- DL manuals

- Keating Of Chicago

- Fryer

- GAS FRYER

- Service Manual

Keating Of Chicago GAS FRYER Service Manual - Post This Label In A

i

POST THIS LABEL IN A

PROMINENT LOCATION ON

YOUR UNIT

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

IMPORTANT

IN THE EVENT A GAS ODOR IS

DETECTED, SHUT DOWN UNITS AT

MAIN SHUT OFF VALVE AND CONTACT

THE LOCAL GAS COMPANY OR GAS

SUPPLIER FOR SERVICE.

Summary of GAS FRYER

Page 1

Instant recovery® gas fryer service manual keep this manual for training new personnel 1-800-keating www.Keatingofchicago.Com.

Page 2: Table of Contents

Table of contents section i introduction safety precautions . . . . . . . . . . . . . . . . . . . . . . .1-2 section ii installation damage during shipment . . . . . . . . . . . . . . . . . . .2 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 positioning . . . . . . . . . ....

Page 3: Post This Label In A

I post this label in a prominent location on your unit warning improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment. For...

Page 4: I Introduction

I introduction safety precautions warning this symbol warns you that serious burns or other injuries may result if safety instructions are not followed. This service manual should be retained in a safe place for future reference. The installation of your new fryer must conform to local codes or in t...

Page 5: II Installation

2 installed in accordance with all local codes, or in the absence of local codes, with the current national fuel gas code z223.1/nfpa 54, natural gas installation can/cga-b149.1 or propane installation code can/cga-b149.2 installed under a properly designed operating exhaust hood. Connected to the t...

Page 6

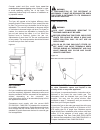

3 counter model and floor model fryers must be restrained to prevent tipping when installed in order to avoid splashing, spilling, etc. Of hot liquid. The restraining method may be a manner of installation or by separate means. Leveling the fryer will operate at its highest efficiency when properly ...

Page 7: III Operating

4 a 3/4” npt manual gas valve is factory installed with each floor model fryer (for single fryers and batteries), except for 10x11aa – 20aa models which use a 1/2” npt valve. The required gas pressure for proper operation of each fryer is 4” water column for natural gas and 10” water column for prop...

Page 8

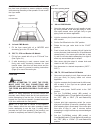

Caution: oil expands when heated. The “fill level” line has been provided to ensure optimum cooking while ensuring the safety of the operator. Do not overfill the fryer vessel. Figure 3-1 fill level line a. Aa and cmg models 1. Fill the fryer vessel with oil or melted solid shortening up to the “fil...

Page 9

6 7. Set the thermostat to the desired temperature (325°f - 335°f). Melting the keating melt cycle safely melts solid shortening in the fryer vessel without scorching. Warning before attempting to use the fryer, make sure the fryer has been properly filled with oil. A. Bb, ts and basket-lift models ...

Page 10

6. Push “start/stop” button on timers(s). Basket(s) will automatically lower into fryer vessel. 7. When cooking cycle is complete, an audible alarm will sound and the basket(s) will raise automatically. Allow oil to drain before removing baskets. D. Cpu model see separate fryer instructions or call ...

Page 11

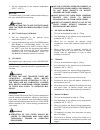

8 figure 3-5 nutroilator filter and fryer warning under no circumstances should you permit hot oil to come in contact with water or ice. All draining should be done under the supervision of properly trained personnel. A drain pipe and covered container suitable for use with hot oil should be used wh...

Page 12

Warning when your fryer is being used in conjunction with a central filter, disconnect power supply before resetting motor to prevent serious injury when reset switch is engaged (see filter manual). 16. Check thermostat bulb positioning – see page 10. 17. Refill the fryer with new or filtered oil. E...

Page 13: IV Maintenance

10 output contacts will close. During the countdown the colon will flash at a one-second rate. When the countdown has reached "00:00" the relay output contacts will open, the display will flash, and the audible alarm will sound. To cancel the audible alarm, press any button. Pause feature to pause a...

Page 14: V Service Diagnosis

C. Thermostat bulb positioning before replacing, test thermostats: these operational problems can easily be corrected by thermostat bulb positioning. Keating’s patented thermostat application is accurate within 2°f of the dial setting between 250°f – 350°f. This accuracy is attained only if the ther...

Page 15

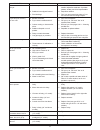

12 a. Trouble shooting the following diagnosis is only to be used as a guide to qualified service personnel. Keating recommends that you use a qualified service company. Call 1-800-keating if you need assistance in locating a qualified service company. Problem probable cause solution constant pilot ...

Page 16

13 problem probable cause solution flames come out front a. Exhaust problems. A. Install deflector to block down draft. Of fryer. Install or adjust flue restrictors. If problem persists, contact your hvac representative. B. Radiants have slipped forward. B. Reposition radiants. C. Flue blockage. C. ...

Page 17: VI Parts Lists

14 vi parts lists ordering parts parts may be ordered by part number by calling keating at 1-800-keating or your local service company. You may also order on-line at keating’s part store, www.Keatingofchicago.Com refer to the keating instant recovery® gas fryer limited warranty for complete service ...

Page 18

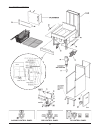

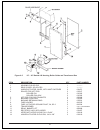

15 ts control panel aa/cmg control panel bb control panel gas fryer assembly.

Page 19

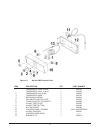

16 runner pilot assembly see page 16 for part numbers..

Page 20

17 figure 6-1 aa and cmg control panel item description qty part number 1 thermostat 14cm & 14aa 1 023145 thermostat 10x11 18 & up 1 035553 2 thermostat dial plate 1 030833 3 thermostat knob 1 004163 4 retaining screws 3 004610 5 fry/on/off switch plate 1 007997 6 toggle switch, fry/on/off 1 004499 ...

Page 21

18 figure 6-2 bb & ts control panel item description model qty part number 1 thermostat 14 bb & ts 1 035574 thermostat 10x11, 18 & up 1 035575 2 thermostat dial plate bb & ts 1 004164 3 thermostat knob bb & ts 1 004163 4 retaining screws bb & ts 3 004610 5 set of (4) lights 120v, with plates ts 1 00...

Page 22

19 figure 6-3 14" – 24" basket-lift control panel item description qty part number 1 thermostat 14ts 1 035574 thermostat 10x11, 18 & up 1 035575 2 thermostat dial plate 1 004164 3 thermostat knob 1 004163 4 retaining screws 3 004610 5 set of (4) lights 120v, with plates 1 004156 6 pilot on momentary...

Page 23

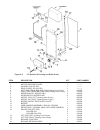

20 figure 6-4 14” basket-lift housing and roller guide item description qty part number 1 motor and wire cover 1 ---------- 2 housing, s/s or crs 1 ---------- 3 rear cover, s/s or crs 1 ---------- 4 left side crank bar and cam (viewing front of fryer) 1 016209 5 right side crank bar and cam (viewing...

Page 24

21 figure 6-5 18" - 24" basket-lift housing, roller guide and transformer box item description qty part number 1 housing, s/s or crs 1 ---------- 2 rear cover, s/s or crs 1 ---------- 3 linear actuator, 24vdc, with limit switches 2 018471 4 roller for lift rod 2 015817 roller pin 2 016393 roller pin...

Page 25: Viii Wiring Diagrams

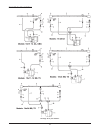

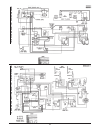

22 viii wiring diagrams note: separate wiring diagrams have been attached to the fryer and on the inside of this manual and should be saved for troubleshooting and maintenance. The wiring diagrams in this section cover standard fryers which may or may not match the diagrams sent with the fryer. Non-...

Page 26

23 bb wiring diagram ts wiring diagram.

Page 27

18” and above ts with basket -lift wiring diagram 24 14 ts with basket -lift wiring diagram.

Page 28: Arranty

L imited w arranty keating of chicago, inc. ("keating”) warrants to the original purchaser . ("customer"), all new keating fryers, filter systems, griddles, keep krisp®, custom pasta systems, top-side™ cookers, computer t imers, fryer & pasta v essels, and keating replacement parts ("products") inst...

Page 29

Keating limited warranty card please complete and mail at once–warranty is not in effect until card is returned company: ______________________________________________________________________________________________________________ address: ___________________________________________________________...