- DL manuals

- KEB

- Portable Generator

- COMBIVERT G6

- Installation manual

KEB COMBIVERT G6 Installation manual

Summary of COMBIVERT G6

Page 1

C o m b i v e r t mat.No. Rev. 00g6nem-dc00 1g gb installation manual housing c power 5.5…11 kw.

Page 3

Gb - 3 table of contents 1. Preface ....................................... 5 1.1 general ...............................................5 1.2 validity and liability ........................... 5 1.3 copyright ............................................6 1.4 specified application .....................

Page 4

Gb - 4 table of contents.

Page 5

Gb - 5 preface 1. Preface 1.1 general first we would like to welcome you as a customer of the company karl e. Brinkmann gmbh and congratulation to the purchase of this product. You have decided for a product on highest technical niveau. The described hard- and software are developments of the karl e...

Page 6

Gb - 6 preface the suspension of liability is especially valid also for operation interruption loss, loss of profit, data loss or other damages. This is also valid, if we referred first to the possibility of such damages. If single regulations should be or become void, invalid or impracticable, the ...

Page 7

Gb - 7 preface 1.6 part code xx g6 c 3 x - 3 9 0 0 cooling 0 air-cooling (housing c, d, e); air-cooling/flat rear (housing a, b) 1 flat rear keyboard/display 0 none 1 with switching frequency; short time current limit; overcurrent cut-off 0 2 khz 125 % 150 % 1 4 khz 125 % 150 % 2 8 khz 125 % 150 % 3...

Page 8

Gb - 8 safety instructions 1. General in operation, drive converters, depending on their degree of protection, may have live, uninsulated, and possibly also moving or rotating parts, as well as hot surfaces. In case of inadmissible removal of the required covers, of improper use, wrong installation ...

Page 9

Gb - 9 technical data 2. Technical data 2.1 operating conditions standard s t a n d a r d / class instructions definition according to en 61800-2 inverter product standard: rated specifications en 61800-5-1 inverter product standard: general safety site altitude max. 2000 m above sea level with site...

Page 10

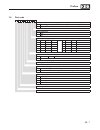

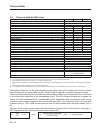

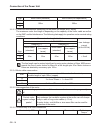

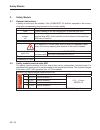

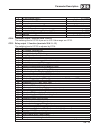

Gb - 10 technical data 2.2 technical data g6 400v class inverter size 13 14 15 housing size c phases 3 output rated power s a [kva] 8.3 11 17 max. Rated motor power pmot [kw] 5.5 7.5 11 output rated current i n [a] 12 16.5 24 max. Short time current i hsr 1) [%] 180 180 150 over current i oc 1) [%] ...

Page 11

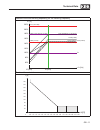

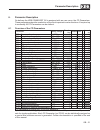

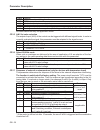

Gb - 11 technical data maximum load and derating depending on the switching frequency 80% 60% 100% 120% 140% 160% 180% 200% 220% fd (6hz) f0 (0hz) f a [hz] i n [%] hsr (13/14.G6) oc (15.G6) i n oc (13/14.G6) hsr (15.G6) 14.G6 (8 khz) 15.G6 (8 khz) 15.G6 (4 khz) 13.G6 (16 khz) 13.G6 (4/8khz) & 14.G6 ...

Page 12

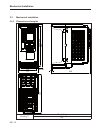

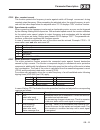

Gb - 12 mechanical installation 2.3 mechanical installation 2.3.2 dimensions and weights 242.5 ±2.5 100 117 260 für m5 230 8 230 housing c weight [kg] 4.6.

Page 13

Gb - 13 mechanical installation 2.3.3 control cabinet installation the power loss for the control cabinet dimension is to be taken from the technical data. Mounting distances dimensi- on distance in mm distance in inch c a b d d a 150 6 b 100 4 c 30 1,2 d 0 0 x 1) 50 2 1) distance to preceding eleme...

Page 14

Gb - 14 unit description 3. Installation and connection 3.1 overview of the combivert g6 overview of the combivert g6 size c 1 x1a terminal strip 4 3 2 1 9 5 6 7 8 connection for three-phase motor , bra- king resistor and dc supply 2 x4a diagnostic interface rs232/485 interface with din66019-ii 3 x2...

Page 15

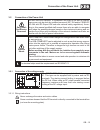

Gb - 15 connection of the power unit 3.2 connection of the power unit only quali- fied electro- personnel all work from the transport, to installation and start-up as well as mainte- nance may only be done by qualified personnel (iec 364 and/or cenelec hd 384 and iec-report 664 and note national saf...

Page 16

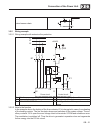

Gb - 16 connection of the power unit 3.2.1.2 ac supply 400v / 3-phase picture 3.2.1.3 connection of the mains supply l1 l2 l3 pe l1 l2 l3 u v w pe pe t1 t2 1 mains voltage 3-phase 400 v ac mains form tn, tt it personal protection rcma with separator or rcd type b earth leakage monitor 2 main fuses t...

Page 17

Gb - 17 connection of the power unit 3.2.1.5 connection at dc voltage supply picture 3.2.1.5 connection at dc voltage supply - - u v w pe pe t1 t2 ++ +u -u 1 dc voltage 420…746 v dc 2 fuses type ar pay attention to the permissible voltage range ! 3 keb combivert g6-c 3.2.1.6 terminal strip x1b pictu...

Page 18

Gb - 18 connection of the power unit size motor cable (standard) motor cable (low capacitance) 13 100 m 200 m 14 15 3.2.2.3 conducted disturbances depending on the motor line length at ac supply the maximum motor line length is depending on the capacity of the motor cable as well as on the emc emitt...

Page 19

Gb - 19 connection of the power unit u, v, w motor connection 0.2-16 mm² awg 26-6 2,3 nm 20.5 lb-inch pe, connection for shielding/ earthing screw m4 for ring thimble 1,3 nm 11 lb inch 3.2.2.7 wiring of the motor l1 l2 l3 u v w pe u v w pe pe t1 t2 1 keb combivert 2 apply motor cable, shielding on b...

Page 20

Gb - 20 connection of the power unit 3.2.4 connection of a temperature detection 3.2.4.1 temperature detection terminals t1, t2 the keb combivert g6 is delivered with a ptc evaluation. The function corresponds to din en 60947-8 and works in accordance with the following table: function of t1, t2 res...

Page 21

Gb - 21 connection of the power unit mixed sensor chain t1 t2 3.2.5 wiring example 3.2.5.1 wiring example with extensive fire protection s2 s1 l1 l2 l3 k1 k1 k1 2 l1 l2 l3 1 4 3 6 5 12 11 14 13 g ++ pb oh1 oh2 pe f i1 com rb +24vdc power circuit control circuit f main fuses s1 push-bottom switch for...

Page 22

Gb - 22 connection of the power unit depending on the case of application (e.G. No generatoric operation) simple circuits can be used. See chapter 7 for instructions of the download. Input i1 must be program- med and inverted in the application mode to "external error". 3.2.6 final test informations...

Page 23

Gb - 23 control 4. Control circuit analog/digital the control circuit provides the following analog and digital functions: • hardware allocation of digital and analog inputs and outputs. • diagnostic interface (parameter display, scope mode) • hardware of the control circuit „safety separated“ accor...

Page 24

Gb - 24 control 4.1.2 keyboard and display lcd display, 160 x 160 pixel, 32 levels of grey the lcd display offers a clear display of the information with plain text display. Function strip the function strip displays the actual possible functions of the keys f1 to f4. A flashing function strip indic...

Page 25

Gb - 25 control 4.1.4 control terminal strip x2a the control terminal strip is designed as a double, plug-in terminal strip with spring cage con- nection. It contains 32 pole. The following instructions must be observed at connection: attention prevent emc malfunctions • use shielded / drilled cable...

Page 26

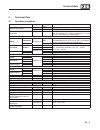

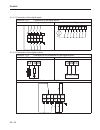

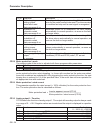

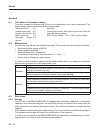

Gb - 26 control 4.1.4.2 assignment of the terminal strip x2a 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 pin name description specifications 1 gnd digital mass; 0v reference potential for digital inputs/outputs and u in 2 u in input external voltage supply ...

Page 27

Gb - 27 control 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 pin name description specifications 17 an1- -analog input 1 adjustable: 0…±10 v (ri=55 kΩ) 0…±20 ma (ri=250 Ω) 4…20 ma (ri=250 Ω) resolution: 10 bit + sign scan time ≤ 2 ms 18 an1+ +analog input 1 ...

Page 28

Gb - 28 control 4.1.4.3 connection of the digital inputs picture 4.1.5.3 connection of the digital inputs with internal voltage supply with external voltage supply 12 11 6 8 10 5 4 3 7 9 5 6 3 4 7 8 9 101112 + 4.1.4.4 connection of the digital outputs picture 4.1.5.4 examples for the connection of t...

Page 29

Gb - 29 control 4.1.4.5 connection of the relay outputs picture 4.1.6.5 examples for the connection of the digital outputs 262830 252729 fla rla.

Page 30

Gb - 30 safety module 5. Safety module 5.1 general instructions a safety module must be installed, if the combivert g6 shall be operated in an environ- ment with corresponding requirements to the intrinsic safety. Safety function description none control release is set via a digital input of termina...

Page 31

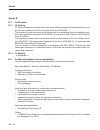

Gb - 31 parameter description 6. Parameter description on delivery the keb combivert g6 is assigned with an user menu, the cp-parameters. These parameters describe a selection of the most important inverter functions. If required up to maximally 48 cp-parameters can be defined. 6.1 overview of the c...

Page 32

Gb - 32 parameter description cp.03 inverter status in parameter „inverter status“ the actual operating condition of the frequency inverter is dis- played. In the case of an error the current error message is displayed, even if the display has already been reset with enter (error-led on the operator...

Page 33

Gb - 33 parameter description cp.25 max. Constant current this function protects the frequency inverter against switch off through overcurrent during constant output frequency. When exceeding the adjusted value, the output frequency is redu- ced until the value drops below the adjusted value. Cp. 03...

Page 34

Gb - 34 parameter description cp.27 response description 2 quick stopping, holding torque, restart after reset status message a.Xx fast stop - holding torque on reaching 0 hz. Correct the error for the restart and activate reset. The drive remains in condition fast stop until a reset signal is recog...

Page 35

Gb - 35 parameter description 5 dc link voltage cp.07 0…1000 v 6 apparent current cp.04 0…2 • rated current 7 active current ru.17 0…2 • ±rated current 8…10 reserved – 11 absolute active current ru.17 0…2 • rated current 12 power stage temperature ru.38 0…100 °c 13…21 reserved – 22 analog input befo...

Page 36

Gb - 36 parameter description value function 80 active current > switching level 83 hsp5 bus synchronized 84 actual value 85 warning, external error input is active 86 warning hsp5 or operator watchdog 88 warning overload summary alarm (switching condition 7, 8, 9 , 10 or 11 is active) no listed val...

Page 37

Gb - 37 parameter description.

Page 38

Gb - 38 annex annex a a.1 calculation of the motor voltage the motor voltage for dimensioning of the drive is depending on the used components. The mains voltage reduces according to the following table: mains choke uk 4 % example: inverter open loop 4 % closed loop inverter with mains- and motor ch...

Page 39

Gb - 39 annex storage period • start-up without special measures storage period 1…2 years • operate frequency inverter one hour without modulation storage period 2…3 years • remove all cables from the power circuit; especially of braking resistor or module • open control release • connect variable t...

Page 40

Gb - 40 annex annex b b.1 certification b.1.1 ce marking ce marked frequency inverters and servo drives were developed and manufactured to com- ply with the regulations of the low-voltage directive 2006/95/ec. The inverter or servo drive must not be started until it is determined that the installati...

Page 41

Gb - 41 notes.

Page 42

Keb antriebstechnik austria gmbh ritzstraße 8 • a -4614 marchtrenk fon: +43 7243 53586-0 • fax: +43 7243 53586-21 net: www.Keb.At • mail: info@keb.At keb antriebstechnik herenveld 2 • b -9500 geraadsbergen fon: +32 5443 7860 • fax: +32 5443 7898 mail: vb.Belgien@keb.De keb power transmission technol...