- DL manuals

- Janome

- Sewing Machine

- 423S -

- Servicing Manual

Janome 423S - Servicing Manual

Summary of 423S -

Page 1

Servicing manual 419s/423s 415.

Page 2: Troubleshooting

1 troubleshooting problem cause remedy reference 1. Skipping 1. Needle is not inserted insert the needle properly. Stitches properly. 2. Needle is bent or worn. Change the needle. 3. Incorrectly threaded rethread. 4. Needle or thread are use the recommended inappropriate for sewing needle and thread...

Page 3

2 problem cause remedy reference 3. Breaking 1. Initial sewing speed is start with medium speed. Upper too fast. 2. Thread path is use the proper thread incorrect. Path. 3. Needle is bent or dull. Replace with a new needle. 4. Upper thread tension is adjust upper thread p. 7 too strong. Tension corr...

Page 4

3 problem cause remedy reference 6. Noisy 1. Backlash between see mechanical p. 13 operation shuttle hook gear and adjustment “clearance lower shaft gear is too between needle and hook great. (no. 2).” 2. Lower shaft gear is eliminate the looseness. Loose. 3. Inappropriate belt see mechanical p. 24 ...

Page 5: Contents

Contents troubleshooting ........................................................................................... 1–3 service access face cover / top cover .............................................................. 4 belt cover ....................................................................

Page 6: Service Access

4 service access face cover (to remove) 1. Remove the face cover by removing the cap (a) and screw (b). (to attach) 2. Attach the face cover with the screw, and then, replace the cap. Face cover (b) (a) top cover (to remove) 1. Remove the face cover. 2. Loosen the setscrew (c) and reme setscrews (d)...

Page 7: Service Access

5 base (to remove) 1. Remove the face cover, top cover (see page 4) and belt cover. 2. Remove 6 screws (b). 3. Remove the base. (to attach) 4. Follow the above procedure in reverse. Belt cover 1. Remove the face cover and top cover (see page 4). 2. Loosen screw (a). 3. Take the belt cover out. (to a...

Page 8: Service Access

6 service access front cover (to remove) 1. Remove the face cover, top cover, belt cover and base (see pages 4-5). 2. Remove the pattern selector dial. 3. Loosen setscrews (a) and (b), and then, remove the front cover by removing setscrews (c) and (d). (to attach) 4. Follow the above procedure in re...

Page 9: Mechanical Adjustment

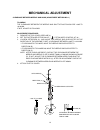

7 mechanical adjustment top tension to check: the standard upper thread tension should be 65–95 g when pulling the thread (cotton thread #50) in the direction of (a) with the tension dial at “3.” (make sure the foot is lowered.) if the tension is out of the standard range, adjust it as follows: adju...

Page 10: Mechanical Adjustment

8 mechanical adjustment bobbin tension to check: set the bobbin in the bobbin case and pass the thread (cotton #50) through the tension spring. The bobbin thread tension should be 45–55g when pulling the thread in the direction of (a). If the tension is out of this range, adjust it as follows: adjus...

Page 11: Mechanical Adjustment

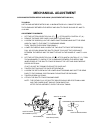

9 mechanical adjustment presser bar height and alignment to check: 1. Raise the presser foot lever (a). 2. The distance between the presser foot (c) and the needle plate (d) should be 6.0 mm (0.24"). Adjustment procedure: 1. Remove the face cover (see page 4). 2. Raise the presser foot lever and loo...

Page 12: Mechanical Adjustment

10 mechanical adjustment needle swing to check: when sewing the zigzag pattern (with maximum zigzag width), if the needle bar starts moving sideways while the needle is in the fabric, adjust the needle swing according to the following procedure. Adjustment procedure: 1. Set the pattern selector dial...

Page 13: Mechanical Adjustment

11 mechanical adjustment needle drop to check: when the needle swings in maximum zigzag width, the distance between both ends of the needle hole on the needle plate and the needle drop positions should be equal. If not, adjust as follows: adjustment procedure: 1. Remove the face cover (see page 4). ...

Page 14: Mechanical Adjustment

12 mechanical adjustment clearance between needle and hook (adjustment method no. 1) to check: the clearance between the needle and shuttle race should be –0.05 to +0.10 mm. If not, adjust as follows: adjustment procedure: 1. Remove the top cover (see page 4). 2. Set the pattern selector dial at ( )...

Page 15: Mechanical Adjustment

13 mechanical adjustment clearance between needle and hook (adjustment method no.2) to check: use this adjustment method no. 2 when method no.1 cannot be used. The clearance between the needle and shuttle race should be –0.05 to +0.10 mm. Adjustment procedure: 1. Set the pattern selector dial at ( )...

Page 16: Mechanical Adjustment

14 mechanical adjustment feed dog height to check: 1. Lower the presser foot. 2. Turn the handwheel toward you to bring the feed dog to its heighest position. The height of the feed dog from the needle plate should be 0.75 to 0.90 mm. If it is not in the range, adjust as follows. Adjustment procedur...

Page 17: Mechanical Adjustment

15 mechanical adjustment needle bar height to check: when the tip of shuttle hook meets the left side of the needle in ascending travel of the needle from its left and lowest position, the distance between the top of the needle eye and the tip of the shuttle hook should be in the range of 2.9–3.5mm....

Page 18: Mechanical Adjustment

16 mechanical adjustment needle timing to shuttle to check: the height of the needle point from its lowest point should be in the range of 1.45–1.95 mm when the tip of the shuttle hook meets the left side of the needle at the left needle position in ascending travel. Adjustment procedure: 1. Set the...

Page 19: Mechanical Adjustment

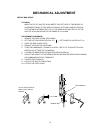

17 mechanical adjustment buttonhole feed balance to check: when sewing a buttonhole, the stitches on each side of the buttonhole should be of the same stitch density. A range of 9–12 stitches in the “backward feeding” (right side row) against 10 stitches in the “forward feeding” (left side row) is c...

Page 20: Mechanical Adjustment

18 mechanical adjustment feed balance on stretch stitch to check: if the stretch stitch patterns are distorted when setting the stitch length control at "s.S." (there is a difference between forward feeding and backward feeding, adjust as follows: adjustment procedure: 1. Remove the top cover (see p...

Page 21: Mechanical Adjustment

19 mechanical adjustment bartack feed of buttonhole to check: if the material is fed forward or backward when sewing the bartack on a buttonhole, adjust as follows: adjustment procedure: 1. Set the pattern selector dial at ( ), and the stitch length control at ( 4 ). 2. Remove the top cover (see pag...

Page 22: Mechanical Adjustment

20 mechanical adjustment disengagement of cam follower to check: if the clearance between the cam follower and the top convex of the zigzag cam is not enough, the pattern selector dial is blocked or will not select the correct pattern. Adjustment procedure: 1. Set the pattern selector dial at ( ) an...

Page 23: Mechanical Adjustment

21 needle in straight stich sewing to check: if the needle swings when running the machine with zigzag stitch ( ) at width "0", correct it as follows: at the straight stitch sewing, adjust it as follows: 1. Set the pattern selector dial at ( ) and stitch width control at (0). 2. Remove the front cov...

Page 24: Mechanical Adjustment

22 mechanical adjustment (for model 419s/423s) buttonhole length to check: buttonhole should be about 3 mm longer than the length set by r foot. If the buttonhole length is out of standard range, check and adjust as follows. Adjustment procedure: 1. Remove the face cover (see page 4). 2. Turn the ad...

Page 25: Mechanical Adjustment

23 mechanical adjustment motor belt tension to check: 1. Improper belt tension may cause noise, overload of motor, slow running or motor belt jumping. 2. The belt deflection should be 7mm –9mm when pressing the middle of the motor belt with approximately 300 grams of pressure. Adjustment procedure: ...

Page 26: Wiring

24 wiring (for 110-120v) from lamp socket from motor from motor from lamp socket (for 220-240v).

Page 27: Parts List

Parts list model (423s, 419s).

Page 28: Parts List

Parts list 1 3 2 4 5 6 7 8 9 10 10 11 11 12 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 19 8 43 43 44 45 46 46 46 47 48 49 1.

Page 29: Parts List

Parts list key part no. No. Description 1 303602006 top cover unit 2 303009007 top cover 3 730501011 thread guide plate unit 4 000160102 adjustable nut 4 5 735016307 bobbin winder stopper 6 000101828 setscrew 4x16 7 000071013 plain washer 8 000061205 nut 9 303010001 carrying handle 10 730015002 hand...

Page 30: Parts List

Parts list 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 5 34 5 8 9 (120v) 1 2 3 4 5 5 6 7 5 8 9 35 36 37 38 39 40 41 42 5 44 43 45 46 46 47 48 49 50 51 52 53 54 55 41 42 56 57 5 3.

Page 31: Parts List

Parts list key parts no. No. Description 1 303626006 front bracket unit (australia, u.K. & continental europe) 303627007 front bracket unit (u.S.A. & canada) 2 303018010 front bracket (australia, u.K. & continental europe)) 303068015 front bracket (u.S.A. & canada) 3 303019000 tension release lever ...

Page 32: Parts List

Parts list 1 2 3 4 5 6 6 7 8 11 10 9 12 13 14 15 16 17 18 19 20 23 22 21 24 25 26 27 28 18 29 30 31 32 33 34 35 36 26 37 5.

Page 33: Parts List

Parts list key parts no. No. Description 1 303604008 needle bar supporter unit 2 303020107 needle bar supporter 3 730022002 needle bar supporter pin 4 673022002 spring washer 5 000070609 plain washer 6 6 000002507 snap ring e-4 7 000111902 hexagonal socket screw 3x4 8 303605009 needle threader shaft...

Page 34: Parts List

Parts list 1 2 3 4 5 8 8 7 6 6 9 10 11 12 13 14 15 16 17 18 19 20 21 22 7.

Page 35: Parts List

Parts list key parts no. No. Description 1 303608002 upper shaft (unit) 2 102073003 screw 3 102063000 screw 4 000111304 hexagonal socket screw 5x5 5 553245008 hexagonal socket screw 6 000111108 hexagon socket screw 4x6 7 743029009 felt 8 731312005 felt 9 732003003 upper shaft rear bushing 10 7386340...

Page 36: Parts List

Parts list 1 2 3 4 4 7 8 9 10 11 12 13 14 14 14 15 16 17 18 19 20 21 22 23 24 7 25 26 27 28 29 30 31 31 32 32 33 34 31 5 5 6 6 9.

Page 37: Parts List

Parts list key parts no. No. Description 1 303625005 zigzag mechanism unit 303625108 zigzag mechanism unit (model 419s) 2 303028002 index spring 3 303051004 index spring 4 000078319 setscrew 3x6 5 000101404 setscrew 4x6 6 000115205 tp screw 4x6 7 000081005 setscrew 4x8 8 810220003 setscrew 9 3030520...

Page 38: Parts List

Parts list 1 7 8 9 11 4 12 13 14 10 2 3 4 4 5 6 4 4 4 15 16 17 10 18 19 20 21 22 11.

Page 39: Parts List

Parts list key parts no. No. Description 1 640603104 hook race unit 2 640503000 hook race unit 3 532096007 hook 4 000111304 hexagonal socket screw 5x5 5 647515006 bobbin case unit 6 102261000 bobbin 7 640018003 hook driver shaft bushing 8 626045407 cap 9 735064001 crank rod pin 10 000110107 hexagona...

Page 40: Parts List

Parts list 26 19 3 5 12 7 1 2 4 6 8 9 11 10 13 14 15 16 17 18 16 20 21 22 23 24 25 27 28 29 18 32 30 8 31 13.

Page 41: Parts List

Parts list key part no. No. Description 1 730611004 feed rock shaft unit 2 730057006 feed rock shaft 3 647066007 feed dog base 4 647134007 feed dog base shaft 5 648019008 feed dog base sliding plate 6 102021202 setscrew 7 000002507 snap ring e-4 8 000111108 hexagon socket screw 4x6 9 730184003 feed ...

Page 42: Parts List

Parts list 1 2 3 4 5 6 7 8 9 10 15.

Page 43: Parts List

Parts list key parts no. No. Description 1 739503308 machine socket unit (australia, u.K. & continental europe) 739505403 machine socket unit (u.S.A. & canada) 2 000060802 nut 3 739037007 machine socket cover 4 000107802 tapping screw 3x10b 5 000103509 setscrew 4x10 6 303615002 motor unit (australia...

Page 44: Parts List

Parts list 1 2 3 4 5 6 7 8 9 10 11 12 13 17.

Page 45: Parts List

Parts list key parts no. No. Description 1 303870018 accessory set 2 653802002 screw driver 3 741814003 oil 4 102261000 bobbin 5 647808009 seam ripper/buttonhole opener 6 540401026 needle set 7 740801004 automatic buttonhole foot 8 743815000 hemmer foot 9 611406002 zipper foot 10 674401002 hem guide...