- DL manuals

- Jasic

- Welding System

- Cut 160

- Operator's Manual

Jasic Cut 160 Operator's Manual

Summary of Cut 160

Page 1

Wilkinsonstar.Com cut 160 air plasma cutting machine order code ! Jp-160 operator manual.

Page 2: Your New Product

Your new product thank you for selecting this jasic technology, wilkinson star product. This product manual has been designed to ensure that you get the most from your new product. Please ensure that you are fully conversant with the information provided paying particular attention to the safety pre...

Page 3: Safety Precautions

Safety precautions 1 these general safety norms cover both arc welding machines and plasma cutting machines unless otherwise noted. The equipment must only be used for the purpose it was designed for. Using it in any other way could result in damage or injury and in breach of the safety rules. Only ...

Page 4

Do not weld on coated metals, unless the coating is removed from the weld area, the area is well ventilated, and while wearing an air-supplied respirator. The coatings on many metals can give off toxic fumes if welded. Prevention against burns and radiation arc rays from the welding process produce i...

Page 5

Rf declaration equipment that complies with directive 2004/108/ec concerning electromagnetic compatibility (emc) and the technical requirements of en60974-10 is designed for use in industrial buildings and not those for domestic use where electricity is provided via the low voltage public distributi...

Page 6: Product Overview

Product overview 2 features the machine adopts advanced inverter technology. The high inverter frequency of 20khz greatly reduces the size and weight of the cutter. There is a great reduction in magnetic and resistance loss which enhances the cutting efficiency and energy saving effect. A closed loop f...

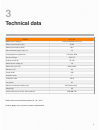

Page 7: Technical Data

Technical data 3 tested at the environment temperature of -10 0 - 40 0 c product design may vary due to customer requirements. 6 model cut 160 rated input voltage (v) three phase 400v ac±15% rated input frequency (hz) 50/60 rated input capacity (kva) 29.2 recommended supply fuse (a) 50 compressed ai...

Page 8: Controls

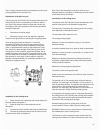

Controls 4 panel layout 7 1 digital meter 6 cutting current adjuster 2 gas selector 7 secondary gas regulator 3 2t/4t (automatic operation) 8 air pressure guage 4 torch connector 9 alarm indicators 5 work return socket.

Page 9

1 2 3 4 5 6 1 air inlet 4 fuse 2 air filter 5 mains input cable 3 fan 6 mains on/off switch.

Page 10: Installation

Installation 5 unpacking check the packaging for any signs of damage. Carefully remove the machine and retain the packaging until the installation is complete. Location the machine should be located in a suitable position and environment. Care should be taken to avoid moisture, dust, steam, oil or c...

Page 11

The air supply pressure should not exceed 8 bar and normal cutting pressure will be around 6 bar. Adjustment of the pilot arc gas the pilot arc gas of cut160 (l307) is appropriately set when leaving factory, and it is unnecessary for users to adjust it any more. If the operator wants to adjust the p...

Page 12

P150lt compatible cebora gas: single • air flow: 220 litres per min • rating: 150 amp @ 60% duty cycle • cutting capacity: 35mm most materials torch packages item nodescription list price each £ c1576lt hand torch 6mt central fitting 670.55 c1578lt hand torch 12mt central fitting 792.15 c1577 machin...

Page 13: Operation

Operation before starting any cutting activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the area. Check that all connections have been made as shown above check the following before starting the machine. 1) chec...

Page 14

Maintenance and troubleshooting 6 the following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. I...

Page 15

14 malfunction cause and solution the gas lack indicator illuminates withyellow. Check and make sure that the gas supplycircuitisconnectedtothepower supply,andthatthegassupplycircuitis poweredon. Checkifthereisgasleakageinthegas supply circuit, and test the pressure of theinputgas. Arccannotbetransf...

Page 16: Parts

Parts 7 15 position part number description position part number description 1 10004622 torch connector 29 10050741 filter protection cover 2 10050737 front panel 30 10050738 rear panel 3 10034377 quick connector 31 10004935 switch 4 10028232 rc module 32 10046896 handle 5 10006523 contactor 33 1000...

Page 18

17.

Page 19

Position part number description position part number description 57 10047376 right cover 68 10035396 igbt connector 58 10045291 fuse holder 69 10047561 igbt heatsink 59 10005913 non inductive capacitor 70 10053633 holder 1 60 10046425 current sampling board 71 10053637 holder 2 61 10016634 bracket ...

Page 20: Order Code !jp-160

Cut 160 air plasma cutting machine order code !Jp-160 © wilkinson star limited issue 1 june 2015 product is subject to change without notice xix.