- DL manuals

- KEB

- Lifting Systems

- COMBIVERT F4-F

- Instruction Manual

KEB COMBIVERT F4-F Instruction Manual

Summary of COMBIVERT F4-F

Page 1

10/98 00.F4.L1b-k140 keb combivert f4-f lift aufzugstechnik version 1.4 (lift-servo) lift technology betriebsanleitung instruction manual a n t r i e b s t e c h n i k.

Page 2

Information hilfe tip gefahr warnung vorsicht achtung, unbedingt beachten diese betriebsanleitung – ist gültig für den frequenzumrichter keb combivert f4-f lift version 1.4 – muß jedem anwender zugänglich gemacht werden die in dieser betriebsanleitung verwendeten pictogramme ent- sprechen folgender ...

Page 3

Antriebstechnik gb 3 gb 1. Operating specifications ............................................................ 4 1.1 application ................................................................................................................. 4 1.2 protective separation ..............................

Page 4

Gb 4 gb 1. Operating specifications the frequency inverter keb combivert f4-f lift version 1.4 is a drive component, which is specified for lift technology. The frequency inverter is exclusively for stepless open loop /closed loop speed control of three-phase asynchronous motors and permanent magnet...

Page 5

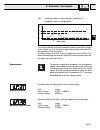

Antriebstechnik gb 5 gb star t sto p ent er f/r fun c. Spe ed 2. Summary 9-pole sub-d socket parameter interface ! Operator only optional ! See page e 21 x4 15-pole sub-d socket connection incremental encoder x5 9-pole sub-d socket incremental encoder simulation x2 terminal strip connection control ...

Page 6

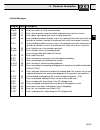

Gb 6 gb 3. Inputs/outputs 3.1 terminal x2 control terminals terminal function 1 control release 2 reset digital inputs: 3 direction of travel forward noise immunity: 2 kv 4 direction of travel reverse logic 1: ± 12…30 v 5 control mode internal input resistor: approx. 2 k Ω 6 door drive active pnp-lo...

Page 7

Antriebstechnik gb 7 gb 3.2 terminal x3 i/o-expander terminal function 1 digital input signal: contactor control (see page gb 9) max. Voltage endurance to ground: 100v 2 setpoint input control speed: v b digital inputs for setpoint activation 3 setpoint input positioning speed: v e ! Only valid with...

Page 8

Gb 8 gb 3. Inputs/outputs 3.3 function of the digital inputs terminal description x2.1 control to control the power modules the input must have +24v. If the input is not release set, the inverter shows the message „nop“ (no operation). !Observe the operating sequence of the inputs/outputs! See also ...

Page 9

Antriebstechnik gb 9 gb terminal description x2.5 control mode in activating the input you can switch from open loop operation to speed controlled operation. ! Only when lf.30 = 1 ! X2.6 door drive in addition to the main drive the inverter can also start a door drive. The active activation of the i...

Page 10

Gb 10 gb 3.4 function of the digital outputs / relay outputs after the voltage is switched on several digital outputs need approximately 2s for initialization. All switching thresholds have 12% hysteresis, exept for output x3.22 which has 6%. Exception: output x3.22 has 6% hysteresis. Terminal descr...

Page 11

Antriebstechnik gb 11 gb terminal description x3.14 operating the output is reset, when the heat sink is approx. 50°c warm. Frequency for the next drive the operating frequency is reduced to 8 khz. Warning after cooling down (heat sink temperature approx. 40°c) the operating frequency increases to 1...

Page 12

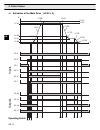

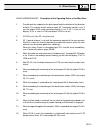

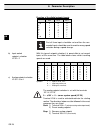

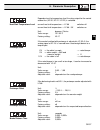

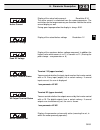

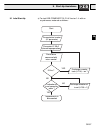

Gb 12 gb t x3.3 x2.4 x2.3 x3.17 x3.20 x3.15 x3.18 x3.4 x3.1 x2.1 v lf.62 lf.63 lf.60 lf.50 lf.51 lf.50 lf.42 lf.61 lf.52 lf.53 lf.52 lf.54 lf.53 lf.54 lf.41 1 2 3 4 5 6 7 8 9 10 11 12 13 4.1 activation of the main drive (lf.02 = 2) inputs outputs operating points 4. Drive curves.

Page 13

Antriebstechnik gb 13 gb what happens when? Description of the operating points of the main drive 1: presetting of the setpoint for the drive speed and the selection of the direction of travel. The inverter checks whether input x3.1 (contactor control) is set. If yes the output x3.20 (main contactor...

Page 14

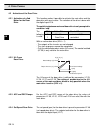

Gb 14 gb 4.2.2 u/f-curve door drive this function makes it possible to activate the main drive and the door drive with one inverter. The selection of the drive is done with the digital input x2.6. The switching between main and door drive is only accepted in condition ‘nop’. The following is valid: ...

Page 15

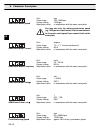

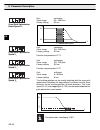

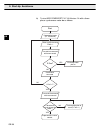

Antriebstechnik gb 15 gb t x2.4 v lf.46 1 2 lf.50 lf.51 lf.50 lf.54 lf.53 lf.54 x2.6 x2.3 x2.1 x2.7 inputs operating points what happens when? Description of the operating points of the door drive. 1: the acceleration process starts after the setpoint input is activated (x2.7 = 1). Condition: door d...

Page 16

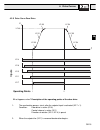

Gb 16 gb when the heat sink temperature reaches approximately 50°c, the signal at output x3.14 (operating frequency warning) is reset. With a heat sink temperature of approx. 40°c the signal at the output is set again. 5. Changes in the operating frequency to protect keb combivert f4-f lift from ove...

Page 17

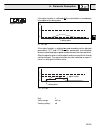

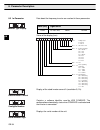

Antriebstechnik gb 17 gb 6. Connection 6.1 wiring diagram: control terminal x2 and i/o-expander x3 x2.8 braking control deceleration control positioning speed main contactor control relay contact dc-monitoring operating frequency warning digital outputs: control release direction of travel reverse c...

Page 18

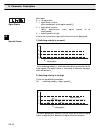

Gb 18 gb 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 the incremental encoder of the motor is connected to the 15-pole sub-d-socket. 6.2 connection x4 incremental encoder the connector may only be connected / disconnected when the inverter and voltage supply are shut off. Encoder specification: 1- voltage su...

Page 19

Antriebstechnik gb 19 gb a+ b- b+ a- a+ b- b+ a- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 or sinusoidal 1 vss signals two sinusoidal incremental signals that are electrically by 90° out of phase and their inverse signals 3- output signals: rectangular pulse signal two square-wave pulses that are electric...

Page 20

Gb 20 gb 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 the 9-pole sub-d-socket is used as an incremental encoder output. The signals are emitted corresponding to the signals on the incremental encoder input x4 in rs422 specifications. ! See also parameter lf.3 ! 6. Connection the connector m...

Page 21

Antriebstechnik gb 21 gb 1 2 3 4 5 6 7 8 9 start stop func. Speed enter f/r 7. Operation an operator is a necessary for local operation of the inverter keb combivert f4-f. To prevent malfunctions, the inverter must be brought into nop status (control release terminal x2.1 ). The operator is not nece...

Page 22

Gb 22 gb enter f/r start stop func. Speed enter f/r start stop func. Speed enter f/r 7. Operation 7.2 parameter identification the blinking point determines the active (changeable) part of the parameter identification display parameter group display parameter number 7.3 parameter selection change be...

Page 23

Antriebstechnik gb 23 gb start stop func. Speed start stop func. Speed enter f/r start stop func. Speed enter f/r 7. Operation 7.4 changing parameter values display parameter identification display parameter value increase/decrease parameter value read-only parameters can only be read out but not ch...

Page 24

Gb 24 gb start stop enter f/r 7.6 storing parameter values 7.7 error messages only the error message is reset with up / down. To reset the error remove the cause and reset terminal x2.2 or do a power on reset. Inverter status message (running /error message) see p. Gb 44 - gb 45 error / malfunction ...

Page 25

Antriebstechnik gb 25 gb 8. Parameter description in order to prevent unauthorized adjustment, a password (factory setting: 440) must be entered (see also parameter lf.01). The inverter can be barred from further use by entering 400 or by switching off the supply voltage. Possible displays : - 4 = r...

Page 26

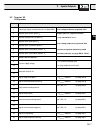

Gb 26 gb with this type of setpoint selection it is permissible to set several inputs at the same time. The table below shows which travelling speeds are used. Symbole: 1 = input is set at 24 v 0 = input may not be set x = setting has no effect function of the digital setpoint inputs x3.2 x3.3 x3.4 ...

Page 27

Antriebstechnik gb 27 gb with lf.3 you can preselect a divider for the signals of the incremental encoder output (x5). The adjusted value is valid after a power-on- reset. Unit: 1 value range: 1...128 factory setting: 1 divider incremental encoder output 8. Parameter description no divider possible ...

Page 28

Gb 28 gb unit: ampere value range: 1,0...1,1 * inverter rated current factory setting: 8,0 a adjustment value: in accordance with the motor name plate unit: hertz value range: 20...100 hz factory setting : 50 hz adjustment value: in accordance with the motor name plate unit: rpm value range : 100......

Page 29

Antriebstechnik gb 29 gb 8. Parameter description asm-encoder pulse number unit: pulse per revolution value range: 256...10000 pulse per revolution factory setting: 2500 pulse per revolution adjustment value: in accordance with the manufacturer specifications if the incremental encoder pulse number ...

Page 30

Gb 30 gb unit: 1 value range: 1,00 ... 99,99 factory setting: 30,00 adjustment value: in accordance with the gear name plate, (determine by counting the revolutions of the handwheel during a traction sheave revolution). Traction sheave diamter unit: millimeter value range: 200...2000 mm factory sett...

Page 31

Antriebstechnik gb 31 gb rated voltage of the door drive unit: volt value range: 1...650 v factory setting: 400 v control method unit: 1 value range: 1...65535 factory setting : 3000 adjustment value: dependent on ratio of inverter / motor asm kp speed unit: 1 value range: 1...65535 factory setting:...

Page 32

Gb 32 gb asm ki speed offset asm kp current for a better load transfer at high efficiency gears. Unit: 1 value range: 0...65535 factory setting: 1000 adjustment value: dependent on ratio of inverter / motor and gear type unit: 1 value range: 1...65535 factory setting: 1500 adjustment value: dependen...

Page 33

Antriebstechnik gb 33 gb unit: meter per second value range: 0.000...0.300 m/s factory setting: 0.000 m/s adjusted value: approx. 0,02 m/s - to improve the positioning the set speed change occurs without jerk limit. - if the correction speed is selected for the actual set speed it is not possible to...

Page 34

Gb 34 gb lf.50 lf.50 lf.51 unit: meter per second 3 value range: off, 0,11...9,99 m/s factory setting: 0,60 m/s 3 adjusted value: dependent on the mechanical system (adjustment values which are too high can lead to oscillations in the cabin) general: the jerk or shock, which always occurs during the...

Page 35

Antriebstechnik gb 35 gb 8. Parameter description unit: meter per second 2 value range: 0,10...2,00 m/s 2 factory setting: 0,90 m/s 2 adjustment value: according to comfort empirical values: 0,5...0,8 m/s 2 for retirement homes, hospitals, apartment buildings 0,8...1,2 m/s 2 for office buildings, ba...

Page 36

Gb 36 gb level crawl speed dc-voltage circuit control unit: meter per second value range: 0,000...0,300 m/s factory setting: 0,250 m/s adjusted value: dependent on the running time of the door and speed unit: volt value range: 0...800 v factory setting: 0 v monitors the dc-bus-voltage. If the level ...

Page 37

Antriebstechnik gb 37 gb heat sink temperature level pretorque gain 8. Parameter description dependent on the temperature level the relay output for the control cabinet fan (x2.20 / x2.21 / x2.22) is switched. Current heat sink temperature > lf.66 switches off current heat sink temperature switches ...

Page 38

Gb 38 gb lf.71 lf.71 stop switch 8. Parameter description crawl path optimization speed v 2 unit: centimeter value range: 0.0...200.0 cm factory setting: 0.0 cm crawl path optimization rated speed v n crawl path optimization speed v 1 unit: centimeter value range: 0,0...200,0 cm factory setting: 0,0...

Page 39

Antriebstechnik gb 39 gb 8. Parameter description v n v e t v unit: 1 value range: off / on factory setting: off ogive function v v n if the ogive function is switched off the acceleration is immediately interrupted at the delay point. Delay point lf. 75 = off if the ogive function is switched on an...

Page 40

Gb 40 gb 8. Parameter description messages: 0 → no ogive drive 1 → ogive drive is active (drive accelerates to the ogive speed v s ) 2 → ogive drive is active (drive decelerates from ogive speed v s to crawl speed) 4 → actual speed is to high if there are several messages active then the sum is disp...

Page 41

Antriebstechnik gb 41 gb 8. Parameter description 2b) switching velocity s , because a complete s-curve is not possible. T delay point v v n v e ogive-status v s the inverter identify that the changeover speed is too high,the ogive status will be set at 4 and than a ogive drive will be executed. The...

Page 42

Gb 42 gb 8. Parameter description terminal x2 (upper terminal) with the x.2 input state it is easy to control whether the input signals reached the inverter control. Every input (output) has a specific valency. If some inputs are set, the sum of the valency is shown. Value table: x2 input state disp...

Page 43

Antriebstechnik gb 43 gb 8. Parameter description terminal strip x3 (lower terminal) see parameter lf.82 for functional description. Value table: x3 input state x3 output state terminal x3 (lower terminal) see parameter lf.83 for functional description. Value table: display value: 0 1 2 3 4 5 6 7 sp...

Page 44

Gb 44 gb the value shows the real speed in rpm, led from the impulses of the incremental encoder . Actual speed actual lft speed asm - rated motor torque display of the speed in m/s; only when the encoder is connected. 8. Parameter description display significance stop no setpoint selection s.Co set...

Page 45

Antriebstechnik gb 45 gb display value description e.Bus 18 error, bus, failure in serial communication e.Doh 9 error, drive-overheat, motor overheats and prewarning time has run out e.Dsp 51 error, digital signal processor, error in signal processor e.Prf 46 error, prohibited rotation forward, erro...

Page 46

Gb 46 gb using the rating plate data the inverter determines the motor rated output in the rated point. Unit: kilowatt factory setting: 0,00 kw 8. Parameter description ssm rated motor output (only display) ssm rated motor speed ssm rated motor current rated motor frequency static current unit: rota...

Page 47

Antriebstechnik gb 47 gb 8. Parameter description unit: impulse per revolution value range: 256 … 10000 imp/r factory setting: 2048 imp/r adjusted value: in accordance with the motor name plate ssm encoder (inc/r) unit: 1 value range: 1 … pole pair of the motor factory setting: 1 adjusted value: acc...

Page 48

Gb 48 gb unit: 1 value range: 0 … 5 factory setting: 3 adjusted value: according to speed real value smoothing speed scan rate do not change the parameter! Unit: 1 value range: 0 … 255 factory setting: 0 adjusted value: according to real speed fluctuations reso-error-trimming do not change the param...

Page 49

Antriebstechnik gb 49 gb unit: 1 value range: 0 … 65535 factory setting: 70 adjusted value: dependent on ratio of inverter / motor ssm ki speed unit: 1 value range: 0 … 65535 factory setting: 230 adjusted value: dependent on ratio of inverter / motor ssm kp speed unit: 1 value range: 0 … 65535 facto...

Page 50

Gb 50 gb apparent current 8.2 ru-parameter display inverter status actual torque display set speed display peak inverter utilization 8. Parameter description display of the actual apparent current. Resolution 0.1a shows the actual inverter status. See status/error messages pages gb 44 - gb 45 ru.8 m...

Page 51

Antriebstechnik gb 51 gb display of the maximum dc-bus voltage measured. In addition the highest value which occurs in ru.11 is stored in ru.12. (erasing the peak storage : see parameter ru. 8) display of the actual active current. Resolution 0.1a the active current is calculated from the motor para...

Page 52

Gb 52 gb 8. Parameter description heat sink temperature displays the current heat sink temperature in celsius (°c). Ref 1 display display of the applied analog voltage in % (10 v = 100%) at ref 1 (setpoint input). Ol counter display display of the applied anaolg voltage in % (10 v = 100%) at ref 2 (...

Page 53

Antriebstechnik gb 53 gb 8. Parameter description power on counter modulation on counter shows the time that the inverter was supplied with power. Resolution: 1 hour shows how long the inverter was active. Resolution: 1 hour. (modulation active, motor supplied with voltage)..

Page 54

Gb 54 gb 8. Parameter description inverter type display 8.3 in-parameter data about the frequency inverter are read out in these parameters rated inverter current display of the rated inverter current a (resolution 0,1 a). Configfile number contains a software identifier used by keb combivis. The co...

Page 55

Antriebstechnik gb 55 gb serial number low serial number order no. High displays the serial number of the unit. 8. Parameter description displays the serial number of the unit. Serial number order no. Low customer number high displays the customer number. Customer number low displays the customer nu...

Page 56

Gb 56 gb 8. Parameter description error counter wd shows the total number of watchdog errors (bus) that occur of each type. The maximum value is 255. Software id version dsp the software version number and the control software are coded in this parameter. Feedback system channel 2 shows which feedba...

Page 57

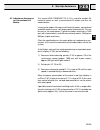

Antriebstechnik gb 57 gb 9. Start-up assistance a) to start keb combivert f4-f lift version 1.4 with an asynchronous motor do as follows: 9.1 inital start-up start parameterize inverter (lf-parameter) parameter lf.30=2 (closed loop operation) preset drive command with return control no yes yes no is...

Page 58

Gb 58 gb 9. Start-up assistance b) to start keb combivert f4-f lift version 1.4 with a three- phase synchronous motor do as follows: parameterize inverter (lf - parameter) start system trimming lf.B5 = 1 preset drive command with return control e.Enc? Yes is direction of travel correct for cabin ? I...

Page 59

Antriebstechnik gb 59 gb 9. Start-up assistance 9.2 adjustment assistance for conventional lift motors the inverter keb combivert f4-f lift is suited for modern lift/ industrial motors as well as conventional lift motors and thus for modernization. In contrast to modern lift motors and industrial mo...

Page 60

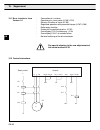

Gb 60 gb u v w x2.23 x3.10 x2.11 x3.11 x2.1 x3.21 x3.20 24v 0v k12 24v 24v 0v k11 k11 k11 k1 k2 k12 n m pe 3 ~ l inverter safety circuit 10.1 new functions from version 1.4 - connection of a resolver - operation of a servo motor (lf.A0-lf.C5) - reverse direction of travel (lf.05) - regulated operati...

Page 61

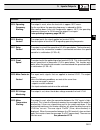

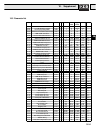

Antriebstechnik gb 61 gb 10.3 parameter list para. Name address e r res. Lower limit upper limit default unit lf.00 password 3500 e 1 0 9999 -4 - lf.01 user-defined password 3501 e 1 0 9999 440 - lf.02 steering/operating mode 3502 e 1 1 4 1 - lf.03 divider incremental encoder output 3503 1 1 128 1 -...

Page 62

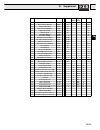

Gb 62 gb para. Name address e r res. Lower limit upper limit default unit lf.67 pretorque gain 3543 0,01 0,50 1,50 1,00 - lf.68 pretorque offset 3544 0,1 -25,0 25,0 0 % lf.69 pretorque direction 3545 e 1 0 1 0 - lf.70 brake release time 3546 0,001 0,300 3,000 0,300 s lf.71 crawl path optimization vn...

Page 63

Antriebstechnik gb 63 gb 10. Supplement para. Name address e r res. Lower limit upper limit default unit ru.00 display inverter status 2000 r table - ru.02 actual torque display 2002 r 0,1 nm ru.04 set speed display 2004 r 0,5 rpm ru.08 peak inverter utilization 2008 0,1 % ru.09 apparent current 200...

Page 64

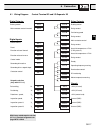

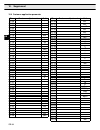

Gb 64 gb size customer adjustment unit lf.00 - lf.01 - lf.02 - lf.03 - lf.04 - lf.05 - lf.10 kw lf.11 rpm lf.12 a lf.13 hz lf.14 v lf.15 - lf.16 rpm lf.17 imp/u lf.18 - lf.19 v lf.20 m/s lf.21 mm lf.22 - lf.23 - lf.24 kg lf.25 % lf.26 rpm lf.27 hz lf.28 v lf.30 - lf.31 - lf.32 - lf.33 - lf.34 - lf.3...

Page 65

Antriebstechnik.

Page 66

Karl e. Brinkmann gmbh försterweg 36 - 38 • d - 32683 barntrup telefon 00 49 / 52 63 / 4 01 - 0 • fax 00 49 / 52 63 / 4 01 - 1 16 internet: www.Keb.De • e-mail: info@keb.De keb antriebstechnik gmbh & co. Kg wildbacher str. 5 • d - 08289 schneeberg telefon 0049 / 37 72 / 67 - 0 • telefax 0049 / 37 72...