- DL manuals

- Karcher

- Pressure Washer

- MC 50

- Original Instructions Manual

Karcher MC 50 Original Instructions Manual

Summary of MC 50

Page 1

Www .Kaercher .Com/register-and-win mc 50 mic 34c 59633150 09/13.

Page 2

2.

Page 3

- 1 please read and comply with these original instructions prior to the initial operation of your appliance and store them for later use or subsequent own- ers. Before first start-up it is definitely neces- sary to read the safety indications no. 5.956-250! These operating instructions describe 2 a...

Page 4

- 2 your sales outlet should be informed about any transit damage noted when unpacking the product. – read and adhere to the operating in- structions and safety notes of the at- tachments affixed to the appliance. – warning and information plates on the machine provide important directions for safe ...

Page 5

- 3 – the machine with working equipment must be checked to ensure that it is in proper working order and is operating safely prior to use. Otherwise, the appli- ance must not be used. – appliances may not be used in outside areas in low temperatures. – if the appliance is used in hazardous ar- eas ...

Page 6

- 4 1 door handle * 2 steering column * 3 work light 4 steering wheel 5 ceiling panel * 6 tank lid 7 filling nozzle for fresh water tank 8 diffuser 9 fresh water level display 10 hydraulic oil sight glass 11 hose coupling of water circulation sys- tem (option) 12 tank indicator f = full e = empty 13...

Page 7

- 5 1 door handle * 2 steering column * 3 work light 4 steering wheel 5 ceiling panel * 6 tank lid 7 license plate holder 8 hydraulic oil sight glass 9 balance weight with attachment hitch 10 container windshield washer system 11 drive light/direction indicator 12 tank indicator f = full e = empty 1...

Page 8

- 6 1 brake pedal 2 locking mechanism of brake pedal (emergency brake) 3 stop work speed 4 accelerator pedal, forwards 5 accelerator pedal, reverse press the brake pedal all the way. put the lock. release the brake pedal. press the brake pedal all the way. unlock the lock. release the br...

Page 9

- 7 a control lever 2.Pto connection side brush on, sweep side brush stop side brush on, reversal of rota- tion b control lever front power lift lower work appliance, floating lower work appliance and press down lift work appliance (only while en- gine is running) c control lever aux 1 connection 3....

Page 10

- 8 a control lever 2.Pto connection b control lever front power lift c control lever aux 1 connection d control lever aux 2 connection note: in connection with the front appli- ance carrier and the weed broom a mul- tifunction lever is available instead of the control lever (optional) e for working...

Page 11

- 9 a multifunction lever in connection with front appliance carrier and weed broom is optionally available. attach the document pouch to the rear window as instructed in the enclosed in- structions. Danger risk of explosion! – do not refuel the machine in enclosed spaces. – smoking and naked flam...

Page 12

- 10 the following safety tests must be conduct- ed prior to each operation: danger risk of accidents, injuries. If one point of the safety check is not fullfilled, the appli- ance must not be taken into operation, but must be repaired. Perform the safety check while the ignition is switched on (pos...

Page 13

- 11 push lever a towards the front. Side brush sweeping is switched on. pushbutton (7) switch on work hydrau- lics main pto. Suction turbine is running. when sweeping dry waste: switch on switch (6) for irrigation of the side brush. Switch on the water circulation system if needed (option). ...

Page 14

- 12 if frost is expected, check whether there is enough anti-frosting agent in the cooling water. empty the water reservoir and the pipe system; refer to chapter "maintenance work/empty water reservoir") (option). Caution risk of damage! Never attach the appli- ance to the brush system or tow i...

Page 15

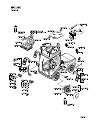

- 13 1 hydraulic couplings aux2 hydraulic couplings, swivel drive 2 hydraulic couplings main pto hydraulic couplings, brush roller drive 3 hydraulic hoses, brush roller drive 4 hydraulic hoses, swivel drive if the front brush roller is to be used while the waste container/fresh water tank is at- tac...

Page 16

- 14 route the cables as shown above. connect the plug on the rear of the sweeper. – if no caster is attached, the balance weight (option) must be attached to the rear of the machine for driving on public roads, when the waste container/water tank is removed. Note: removing the waste container/f...

Page 17

- 15 remove the protective caps from the hydraulic coupling and connect the hy- draulic hoses with the respective cou- plings. connect the protective caps to each other to protect from contamination. connect the plug on the rear of the sweeper. secure the cable if necessary to pre- vent it f...

Page 18

- 16 install the safety support prior to working on the machine with the waste container raised: 1 spring pin 2 safety support pull out the spring plug. remove the safety support from the waste container. 1 safety support 2 piston rod insert safety support onto the piston rod of a lifting cyli...

Page 19

- 17 start the appliance. set engine speed to eco. place the water hose in front of the suc- tion opening and open the water supply. switch on the suction turbine. let the suction turbine run for approx. 2 minutes. switch off the suction turbine. change-over switch (14) to waste con- t...

Page 20

- 18 lap the inlet and outlet valve seats (by customer service). safety inspection according to local regulations by customer service. Danger risk to life when carrying out repairs, remove the ve- hicle from the danger zone of passing traf- fic and wear reflective clothing. Danger risk of injury...

Page 21

- 19 intake points for the jack loosen the wheel nuts/wheel bolts by about 1 revolution using a suitable tool. raise machine using vehicle jack. unscrew the wheel nuts/wheel bolts and remove them. remove wheel. have the defective wheel repaired by a specialised repair shop. place the whe...

Page 22

- 20 danger risk of burns due to hot oil or possible hot hose lines! ready a catch bin for appr. 6 litre oil. allow engine to cool down. unscrew oil drain plug. unscrew the oil fill lid. drain off oil. unscrew the oil filter. clean the intake and sealing areas. coat the washer of the...

Page 23

- 21 – use a water and antifreeze mixture to refill. – do not mix different antifreeze types. – use only soft water for the water and antifreeze mixture. – refill cooling water only while the en- gine is cool. remove the right engine panel. If the cooling water reservoir is completely empty, first...

Page 24

- 22 caution risk of damage. Do not ventilate the fuel system by activating the starter. check if the fuel tank is filled. open the drain tap on the fuel filter and on the water separator. 1 pump lever press the pump lever down several times until the fuel system is ventilated. start the mot...

Page 25

- 23 1 v-belt caution risk of functional disturbances. Do not let the v-belts get in contact with the grease. lubricate the grease nipples marked with an arrow with the grease gun. lubricate the grease nipples marked with "*" arrows prior to starting work dai- ly. use high quality multi-purpos...

Page 26

- 24 1 v-belt caution risk of functional disturbances. Do not let the v-belts get in contact with the grease. lubricate the grease nipples marked with an arrow with the grease gun. lubricate the grease nipples marked with "*" arrows prior to starting work dai- ly. use high quality multi-purpos...

Page 27

- 25 lower the brush. turn off the appliance. separate the couplings. raise the brush manually and unhook the wire rope. swing the safety pin forward and pull it out. lift off the sweeping system. Note if the water tank had got completely empty, then it is necessary to deaerate the spray...

Page 28

- 26 loosen the screws. remove the headlights. remove defective bulb. insert new bulb. Note: wear clean and grease-free gloves. turn the bulb seating in the direction of the arrow and pull it out. 1 bulb pull the bulb out of the seating and in- sert a new bulb. Note: wear clean and greas...

Page 29

- 27 1 cover remove the lid. 1 fuse 10 a indicator lamps, cooling water tempera- ture buzzer, fuel pump, reverse horn, 7- way socket outlet front, 2-way socket outlet front, motor shutoff valve timer, motor shutoff valve (holding current) 2 fuse 20 a 2-pin socket front, 7-pin socket front, 2- pin ...

Page 30

- 28 troubleshooting faults with display display cause remedy by whom warning lamp for motor temperature lights up engine is overheated set the engine speed to idle. Clean the radiator (see "care and maintenance). Run the engine in idle until the warning lamp turns off. Check the level of cooling li...

Page 31

- 29 caution risk of damage. The appliance must not be towed. Do not move the sweeper at a speed higher than walking speed. Danger the appliance is not approved for crane loading. Note make sure the brush system is not dam- aged while pushing (for sweepers). drain the spray water (for sweepers). ...

Page 32

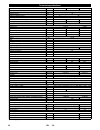

- 30 * with sweeping unit technical specifications mc 50 classic mc 50 advanced mic 34c drive speed, forward km/h 20 drive speed, reverse km/h 8 working speed km/h 10 climbing capability (max.) % 15 25 driven axles 2 theoretical surface cleaning performance m 2 /h 14000 14000 14000* working width mm...

Page 33

- 31 centre of gravity position when the appli- ance is fully loaded. Position of centre of gravity without attach- ments installed. We hereby declare that the machine de- scribed below complies with the relevant basic safety and health requirements of the eu directives, both in its basic design and...

Page 36

Http://www.Kaercher.Com/dealersearch.