- DL manuals

- Karcher

- Pressure Washer

- HDS 10/20-4 M

- Instruction Manual

Karcher HDS 10/20-4 M Instruction Manual

Register and win!

www

.kaercher

.com

HDS 7/11-4 M/MX

HDS 7/12-4 M/MX

HDS 8/17-4 M/MX

HDS 10/20-4 M/MX

HDS 12/18-4 S/SX

59648860

11/12

Deutsch

7

English

24

Français

41

Italiano

59

Nederlands

77

Español

94

Português

112

Dansk

130

Norsk

146

Svenska

162

Suomi

179

Ελληνικά

196

Türkçe

215

Русский

232

Magyar

251

Čeština

268

Slovenščina

285

Polski

302

Româneşte

320

Slovenčina

338

Hrvatski

355

Srpski

372

Български

389

Eesti

408

Latviešu

425

Lietuviškai

442

Українська

459

Summary of HDS 10/20-4 M

Page 1

Register and win! Www .Kaercher .Com hds 7/11-4 m/mx hds 7/12-4 m/mx hds 8/17-4 m/mx hds 10/20-4 m/mx hds 12/18-4 s/sx 59648860 11/12 deutsch 7 english 24 français 41 italiano 59 nederlands 77 español 94 português 112 dansk 130 norsk 146 svenska 162 suomi 179 Ελληνικά 196 türkçe 215 Русский 232 magy...

Page 2: Mx/sx

1 27 26 25 24 23 22 21 20 19 2 3 4 5 28 29 30 31 32 1 mx/sx m/s 7 6 12 15 18 16 17 8 9 11 10 9 14 13 3.

Page 3

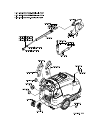

33 34 min max max min 35 36 37 38 39 40 41 42 43 4.

Page 4

2 3 4 5 6 1. 2. 5.

Page 5

7 8 9 10 11 12 6.

Page 6: Contents

– 1 please read and comply with these original instructions prior to the initial operation of your appliance and store them for later use or subsequent own- ers. – before first start-up it is definitely nec- essary to read the operating instruc- tions and safety indications nr. 5.951- 949.0! – in ca...

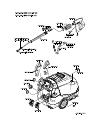

Page 7: Overview

– 2 figure 1 1 cover 2 support for spray lance (both sides) 3 fill opening for system care advance rm 110/rm 111 4 steering roller with fixed position brake 5 mounting location for transport (both sides) 6 wheel 7 water supply set 8 high pressure connection (m/s only) 9 o-ring set (for replacement) ...

Page 8: Proper Use

– 3 cleaning of: machines, vehicles, struc- tures, tools, facades, terraces, garden- ing tools, etc. Danger risk of injury! Follow the respective safety regulations when operating at gas stations or other dangerous areas. – please follow the national rules and regulations for fuel spray jets of the ...

Page 9: Start Up

– 4 몇 warning risk of injury! Device, tubes, high pressure hose and connections must be in faultless condition. Otherwise, the appliance must not be used. Lock parking brake. Figure 3 caution hook the electric supply line into the cable guide of the right handle bow. Ensure that the cable is not dam...

Page 10

– 5 figure 4 connect ray tube with hand spray gun tighten the screw connection of the spray lance fingertight. Insert high pressure nozzle into cover- ing nut install covering nut and tighten firmly – appliance without hose drum: connect the high pressure hose to the high pressure connection point o...

Page 11: Operation

– 6 danger never suck in water from a drinking water container. Never suck in liquids which con- tain solvents like lacquer thinner, petrol, oil or unfiltered water. The sealings within the device are not solvent resistant. The spray mist of solvents is highly inflammable, ex- plosive and poisonous....

Page 12

– 7 set appliance switch to desired operat- ing mode. Indicator lamp for operational readiness lights up. The device starts briefly and turns off, as soon as the working pressure is reached. Note: if the indicator lamps for pump, rota- tion direction, burner malfunction or engine are on during opera...

Page 13

– 8 removal of light contaminations and clear rinse, i.E.: gardening tools, terrace, tools, etc. Set operating pressure according to need. The appliance works in the most economi- cal temperature range. Note: the temperature can be regulated up to 60 °c. We recommend the following cleaning tem- pera...

Page 14: Storage

– 9 lock in the steel pipe into the holder of the appliance hood. Roll up high pressure hose and electri- cal conduit and hang them into the re- spective holders. Device with hose drum: before rolling up, stretch out the high pressure hose. Turn the hand crank clockwise (direc- tion of the arrow). N...

Page 15: Troubleshooting

– 10 clean the sieve in the water connection. Clean the fine filter. Check oil level. Caution in case of lacteous oil inform kärcher cus- tomer service immediately clean sieve in the water shortage safe guard. Clean filter at the detergent suck hose. Oil change. Perform the pressure test as per manu...

Page 16

– 11 figure 12 exchange the poles at the appliance plug. – no line voltage, see "appliance is not running". – contactor error set the appliance switch to "0/off“. Turn on the appliance. – error occurs repeatedly. Inform customer service – engine overload/overheat set the appliance switch to "0/off“....

Page 17

– 12 – detergent tank 2 is empty. Refill detergent. – no power check power connection/conduit. – air within the system vent pump: set dosing value for detergent to "0". With open hand spray gun turn device on and off multiple times with the device switch. Open and close the pressure/quantity regulat...

Page 18: Warranty

– 13 the warranty terms published by our com- petent sales company are applicable in each country. We will repair potential fail- ures of the appliance within the warranty period free of charge, provided that such failure is caused by faulty material or de- fects in fabrication. Note: when connectin...

Page 19: Ec Declaration of Conformity

– 14 we hereby declare that the machine de- scribed below complies with the relevant basic safety and health requirements of the eu directives, both in its basic design and construction as well as in the version put into circulation by us. This declaration shall cease to be valid if the machine is m...

Page 20: Technical Specifications

– 15 technical specifications hds 7/11 classic *kap hds 7/12 *au hds 8/17 classic *kap hds 8/17 *au/classic *eu main supply voltage v 220 240 220 400-420 current type hz 1~ 60 1~ 50 3~ 60 3~ 50 connected load kw 3,4 3,4 5,5 5,5 protection (slow) a 16 15 32 16 type of protection -- ipx5 ipx5 ipx5 ipx...

Page 21

– 16 hds 10/20 classic *kap hds 10/20 *au/classic *eu hds 12/18 classic *kap hds 12/18 *au/classic *eu main supply voltage v 220 400-420 220 400-420 current type hz 3~ 60 3~ 50 3~ 60 3~ 50 connected load kw 7,8 7,8 8,4 8,4 protection (slow) a 32 16 32 16 type of protection -- ipx5 ipx5 ipx5 ipx5 pro...

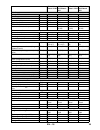

Page 22: Recurring Tests

– 17 note: the recommended testing frequencies of the respective statutory regulations of the country of operation are to be followed. Recurring tests testing done by: external testing internal testing leak-proof tests name signature of the authorised person/ date signature of the authorised person/...

Page 25

06/12 ae karcher fze, p.O. Box 17416, jebel ali free zone (south), dubai, united arab emirates, +971 4 886-1177, www.Kaercher.Com ar kärcher s.A., urugguay 2887 (1646) san fernando, pcia. De buenos aires +54-11 4506 3343, www.Karcher.Com.Ar at alfred kärcher ges.M.B.H., lichtblaustraße 7, 1220 wien,...