- DL manuals

- Karcher

- Pressure Washer

- HD 6/15-4

- Service Manual

Karcher HD 6/15-4 Service Manual

Summary of HD 6/15-4

Page 1

English 5.906-565.0 rev. 00 (12/12) 1 hd 6/15-4, hd 7/11-4 service manual.

Page 2

2 english 5.906-565.0 rev. 00 (12/12) 1 contents 1 contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 2 preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 3 safety in...

Page 3

English 5.906-565.0 rev. 00 (12/12) 3 7.16.3 dismantling the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 7.16.4 dismantling the crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 7.16.5 dismantling the oil seals. . . . . . . ....

Page 4

4 english 5.906-565.0 rev. 00 (12/12) good service work requires extensive and practice- oriented training as well as well-structured training materials. Hence we offer regular basic and advanced training programmes covering the entire product range for all service engineers. In addition to this, we...

Page 5

English 5.906-565.0 rev. 00 (12/12) 5 the type plate is located on the right side of the ap- pliance. 1 part number 2 year of manufacture 3 type of protection 4 typical operating weight 5 flow rate 6 nozzle size 7 max. Feed temperature 8 address of manufacturer 9 bar code. Contains part and serial n...

Page 6

6 english 5.906-565.0 rev. 00 (12/12) 1 push handle 2 high pressure hose 3 machine frame 4 wheel 5 waterfilter 6 high pressure connection 7 high pressure pump 8 nozzle screws power nozzle 9 cover 10 spray lance 11 power switch 12 trigger gun 13 rotary coupling 6 parts of the system 6.1 overview.

Page 7

English 5.906-565.0 rev. 00 (12/12) 7 1 trigger gun storage clip 2 oil level indicator 3 oil drain screw 4 storage for spray pipe 5 step depression 6 nameplate 7 water connection 8 mains cable with mains plug 9 cable hook, rotating 10 storage compartment for hoses.

Page 8

8 english 5.906-565.0 rev. 00 (12/12) 1 cover 2 storage compartment 3 water connection 4 motor 5 pressure and volume regulation 6 cylinder head 7 crankcase 8 oil fill screw 9 flange 10 storage compartment for nozzles.

Page 9

English 5.906-565.0 rev. 00 (12/12) 9 1 power switch 2 water drain 3 startup capacitor 4 operating capacitor 5 resistor 6 connection terminals 7 cable from the motor, 5 wires 8 cord grip 9 power cable, 3 wires 10 cable from the pressure switch.

Page 10

10 english 5.906-565.0 rev. 00 (12/12) danger first pull out the plug from the mains before carrying out any tasks on the machine. Activate hand spray gun until device is pressure less. 7 basic settings and service procedures 7.1 overview appliance components 7.1.1 frame.

Page 11

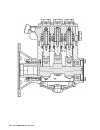

English 5.906-565.0 rev. 00 (12/12) 11 a locking screw (delivery condition) b ventilation screw (operation) 7.1.2 motor 7.1.3 crank drive.

Page 12

12 english 5.906-565.0 rev. 00 (12/12).

Page 13

English 5.906-565.0 rev. 00 (12/12) 13 7.1.4 cylinder head.

Page 14

14 english 5.906-565.0 rev. 00 (12/12).

Page 15

English 5.906-565.0 rev. 00 (12/12) 15 pull out both bearings. Remove the hood. Note see "technical details" for details of oil quantity and type. Open the device hood. Unscrew oil drain plug. Drain the oil in a collection basin. Fix in the oil drain screw and tighten it. Torque 20...25 nm. Turn the...

Page 16

16 english 5.906-565.0 rev. 00 (12/12) unscrew the covering nut. Unscrew the filter casing. Take out the filter inlay. Clean the filter casing. Clean the filter inlay. Install the water filter. Loosen the hose clip. Pull out the hose. Unscrew 2 screws. Remove connection nozzle. 7.4 clean water filte...

Page 17

English 5.906-565.0 rev. 00 (12/12) 17 pull down circlip. Remove the pressure switch. Disconnect the water supply hose from the cylin- der head. Note: should you wish to replace the valves of the pump as well, perform the following steps prior to dismantling the cylinder head: – loosen the valve scr...

Page 18

18 english 5.906-565.0 rev. 00 (12/12) dismount cylinder head (see "dismounting the cylinder head"). 1 crankcase turn the low pressure gasket packages back and forth and pull them off the piston at the same time. Clean the ceramic piston and check for cracks. If there is oil on the piston side of th...

Page 19

English 5.906-565.0 rev. 00 (12/12) 19 push the sealing ring onto the installation mandrel (special tool). Place the installation sleeve on the cylinder head. Push the sealing ring through the installation sleeve (special tool) into the cylinder head using the installation mandrel. Lightly grease th...

Page 20

20 english 5.906-565.0 rev. 00 (12/12) 1 valve screw 2 valve 3 o ring 4 screwed sealing plug unscrew the valve screws. Remove the valve and o-ring. Insert a new o-ring in the drilled hole. Insert a new valve. Check the o-ring of the valve screw, replace if necessary. Insert and tighten the valve scr...

Page 21

English 5.906-565.0 rev. 00 (12/12) 21 pull off the rotary handle. Unscrew the overflow valve (wrench size 32 mm). Clean valve. Check ball for wear. Clean valve seat. Check valve seat for wear. Dismantle the worn valve seat by means of valve pliers. 7.11 checking the overflow valve.

Page 22

22 english 5.906-565.0 rev. 00 (12/12) install a nozzle size 018 (special tool 5.765-092) on the spray lance. Install a pressure gauge (special tool) between the high-pressure connection and the high-pressure hose. Set up the power and water supply. Pull off the rotary handle. 1 rating nut 2 set scr...

Page 23

English 5.906-565.0 rev. 00 (12/12) 23 1 sleeve 2 leakage boring unscrew the sleeve (wrench size 21 mm). Note: if water leaks from the leakage boring during opera- tion, the entire mechanics of the pressure switch must be replaced. Remove and clean the piston and spring. Note: the disc and gasket sh...

Page 24

24 english 5.906-565.0 rev. 00 (12/12) disconnect the water supply hose from the cylin- der head. (see "dismantling the cylinder head".) remove the pressure switch. (see "removing the pressure switch".) note: if the pump is to be disassembled afterwards, loosen all necessary screws prior to disconne...

Page 25

English 5.906-565.0 rev. 00 (12/12) 25 mark the bearing shells (in the example: 1, 2, 3). Loosen 6 screws. Remove the bearing shells. Mark the piston rods (in the example: 1 dot, 2 dots, 3 dots). 1 flange loosen 4 screws. Pull the flange off the crankshaft casing. 1 cover 2 bearing cover loosen 4 sc...

Page 26

26 english 5.906-565.0 rev. 00 (12/12) squeeze out the crankshaft in small steps. Be- tween every step, ensure that the piston rods are not jammed or damaged by the crankshaft. Insert a suitable pipe section, e.G. 50x2x250 mm. Squeeze out the ball bearing and dispose of. Caution risk of damage for t...

Page 27

English 5.906-565.0 rev. 00 (12/12) 27 clean and check the gasket seat. Place the oil seal on the installation mandrel (spe- cial tool) and moisten with water. Do not use oil or grease. Drive the oil seal into the drilled hole by means of the installation mandrel. Lightly lubricate the piston and pi...

Page 28

28 english 5.906-565.0 rev. 00 (12/12) 1 o ring replace o-ring. Attach the flange on the crankshaft casing. Mount the retaining ring to the crankshaft. Lightly grease the new cover and press it in. Mount the lid. Install the bearing shells of the piston rods, ob- serve marking. Apply soluble screw s...

Page 29

English 5.906-565.0 rev. 00 (12/12) 29 danger risk of electric shock. Prior to opening the electric casing, the appliance must be de-energised (pull the mains plug) and se- cured against accidental restart. Loosen 4 screws. Remove the lid. Opening the electric casing (see "opening the electric casin...

Page 30

30 english 5.906-565.0 rev. 00 (12/12) reconnect the cable from the old to the new switch. Reinstall the switch and the rotary knob. Close the electric casing. 1 back panel loosen 4 screws. Remove back panel. Loosen the nut. Take out the traction relief from the holder. Opening the electric casing (...

Page 31

English 5.906-565.0 rev. 00 (12/12) 31 dismantle the push handle (2 screws) and remove it. Remove pressure switch (see "removing the pressure switch"). Loosen 4 screws. Opening the electric casing (see "opening the electric casing") 1 cord grip 2 screw unscrew 2 screws. Remove the traction relief. L...

Page 32

32 english 5.906-565.0 rev. 00 (12/12) danger risk of electric shock. Prior to opening the electric casing, the appliance must be de-energised (pull the mains plug) and se- cured against accidental restart. Remove the high pressure pump from the electric motor. Detach the electric motor from the fra...

Page 33

English 5.906-565.0 rev. 00 (12/12) 33 check connection cable for damages. Check the supply voltage. Check/replace the appliance switch. Check/replace the pressure switch set the pressure and quantity regulation to "max". (turn in a clockwise direction to the stop). Check the nozzle size, install co...

Page 34

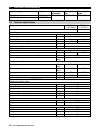

34 english 5.906-565.0 rev. 00 (12/12) 9 technical documentation appliance type appliance no.: operating in- structions spare parts list circuit dia- gram hd 6/15-4 1.367-301.0 5.964-718.0 9.761-167.0 9.761-243.0 hd 7/11-4 1.367-302.0 9.1 technical specifications type hd 6/15-4 1.367-302.0 hd 7/11-4...

Page 35

English 5.906-565.0 rev. 00 (12/12) 35 9.2 special tools electric measuring appliance 6.803-022.0 shut-off valve with thermometer 2.901-030.0 removal pliers, pressure/suction valves and water sieves 4.901-062.0 installation mandrel oil seal 2.901-033.0 installation mandrel high pressure gasket 5.901...

Page 36

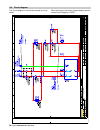

36 english 5.906-565.0 rev. 00 (12/12) the circuit diagram in the service manual is not up- dated. When working on the device, please always use the current circuit diagram in disis. 9.4 circuit diagram.