- DL manuals

- Karcher

- Pressure Washer

- HDS 13/20 De Tr1

- Service Manual

Karcher HDS 13/20 De Tr1 Service Manual

Summary of HDS 13/20 De Tr1

Page 1

English 5.906-736.0 rev. 00 (07/15) 1 hds 9/50 de tr1 hds 13/35 de tr1 hds 13/20 de tr1 hds 17/20 de tr1 service manual.

Page 2

2 english 5.906-736.0 rev. 00 (07/15) 1 contents 1 contents 2 2 preface 6 3 regarding this service manual 6 3.1 target groups for this manual 6 4 environmental protection 6 5 safety instructions 6 5.1 general 6 5.2 hazard levels 7 5.3 symbols on the plant 7 5.4 hearing protection 7 6 technical featu...

Page 3

English 5.906-736.0 rev. 00 (07/15) 3 8.7.9 service motor 38 8.7.10 service pump 39 8.7.11 service burner 39 8.7.12 service gun 39 9 function 40 9.1 flow pattern 40 9.2 overview sensor technology and electrical components 41 9.2.1 switching functions of the sensor technology 42 9.3 axle / drawbar 45...

Page 4

4 english 5.906-736.0 rev. 00 (07/15) 10.10 water connection 93 10.10.1 operation with external water supply 93 10.10.2 operation with water from the water tanks 94 10.11 refill fuel 94 10.12 refill detergent 94 10.13 refill liquid softener 94 11 basic settings and service procedures 95 11.1 axle / ...

Page 5

English 5.906-736.0 rev. 00 (07/15) 5 11.12.5 cleaning / changing the temperature sensor exhaust gas 146 11.12.6 cleaning / changing the temperature sensor warm water 147 11.12.7 dismantling the booster heater 148 11.13 settings, burner 149 11.14 high pressure outlet 151 11.14.1 uninstall / install ...

Page 6

6 english 5.906-736.0 rev. 00 (07/15) good service work requires extensive and practice-orient- ed training as well as well-structured training materials. Hence we offer regular basic and advanced training pro- grammes covering the entire product range for all service engineers. In addition to this,...

Page 7

English 5.906-736.0 rev. 00 (07/15) 7 please remember: – that you have understood all the instructions – that all users of the plant are informed about the instruc- tions and have understood them. All individuals,who are involved, in the installation, the op- eration, the maintenance and service of ...

Page 8

8 english 5.906-736.0 rev. 00 (07/15) mobile hot water high-pressure cleaners in various perfor- mance classes for commercial use. – high-performance burner with an upright heating coil – built-in calcification protection – burner blower and fuel pump with separate dc motor – a diesel engine for all...

Page 9

English 5.906-736.0 rev. 00 (07/15) 9 exemplary illustration for type hds 13/200 de tr1 1 appliance description 2 performance data motor, speed motor, total weight trailer 3 information regarding the flow rate, working pressure, maximum pressure of the safety valve, maximum work temperature, maximum...

Page 10

10 english 5.906-736.0 rev. 00 (07/15) 1 reflector (on both sides) 2 rear cover 3 combined brake/tail light with direction indicator (left) 4 recessed grip of the rear cover or hose inlet with closed rear cover 5 lock rear cover 6 licence plate with licence plate lights 7 combined brake/tail light w...

Page 11

English 5.906-736.0 rev. 00 (07/15) 11 1 diesel engine 2 intermediate gear 3 high-pressure pump 4 safety block 5 exhaust 6 expansion tank motor coolant 7.2 view with opened front and rear cover.

Page 12

12 english 5.906-736.0 rev. 00 (07/15) 1 maintenance opening water tank (left) 2 air filter diesel engine 3 nameplate 4 battery 5 vehicle identification number 6 burner blower 7 fuel pump 8 continuous heater 9 ignition transformer 10 maintenance opening water tank (right).

Page 13

English 5.906-736.0 rev. 00 (07/15) 13 1 cover plate (right) 2 cover plate (left) 3 supply tap water tanks 4 drain-off tap 5 antifreeze hose 6 water pipes 7 water filter 8 manometer 9 supply frost protection or parking position for geka low-pressure connection 10 return flow frost protection or park...

Page 14

14 english 5.906-736.0 rev. 00 (07/15) 1 detergent container (hds 13/20 and hds 17/20 only) 2 filter detergent suction hose (hds 13/20 and hds 17/ 20 only) 3 detergent suction hose with level switch (hds 13/20 and hds 17/20 only) 4 detergent dosing valve (hds 13/20 and hds 17/20 only) 5 storage comp...

Page 15

English 5.906-736.0 rev. 00 (07/15) 15 1 cover plates the cover plates can be lifted up and removed. 1 connection tank on the left side - tank on the right side 2 supply from the float container 3 stop cock drain water tanks 4 supply to the high-pressure pump 5 stop cock water tanks 6 supply from wa...

Page 16

16 english 5.906-736.0 rev. 00 (07/15) view with opened maintenance flap on the left 1 inverter 2 thermostat switch water temperature in the float con- tainer view with opened maintenance flap on the right 1 thermostat switch emission temperature view with opened maintenance flap on the right 1 leve...

Page 17

English 5.906-736.0 rev. 00 (07/15) 17 1 temperature sensor booster heater 2 high-pressure line from the boiler to the high-pressure connection 3 high-pressure line from the safety block to the boiler 4 heat exchanger 5 drain screw heat exchanger 6 axle (drawbar) note in the underbody area, there is...

Page 18

18 english 5.906-736.0 rev. 00 (07/15) 1 display 2 operating type switch 3 indicator light preheating (red) 4 indicator light standby mode (red), the charge control is active 5 key switch 6 indicator lamp front cover/emergency stop (red) 7 operating mode cold/warm water (0-100 °c, temperature select...

Page 19

English 5.906-736.0 rev. 00 (07/15) 19 during normal operating mode, the control panel display alternates between: – normal operation – service: due maintenance tasks to be performed by the customer service (see care and maintenance). If more than one maintenance procedure is required, these will be...

Page 20

20 english 5.906-736.0 rev. 00 (07/15) display malfunction 1 malfunction no. 2 motor off (off) list malfunction number with corresponding error mes- sage – error 1 charging current – error 3 coolant or temperature water in the float container – error 4 water shortage – error 5 flow switch/pressure s...

Page 21

English 5.906-736.0 rev. 00 (07/15) 21 electric components are located in the control cabinet and in the control cabinet door. 7.4.2 control panel, view from the inside.

Page 22

22 english 5.906-736.0 rev. 00 (07/15) electric components in the control cabinet 1 relay k4 (safety relay yanmar) 2 relay k7, release 3 fuse f1, 30a: blower motor 4 fuse f2, 30a: pre-heat 5 fuse f3, 30a 6 fuse f4, 5a 7 fuse f5, 7.5a: emergency stop and cover switch 8 fuse f6, 3a: connection transfo...

Page 23

English 5.906-736.0 rev. 00 (07/15) 23 electric components in the control cabinet door 1 printed circuit board a1 with display 2 indicator light h3 front cover/emergency stop (red) 3 operating type switch 4 indicator light h1 preheating (red) 5 key switch 6 indicator light h2 charge regulator (red).

Page 24

24 english 5.906-736.0 rev. 00 (07/15) control board a1 inputs 1 lch1: monitoring oil pressure diesel engine 2 lch2: monitoring temperature water in the float con- tainer and monitoring temperature coolant diesel en- gine 3 fuel: level sensor for fuel tank 4 ldgt: level switch liquid softener 5 ldr:...

Page 25

English 5.906-736.0 rev. 00 (07/15) 25 distributor printed circuit board a2 inputs 1 wsk: level switch water shortage float container 2 dsein: pressure switch 3 dsaus: charge regulator 4 oelsi: level switch detergent can 5 printed circuit board: connection between con- trol board a1 and distributor ...

Page 26

26 english 5.906-736.0 rev. 00 (07/15) danger risk of explosion! Do not spray flammable liquids. Danger risk of injury! Never use the appliance without the spray lance attached. Check and ensure proper fitting of the spray lance prior to each use. The screw connection of the spray lance must be fing...

Page 27

English 5.906-736.0 rev. 00 (07/15) 27 hds 9/50, hds 13/35 only: note if the motor speed is increased, the operating pressure also rises. This can be read from the pressure gauge. – increasing the speed: push up the lever of the speed control. – reducing the speed: push down the lever of the speed c...

Page 28

28 english 5.906-736.0 rev. 00 (07/15) release the lever on the trigger gun. Note when the lever of the hand spray gun is released, the en- gine continues to run at zero speed. This way the water cir- culates between the float container and the high-pressure pump and heats up. If the maximum admissi...

Page 29

English 5.906-736.0 rev. 00 (07/15) 29 note operating and maintenance displays are shown one after the other like in a slide show. Each picture for 3 seconds. The fault displays remain until the device is switched off. 8.2 operating displays display explanation remark maintenance for motor due after...

Page 30

30 english 5.906-736.0 rev. 00 (07/15) to protect from freeze damages, the appliance must be flushed with antifreeze. Note use normal glycol-based anti-freezing agents for automo- biles. Note observe handling instructions of the anti-freeze agent manufacturer. A certain corrosion protection is achie...

Page 31

English 5.906-736.0 rev. 00 (07/15) 31 close the supply tap of the water tanks and the drain tap. With unit types hds 13/20 and hds 17/20: set the detergent dosing valve to the maximum dosing level. Take the detergent suction lance out of the container and put it down in a way that it can be sucked ...

Page 32

32 english 5.906-736.0 rev. 00 (07/15) the antifreeze liquid is pumped through the appliance in a circuit. Lead the residual water via the frost protection hose into the anti-freeze container. As soon as antifreeze exits the antifreeze hose, wait 5 seconds, and put the actuation lever of the frost p...

Page 33

English 5.906-736.0 rev. 00 (07/15) 33 1 service switch 2 position marking setting the water hardness the setting of the liquid softener dosing is done in accord- ance with the local water hardness (ask your local water supply company or determine by means of a hardness tester). Note when using rm 1...

Page 34

34 english 5.906-736.0 rev. 00 (07/15) 1 setting, water temperature service mode if the service switch is in the "service" position upon switching on the device, the service mode of the device is activated. Selection of the service functions the available service functions are selected via the water...

Page 35

English 5.906-736.0 rev. 00 (07/15) 35 turn off the appliance. Make a note of the position of the service switch. Set the service switch to service. Turn on the appliance. Set temperature regulator to the relevant temperature. 30°c - behaviour after 45 minutes continuous operation or continuous brea...

Page 36

36 english 5.906-736.0 rev. 00 (07/15) note in order to change between the actuators, keep the service switch on "set" for one second. In order to operate the selected actuator, set the service switch to level "4". 8.7.4 test actuators / test output signals display explanation remark 40? Manual swit...

Page 37

English 5.906-736.0 rev. 00 (07/15) 37 note the test takes place as follows: operate the sensor manually. Observe the indicator change on the display. If the indi- cation changes upon operation, the sensor is ok. Note use set to switch over to the next fault. With switch-off - hold set - switch-on t...

Page 38

38 english 5.906-736.0 rev. 00 (07/15) display explanation remark 60? 1 malfunction no. 2 indication, for how many hours the mal- function has occurred – error 1 charging current – error 3 coolant or temperature water in the float con- tainer – error 4 water shortage – error 5 flow switch/pressure s...

Page 39

English 5.906-736.0 rev. 00 (07/15) 39 8.7.10 service pump display explanation remark 70? Number of total pump maintenances total operation duration of the pump operation duration pump since the last mainte- nance delete service: turn off the appliance. Hold set (2-3 seconds). Turn on the appliance....

Page 40

40 english 5.906-736.0 rev. 00 (07/15) colour assignment: black: water red: detergent brown: fuel (diesel) blue: cooling circuit motor 1 antifreeze container 2 liquid softener container with level switch and dosing valve 3 water inlet 4 low-pressure hose drum 5 water filter 6 ball tap frost protecti...

Page 41

English 5.906-736.0 rev. 00 (07/15) 41 1 battery 2 motor burner blower 3 valve fuel burner 4 starter motor 5 alternator 6 flame sensor 7 temperature sensor high-pressure outlet (booster heater) 8 ignition transformer 9 thermostat switch emission temperature 10 level sensor for fuel tank 11 emergency...

Page 42

42 english 5.906-736.0 rev. 00 (07/15) note the following switching functions serve the general under- standing of the respective functionality as well as the pos- sibility how which sensor can be tested. Emergency stop and cover switch when operating the emergency stop switch (-s1) or the cover swi...

Page 43

English 5.906-736.0 rev. 00 (07/15) 43 dosing liquid softener, valve -y4 burner programme selected and flow present: – pulse time liquid softener is approx. 85ms, equals ap- prox. 0.5 ml. – the waiting time between the pulses depends on the position of the dip switches and the set level: note dip sw...

Page 44

44 english 5.906-736.0 rev. 00 (07/15) burner operation, contactor k8 for the release of the burner the following conditions must be met: – flow present (-s7). – level fuel tank > 3 bars. – temperature sensor booster heater (-r 3) is connect- ed. – hot water operation selected. – measured temperatur...

Page 45

English 5.906-736.0 rev. 00 (07/15) 45 1 parking brake 2 connector vehicle lighting 3 support wheel crank handle 4 support wheel 5 overrun brake 6 tear-off rope 7 coupling lever 8 towing hitch the axle is an approved purchased item with its own type plate for axle and overrun unit that is located in...

Page 46

46 english 5.906-736.0 rev. 00 (07/15) 1 reflector (on both sides) 2 marker light (on both sides).

Page 47

English 5.906-736.0 rev. 00 (07/15) 47 front cover 1 recessed grip 2 hood 3 locking rear cover 1 hood 2 handle 3 locking the entire technical unit with motor, high-pressure pump and burner is located underneath the front cover. An ex- haust opening serves the discharge of the exhaust gases of the bu...

Page 48

48 english 5.906-736.0 rev. 00 (07/15) 1 maintenance opening tank on the right 2 maintenance opening tank on the left the trailer is equipped with two water tanks that are con- nected to each other. Each tank has a capacity of 250 li- tres. The tanks enable independent work without a connection to a...

Page 49

English 5.906-736.0 rev. 00 (07/15) 49 1 storage operating instructions 2 storage compartment for trigger gun 3 storage compartment for 2nd spray lance 4 storage compartment for helmet slide-in units, which can be used as storage compart- ments, are integrated in the rotation parts of the two water ...

Page 50

50 english 5.906-736.0 rev. 00 (07/15) battery 12v, 36ah 1 battery terminal (+), red 2 battery (voltage and capacity, see "specifications“) 3 battery terminal (-), black 4 battery holder view with opened maintenance flap on the left 1 inverter inverter the control board a1 requires a supply voltage ...

Page 51

English 5.906-736.0 rev. 00 (07/15) 51 low-pressure hose drum 1 water supply hose 2 brake lever connection to an external water supply is established by means of the water supply hose dn19, connection, max. Length: 30 metres to unroll or roll up the hose, the brake must be released. For this purpose...

Page 52

52 english 5.906-736.0 rev. 00 (07/15) in the lower area of the float container the sensors for the filling level monitoring (empty message) and water temper- ature are mounted onto a joint holder. 1 support 2 temperature sensor 3 filling level monitoring (empty message) 4 inflow return line of high...

Page 53

English 5.906-736.0 rev. 00 (07/15) 53 1 connection tank on the left side - tank on the right side 2 supply from the float container 3 stop cock drain water tanks 4 supply to the high-pressure pump 5 stop cock water tanks 6 supply from water tank on the right operation with water supply via the wate...

Page 54

54 english 5.906-736.0 rev. 00 (07/15) 1 liquid softener reservoir 2 level sensor 1 liquid softener reservoir 2 level sensor 3 dosing valve 1 supply from the water distribution 2 supply to the high-pressure pump the heat exchanger serves the motor cooling and the si- multaneous preheating of the was...

Page 55

English 5.906-736.0 rev. 00 (07/15) 55 overview pump types 13/20 and 17/20 1 overflow 2 speed control idle mode / full load 3 pump head 4 pressure switch 5 valve set frost protection 6 supply water with fine filter 7 intermediate gear 8 detergent supply to the pump 1 pump casing 2 outlet high pressu...

Page 56

56 english 5.906-736.0 rev. 00 (07/15) schematic diagram for all pump types 1 lock screw, suction side, with o-ring 2 disc 3 suction valve with o-ring 4 ceramic piston 5 piston screw 6 oil seal ring 7 push bar 8 pump casing 9 bolt, push bar 10 oil drain screw 11 piston rod top 12 crankshaft 13 pisto...

Page 57

English 5.906-736.0 rev. 00 (07/15) 57 1 casing 2 valve 3 spring if pressure is applied to the casing (1) during operation of the pump, the valve (2) closes and no flow is possible. In low pressure operation the spring (3) pushes onto the valve (2) so that the gate of the valve is opened. As a re- s...

Page 58

58 english 5.906-736.0 rev. 00 (07/15) 1 screwed sealing plug 2 spring 3 piston 4 casing 5 bowden cable 6 adjustment screw if pressure is applied to the casing (5) during operation of the pump, the piston (3) is pressed against the spring (2) and thus pulls the bowden cable (6) into the casing. This...

Page 59

English 5.906-736.0 rev. 00 (07/15) 59 illustration for pump types 13/20 and 17/20 1 bearing (closed bearing side) 2 crankshaft 3 cover oil filler neck 4 cover 5 piston rod 6 covering lid 7 screw 8 oil sight glass 9 screwed sealing plug 10 o ring 11 seal casing cover 12 bearing (open bearing side) 1...

Page 60

60 english 5.906-736.0 rev. 00 (07/15) illustration for pump types 9/50 and 13/35 1 covering lid 2 screw 3 seal casing cover 4 piston rod 5 o ring 6 container 7 stopper 8 cover oil filler neck 9 cylinder roller bearing 10 o ring 11 screw 12 bearing (open bearing side) 13 radial seal 14 shaft seal ri...

Page 61

English 5.906-736.0 rev. 00 (07/15) 61 illustration for pump types 13/20 and 17/20 high-pressure valves and water inlet 1 valve screw 2 o ring 3 suction valve 4 pressure valve piston seals 5 seal kit 9.14.6 cylinder head: high-pressure valve and water inlet / piston seals.

Page 62

62 english 5.906-736.0 rev. 00 (07/15) illustration for pump types 9/50 and 13/35 high-pressure valves and water inlet 1 valve screw 2 o ring 3 suction valve 4 pressure valve piston seals 5 screwed sealing plug 6 o ring 7 seal kit 8 bushing 9 seal kit.

Page 63

English 5.906-736.0 rev. 00 (07/15) 63 exemplary illustration for all 4 pump types 1 overflow 2 hollow screw 3 banjo bolt bypass 4 pump head note both hollow screws must be loosened or tightened simul- taneously while exchanging the knot section in order to avoid damage to the o-rings. Tightening to...

Page 64

64 english 5.906-736.0 rev. 00 (07/15) exemplary illustration. The overflow valves for the 4 pumps are similarly designed, they differ in the spring force relative to the pressure range. The overflow valves are permanently set and sealed. A high-pressure inlet b high-pressure outlet c low pressure r...

Page 65

English 5.906-736.0 rev. 00 (07/15) 65 safety block 200bar 1 screwed sealing plug 2 flow switch 3 clamping bracket 4 high-pressure outlet to the booster heater 5 high pressure input 6 safety valve 7 adjusting screw note the safety valve can be adjusted in the range 185-250bar. The presetting at 240b...

Page 66

66 english 5.906-736.0 rev. 00 (07/15) illustration for pump types 13/20 and 17/20 1 spring 2 valve ball 3 valve seat illustration for pump types 9/50 and 13/35 1 spring 2 valve disks 3 valve seat if the overflow valve is defective, the safety valve guides the entire flow rate of the pump to the out...

Page 67

English 5.906-736.0 rev. 00 (07/15) 67 illustration for pump types 13/20 and 17/20 1 magnetic piston illustration for pump types 9/50 and 13/35 1 magnetic piston the flow switch prevents the burner from switching on in case of missing or insufficient water volume and thus pro- tects the booster heat...

Page 68

68 english 5.906-736.0 rev. 00 (07/15) 1 continuous heater 2 fuel pump 3 blower lid 4 pressure line 5 rubber collar 6 solenoid valve 7 setting fuel pressure 8 fuel line 9 filter 10 return 1 rubber collar 2 air flap 3 screw 4 burner blower 1 solenoid valve 2 setting fuel pressure 3 connection pressur...

Page 69

English 5.906-736.0 rev. 00 (07/15) 69 1 blower wheel 2 fastening screw blower wheel burner blower the blower supplies the burner with combustion air. The air flap is used to adjust the air value to optimised combustion values. The blower wheel is mounted to the motor shaft by means of 2 feather key...

Page 70

70 english 5.906-736.0 rev. 00 (07/15) view with opened maintenance flap on the right 1 thermostat switch emission temperature note when the set emission temperature of 292°c +/-7k is ex- ceeded, the burner switches off automatically. Restart after a temperature drop by 9 +/-4.5k. The type plate of ...

Page 71

English 5.906-736.0 rev. 00 (07/15) 71 1 ignition electrodes 2 fuel nozzle 3 pressure plate 4 flame pipe 5 burning chamber 6 boiler floor 7 boiler input 8 air supply from burner blower 9 boiler exterior, double-walled 10 heating coil spiral, exterior 11 heating coil spiral, interior 12 exhaust nozzl...

Page 72

72 english 5.906-736.0 rev. 00 (07/15) mode of operation the water from the high pressure pump enters the interior heating coil spiral, is heated while flowing through and ex- its to the bottom from the heating coil spiral. The fuel is vaporised by the fuel nozzle and ignited by the spark of the ign...

Page 73

English 5.906-736.0 rev. 00 (07/15) 73 1 ignition electrodes 2 fuel nozzle holder 3 fuel nozzle 4 spray angle 45° or 60°, depending on the type of appli- ance 5 screw 6 burner cover 7 connection ignition electrodes burner there is a strong spark created between the two ignition electrodes to ensure ...

Page 74

74 english 5.906-736.0 rev. 00 (07/15) 1 ignition electrode 2 fuel nozzle 3 pressure plate 1 ignition electrode 2 fuel nozzle view from below 1 temperature sensor warm water 2 high-pressure line from the booster heater to the high- pressure connection 3 high-pressure line from the safety block to th...

Page 75

English 5.906-736.0 rev. 00 (07/15) 75 1 manometer 2 catch high-pressure hose reel 3 high-pressure hose drum 4 high pressure hose there is also equipment without a high-pressure hose reel. In this case, a separate high-pressure hose is connected to the high-pressure connection in the area of the pre...

Page 76

76 english 5.906-736.0 rev. 00 (07/15) diesel engine 1 connection coolant hose 2 filling hole motor oil (top) 3 thermostat switch motor 4 connection coolant hose 5 cooling fan, motor diesel engine 1 expansion tank motor coolant 2 exhaust system 3 muffler 4 air filter 5 starter 6 alternator diesel en...

Page 77

English 5.906-736.0 rev. 00 (07/15) 77 diesel engine - circuit coolant 1 connection coolant hose 2 connection from the expansion tank motor coolant 3 drain screw coolant 4 connection from the water distribution 5 connection to the hp pump antifreeze motor check the coolant circuit of the motor for s...

Page 78

78 english 5.906-736.0 rev. 00 (07/15) 1 bowden cable speed control from the piston on the high-pressure pump 2 deflection 3 speed control motor the speed control lowers the motor speed when the hand spray gun is closed. 1 speed control (full load / idle mode) 2 bowden cable to the motor 9.22.1 spee...

Page 79

English 5.906-736.0 rev. 00 (07/15) 79 note this equipment is only available for hds 9/50 and hds 13/35. 1 speed control (full load / idle mode) 2 bowden cable from the control lever (limitation max. Motor speed for controlling volume and pressure) 3 control lever for speed control 4 speed control m...

Page 80

80 english 5.906-736.0 rev. 00 (07/15) 1 tank filler neck with cap the fuel tank is located in the air casing, which separates the motor compartment from the operator side. Note if the refuelling is done by means of cans, the accompany- ing filter sieve should be inserted in the tank filler neck in ...

Page 81

English 5.906-736.0 rev. 00 (07/15) 81 note this equipment is only available for hds 13/20 and hds 17/20. Detergent is drawn via the dosing valve from the detergent container. The dosing level is adjusted via the dosing valve. With pump operation the solenoid valve before the high-pressure pump open...

Page 82

82 english 5.906-736.0 rev. 00 (07/15) detergent dosing valve 1 connection from the detergent tank (labelled with "1") 2 connection to the pump (labelled with "p") solenoid valve dosing detergent 1 motor flange 2 connection from the detergent tank 3 solenoid valve 4 connection to the pump 5 pump cas...

Page 83

English 5.906-736.0 rev. 00 (07/15) 83 1 fine filter 2 aperture note in order to improve the suction behaviour of the pump for the detergent, an orifice plate is installed in the inlet to the fine filter..

Page 84

84 english 5.906-736.0 rev. 00 (07/15) if the trailer needs to be moved for service tasks, this can be done in trailer operation or by means of a crane. 몇 caution risk of injury and damage! Observe the weight of the ap- pliance when you transport it. Note the driver, who operates the towing vehicle ...

Page 85

English 5.906-736.0 rev. 00 (07/15) 85 1 parking brake 2 plug storage 3 crank for support wheel adjustment choose the installation site in a way that the exhaust gas opening is not covered. Lock parking brake. Lower the support wheel by means of the crank. Remove the tear-off rope from the towing ve...

Page 86

86 english 5.906-736.0 rev. 00 (07/15) view from the inside 1 lock 2 catch hook note the lock of the front cover is equipped with an additional catch hook in order to prevent unintended opening. The catch hook must, like with a motorcar, be pushed to the side manually after opening the lock to relea...

Page 87

English 5.906-736.0 rev. 00 (07/15) 87 a safety switch stops the motor upon opening the front cover, starting the motor is not possible when the front cov- er is open. In order to still be able to perform maintenance and service tasks while the motor is running, the safety switch must be bridged. Th...

Page 88

88 english 5.906-736.0 rev. 00 (07/15) danger danger on account of falling trailer. When lifting the trailer by means of a jack, ensure that it stands on a solid, level ground! Ensure that the trailer is secured against rolling away with all wheels that are on the ground. Ensure that no unauthorised...

Page 89

English 5.906-736.0 rev. 00 (07/15) 89 1 cross strut of the axle 2 support point jack lift the trailer on the square tube of the cross strut in the area of the suspension. Exemplary illustration for lifted trailer. Attention risk of damage to equipment. Use the designated lifting points when lifting...

Page 90

90 english 5.906-736.0 rev. 00 (07/15) for service tasks in the front area of the motor compart- ment, it may be advisable to remove the front plate in order to enable better access to, for example, the safety block or the fine filter in the pump inlet. Unscrew the 2 x 3 screws for fastening the fro...

Page 91

English 5.906-736.0 rev. 00 (07/15) 91 the maintenance flap on the right must be dismantled for service tasks on the thermostat switch emission tempera- ture or at the filling level sensor and the fuel lines of the die- sel tank. 1 maintenance flap on the right pull the cable off the ignition transf...

Page 92

92 english 5.906-736.0 rev. 00 (07/15) for service tasks on the thermostat switch water tempera- ture or on the inverter, the maintenance flap on the left must be dismantled. 1 maintenance flap on the left 2 hose air filter - motor if necessary, remove the hose from the air filter. Unscrew the 6 scr...

Page 93

English 5.906-736.0 rev. 00 (07/15) 93 for service tasks from the bottom, the two pvc protective plates must be dismantled. Note for the oil change of the motor it is enough to remove the left pvc plate. For the disassembly of the booster heater, it is enough to remove the right pvc plate. For tasks...

Page 94

94 english 5.906-736.0 rev. 00 (07/15) open stop cock water tanks. Uncoil the water hose from the hose reel and connect it to the water supply (e.G. Tap). Open the water supply. The water tanks are filled via the float container. When the water tanks are filled, the float valve in the float con- tai...

Page 95

English 5.906-736.0 rev. 00 (07/15) 95 danger prior to all work on the device that can be performed with- out the drive running, switch off the key switch and remove the key. Attention risk of damage to equipment. With all service tasks, en- sure that no parts fall into the booster heater through th...

Page 96

96 english 5.906-736.0 rev. 00 (07/15) unscrew 2 screws. Remove bowl of the lamp. Change lamp. Lamp type: c5w-12v, part number 7.651-009.0 unscrew 4 screws. Remove bowl of the lamp. Change lamp. Lamp type: 1 license plate lights r10w-ba15s-12v, part number 7.651-006.0 2 direction-indicator lamp py21...

Page 97

English 5.906-736.0 rev. 00 (07/15) 97 rear cover 1 fastening bolt with fork on the cover 2 gas pressure damper 3 fastening bolt with ball head on air casing note the piston rod is installed towards the cover side. 1 fastening bolt with fork on the cover 2 splint 몇 caution risk of damage! Secure the...

Page 98

98 english 5.906-736.0 rev. 00 (07/15) front cover 1 gas pressure damper 2 fastening bolt with ball head on the cover 3 fastening bolt with ball head on air casing note the piston rod is installed towards the air casing side. 1 nut with washer 2 splint 3 ball head 몇 caution risk of damage! Secure th...

Page 99

English 5.906-736.0 rev. 00 (07/15) 99 push the ball head out of the retainer by slightly hitting it. Repeat the same procedure on the opposite side of the gas pressure damper and exchange the gas pressure damper. Note the disassembly of the two covers is similar and is only il- lustrated exemplaril...

Page 100

100 english 5.906-736.0 rev. 00 (07/15) carefully remove the cover and put it down in a clean, secure place. 몇 warning risk of injury! Battery acid is very corrosive! Always wear acid-resistant goggles, gloves and an apron when working with battery acid. Never charge the battery in the vicinity of o...

Page 101

English 5.906-736.0 rev. 00 (07/15) 101 in order to access the connection of the positive termi- nal, fold up and remove the red protective cover. 몇 caution risk of damage! Do not place tools on top of the battery if the protective cover has been removed, as this could lead to a short cir- cuit. Loa...

Page 102

102 english 5.906-736.0 rev. 00 (07/15) view with opened maintenance flap on the left 1 inverter dismantle the maintenance flap on the left. Disconnect the supply voltage and connection 24v ac in the control cabinet. Unscrew 4 screws from the bottom. Replace the inverter. Observe the cable run with ...

Page 103

English 5.906-736.0 rev. 00 (07/15) 103 disconnect the external water supply from the mains. Empty the trough area. Unscrew the filter cup. Take out the filter inlay. Clean filter insert or replace if too dirty. Install the filter cup and hand-tighten it. Note check for leaks as soon as water is app...

Page 104

104 english 5.906-736.0 rev. 00 (07/15) remove the console with the cover from the liquid sof- tener container. 1 container liquid softener 2 fastening clips 3 level switch liquid softener 4 dosing valve unclip the container from the anchor. Empty the container, contain liquid softener. 1 bracket 2 ...

Page 105

English 5.906-736.0 rev. 00 (07/15) 105 1 level switch liquid softener pull the level switch out of the container bottom. If necessary, exchange the level switch. Observe the cable run with the electrical connection! Note if spare parts are required, the container is available com- plete with the le...

Page 106

106 english 5.906-736.0 rev. 00 (07/15) unscrew the screws. 1 inlet hose 2 connection float valve detach the supply hoses from the two float valves. Lift the locking catch on the float valve. Push out the float valve. 1 swimmer valve.

Page 107

English 5.906-736.0 rev. 00 (07/15) 107 illustration with dismantled float valves. Unscrew the holder for the temperature sensor and lev- el switch in the lower area of the float container. 1 support 2 temperature sensor water in the float container (green cable) 3 level switch float container (grey...

Page 108

108 english 5.906-736.0 rev. 00 (07/15) view with opened maintenance flap on the left 1 thermostat switch water temperature in the float con- tainer 2 screw unscrew the maintenance flap on the left. Upon changing the temperature sensor: disconnect it at the thermostat switch. Upon replacement with t...

Page 109

English 5.906-736.0 rev. 00 (07/15) 109 lift the trailer, disassembly of both pvc protective plates at the bottom. Uninstall the high-pressure line from the safety block to the booster heater. Unscrew the holder of the heat exchanger from the bot- tom plate. Unscrew the two covers front / back. Unth...

Page 110

110 english 5.906-736.0 rev. 00 (07/15) 1 pump casing 2 oil filling nozzle 3 overflow 4 speed control idle mode / full load 5 pressure switch 6 valve set frost protection 7 pump head 8 outlet return line to the float container 9 outlet high pressure note the following pictures apply exemplarily! If ...

Page 111

English 5.906-736.0 rev. 00 (07/15) 111 note dispose of the waste oil according to the local provisions. Replace the oil while the motor has operating temperature. Align the appliance horizontally prior to the oil change. 몇 caution risk of burns when draining hot oil. Pump types 13/20 and 17/20 1 pu...

Page 112

112 english 5.906-736.0 rev. 00 (07/15) 1 union nut water hose 2 fine filter 3 lock nut filter casing unpressurize the appliance. Open the union nut of the water supply, remove hose. Note it is recommended to dismantle the front plate to provide better access to the lower area of the fine filter. Un...

Page 113

English 5.906-736.0 rev. 00 (07/15) 113 1 fine filter 2 aperture note make sure not to lose the orifice plate in the inlet of the fine filter!.

Page 114

114 english 5.906-736.0 rev. 00 (07/15) 1 speed control 2 bowden cable to the motor open the screw of the piston. Note when the screw is loosened, the spring pushes onto the screw head. Check the piston movement for free run by means of special pliers. Grease o-rings. 11.9.4 check and adjust the spe...

Page 115

English 5.906-736.0 rev. 00 (07/15) 115 1 bowden cable from the piston to the high-pressure pump 2 deflection 3 speed control motor if necessary, change the entire unit. Detach the bowden cable at the deflection. Pull the piston with the bowden cable out of the casing. Thread new unit through and ad...

Page 116

116 english 5.906-736.0 rev. 00 (07/15) unscrew the lower casing part of the overflow device from the pump. Note ensure that also the valve seat with the o-ring is removed from the pump casing; remove by means of pliers if neces- sary. Wear parts: 1 casing with taper seat 2 spring 3 valve seat with ...

Page 117

English 5.906-736.0 rev. 00 (07/15) 117 disconnect the hose from the valve box. Unscrew the valve box for the frost protection from the pump. Attention risk of damage to equipment. Observe torque of 35- 40 nm, as otherwise the casing can get damaged. Note ensure that the valve seat underneath is not...

Page 118

118 english 5.906-736.0 rev. 00 (07/15) components in the disassembled condition 1 o ring 2 o ring 3 valve 4 spring 1 holding bow 2 pressure switch push the retaining bracket to the front. Remove the pressure switch towards the top. 1 valve casing unscrew the valve box of the pressure switch from th...

Page 119

English 5.906-736.0 rev. 00 (07/15) 119 remove the valve from the pump seat. Components in the disassembled condition 1 piston with tappet 2 spring 3 valve casing 4 diaphragm switch off the operating mode switch and secure it against restart. Shut off water supply. Take the pressure off the high pre...

Page 120

120 english 5.906-736.0 rev. 00 (07/15) pull out the suction valves using special pliers (4.901- 602.0). If the valve seat gets stuck in the pump head, you can pull it out using the drawing tool (6.815-013.0). Suction/pressure valve setup.

Page 121

English 5.906-736.0 rev. 00 (07/15) 121 press in the new suction valves (lubricate the o-rings with silicon grease). Note ensure the correct alignment of the valve crosspieces. Insert the lockscrews of the suction valves and tighten them to 40 nm (grease o-rings)..

Page 122

122 english 5.906-736.0 rev. 00 (07/15) switch off the operating mode switch and secure it against restart. Shut off water supply. Take the pressure off the high pressure system by opening the gun. Check the pressure ratio of the high pressure system on the pump manometer. Loosen the lockscrews of t...

Page 123

English 5.906-736.0 rev. 00 (07/15) 123 press in the new pressure valves manually (grease the o-rings). Note ensure the correct alignment of the valve crosspieces..

Page 124

124 english 5.906-736.0 rev. 00 (07/15) 1 connection high pressure 2 connection of frost protection valve 3 connection return flow (bypass) disconnect the connections at the overflow valve. 1 banjo bolt pressure side 2 banjo bolt bypass evenly unscrew the banjo bolts on the overflow valve and remove...

Page 125

English 5.906-736.0 rev. 00 (07/15) 125 unscrew the overflow or slightly loosen the hollow screws that secure the overflow. Unscrew the 8 screws from the pump head. Carefully pull out the cylinder head using both hands. Attention do not cant during the removal as the ceramic sleeves could break! Loo...

Page 126

126 english 5.906-736.0 rev. 00 (07/15) pump types 9/50 and 13/35 1 screwed sealing plug 2 o ring 3 seal kit 4 bushing 5 seal kit insert the new washers into the screw insert. Insert and press in the new seal package into the cylin- der head using the installation sleeve and the driver. Observe the ...

Page 127

English 5.906-736.0 rev. 00 (07/15) 127 tighten the stopping bushings using the special tool 5.511-001.0 to 50 nm. Assemble the cylinder head in the reverse sequence. Disconnect crankshaft casing from the intermediate gear of the diesel engine note for details see further back in the chapter. Exempl...

Page 128

128 english 5.906-736.0 rev. 00 (07/15) mark the bearing shells with the piston rod so that they do not get interchanged during assembling. Note every bearing cup must later be refastened to the same piston rod with the same alignment. Therefore, mark the components prior to removal. Loosen the bear...

Page 129

English 5.906-736.0 rev. 00 (07/15) 129 dismantle both flange bearings on the pump casing; in order to do so, the 4 screws on the flange must be loos- ened respectively. At the end, you can pull out the flange bearings. Tightening torque 20 nm..

Page 130

130 english 5.906-736.0 rev. 00 (07/15) note with the 200bar pumps tapered roller bearings are used. The axial load is adjusted on the open bearing side by means of spacer discs (adjustment is performed by the factory!). Ensure that the relevant spacer disc(s) are con- clusively reinstalled! Press t...

Page 131

English 5.906-736.0 rev. 00 (07/15) 131 unscrew the piston screws using an allen wrench and pull out the piston rod from the rear. 1 special pliers to remove the oil seal rings 2 oil seal ring 3 pump casing remove 3 oil seals from the pump housing with the special pliers. Note make sure that the bor...

Page 132

132 english 5.906-736.0 rev. 00 (07/15) after replacing the oil groove rings, the piston rod is pushed back into the straight pushing guide and the pistons are screwed on (observe tightening torque, see in the back). Clean the threads before screwing, apply screw securing adhesive (soluble) to the t...

Page 133

English 5.906-736.0 rev. 00 (07/15) 133 1 oil fill container 2 pump casing 3 crankshaft bearing cover with crankshaft bearing and o-ring 4 crankshaft housing cover with o-ring 5 piston rod bottom parts, marked 6 crankshaft bearing with flange, o-ring and shaft seal 7 crankshaft 8 piston rod top part...

Page 134

134 english 5.906-736.0 rev. 00 (07/15) now, the crankshaft can be put back in. Fixate it with flange bearings. Then screw the bearing cups into the piston rod nm = 8...9. Assemble back the parts in the reverse sequence. Fill in oil up to the sight glass. Oil fill volume and type pump gear 350/500ba...

Page 135

English 5.906-736.0 rev. 00 (07/15) 135 safety block 200bar 1 adjustment screw 2 safety valve 3 clamping bracket 4 reed switch 5 high pressure pipe to the on-demand heater 6 screwed sealing plug note only when changing the safety block, a complete removal is required. Work on the reed switch and for...

Page 136

136 english 5.906-736.0 rev. 00 (07/15) disconnect the high-pressure outlet to the booster heater. Unscrew the screw for fastening the safety block form the console, remove the block. Clean / change the reed switch for flow monitoring note observe the installation position of the reed switch on the ...

Page 137

English 5.906-736.0 rev. 00 (07/15) 137 loosen screws. Remove and clean magnetic pen. Adjust safety valve note the safety valve is adjusted via the pressure increase in the system with the burner turned on, so that it limits the pressure increase to the max. Permissible value (see specifications) wi...

Page 138

138 english 5.906-736.0 rev. 00 (07/15) overview 1 continuous heater 2 fuel pump 3 blower lid 4 pressure line 5 rubber collar 6 solenoid valve 7 setting fuel pressure 8 fuel line 9 filter 10 return 1 filter loosen the hose clamp before and after the filter, re- move hoses. Change filter. Attention c...

Page 139

English 5.906-736.0 rev. 00 (07/15) 139 view with pulled out clip. 1 solenoid valve 2 fuel line 3 pressure line 4 fuel pump 5 coupling 6 return remove the pump unit with the coupling from the cas- ing. Remove magnetic coil. Remove the connections of the fuel line (supply), pres- sure line and return...

Page 140

140 english 5.906-736.0 rev. 00 (07/15) carefully slide the blower unit to the back so that the branch is pulled out of the rubber cuff. Lift the blower and put it down horizontally. Mark the position of the air flap. 1 screw 2 screw for locking the air flap 3 air flap unscrew the screw for locking ...

Page 141

English 5.906-736.0 rev. 00 (07/15) 141 1 fan wheel 2 screw open the screw at the hub. Pull the fan wheel off. Note removing the fan wheel requires some force. Carefully wobble the fan wheel all around and lever it out. 1 fitting key remove the two feather keys of the motor shaft. Unscrew 4 screws. ...

Page 142

142 english 5.906-736.0 rev. 00 (07/15) 1 nut disconnect battery. Loosen 2 nuts. Remove the hood. Note in the original condition, these are special nuts that fasten the cover. After the first opening, it is recommended to re- place them with stop nuts. 1 tensioning ring open and remove the clamping ...

Page 143

English 5.906-736.0 rev. 00 (07/15) 143 pull back the retaining spring. Insert new carbon block and push it in. Electrically connect the carbon block. 1 protective element 2 tensioning ring insert the protective element in a way that it is located under the clamping point of the clamping ring. Slide...

Page 144

144 english 5.906-736.0 rev. 00 (07/15) 1 burner cover 2 ignition cable 3 flame sensor unscrew the holder for the flame sensor. Remove the plug for the ignition cable. 1 screw 2 fuel line separate the fuel line. Unscrew 2 screws from the cover. Note when detaching the connection of the fuel line, pa...

Page 145

English 5.906-736.0 rev. 00 (07/15) 145 - notice you need to carefully adjust the distance between the igni- tion electrodes to bring about a stronger ignition spark. Replace burnt out ignition electrodes. 1 pressure plate 2 fuel nozzle 3 ignition electrodes 4 screw 5 burner cover 1 connection fuel ...

Page 146

146 english 5.906-736.0 rev. 00 (07/15) 1 ignition transformer 2 screw 3 cable connections remove 3 cables from the ignition transformer. Loosen the screw. Disconnect the ignition transformer electrically. Note observe the cable run with the electrical connection! Note the two lower cable connection...

Page 147

English 5.906-736.0 rev. 00 (07/15) 147 view with opened maintenance flap on the right 1 screw 2 support 3 thermostat switch emission temperature unscrew the maintenance flap on the right. Upon changing the temperature sensor: disconnect it at the thermostat switch. Upon replacement with thermostat ...

Page 148

148 english 5.906-736.0 rev. 00 (07/15) 1 exhaust unscrew the burner cover. Pull out the temperature sensor emission temperature. Unscrew the coolant container and ignition transformer. Unscrew the exhaust pipe from the muffler. Uninstall the burner blower completely with the con- sole. View from be...

Page 149

English 5.906-736.0 rev. 00 (07/15) 149 note an accurate basic adjustment of the burner is only possible if the heating coil was previously thoroughly desooted and the deposits were removed. 1 adjustment screw, fuel pressure 2 pressure line to the burner 3 fuel pump 4 return hose to the fuel tank 5 ...

Page 150

150 english 5.906-736.0 rev. 00 (07/15) 1 air door, air volume adjustment 2 stop screw note adjusting the air flaps in the plus direction increases the air quantity, adjustment in the minus direction reduces the air quantity. Measure water temperature install the shut-off valve with thermometer (spe...

Page 151

English 5.906-736.0 rev. 00 (07/15) 151 1 high-pressure hose (uncoiled) 2 hose connection unwind the hp hose from the hose reel. Disconnect the hose at the hose connection. 1 screw connection 2 manometer disconnect the screw connection. Remove the pressure gauge. 1 bypass unit 2 water pipes 3 high p...

Page 152

152 english 5.906-736.0 rev. 00 (07/15) 1 safety valve 2 pipe connection note the pressure of the safety valve is permanently adjusted to 6 bar and cannot be changed. Remove both hoses from the plug connection. Unscrew c-coupling for the water hose. 1 screw open the nuts of the two hose connections....

Page 153

English 5.906-736.0 rev. 00 (07/15) 153 danger risk of injury! Before carrying out any tasks on the machine, switch off the key switch and the battery switch and remove the key. Prevent inadvertent startups of the appliance during main- tenance procedures via third persons by attaching signs on the ...

Page 154

154 english 5.906-736.0 rev. 00 (07/15) diesel engine 1 expansion tank motor coolant 2 exhaust system 3 muffler 4 air filter 5 starter 6 alternator.

Page 155

English 5.906-736.0 rev. 00 (07/15) 155 몇 caution risk of damage! Observe the brand of antifreeze used. The mixture can cause a chemical reaction and hazardous substances can be generated. Do not mix different antifreeze types. 몇 warning risk of injury! The motor can overheat if there is a lack of c...

Page 156

156 english 5.906-736.0 rev. 00 (07/15) 1 air filter 2 blow-out lip loosen the spring tension bracket, remove the cover and eliminate the dust deposits. Note severely contaminated or defective filter inserts must al- ways be replaced. Take out the filter inlay. Blow out the filter insert with compre...

Page 157

English 5.906-736.0 rev. 00 (07/15) 157 check the tension of the v-belt 몇 caution risk of damage! If the v-belt is not sufficiently tensioned, this can cause an overheating of the engine and to an insufficient battery charge. Defective v-belts must be replaced immediately. Shut off the motor and rem...

Page 158

158 english 5.906-736.0 rev. 00 (07/15) 1 alternator 2 screw slightly loosen the screw for fastening the alternator. Move the alternator towards the motor and slacken the v-belt this way. 1 v-belt 2 fan wheel remove and unthread the v-belt over the fan wheel. Note when installing the v-belt, positio...

Page 159

English 5.906-736.0 rev. 00 (07/15) 159 1 connecting cable 2 starter 3 nut disconnect battery. Disconnect the earth connection and the connection cable from the starter. Open the nuts, remove the starter. Install and electrically connect new starter. Mind the cable run! Connect the battery. Note onl...

Page 160

160 english 5.906-736.0 rev. 00 (07/15) note replace the oil while the motor has operating temperature. Align the appliance horizontally prior to the oil change. Dispose of the waste oil according to the local provisions. View from below 1 heat exchanger 2 oil drain screw engine the oil drain screw ...

Page 161

English 5.906-736.0 rev. 00 (07/15) 161 1 seal coat the washer of the new oil filter with oil before fitting it. 1 seal seat clean the seal seat and apply oil prior to installation of the new oil filter. Screw the oil filter in finger tight. Turn the oil filter another 1/8 turn using the oil filter ...

Page 162

162 english 5.906-736.0 rev. 00 (07/15) note collected diesel fuel must be disposed of according to lo- cal regulations. 1 valve tap 2 fuel filter as a precaution, place suitable container or absorbing sheets underneath the fuel filter. Set the valve to "off", for this purpose, turn the tap up- ward...

Page 163

English 5.906-736.0 rev. 00 (07/15) 163 note collected diesel fuel must be disposed of according to lo- cal regulations. 1 water separator 2 valve tap as a precaution, place suitable container or absorbing sheets underneath the water separator. Set the valve to "off", for this purpose, turn the tap ...

Page 164

164 english 5.906-736.0 rev. 00 (07/15) 1 intermediate gear 2 cover filling hole 3 oil sight glass 4 oil drain screw check the oil level in the intermediate gear. If the oil level is below the oil looking glass, add oil. Fill the appropriate amount of oil into the filling hole. Check the oil level a...

Page 165

English 5.906-736.0 rev. 00 (07/15) 165 disconnect the high-pressure outlet and return line from the pump head. Disconnect water supply and optionally the detergent connection from the pump head. Note this detergent connection is only available with the devic- es hds 13/20 and hds 17/20. 1 speed con...

Page 166

166 english 5.906-736.0 rev. 00 (07/15) unscrew the screw of the front rubber buffer support. Note the structure with the 350/500 bar pumps is similar. 1 drive shaft remove the pump with the intermediate gear from the drive shaft. Note if necessary, support by levering out in the recesses on the fla...

Page 167

English 5.906-736.0 rev. 00 (07/15) 167 note the pictures are of a purely informative nature, they do not depict the situation on the mini trailer. Drain the oil from the intermediate gear. Unscrew 4 screws and remove the casing. Open the safety screw. Pull off the toothed wheel. Note upon installat...

Page 168

168 english 5.906-736.0 rev. 00 (07/15) unscrew 4 screws and remove the flange from the pump unit. Note ensure that no o-rings are lost! Note after assembly, fill oil (sae 90) into the oil filler neck while the appliance is in a horizontal position until the oil level reaches the upper edge of the o...

Page 169

English 5.906-736.0 rev. 00 (07/15) 169 view with opened maintenance flaps 1 level sensor for fuel tank 2 support 3 nut unscrew both maintenance flaps. Unscrew 2 nuts. Unthread the holder, mind the cable while doing so. Carefully lever out the level sensor at the edge of the upper rubber cuff along ...

Page 170

170 english 5.906-736.0 rev. 00 (07/15) check level sensor for proper function. For this purpose, set the float contact to the various fill- ing level positions on the level sensor and match it with the relevant indication on the display. If necessary, disconnect and replace the level sensor on the ...

Page 171

English 5.906-736.0 rev. 00 (07/15) 171 1 dosage valve for detergent detach the hoses on the back of the valve (open clamp by means of pliers) slightly push in the catches of the valve from the back and pull off the valve towards the front. Detergent dosing valve 1 connection from the detergent tank...

Page 172

172 english 5.906-736.0 rev. 00 (07/15) 1 valve body 2 tappet with hexagon nut 3 magnet coil open the hexagon nut on the tappet. Pull the tappet out of the valve body. Clean the valve body. Clean the tappet with a soft cloth if necessary. Note when changing the complete solenoid valve, the hoses mus...

Page 173

English 5.906-736.0 rev. 00 (07/15) 173 note the description for adjustment is done jointly for all unit types. Deviations that must be observed with the unit types hds 13/20 and 17/20 are listed separately. The technical data required for this is listed in chapter 15. Perform standard settings on t...

Page 174

174 english 5.906-736.0 rev. 00 (07/15) open gun. With hds 13/20 and hds 17/20: completely open the pressure and volume regulation on the gun (set to "+"). Set the maximum speed (+/-50 1/min) on the stop screw full load. Secure the setting by means of a locknut. Close gun. Set the minimum speed (+/-...

Page 175

English 5.906-736.0 rev. 00 (07/15) 175 1 adjustment screw, high pressure 2 lock nut, adjustment screw, high pressure 3 spindle, pressure and quantity regulation 4 housing, overflow valve adjustment overflow device note the adjustment is done with the test nozzle. Install the test manometer (special...

Page 176

176 english 5.906-736.0 rev. 00 (07/15) the device must always be kept in a clean condition. Main- tenance cleaning must be performed periodically by the operator or service personnel considering the state of cleanliness. The exterior cleaning can be performed with a high-pres- sure device, however,...

Page 177

English 5.906-736.0 rev. 00 (07/15) 177 1 water pipes 2 high pressure hose disconnect the trigger gun from the high-pressure hose. Connect the high-pressure hose to the frost protection inlet. Disconnect the water hose from the water supply. Connect the water hose to the return flow of the frost pro...

Page 178

178 english 5.906-736.0 rev. 00 (07/15) danger risk of chemical burns from strong brine! Wear safety gog- gles and protective gloves. Observe the safety instructions for the detergent! Let the device warm up in the burner operation, then switch it off. Depressurise the device by opening the gun. Uns...

Page 179

English 5.906-736.0 rev. 00 (07/15) 179 the malfunction is shown on the display as follows. 1 malfunction no. 2 indication, for how many hours the malfunction has oc- curred note further information about the test of the sensor technology can be found in chapter 9.2.1. 13 troubleshooting 13.1 faults...

Page 180

180 english 5.906-736.0 rev. 00 (07/15) * cleaning operation with cold water is possible. Error 9* emission temperature thermostat switch or temperature switch defective. Burner has been wrongly set. Heating coil is sooted. Check heating coil for internal deposits. Error 10* temperature sensor boost...

Page 181

English 5.906-736.0 rev. 00 (07/15) 181 13.2 faults without display on the console fault possible cause water pressure too low / the device does not reach the full pressure check / clean the water filter. Check water supply volume, increase if necessary. Check the water quantity in the two 250 l tan...

Page 182

182 english 5.906-736.0 rev. 00 (07/15) 13.3 troubleshooting yanmar diesel engine.

Page 183

English 5.906-736.0 rev. 00 (07/15) 183 note the current inspection and maintenance checklist 5.965- 663.0 is recorded in the disis. 14 maintenance plans 14.1 inspection and maintenance checklist 14.2 maintenance plan trailer.

Page 184

184 english 5.906-736.0 rev. 00 (07/15).

Page 185

English 5.906-736.0 rev. 00 (07/15) 185 14.3 maintenance plan yanmar diesel engine.

Page 186

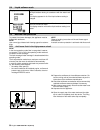

186 english 5.906-736.0 rev. 00 (07/15) 15 technical specifications hds 9/50 detr1 hds 13/35 detr1 hds 17/20 detr1 hds 13/20 detr1 internal combustion engine idling speed rpm 1600 1600 1600 1600 full load speed (gun opened) rpm 3100 3100 3100 2700 amount of oil l 3,5 3,5 3,5 3,5 oil grade 15 w40 15 ...

Page 187

English 5.906-736.0 rev. 00 (07/15) 187 safety valve completely opened (testing manometer) mpa 25,8 overflow valve opening pressure (testing manometer) mpa 58,5 - 58,5 37,5 - 38,5 21,0 - 22,0 21,0 - 22,0 water shortage safeguard off l/h 50 - 150 50 - 150 50 - 150 50 - 150 water shortage safeguard on...

Page 188

188 english 5.906-736.0 rev. 00 (07/15) hds 13/20 and 17/20 - high-pressure pump hds 13/20 and 17/20 - overflow device 15.1 tightening torques.

Page 189

English 5.906-736.0 rev. 00 (07/15) 189 hds 13/20 and 17/20 - safety block.

Page 190

190 english 5.906-736.0 rev. 00 (07/15) hds 9/50 and 13/35 - pump head.

Page 191

English 5.906-736.0 rev. 00 (07/15) 191 hds 9/50 and 13/35 - speed control hds 9/50 and 13/35 - frost protection valve hds 9/50 and 13/35 - overflow device.

Page 192

192 english 5.906-736.0 rev. 00 (07/15) hds 9/50 and 13/35 - transmission hds 9/50 and 13/35 - safety block.

Page 193

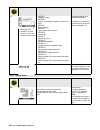

English 5.906-736.0 rev. 00 (07/15) 193 16 special tools special tools 4.742-025.0 test pressure gauge 0 - 250 bar (hds 13/20, hds 17/20) 4.742-040.0 test pressure gauge 0 - 800 bar (hds 9/50, hds 13/35) 4.901-060.0 pressure gauge fuel pressure for measuring the pump pressure of the fuel pump at the...

Page 194

194 english 5.906-736.0 rev. 00 (07/15) 6.423-029.0 thermometer exhaust gas measurement for measuring the exhaust gas temperature air pressure gauge at the burner cover no kärcher part number recommendation: testo 510, order number 0560 05610 hose set: order number 0554 0448 measurement co2 content ...

Page 195

English 5.906-736.0 rev. 00 (07/15) 195 5.901-055.0 installation mandrel for hp seals for piston d20mm (hds 13/20, hds 17/20) 6.815-258.0 installation mandrel for oil seals (hds 13/20, hds 17/20) 6.815-209.0 screw attachment locking screw (hds 9/50, hds 13/35) (crown wrench for brass bush low-pressu...

Page 196

196 english 5.906-736.0 rev. 00 (07/15) oil filter wrench no kärcher part number recommendation: oil filter claw hazet 2172 6.491-361.0 revolution counter for motor speed 6.803-003.0 magnetic field tester for the function test of magnetic coils 6.768-004.0 hardness indicators for measuring the overa...

Page 197

English 5.906-736.0 rev. 00 (07/15) 197 note please use the circuit diagram associated with the ma- chine. An excerpt of the circuit diagram, version 07/2015, is en- closed for your information. 17 circuit diagram.

Page 198

198 english 5.906-736.0 rev. 00 (07/15).

Page 199

English 5.906-736.0 rev. 00 (07/15) 199.

Page 200

200 english 5.906-736.0 rev. 00 (07/15).

Page 201

English 5.906-736.0 rev. 00 (07/15) 201.

Page 202

202 english 5.906-736.0 rev. 00 (07/15).

Page 203

English 5.906-736.0 rev. 00 (07/15) 203.

Page 204

204 english 5.906-736.0 rev. 00 (07/15).

Page 205

English 5.906-736.0 rev. 00 (07/15) 205.

Page 206

206 english 5.906-736.0 rev. 00 (07/15).