- DL manuals

- Karcher

- Pressure Washer

- HD 10/25 S USA

- Service Manual

Karcher HD 10/25 S USA Service Manual

Summary of HD 10/25 S USA

Page 1

English 5.905-945.0 rev. 00 (06/15) 1 hd 10/25 s hd 13/18 s service manual.

Page 2

2 english 5.905-945.0 rev. 00 (06/15) 1 contents 2 preface 3 3 safety instructions 3 3.1 hazard levels 3 4 technical features 4 4.1 drive 4 4.2 pump 4 4.3 detergent system 4 4.4 electrical system 4 4.5 electronics system 4 4.6 other features 4 4.7 field of application 5 4.8 type plate 5 5 parts of t...

Page 3

English 5.905-945.0 rev. 00 (06/15) 3 good service work requires extensive and practice-orient- ed training as well as well-structured training materials. Hence we offer regular basic and advanced training pro- grammes covering the entire product range for all service engineers. In addition to this,...

Page 4

4 english 5.905-945.0 rev. 00 (06/15) these ac devices are the new top models among the mo- bile high-pressure cleaners of the super-class devices. Their compact and vertical design allows easy handling and space-saving storage. – 3 piston axial pump, piston with ceramic coating – cylinder head and ...

Page 5

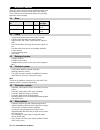

English 5.905-945.0 rev. 00 (06/15) 5 this service manual describes the following appliances: the type plate is located on the rear of the appliance. 1 appliance description 2 connected load 3 part number 4 year of manufacture 5 serial number 6 nozzle size 7 address of manufacturer 8 bar code. Conta...

Page 6

6 english 5.905-945.0 rev. 00 (06/15) 5 parts of the system 5.1 front view 1 mains plug 2 mains connection 3 water connection 4 oil level indicator 5 power switch q1/s1 6 operating display (led) d1 7 screw of the cover 8 storage, power cord 9 transport handle 10 power press regulator pressure/ quant...

Page 7

English 5.905-945.0 rev. 00 (06/15) 7 unit without hose drum 1 storage, power cord 2 storage dirt grinder 3 storage triple nozzle 4 kick plate to tilt the appliance 5 wheel 6 storage compartment for accessories 7 detergent tank lid dosing valve 8 transport handle 5.2 view from behind.

Page 8

8 english 5.905-945.0 rev. 00 (06/15) device with hose drum 1 crank, hose drum 2 hose drum 3 storage dirt grinder 4 storage triple nozzle 5 wheel 6 kick plate to tilt the appliance 7 storage compartment for accessories 8 detergent tank lid dosing valve 9 transport handle unit without hose drum 5.3 v...

Page 9

English 5.905-945.0 rev. 00 (06/15) 9 device with hose drum unit without hose drum 1 rubber feet 2 screw plug pressure retaining valve 3 locking screw for pressure valve 4 pressure switch q2 5 lid of water supply 6 pump head 7 mains connection 8 high pressure hose 5.4 front view (without cover) 1 mo...

Page 10

10 english 5.905-945.0 rev. 00 (06/15) device with hose drum 1 high-pressure hose from the pump to the hose reel 2 motor m1 3 manometer 4 detergent connection with check valve 5 detergent injector 6 bypass valve 7 duct high-pressure hose 8 overflow valve 9 water connection 10 mains connection 11 wat...

Page 11

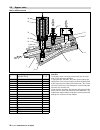

English 5.905-945.0 rev. 00 (06/15) 11 1 motor bearing 2 motor cover 3 motor shaft 4 water cooling 5 stator 6 rotor 7 shaft seal ring 8 fitting key 9 oil bath 10 swash plate 11 piston spring 12 screw plug pressure retaining valve 13 suction valve 14 pressure valve 15 locking screw for pressure valve...

Page 12

12 english 5.905-945.0 rev. 00 (06/15) trigger gun and servopress rotary regulator opened: when the power press regulator is opened all the way, the water flows from the pressure room through the pressure holding valve via the control pressure injector to the high pressure outlet. The ball of the ov...

Page 13

English 5.905-945.0 rev. 00 (06/15) 13 servopress rotary regulator partially closed: with the power press regulator partially closed, the pres- sure in the pressure room will not rise any further. Howev- er, due to less water volume, the effect of the control pressure injector decreases, so that the...

Page 14

14 english 5.905-945.0 rev. 00 (06/15) trigger gun closed: upon closing the trigger gun, the pressure in the pressure room rises abruptly. This pressure peak will affect the pis- ton rod and the pressure switch via the connecting boring. The ball is pressed out of its seat by the piston road and the...

Page 15

English 5.905-945.0 rev. 00 (06/15) 15 1 lock trigger gun 2 casing shell 3 hand lever 4 high pressure hose 5 hose guide 6 safety clip 7 needle bearing 8 coupling high-pressure hose/trigger gun 9 o ring 10 node piece function when the manual lever is actuated, the valve in the node piece opens and th...

Page 16

16 english 5.905-945.0 rev. 00 (06/15) 1 connection trigger gun 2 connecting pin 3 ceramic disc on gun side 4 ceramic disc on spray pipe side 5 casing of rotating regulator 6 handle of rotary regulator 7 spray lance connection the pressure and volume regulation is designed as a rota- ry regulator be...

Page 17

English 5.905-945.0 rev. 00 (06/15) 17 a position point jet b initial position c position flat stream function the triple nozzle has two adjustable positions. By rotating the nozzle head, you can switch between the chemicals nozzle (low pressure) and the high-pressure nozzles. The selection between ...

Page 18

18 english 5.905-945.0 rev. 00 (06/15) the device is equipped with a control and monitoring elec- tronic system that monitors a number of functions. In case of a continuous operation or a continuous break of 30 minutes, the immediate switch-off and locking of the de- vice takes place. Moreover, a vi...

Page 19

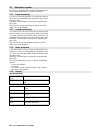

English 5.905-945.0 rev. 00 (06/15) 19 the resetting of the system in case of faults takes place by switching on and off the power switch. 6.7.5 reset 6.7.6 setting the dip switches on off 1 1-phase device 3-phase device 2 do not use no after run of the pump 3 leakage monitoring no monitoring 4 30 m...

Page 20

20 english 5.905-945.0 rev. 00 (06/15) device with hose drum function the bypass valve is to keep the pressure loss at a mini- mum in high pressure operation. In high pressure operation, the piston opens against the spring force of the pressure spring and lets the water flow to the high pressure out...

Page 21

English 5.905-945.0 rev. 00 (06/15) 21 danger prior to all work on the appliance, switch off the appliance and pull the power plug. Shut off water supply. Drain off water pressure. 1 overflow valve spindle with hexagon 2 counter-nut 3 rating nut 4 spring connect the test manometer with high-pressu...

Page 22

22 english 5.905-945.0 rev. 00 (06/15) device with hose drum 1 high pressure hose 2 safety clip 3 node piece pull out the safety clip. pull the high-pressure hose off the connection piece. 1 screws 2 hose drum unscrew the screws. remove the hose reel. 1 high pressure hose 2 safety clip 3 hig...

Page 23

English 5.905-945.0 rev. 00 (06/15) 23 1 high pressure hose 2 washers 3 high pressure outlet pull the high pressure hose out of the high pressure outlet. 1 crank remove the crank from the hose reel straightly. 1 holder hose reel 2 screws 3 hose drum unscrew the screws. remove half shells of ...

Page 24

24 english 5.905-945.0 rev. 00 (06/15) 1 seal screw 2 node piece 3 axle 4 o rings remove o-rings. check axle and connection piece for signs of wear. Installation information replace the o-rings. Grease the o-rings. Grease 6.288-088.0

Page 25

English 5.905-945.0 rev. 00 (06/15) 25 8 troubleshooting findings possible cause correction appliance is not running power supply interrupted check connection cable for damages. Check mains fuses and mains voltage disturbances in the electrical sys- tem check / replace transformer. Check/replace the...

Page 26

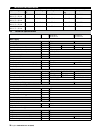

26 english 5.905-945.0 rev. 00 (06/15) 9 technical documentation appliance type appliance no. Circuit diagram operating instructions maintenance log spare parts list hd 10/25 s eu i 400 v / 3~ / 50 hz 1.286-120.0 0.090-000.0 5.964-882.0 5.950-582.0 5.971-980.0 hd 10/25 sx eu i 400 v / 3~ / 50 hz 1.2...

Page 27

English 5.905-945.0 rev. 00 (06/15) 27 10 special tools electric measuring appliance 6.803-022.0 shut-off valve with thermometer 2.901-030.0 puller for swashing plate 4.901-038.0 installation mandrel oil seal, high-pressure seal piston diameter 20mm 5.901-055.0 installation sleeve, high pressure sea...

Page 28

28 english 5.905-945.0 rev. 00 (06/15) test manometer for working pressure 4.742-025.0 installation and removal tools, overflow valve seat 4.901-054.0 removal pliers, pressure/suction valves and water sieves 4.901-062.0

Page 29

English 5.905-945.0 rev. 00 (06/15) 29 when working on the device, please always use the cur- rent circuit diagram in disis. 11 circuit diagram a1 control chip b1 pressure switch d1 operating display (led) f1 fuse k1 contactor m1 motor q1/s1 power switch q2 pressure switch t1 transformer ws_m1 windi...

Page 30

30 english 5.905-945.0 rev. 00 (06/15) 12 torques name nm cylinder head screws 50 - 60 piston casing 5 - 7 trigger gun, pressure regulator 40 screw connection pressure valves 40 - 45 screw connection pressure switch 15 - 17 screw connection suction valves 5 - 8 overflow valve seat 8 - 10 swash plate...