- DL manuals

- Janome

- Sewing Machine

- MC 300E -

- Service Manual & Parts List

Janome MC 300E - Service Manual & Parts List

Summary of MC 300E -

Page 1

Service manual & parts list mc300e.

Page 2

Mechanical adjustment changing external parts (1) face cover ................................................................... 1 changing external parts (2) belt cover ..................................................................... 2 changing external parts (3) base cover ......................

Page 3

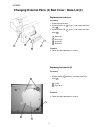

1 mc300e changing external parts (1) face cover to remove: 1. Remove the cap and screw and remove the face cover . Cap screw face cover to attach: 2. Attach the face cover and tighten screw , then attach the cap . Replacing the face cover 3 1 2 1 2 3 3 2 1 1 2 3.

Page 4

2 mc300e changing external parts (2) belt cover replacing the belt cover to remove: 1. Remove the cap and screw (a) . 2. Loosen screw (b) . 3. Lay the machine down on its back and remove screws c and d , then remove the belt cover . Cap screw (a) screw (b) screw (c) screw (d) belt cover to attach: 4...

Page 5

3 mc300e changing external parts (3) base cover replacing the base cover to remove: 1 remove screws (4 pieces) to remove the base cover . Screw base cover to attach: 2 follow the above procedure in reverse. 1 2 1 1 2 1 1 1 2.

Page 6

4 mc300e changing external parts (4) bed cover / base lid (2) replacing the bed cover to remove: 1 remove the base cover. 2 remove screws (a) (2 pcs.), and remove the base lid (1) . 3 remove screws (b) (2 pcs.), and remove the bed cover . Screw (a) base lid (1) screw (b) bed cover to attach: 4 follo...

Page 7

5 mc300e changing external parts (5) base unit base to remove: 1 remove the belt cover. (see page 2) 2 remove screws (a) (4 pcs.), and remove the base unit . 3 disconnect the x motor and y motor connectors from the printed circuit board (a). Screws (a) x-motor connector (blue) y- motor connector (wh...

Page 8

6 mc300e to remove: 1 remove the face cover, belt cover, base cover and bed cover. (see page 1 - 4). 2 remove screw (a) and remove the arm thread guide (lower) . 3 remove screw (b) . 4 loosen screws (c) , (d) . 5 disconnect each connector and remove the front cover. Note: unlock the hooks before rem...

Page 9

7 mc300e changing external parts (7) rear cover 1 remove the face cover and belt cover. 2 loosen screws (a) , and (b) . 3 raise the handle and remove screw (c) , and cap , then remove screw (d) . Remove the rear cover . Screw (a) screw (b) screw (c) cap screw (d) rear cover to attach: 3 follow the a...

Page 10

8 mc300e adjusting needle drop position 1 lower the needle to its lowest position by turning the handwheel. 2 remove the face cover and loosen screw , move the needle bar supporter to the right or left until the needle comes to the center of the needle plate hole . 3 tighten the screw . 4 attach the...

Page 11: Adjusting Hook Timing

9 mc300e adjusting hook timing 1 remove the belt cover, bed cover, base cover, base lid (1) and base lid (2). 2 remove the presser foot, needle plate and bobbin holder . 3 lower the needle bar to its lowest position by turning the handwheel toward you. 4 raise the needle bar further 3.4 mm from the ...

Page 12: Adjusting Needle Bar Height

10 mc300e adjusting needle bar height 1 remove the presser foot, needle plate and bobbin holder . 2 remove the face cover. 3 turn the handwheel to raise the needle bar from the lowest position until the tip of the rotary hook meets with the right side of the needle . 4 loosen screw . 5 move the need...

Page 13

11 mc300e adjusting clearance between needle and hook the clearance between needle and rotary hook should be -0.10 to + 0.05 mm. 1 remove the needle plate, bobbin holder, base cover and bed cover (see page 3 - 4). Replace the needle with the test pin . 2 loosen screws (a) , (b) , (c) and tighten scr...

Page 14: Shaft Gear

12 mc300e adjusting backlash between hook drive gear and lower shaft gear the rotary play of the hook should be 0.8 mm or less. Adjust the backlash after the adjustment of the clearance between needle and rotary hook. A b 1 2 3 to check: 1 turn the power switch “off”. 2 remove the base cover, bed co...

Page 15

13 mc300e adjusting upper shaft shield plate position 1 remove the front cover unit. (see page 6) 2 turn the power switch “on” and press start / stop button twice. Stop the machine with the needle in the up position. 3 (a) if the needle stops higher than 14.2 mm, loosen screw and turn the upper shaf...

Page 16

14 mc300e adjusting needle thread tension the standard upper thread tension should be 51 to 59 grams when the tension dial is set at “3”, measured with a #50 polyester thread being pulled at approximately 110 mm/sec. In the direction of arrow. 1 set the thread tension dial at “3”. 2 lower the presse...

Page 17

15 mc300e adjusting tension release mechanism 1 remove the front cover unit. (see page 6) 2 lower the presser foot lifter, set the thread tension dial at “9” and loosen the screw . 3 adjust the play between the tension release rod (2) and the spring holder approximately 0.3 - 0.5 mm and tighten the ...

Page 18

16 mc300e changing thread tension unit to remove: 1 remove the front cover unit. (see page 6) 2 remove screws (a) , (b) , and remove the thread tension unit. To attach: 3 follow the above procedure in reverse. Note: after the replacement, adjust “thread tension release machanism” and solenoid. Screw...

Page 19

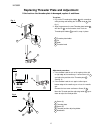

17 mc300e replacing threader plate and adjustment if the hook on the threader plate is damaged, replace it asfollows. 1 2 3 view-x (x) fig. 1 fig. 2 fig. 3 3 1 2 4 5 2 1 4 3 5 to replace: 1 pry out the threader plate holder with screwdriver while pushing and holding the threader knob (see fig.1.). 2...

Page 20

18 mc300e adjusting height of embroidery foot p space between the needle plate and the bottom surface of the foot (p) should be 1.0 to 1.6 mm, when the needle bar is at its lowest position. 1 remove the front cover unit. (see page 6) 2 lower the needle bar and lower the presser foot lifter. 3 insert...

Page 21: Connector Connection Diagarm

19 mc300e connector connection diagarm please see the following connector connection diagram for the printed circuit board a. 5 1 2 3 4 11 12 13 14 10 6 7 8 9 touch panel lcd harness printed circuit board f( black ) bobbin winder sensor ( blue ) upper shaft sensor ( black ) thread detection sensor (...

Page 22

20 mc300e replacing printed circuit board a to remove: 1 remove the front cover. (see page 6) 2 pull out the connectors of printed circuit board f lcd harness, inverter and touch panel. 3 remove screws (5 pieces) and the printed circuit board a with the card guide . To attach: 4 follow the above pro...

Page 23: Replacing Touch Panel

21 mc300e replacing touch panel to remove: 1 remove the front cover. (see page 6) 2 pull out the connectors of printed circuit board f , lcd harness and inverter connector and touch panel connectors . 3 remove screws (4 pieces) and remove the touch panel . To attach: 4 place the touch panel and pres...

Page 24

22 mc300e replacing printed circuit board f to remove: 1 remove the front cover. (see page 6) 2 pull out the connectors from the printed circuit board a. 3 remove screws (2 pieces) and remove the printed circuit board f . To attach: 4 follow the above procedure in reverse. 2 1 screws (2 pieces) prin...

Page 25: Adjusting Solenoid

23 mc300e adjusting solenoid 1. Remove the front cover. (see page 6) 2. Loosen screws (2 pieces). 3. Slide the solenoid to the right most position. 4 tighten screws . 5 to check tension release function a.Turn the power switch “on” while pressing the start/stop button. Touch panel indicates the self...

Page 26

24 mc300e replacing dc motor and motor belt tension adjustment to remove: 1 remove the belt cover. (see page 2) 2 remove the motor belt . 3 disconnect the motor connector from the printed circuit board a. 4 remove screws (a) (2 pieces) and replace the motor. To attach: 5 follow the above procedure i...

Page 27

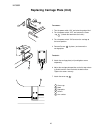

25 mc300e replacing carriage plate (unit) to remove: 1 turn the power switch “on” and select the pattern no.1. 2 turn the power switch “off” and remove the cover cap . (unlock the hook from the inside.) 3 turn the power switch “on” to return the carriage to the home position. 4 remove screws (3 piec...

Page 28: Adjusting X And Y Sensors

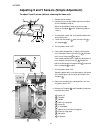

26 mc300e adjusting x and y sensors to adjust x and y sensors: 1 turn the power switch “on” (the carriage is automatically set at starting position.) 2 turn the power switch “off” and then remove the base unit. 3 loosen screw a and move the y-sensor fixing plate to adjust the carriage position. Turn...

Page 29

27 mc300e adjusting x and y sensors (simple adjustment) to adjust x and y sensor (without removing the base unit): 1 remove the base cover. 2 remove the presser foot holder and place the fabric on the embroidery hoop (a). Attach the embroidery hoop (a) on the carriage. (place the template on the emb...

Page 30: Adjusting X Motor Gear

28 mc300e adjusting x motor gear if the machine is noisy when sewing an embroidery design, adjust the x-motor as follows. To remove: 1 remove the base unit (see page 5). 2 remove the presser foot. 3 remove screw (a) and remove the nylon clip from the cords. Adjustment procedure: 4 connect the x ,y m...

Page 31

29 mc300e replacing switching power supply to remove: 1 remove the face cover, belt cover, front cover and rear cover. 2 remove screws (a) ,(b) and remove the machine socket and fixing plate. 3 pull out the machine socket unit connector . 4 remove screw (c) and remove the idler. 5 remove screws (d) ...