension: 1–4 stitch length: 0.5–1.5 stitch width: 5 4 1 2 3 knit stitch pattern selector: g presser foot: zigzag foot thread tension: 1–4 stitch length: s.S. Stitch width: 5 4 1 2 3 this stitch is used to finish th...

Page 20

18 1 2 3 4 straight stretch stitch pattern selector: a presser foot: zigzag foot thread tension: 2–6 stitch length: s.S. Stitch width: (0) or (5) 4 1 2 3 the stitch is sewn with two stitches forward and one stitch backward forming a seam that does not rip easily. 5 5.

Page 21

19 sewing on buttons 1 2 3 pattern selector: c presser foot: zigzag foot thread tension: 1–3 stitch length: any stitch width: adjust as necessary feed dog: dropped 4 1 2 3 5 4 5 6 6 1 2 3 4 5 1 push the drop feed lever to the right to lower the feed dog. Set the pattern selector dial at "c" and stit...

Page 22

20 buttonhole pattern selector: presser foot: automatic buttonhole foot thread tension: 1–5 stitch length: (0.5–1) stitch width: 5 4 1 2 3 4 1 2 3 5 5 1 2 3 4 5 6 1 turn the handwheel toward you to raise the needle to its highest position. Raise the presser foot lifter. 2 select the pattern "bh" by ...

Page 23

21 0 1 2 3 4 s.S. To adjust buttonhole stitch density. Set the stitch length control between 0.5 and 1.0 to adjust the buttonhole stitch density. 9 sew slowly and stop the machine when a buttonhole is completed. * the machine sews the front bartack and left row first, then the back bartack and right...

Page 24

22 1 use the same procedure as automatic buttonhole. * set the stitch width to match with the thickness of the cord used. With the buttonhole foot raised, hook the filler cord on the spur at the back of the buttonhole foot. Bring the ends toward you under the buttonhole foot, clearing the front end....

Page 25

23 zipper application pin or baste zipper tape to fabric and place it under the foot. Smooth the threads toward the back and lower the foot. To sew the left side of the zipper, guide the zipper teeth along the edge of the foot and stitch through the garment and zipper tape. Turn the fabric and sew t...

Page 26

24 blind stitch hemming 1 2 4 1 2 4 3 pattern selector: e or f presser foot: zigzag foot thread tension: 2–4 stitch length: 1–3 stitch width: 5 hem guide 4 1 2 3 3 2 1 5 2 1 [a] [b] 3 4 5 1 fold up the hem and fold it back to from a 0.4 to 0.7cm (1/4") allowance as illustrated. 1 2 3 4 5 wrong side ...

Page 27

25 rolled hem pattern selector: a presser foot: hemmer foot thread tension: 2–6 stitch length: 1.5–4 stitch width: (5) 4 1 2 3 5 1 make a double 0.25 cm (1/8") fold approximately 8 cm (3") in length. 0.25 cm (1/8") 8 cm (3") 2 lower the needle into the fabric at the point where sewing is to begin, t...

Page 28

26 shell tuck pattern selector: g presser foot: zigzag foot thread tension: 6–8 stitch length: 2–3 stitch width: 5 4 1 2 3 section 5. Decorative stitching 4 1 2 3 4 1 2 3 stretch stitch patterns pattern selector: a–j (model 419s) a–l (model 423s) presser foot: zigzag foot thread tension: 1–4 stitch ...

Page 29

27 smocking pattern selector: d presser foot: zigzag foot thread tension: 1–4 stitch length: s.S. Stitch width: 5 4 1 2 3 with the stitch length at "4", sew straight stitching lines 1 cm (3/8") apart, across the area to be smocked. Note : loosen the needle thread tension to make gathering easier. Kn...

Page 30

28 applique pattern selector: c presser foot: zigzag foot thread tension: 1–4 stitch length: 0.5–1 stitch width: 5 presser dial: 2 4 1 2 3 5 2 3 baste (or fuse with iron-on fabric joiner) applique pieces on the fabric. Stitch around the applique making sure the needle falls along the outer edge of t...

Page 31

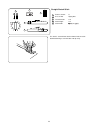

29 cleaning the feed dog remove the needle and the presser foot. Remove the needle plate set screw and remove the needle plate. With a brush, clean out dust and lint clogging on the feed dog teeth. Reset the needle plate. Note : turn off the power switch and/or unplug the machine before cleaning the...

Page 32

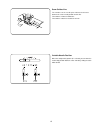

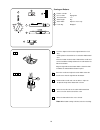

30 oiling the machine note:turn off the power switch when oiling the machine. Oil the points as shown at least once a year. Use good quality sewing machine oil. One or two drops of oil is sufficient. Wipe off excess oil, otherwise it may stain fabric. If machine has not been used for an extended tim...

Page 33

31 see page 9 see page 11 see page 6 see page 6 see page 14 see page 6 see page 8 clean the bobbin case. Exchange bobbin. See page 6 see page 6 see page 6 see page 11 see page 14 see page 6 see page 12 see page 6 see page 6 see page 6 see page 6 see page 9 see page 11 see page 9 see page 6 make the ...

Page 34

Printed in taiwan 303-800-051.