- DL manuals

- Keating Of Chicago

- Fryer

- INSTANT RECOVERY GAS FRYER

- Service Manual

Keating Of Chicago INSTANT RECOVERY GAS FRYER Service Manual

Summary of INSTANT RECOVERY GAS FRYER

Page 1

Instant recovery® electric fryer service manual keep this manual for training new personnel 1-800-keating www.Keatingofchicago.Com elecfrypre2000_0310 03/13 part#000784.

Page 2: Table of Contents

I table of contents section i introduction general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 standard features . . . . . . . . . . . . . . . . . . . . . . . . . .1 model variations . . . . . . . . . . . . . . . . . . . . . . . . . . .1 safety precautions . . . . . . . . . ...

Page 3: I Introduction

1 i introduction general keating instant recovery® electric fryers are designed to give maximum production efficiency, delivering high quality food products. The following design features are incorporated in keating instant recovery® electric fryers. Standard features highly polished stainless steel...

Page 4: II Installation

2 never move a fryer when full of hot oil. Never introduce objects or liquids into fryer, while operational, which are not designed or made for cooking. This fryer may not be altered, modified or changed in any way. Warning improper installation, service or maintenance can cause property damage, inj...

Page 5: III Operating

3 restraining devices on fryer installations with casters, casters and jam nuts must be completely tightened. Adequate means must also be provided to limit the movement of the appliance. Electrical connection the keating instant recovery® electric fryer is equipped with a three wire terminal block f...

Page 6

4 bb & ts, cpu and basket-lift models 1. Fill the fryer vessel with oil up to the “fill level” line. (refer to pages 37 and 38 for the oil capacity of your particular model). 2. If using solid shortening is used, remove screen and firmly pack solid shortening between the heating elements. Proceed to...

Page 7

5 b. Ts model 1. Fill fryer as described on page 3 and 4 - filling. 2. Set on/off switch to the “on” position. “heat” light will be illuminated. 3. Set thermostat to the desired frying temperature (between 325°c and 335°c). 4. When the oil reaches the desired frying temperature, the “heat” light wil...

Page 8

6 figure 3-5 rear drain valve warning under no circumstances should you permit hot oil to come in contact with water or ice. All draining should be done under the supervision of properly trained personnel. A drain pipe and covered container suitable for use with hot oil should be used whenever a fry...

Page 9

7 14. Prior to refilling with oil, wipe the inside of the fryer vessel making sure all water and klenzer has been removed. Warning water in any form and hot oil don’t mix!!! 15. Close drain valve. Warning failure to close drain valve before refilling the fryer may result in serious injury. Warning w...

Page 10

8 0 = seconds (000.1 to 999.9) 5 second alarm 1 = minutes : seconds (00:01 to 59:59) 5 second alarm 2 = seconds (0001 to 9999) 5 second alarm 3 = hours : minutes (00:01 to 23:59) 5 second alarm 4 = seconds (000.1 to 999.9) continuous alarm 5 = minutes : seconds (00:01 to 59:59) continuous alarm 6 = ...

Page 11: IV Maintenance

9 iv maintenance warranty repairs keating’s warranty begins with the date of installation. In the event that your fryer, under warranty, needs repairs other than routine maintenance or cleaning, you are requested to contact keating of chicago (at 1- 800-keating) before calling a local service compan...

Page 12: V Service Diagnosis

Simply loosen three dial plate retaining screws, rotate dial plate to match thermometer reading and tighten screws. For calibration over a 15°f difference, contact your local service distributor. Note: locate thermometer in same position for every calibration. Position next to upper heating element ...

Page 13: V Service Diagnosis

11 problem probable cause solution fryer has poor recovery a. Over-filling baskets. A. Don’t over fill baskets. Or runs cold. B. Fryer vessel overfilled with oil. B. Fill fryer up to “fill level” line as oil expands when heated. C. Thermostat out of calibration. C. Calibrate thermostat. See page 9 -...

Page 14: V Service Diagnosis

12 problem probable cause solution basket-lift mechanism a. Connections are loose or time is a. Tighten connections. Replace timer if will not operate. Faulty. B. Motor limit switch is faulty. B. Replace limit switch (10x11 and 14 ts bl replace actuator (18 ts bl model and above.) c. Lift motor is f...

Page 15

13 electric fryer parts list item description models part # 10x11 14 18 20 24 34x24 1 heating element 2500 w bb 004347 3 3800 w ts 005623 3 4350 w bb 004349 3 6000 w bb 004353 3 3 ts 004353 4 4 bb 004355 4 5 ts 004355 5 6 6500 w ts 014493 3 teflon ring bb, ts 004318 2 per element 5/8” flat washer bb...

Page 16

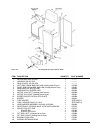

14 electric fr yer assembl y i note: part numbers correspond with the electric fryer parts list on page 13. Electric fr yer assembl y ii exploded view of heating element wire connection hardware.

Page 17

15 item description quantity part number 1 thermostat 1 031099 2 thermostat dial plate 1 058037 3 thermostat knob, black 1 060612 4 retaining screws 3 004610 5 on/off/melt switch plate 1 009919 6 toggle switch, on/off/melt 1 004326 7 indicating light - amber 220v 2 004157 8 hi-limit test plate 1 004...

Page 18

16 item description quantity part number 1 thermostat 1 031099 2 thermostat dial plate 1 058037 3 thermostat knob, black 1 060612 4 retaining screws 3 004610 5 lights, white 3 016639 light, red 1 016640 mounting plate 1 ---------- 6 toggle switch, on/off/melt 1 004326 7 hi-limit test button 1 004304...

Page 19

17 item description quantity part number 1 thermostat 1 031099 2 thermostat dial plate 1 058037 3 thermostat knob, black 1 060612 4 retaining screws 3 004610 5 set of (4) lights, 120v, with plates 1 004156 6 toggle switch, on/off/melt 1 004326 7 hi-limit test button 1 004304 8 timer 2 023709 9 melt ...

Page 20

18 figure 6-4 18” - 34”x 24” basket-lift control panel item description quantity part number 1 thermostat 1 031099 2 thermostat dial plate 1 058037 3 thermostat knob, black 1 060612 4 retaining screws 3 004610 5 set of (4) lights, 120v, with plates 1 004156 6 toggle switch, on/off/melt 1 004326 7 hi...

Page 21

19 figure 6-5 14” basket-lift housing and roller guide item description quantity part number 1 motor and wire cover 1 ---------- 2 housing, s/s or crs 1 ---------- 3 rear cover, s/s or crs 1 ---------- 4 left side crank bar and cam (viewing front of fryer) 1 016209 5 right side crank bar and cam (vi...

Page 22

20 figure 6-6 18” - 34”x24” basket-lift housing, roller guide and transformer box item description quantity part number 1 housing, s/s or crs 1 ---------- 2 rear cover, s/s or crs 1 ---------- 3 linear actuator, 24vdc, with limit switches 2 018471 4 roller for lift rod 2 015817 roller pin 2 016393 r...

Page 23: Vii Wiring Diagrams

14 bb and 14 bb with whirl-o-swirl-a-w a y wiring diagrams 21 vii wiring diagrams note: a separate wiring diagram has been included with this manual and should be saved for troubleshooting and maintaining the fryer. The wiring diagrams in this section cover standard fryers which may or may not match...

Page 24

22 14 ts and 14 ts with whirl-o-swirl-a-w a y wiring diagrams 14 ts with whirl-o-swirl-a-way 14 ts.

Page 25

23 14, 20 ts & 18 20 ts with whirl-o-swirl-a-w a y wiring diagrams 18, 20 ts 18, 20 ts with whirl-o-swirl-a-way.

Page 26

24 14 ts with basket -lift with whirl-o-swirl-a-w a y wiring diagrams 14 ts with basket-lift 14 ts with basket-lift with whirl-o-swirl-a-way.

Page 27

25 24 ts with basket -lift with whirl-o-swirl-a-w a y wiring diagrams 24 ts with basket-lift 24 ts with basket-lift.

Page 28

26 ix keating fryer specifications bb fm-e models a m p s volts kw single l1 l2 l3 phase 208 6.7 19 19 19 32 220 7.5 20 20 20 34 240 8.9 22 22 22 37 amps per line-three phase 3 elements (2500 w each) a m p s volts kw single l1 l2 l3 phase 208 11.7 32 32 32 56 220 13.1 34 34 34 59 240 15.5 37 37 37 6...

Page 29

27 ts fm-e models a m p s volts kw single l1 l2 l3 phase 208 10.2 28 28 28 49 220 11.4 30 30 30 52 240 13.6 33 33 33 57 amps per line-three phase 3 elements (3800 w each) a m p s volts kw single l1 l2 l3 phase 208 17.4 48 48 48 84 220 19.5 51 51 51 89 240 23.2 56 56 56 97 amps per line-three phase 3...

Page 31

Service information if you have a service related question call 1-800-keating. Please state the nature of the call; it will ensure speaking with the appropriate person. Have your serial and model number available when ordering parts. Keating of chicago, inc. 8901 w. 50th street mc cook, il 60525-600...