- DL manuals

- KeepRite

- Air Conditioner

- K40-CU-IM-13

- Installation And Maintenance Instructions Manual

KeepRite K40-CU-IM-13 Installation And Maintenance Instructions Manual

K40-CU-IM-13

1068155

Installation and Maintenance

Instructions

for

Air-Cooled, Remote and Water-Cooled

Condensing Units

National Refrigeration and Air Conditioning Canada Corp.,

159 Roy Blvd., P.O. Box 2020, Brantford, Ontario, N3T 5Y6

Phone: 800-463-9517, 519-751-0444 Fax: 519-753-1140

Visit our web site at www.keepriterefrigeration.com

Summary of K40-CU-IM-13

Page 1

K40-cu-im-13 1068155 installation and maintenance instructions for air-cooled, remote and water-cooled condensing units national refrigeration and air conditioning canada corp., 159 roy blvd., p.O. Box 2020, brantford, ontario, n3t 5y6 phone: 800-463-9517, 519-751-0444 fax: 519-753-1140 visit our we...

Page 2

2 table of contents pages general safety, inspection & general warranty policy 3 handling, placement & installation 4 – 6 electrical information & wiring diagrams 7 – 14 refrigerant piping 15 – 16 water-cooled condensers, piping & flow rates 17 – 18 system accessories 19 leak testing, evacuation & d...

Page 3

3 general safety important safety note only a qualified refrigeration mechanic who is familiar with refrigeration systems and components, including all controls should perform the installation and start-up of the system. To avoid potential injury, use care when working around coil surfaces (if appli...

Page 4

4 air cooled condensing unit minimum clearance (for horizontal air flow units) * height of condensing unit minimum * no closer than 24" (.62 m) walls * width of condensing unit minimum * width of condensing unit minimum 48" (1.2 m) minimum air flow air flow condensing unit condensing unit handling, ...

Page 5

5 special note for large air cooled condensing units: vertical flow air cooled condensing units are large and heavy pieces of mechanical equipment and must be handled as such. A fully qualified and properly equipped crew with the necessary tackle and rigging should be engaged to locate the condensin...

Page 6

6 ventilation if the compressors or condensing units are to be located in machine rooms, adequate ventilation air must be provided in order to avoid an excessive temperature rise in the room. Air requirements vary with ambient air temperatures and the refrigeration load, however the following rule o...

Page 7

7 electrical information warning all wiring and connections to the unit must be made in accordance with national as well as local electrical codes and by-laws. Electrical wiring should be sized in accordance with the minimum circuit ampacities shown on the unit nameplate and applicable electrical co...

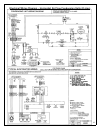

Page 8

8 electrical wiring diagram – horizontal air flow condensing units (k-line).

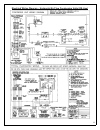

Page 9

9 electrical wiring diagram – horizontal air flow condensing units (k-line).

Page 10

10 electrical wiring diagram – horizontal air flow condensing units (k-line).

Page 11

11 electrical wiring diagram – horizontal air flow condensing units (ke-line).

Page 12

12 electrical wiring diagram – horizontal air flow condensing units (ke-line).

Page 13

13 electrical wiring diagram – horizontal air flow condensing units (ke-line).

Page 14

14 electrical wiring diagram – vertical air flow condensing units.

Page 15

15 refrigerant piping warning all local codes must be observed in the installation of refrigerant piping. Important piping note appropriate line sizing practices must be used throughout the installation of the refrigeration system. Special consideration must be taken when the condensing unit is inst...

Page 16

16 at the temperatures encountered in the condenser, receiver and liquid line a certain amount of oil is always being circulated with the refrigerant through the system by the compressor. However, at the evaporator temperature, and with the refrigerant in a vapor state, the oil and refrigerant separ...

Page 17

17 water-cooled condensers warning all water and drain connections to the unit must be made in accordance with national as well as local plumbing codes and by-laws. Cooling water circuits in some shell and tube water-cooled condensers may be either series or parallel as required by the particular ap...

Page 18

18 (c) if the condenser is installed more than 5 ft (1.52 m) higher than the outlet drain point of the condenser, a vacuum breaker or open vent line should be provided to prevent the outlet line from creating a partial vacuum condition. Consult the factory or local sales representive for further inf...

Page 19

19 system accessories in order to ensure trouble free operation of the refrigeration system it is important that the following system accessories be reviewed and installed. (a) a moisture indicating liquid sight glass should be installed in the liquid line between the receiver and as close as possib...

Page 20

20 leak testing important: all system piping, including the condensing unit and accessories should be thoroughly tested for leaks prior to start up and charging. The system should be initially pressurized to a maximum of 150 psig (1136 kpa) with dry nitrogen to ensure that the system is free of majo...

Page 21

21 line insulation after the final system leak test is complete, it is important that all refrigerant lines exposed to high ambient conditions must be insulated to reduce the heat pick-up and prevent the formation of flash gas in the liquid lines. Suction lines should be insulated with 3/4 inch wall...

Page 22

22 for r-134a charges consult factory. Line size (inches) r-134a, r-22 r-404a, r-507 3/8 0.4 0.34 1/2 0.74 0.64 5/8 1.19 1.03 7/8 2.47 2.12 1 1/8 4.22 3.61 1 3/8 6.42 5.5 1 5/8 9.1 7.8 refrigerant charge (lbs) for liquid lines (per 10 feet) model hp r-22 r-404a / r-507 model hp r-22 r-404a / r-507 1...

Page 23

23 typical air-cooled condensing unit (with vertical airflow condensers) refrigerant operating charges (lbs) (less evaporator and liquid lines) type hp +40f -40f +40f -40f r22 r404a 15 h 25.7 --- 30.0 47.7 --- --- 20 h 25.7 --- 30.0 47.7 --- --- 25 h 31.2 --- 36.3 57.9 --- --- 30 h 39.6 --- 46.2 74....

Page 24

24 compressor oils check to see that the oil level is 1/8 to 1/3 up on the compressor sight glass on compressors so equipped before starting the compressor and after 15 to 20 minutes of operation. Caution: oil levels should not be allowed to go above the centre or 1/2 of the sight glass. Excessive o...

Page 25

25 due to the extreme hygroscopic (moisture absorbing) characteristics of polyol ester (poe) oils, systems must never be left open to the atmosphere for any extended period of time. Simply pulling a deep vacuum on the system during the evacuation and dehydration procedure will not remove moisture th...

Page 26

26 system start-up check list important start-up note only a qualified refrigeration mechanic who is familiar with compressor performance and the function and adjustment of all controls and components should start up the compressor. Finishing up work on the installations should be planned so that a ...

Page 27

27 low temperature room pull-down it can take up to two weeks to properly start-up and pull-down a large freezer. Large freezers should be pull- down to temperature in stages. Too fast a pull-down can cause structural problems in pre-fabricated rooms and will damage (crack) concrete floors. Reduce r...

Page 28

28 checking superheat important system balancing note to obtain maximum system capacity and insure trouble free operation it is necessary to check both the compressor and evaporator superheat. Compressor superheat compressor suction superheat must be checked. To check the superheat at the compressor...

Page 29

29 system operational check list when the system has been running trouble free for an extended time (two weeks or more) and design conditions are satisfied, the following check list should be followed: (1) check that compressor discharge and suction pressures are operating within the allowable desig...

Page 30

30 system troubleshooting the following system troubleshooting guide lists the most common types of malfunctions encountered with refrigeration systems. These simple troubleshooting techniques can save time and money minimizing unnecessary downtime and end-user dissatisfaction. Contact the factory o...

Page 31

31 condensing unit problem possible causes compressor noisy or vibrating. 1. Flood back of refrigerant. 2. Improper piping support on the suction or discharge lines. 3. Broken or worn internal compressor parts. 4. Incorrect oil level. 5. Scroll compressor rotating in reverse (three phase). 6. Improp...

Page 32

32 system troubleshooting guide fixture problem possible causes room temperature too high. 1. Defective room thermostat or improper differential / setting. 2. Malfunctioning liquid line solenoid valve. 3. Insufficient air across evaporator coil (iced up coil, product blocking evaporator, fan blade /...

Page 33

33 customer instructions completely fill in warranty activation certificate located inside of the back cover of this installation and maintenance manual. The top (white) copy should be faxed or mailed per the instructions on this form. The (pink) copy is for the installing contractor’s files and the...

Page 34: Finished Goods Warranty

34 service log date comments finished goods warranty the terms and conditions as described below in the general warranty policy cover all products manufactured by national refrigeration. General warranty policy subject to the terms and conditions hereof, the company warrants all products, including ...

Page 35: Start-Up Information

35 start-up information important: this start-up information should be completely filled in on each installation and remain with the unit as a permanent record for future reference. Future service work may be logged on the proceeding page. Service parts list are attached to the back cover. Please pr...

Page 36

Service parts list canada 159 roy blvd., brantford, ontario, canada n3r 7k1 phone: 1-800-463-9517 (519)751-0444 fax (519)753-1140 due to national refrigeration’s policy of continuous product improvement, we reserve the right to make changes without notice. National refrigeration & air conditioning c...