- DL manuals

- Karcher

- Pressure Washer

- HDS 5/11 U

- Service Manual

Karcher HDS 5/11 U Service Manual

Summary of HDS 5/11 U

Page 1

English 5.906-487.0 rev. 00 (04/10) 1 hds 5/11 u/ux service manual.

Page 2

2 english 5.906-487.0 rev. 00 (04/10) contents 1 preface 4 2 safety instructions 4 2.1 hazard levels 4 3 technical features 4 3.1 general 4 3.2 connection performance of appliance 4 3.3 electrical system 4 3.4 drive 4 3.5 pump 4 3.6 booster heater 4 3.7 cleaner 4 3.8 accessories 4 4 parts of the sys...

Page 3

English 5.906-487.0 rev. 00 (04/10) 3 5.11 motor/pump unit 28 5.11.1 view from above 28 5.11.2 left view 29 5.11.3 sectional illustration 30 5.11.4 cross section of pump head front view 31 5.11.5 single parts, pump head 32 5.11.6 electric box, motor (open) 33 5.11.7 remove the ventilator wheel of th...

Page 4

4 english 5.906-487.0 rev. 00 (04/10) good service work requires extensive and practice- oriented training as well as well-structured training materials. Hence we offer regular basic and advanced training programmes covering the entire product range for all service engineers. In addition to this, we...

Page 5

English 5.906-487.0 rev. 00 (04/10) 5 1 hand spraygun 2 hand lever 3 high pressure hose 4 push handle 5 handgun storage clip 6 hose drum 7 high pressure line 8 cover 9 spray lance 10 water inlet with water fine filter 11 bearing wheel 12 carrying handle 13 high pressure hose output 14 carrying handl...

Page 6

6 english 5.906-487.0 rev. 00 (04/10) 1 hand spraygun 2 hand lever 3 high pressure hose 4 push handle 5 handgun storage clip 6 cover 7 spray lance 8 high-pressure outlet 9 water inlet with water fine filter 10 bearing wheel 11 carrying handle 12 support leg 13 carrying handle 14 power switch 15 exha...

Page 7

English 5.906-487.0 rev. 00 (04/10) 7 1 push handle 2 storage compartment for mains cable 3 power cord with plug 4 lock for fuel tank 5 fill indicators of fuel tank 6 storage for rotor nozzle 7 kick plate to tilt the appliance 8 high-pressure outlet 9 water inlet with water fine filter 10 detergent ...

Page 8

8 english 5.906-487.0 rev. 00 (04/10) 1 deflection rollers high pressure hose 2 support leg 3 carrying handle 4 guide for high pressure hose 5 high pressure hose 6 axle 7 air suction for motor cooling 8 air suction for burner blower 4.4 view from below.

Page 9

English 5.906-487.0 rev. 00 (04/10) 9 to remove the appliance hood, you must unlock it by means of a screwdriver. Unlock the appliance hood from above using a screwdriver and remove it. 1 high pressure line 2 ignition transformer 3 protective conductor 4 burner 5 water inlet with water fine filter 6...

Page 10

10 english 5.906-487.0 rev. 00 (04/10) 1 exhaust nozzle, on-demand heater 2 exhaust temperature sensor 3 fuel line 4 continuous heater 5 aeration/deaeration of the fuel tank 6 fuel tank 7 electronics system 8 air guidance burner blower 9 air volume setting 10 fuel filter 11 screw connection of fuel ...

Page 11

English 5.906-487.0 rev. 00 (04/10) 11 1 water connection 2 suction hose with filter and backflow valve (option) 3 open container 4 water supply hose 5 water fine filter 6 pressure switch 7 detergent injector 8 cooling air routing 9 ventilator wheel, motor cooling 10 ventilator wheel, burner blower ...

Page 12

12 english 5.906-487.0 rev. 00 (04/10) 1 switch position "off" 2 switch position "cold water operation" 3 switch position "hot water operation" 4 power switch the appliance switch on the front of the appliance has three different switch positions. – "off": appliance is switched off – "cold water ope...

Page 13

English 5.906-487.0 rev. 00 (04/10) 13 open the switchbox lift the electric box out of its holder by alternatingly lifting it toward the top. Bend up the four side tabs and remove the top part. 1 electronics system 2 side tabs 3 top part of electric box 1 exhaust temperature monitor 280°c 2 capillar...

Page 14

14 english 5.906-487.0 rev. 00 (04/10) 1 air guidance to the on-demand heater 2 slider, air volume adjustment 3 stop screw, air volume adjustment 4 return to fuel tank 5 fuel hose supply to the fuel pump 6 connecting cable of solenoid valve and fuel pump 7 access opening of fuel pressure adjustment ...

Page 15

English 5.906-487.0 rev. 00 (04/10) 15 burner blower the blower supplies the burner with combustion air. The slider is used to set the air volume to optimal combustion values. The blower wheel is mounted to the motor shaft by means of a fitting key. 1 stop screw 2 air slider 3 mark to adjust the air...

Page 16

16 english 5.906-487.0 rev. 00 (04/10) 1 ignition transformer 2 protective conductor 3 fuel nozzle holder 4 burner cover 5 exhaust nozzle, on-demand heater 6 heating coil 7 exhaust temperature sensor 8 capillary exhaust temperature monitor 9 connection for air pressure measurement 10 fuel line 11 sc...

Page 17

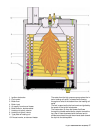

English 5.906-487.0 rev. 00 (04/10) 17 1 ignition electrodes 2 fuel nozzle 3 boiler floor 4 boiler input 5 air supply from burner blower 6 boiler exterior, double-walled 7 heating coil spiral, exterior 8 heating coil spiral, interior 9 type plate of heating coil 10 exhaust nozzle, on-demand heater t...

Page 18

18 english 5.906-487.0 rev. 00 (04/10) the boiler floor is made of fire-resistant insulating concrete. It prevents a radiation of the heat and is used to reroute the flames. The adjustment of the burner to good exhaust values is achieved via the air slider on the blower (air vol- ume) and with the a...

Page 19

English 5.906-487.0 rev. 00 (04/10) 19 1 ignition electrodes 2 fuel nozzle holder 3 fuel nozzle, spray angle 45° or 60°, depending on the type of appliance 4 screw 5 burner cover ignition electrodes there is a strong spark created between the two igni- tion electrodes to ensure that the injected fue...

Page 20

20 english 5.906-487.0 rev. 00 (04/10) pull of the flame ring, if it does not remain in the boiler during removal. 1 ignition transformer 2 burner cover 3 flame ring 4 pressure plate pull off the pressure plate. 1 pressure plate to replace the ignition electrodes, remove the screw and take out the i...

Page 21

English 5.906-487.0 rev. 00 (04/10) 21 1 replacement gun 2 spray lance 3 series gun note there are no spare parts available for the series gun. There are disis spare parts available for the series gun. 5.8 hand spray gun and triple nozzle 5.8.1 hand spraygun.

Page 22

22 english 5.906-487.0 rev. 00 (04/10) the triple nozzle can be adjusted to three different settings. By rotating the nozzle head, you can switch between the chemical nozzle and the high pressure nozzles. The symbols on the nozzle head show which nozzle type is selected. Setting a means high pressur...

Page 23

English 5.906-487.0 rev. 00 (04/10) 23 the entire top part must be removed to gain access to the high pressure pump. A workshop lifting platform is recommended for this procedure. Also see chapter 6.1brief overview, dismantling / as- sembly. Completely unwind the high pressure hose. Pull out the saf...

Page 24

24 english 5.906-487.0 rev. 00 (04/10) 1 fuel line to burner 2 fuel line from the fuel pump set up the appliance. Unlock the holding clip of the temperature sensor with a tool, without damaging the temperature sensor and remove it from the exhaust stack. Remove the temperature sensor and carefully u...

Page 25

English 5.906-487.0 rev. 00 (04/10) 25 remove two screws on the base plate of the on- demand heater. 1 base plate for on-demand heaters 2 screw loosen the screw on the right of the on-demand heater and swivel the holding plate to the side. 1 screw 2 holding plate lift the electric box out of its hol...

Page 26

26 english 5.906-487.0 rev. 00 (04/10) pull out the safety clip of the high pressure line. 1 safety block 2 safety clip 3 high pressure line remove the safety block. 1 safety block 2 high pressure line 1 high pressure line remove the bottom of the appliance from the on- demand heater. 1 temperature ...

Page 27

English 5.906-487.0 rev. 00 (04/10) 27 1 storage for spray pipe 2 holding plate for the base plate of the on-demand heater 3 water inlet with water fine filter 4 electric box, motor 5 blind plug (do not remove, do not fill in liquids) 6 holder, electric box 7 cool air guidance and motor cover 8 burn...

Page 28

28 english 5.906-487.0 rev. 00 (04/10) remove 6 screws from the motor cover. Remove the motor cover. 1 screws, motor cover 2 cool air guidance and motor cover lift the motor/pump unit from the floor group. Remove the fuel pump. 1 motor/pump unit 2 side motor intake (2x) 3 centre motor intake (2x) 4 ...

Page 29

English 5.906-487.0 rev. 00 (04/10) 29 1 ventilator wheel, burner blower 2 ventilator wheel, motor cooling 3 motor intake 4 water inlet with water fine filter 5 fastening screw, water inlet 6 holding clip, water inlet 7 pump head screws 8 pump head 9 holding plate, pressure valves 10 connection dete...

Page 30

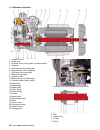

30 english 5.906-487.0 rev. 00 (04/10) 1 pressure switch 2 switch cam 3 overflow valve (control piston, pressure switch) 4 capacitor 5 axial ball bearing, swash plate 6 motor bearing, front (a bearing) 7 shaft seal ring, motor shaft 8 motor winding (stator) 9 solenoid (rotor) 10 motor bearing, rear ...

Page 31

English 5.906-487.0 rev. 00 (04/10) 31 1 pressure spring 2 sphere 3 connection of detergent hose 4 injector 5 holding plate 6 pressure holding valve 7 pressure valve 8 stopper 9 suction area 10 piston 11 cylinder head screws 12 connection, safety block 5.11.4cross section of pump head front view.

Page 32

32 english 5.906-487.0 rev. 00 (04/10) 1 cap 2 pressure valve 3 valve seat 4 pump head 5 restrictor 6 suction valve 7 high pressure seal 8 connecting sleeve 5.11.5single parts, pump head.

Page 33

English 5.906-487.0 rev. 00 (04/10) 33 1 electric box, motor 2 seal 3 cable to the electric box, appliance 4 pressure switch 5 leaf spring 6 switch cam 7 capacitor 8 connection, protective conductor 9 connecting cable, motor 10 fastening screws, electric box note to remove the pump head, the electri...

Page 34

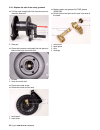

34 english 5.906-487.0 rev. 00 (04/10) remove the screw and pull the ventilator wheel off. 1 screw 2 ventilator wheel, burner blower remove the screws and take off the safety block. 1 safety block 2 screws 1 fastener, reed switch 2 reed switch 3 connection to the pump head 4 safety valve note when i...

Page 35

English 5.906-487.0 rev. 00 (04/10) 35 1 locking screw, lack of water fuse 2 spring 3 adjustment screw, safety valve 4 spring, safety valve 5 valve disks 6 outlet bore, high pressure (not visible here) 7 spring plate 8 high pressure inlet from pump head 9 solenoid piston, lack of water fuse the dete...

Page 36

36 english 5.906-487.0 rev. 00 (04/10) remove the fastening screw of the water inlet on the pump head. Pull the holding clip downwards. Remove the water inlet toward the side. 1 water inlet 2 screw 3 retaining clip note the removal of the pressure switch control piston is not required to remove the ...

Page 37

English 5.906-487.0 rev. 00 (04/10) 37 remove the pump head the pump head screws go through the piston casing and are screwed into the motor casing. Therefore, in order to be able to remove the pump head without having to remove the piston casing, the piston housing must be fastened to the motor cas...

Page 38

38 english 5.906-487.0 rev. 00 (04/10) after repairing the pump, you must perform a test run to check the pump for leaks and proper operation. This can be done without connecting the on-demand heater. Assemble the motor/pump unit and place it into the chassis without the fuel pump . Install the cool...

Page 39

English 5.906-487.0 rev. 00 (04/10) 39 the entire top part must be removed to perform the following work: – working on the pump – working on the motor – working on the electric box of the motor – working on the blower – working on the fuel pump the exact explanation of the work steps is detailed in ...

Page 40

40 english 5.906-487.0 rev. 00 (04/10) the back of the appliance must be removed for the following work: – working on the heating coil – working on the heating coil connections – working on the high pressure lines – working on the mains cable – working on the fuel tank the exact explanation of the w...

Page 41

English 5.906-487.0 rev. 00 (04/10) 41 remove high pressure hose as described in chap- ter 5.9.1remove high pressure hose (ux version only) . Remove the screws on the pushing handle and pull the pushing handle off toward the top. 1 push handle 2 screws remove the safety clip of the high pressure lin...

Page 42

42 english 5.906-487.0 rev. 00 (04/10) pull the crank straight off of the hose drum and re- move the side part. 1 crank 2 side part remove the screws underneath the side part and take out the hose drum half shell. 1 screws 2 hose drum half shell remove the seal screw. Remove the knot and the axle. 1...

Page 43

English 5.906-487.0 rev. 00 (04/10) 43 remove the tank lid. Remove the rear wall (2 screws). Replace the tank lid. 1 screws 2 reservoir cover note an accurate basic adjustment of the burner is only possible if the heating coil was previously thoroughly desooted and the deposits were removed.Eine ex-...

Page 44

44 english 5.906-487.0 rev. 00 (04/10) 1 adjusting screw 2 high pressure connection 3 safety valve (built into the safety block) 4 drain bore increase the opening pressure: turn the adjustment screw in a clockwise direc- tion. Decrease the opening pressure: turn the adjustment screw in an anticlockw...

Page 45

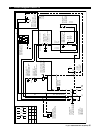

English 5.906-487.0 rev. 00 (04/10) 45 7 circuit diagram 0.089-212 -f1 -c1 kondensator capacitor condensateur condensador -t1 pe pe -y1 -b2 1 c pe pe pe pe pe -d1 pe -p1 h -b1 p -f2 u2 u1 z2 z1 thermokontakt thermostat contact thermo-contact termostÁtico contacto motor motor moteur motor rot red rou...

Page 46

46 english 5.906-487.0 rev. 00 (04/10) 8 troubleshooting fault remedial action unit does not work – no mains power. Check the mains connection. – check/replace the appliance switch. – overflow valve / pressure switch stuck - check, grease, replace. – motor overloaded, overheated; switch off the appl...

Page 47

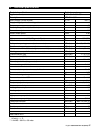

English 5.906-487.0 rev. 00 (04/10) 47 * 1 k(elvin) = 1 °c ** 1 mmws = 98 hpa = 98 mbar 9 technical specifications technical specifications preliminary values appliance number 1.064-001 / 1.064-002 description hds 5/11 u/ux mains voltage / phase number v / ph 230 / 1 supply voltage, permissible volt...

Page 48

48 english 5.906-487.0 rev. 00 (04/10) the current technical specification sheets and circuit diagrams will be included in the next version of the spare parts cd disis/disiplus and in the kaercher- inside (https://kaercher-inside.Com). Appliance type appliance no.: circuit diagram operating instruc-...

Page 49

English 5.906-487.0 rev. 00 (04/10) 49 information about the air pressure gauge testo 510 – differential pressure gauge for pressure measure- ments in the range between 0 and 100 hpa. – temperature compensation – air tightness compensation – incl. Hand sling and belt pouch – lit up display – selecta...

Page 50

50 english 5.906-487.0 rev. 00 (04/10) the maintenance intervals for these appliances are defined in the maintenance book hd/hds appliances 5.950-582. 11 tightening torques detergent connection on the injector nm 12 - 15 cylinder head screws nm 18 - 23 swash plate, screw glued nm 12 - 15 lock screws...