- DL manuals

- Karcher

- Pressure Washer

- HD 16/15-4

- Service Manual

Karcher HD 16/15-4 Service Manual

Summary of HD 16/15-4

Page 1

English 5.906-494.0 rev. 01 (04/11) 1 hd 25/15-4, hd 20/15-4, hd 16/15-4 service manual.

Page 2

2 english 5.906-494.0 rev. 01 (04/11) 1 preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2.1 hazard levels. . . . . . . . ....

Page 3

English 5.906-494.0 rev. 01 (04/11) 3 6 troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 6.1 appliance is not running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 6.2 indicator lamp . . . . . . . . . . ...

Page 4

4 english 5.906-494.0 rev. 01 (04/11) good service work requires extensive and practice- oriented training as well as well-structured training materials. Hence we offer regular basic and advanced training programmes covering the entire product range for all service engineers. In addition to this, we...

Page 5

English 5.906-494.0 rev. 01 (04/11) 5 the case device offers free access to all components and is therefore easy to service. The type and information plates are located: on the pump casing (pump specifications) in the accessories compartment (tyre pressure, nozzle size and oil types used) in the fra...

Page 6

6 english 5.906-494.0 rev. 01 (04/11) 1 water filter 2 water inlet 3 pressure switch 4 manometer 5 overflow casing, pressure regulation 6 oil tank 7 crankshaft housing 8 drive motor connection box 9 connecting flange for drive motor - pump 10 valve screws, pressure side 11 pump head fastening screws...

Page 7

English 5.906-494.0 rev. 01 (04/11) 7 1 water filter 2 water inlet 3 oil drain screw 4 oil sight glass 5 high-pressure outlet 6 accessory compartment 1 indicator lamp 2 power switch 3 intake for hourmeter (option) 4.5 front view 4.6 rear view.

Page 8

8 english 5.906-494.0 rev. 01 (04/11) 1 lock detent 2 accessory compartment 3 information sign 4 hinge, storage compartment 5 cover 6 lock pin 7 type plate, appliance 4.7 view from the inside.

Page 9

English 5.906-494.0 rev. 01 (04/11) 9 service work on the appliance may only be per- formed by the authorized customer service. If so in- structed in the operating instructions, the special tools indicated by kÄrcher must be used. danger danger from electric current and liquids. While work- ing on...

Page 10

10 english 5.906-494.0 rev. 01 (04/11) let the high pressure pump tilt down. Note oil can leak during this tilting process. Remove the high pressure pump from the electric motor..

Page 11

English 5.906-494.0 rev. 01 (04/11) 11 1 valve screw, suction side, with o-ring 2 suction valve 3 disc 4 piston 5 guide sleeve 6 piston screw 7 oil seal ring 8 push bar 9 pump casing 10 bolt, push bar 11 oil drain screw 12 piston rod top 13 crankshaft 14 piston rod bottom 15 piston rod screw 16 oil ...

Page 12

12 english 5.906-494.0 rev. 01 (04/11) unscrew the cylinder head. The exact procedure is described in the chapter "removing the cylin- der head". Unscrew the pistons from the push rods. Unscrew the oil drain screw and collect oil. Remove the crankshaft casing cover. Mark the piston rod top and botto...

Page 13

English 5.906-494.0 rev. 01 (04/11) 13 – grease the inside of the motor shaft with copper paste. – grease the outside of the crankshaft with copper paste. Order no. Copper paste (100g): 6.869-087.0 loosen the two fastening screws of the overflow (hd 25/15-4) 1 valve screw, suction side 2 fastening s...

Page 14

14 english 5.906-494.0 rev. 01 (04/11) overflow setup 1 screw socket 2 o ring 3 o ring 4 nozzle insert 5 manometer 6 screw connections 7 spring 8 valve bolt 9 o ring 10 valve seat 11 o ring 12 o ring 13 valve seat 14 spring 15 valve bolt 16 o ring 17 housing, overflow valve 18 o ring 19 control pist...

Page 15

English 5.906-494.0 rev. 01 (04/11) 15 cross section of the overflow 1 turning handle 2 lock nut, adjustment screw, high pressure 3 adjustment screw, high pressure 4 spindle, pressure and quantity regulation 5 spring plate, top 6 sphere 7 adjustment screw, low pressure 8 lock nut, adjustment screw, ...

Page 16

16 english 5.906-494.0 rev. 01 (04/11) loosen both hollow screws at the same time to re- move the overflow casing in order not to damage the o-rings. 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 adjustment screw, low pres...

Page 17

English 5.906-494.0 rev. 01 (04/11) 17 몇 warning when working on the device, please always use the current circuit diagram in kärcher-inside. 1 power contactor 2 terminal strip 3 terminal strip protective conductor 4 motor protection electronics 5 fuse f1 (1.0 at) 6 gentle start electronics 7 contro...

Page 18

18 english 5.906-494.0 rev. 01 (04/11) the resistance to spray water is ensured by a seal on the shaft. Loosen the 4 fastening screws. Disconnect the cable connections. Remove the appliance switch. Assemble it back in the reverse sequence. 1 protective conductor connection 2 measuring coil 3 dip swi...

Page 19

English 5.906-494.0 rev. 01 (04/11) 19 operation with gentle start in appliances with gentle start, the trailing must be active. When the pressure switch is opened, the pump will shut off with a 30 second delay. Dip switch 2: on = trailing active, off = trailing off switch the appliance off and back...

Page 20

20 english 5.906-494.0 rev. 01 (04/11) the hand spray gun can be disassembled to replace seals or wear parts. Hand-spray gun the individual parts of the hand spray gun. Part numbers, see disis. 1 support ring 2 o ring unscrew all fastening screws. Remove the half of the handle shell. The open gun, t...

Page 21

English 5.906-494.0 rev. 01 (04/11) 21 the removed piston with springs and seal set adhere to the sequence of the seal set and the springs when assembling. The seal set includes an o-ring 14x1,5-nbr 70. Open the screw connection. Replace the support ring and the o-ring. During the assembly, ensure t...

Page 22

22 english 5.906-494.0 rev. 01 (04/11) longitudinal section of the power press regulator 1 gun connection 2 connecting pin 3 ceramic disc on gun side 4 ceramic disc on spray pipe side 5 casing of rotating regulator 6 handle of rotary regulator 7 spray pipe connection 1 safety catch 2 halves of the h...

Page 23

English 5.906-494.0 rev. 01 (04/11) 23 – no power check whether the voltage indicated on the type plate corresponds to the voltage of the socket. Check the mains connection cable for damages. – indicator lamp is blinking green operational readiness period has expired. Switch on/off the appliance aga...

Page 24

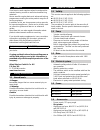

24 english 5.906-494.0 rev. 01 (04/11) 7 technical specifications type hd 25/15-4 hd 20/15-4 hd 16/15-4 power connection voltage v 400 400 400 current type hz 3~50 3~50 3~50 connection output kw 13 11,5 9,5 current pickup, full load (after 1 minutes) a mains fuse (slow-blow) a 25 25 16 maximum allow...

Page 25

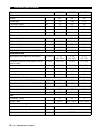

English 5.906-494.0 rev. 01 (04/11) 25 the status of the attached circuit diagram represents the creation date of the service manual. This circuit diagram is not updated. When working on the device, please always use the current circuit diagram in kärcher-inside. 7.1 technical documentation applianc...

Page 26

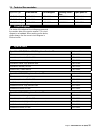

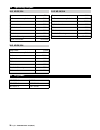

26 english 5.906-494.0 rev. 01 (04/11) 10 tightening torques 10.1 hd 25/15-4 gear cover 5 nm hollow screws on cylinder head 50 nm crown nut 50 nm valve screws 50 nm cylinder head screws 40 nm piston screws 20 nm oil drain screw 40 nm crankshaft bearing cover screws 18-22 nm piston rod screws 18-22 n...